Professional Documents

Culture Documents

Repowering of Old Locomotives

Uploaded by

emmsh71Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Repowering of Old Locomotives

Uploaded by

emmsh71Copyright:

Available Formats

Neil Buckley, CEO, RISP, B.E., M.B.A.

Repowering of Old Locomotives

AusRail Plus 2009

REPOWERING OF OLD LOCOMOTIVES

Neil Buckley, Chief Executive Officer, Rail Industry Service Providers P/L (RISP)

SUMMARY

The average age of the locomotive fleet operating in Australia is in excess of 30 years. Improving the

reliability, availability and productivity of older locomotives is a challenge for many rail operators.

Replacing old locomotives with modern, state-of-the-art units, whilst appealing, may not be economically

viable because the returns that these locomotives can generate in many cases are insufficient to provide a

reasonable payback on the huge capital outlay. Overhauling the locomotives so that they are brought back

to an original specification condition may address reliability issues but the process will not capitalise on

productivity advances in fuel efficiency, environmental emissions and tractive effort that have been made

over the years. Repowering of locomotives, where the engine, alternator and traction control equipment is

replaced with a new upgraded system provides an alternative, cost-effective option for many locomotive

applications in Australia.

1. INTRODUCTION 2. BACKGROUND

It is widely reported that the general freight task An analysis of locomotives still in operation on

in Australia will double between the years 2005 the contestable rail network (i.e. excluding

and 20201. However, for rail to maintain or even private railways) in Australia determines an

grow its current transport market share in average locomotive age of 30.4 years3. Figure 1

Australia of 26%2, there will need to be significant shows the spread of ages of this population of

investment in railway assets, including rolling approximately 1700 locomotives and reveals that

stock. Yet when we look at investment in rail in over a one quarter of Australia’s locomotive fleet

Australia over the last few decades there has only is over 40 years old. This quartile includes the 48

been relatively modest investment in rail outside class locomotive where there are still over one

of coal, mineral and passenger traffics. This hundred of these locomotives listed as

paper will examine some of the reasons why operational and they remain the backbone of

there has been this under investment, regional rail transport in NSW. The youngest

particularly in rolling stock in the general freight locomotives in the Australian fleet, tend to be

market. It will introduce the concept of used on coal and mineral traffics and long

repowering locomotives as an alternative to a distance intermodal.

standard overhaul or investment in new motive

units. The paper will then discuss the costs and

benefits of repowering locomotives and focus on

a case study application of repowering 48 class

locomotives.

AUSRAIL PLUS 2009

17 – 19 November 2009, Adelaide

Neil Buckley, CEO, RISP, B.E., M.B.A. Repowering of Old Locomotives

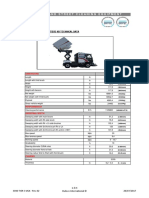

Figure 1 – Age Profile of Locomotives in Australia

It is generally accepted that locomotives have an turn is approximately one third of the total

economic life of 20 to 25 years4. This compares haulage costs, including access charges.

favourably with the average age of locomotives in Therefore each locomotive, if it is viewed as a

the United States, which is reported to be only 8 revenue centre, has to generate approximately 6

years5. Why then is the Australian locomotive times its capital charge or $4.2M per year in

fleet over 3 times the average age of the freight revenue to provide an adequate return.

American fleet and 50% more than the When you look at rail freight traffics around

recognised life of these assets? The underlying Australia, many of them simply do not generate

cause for the aging locomotive fleet and the sufficient revenue to support new assets being

distribution of locomotive ages on different hauls deployed in the operation. For example, in

in Australia is largely a function of the returns the 2007/08 Pacific National earned total revenue of

locomotives can generate and whether they can $99 million from its grain and general freight

support investment in new equipment. Revenue business8. This revenue would support only

for many rail traffics in Australia is capped by approximately 24 new generation locomotives in

competition from road transport, which can the business. PN’s grain/general freight

provide a highly flexible and reliable door to door locomotive fleet, which mainly comprises of 48

service. Added to this, road has an apparent cost class and 80 class locomotives, is in excess of 100

advantage, where the Productivity Commission6 locomotives, so even with replacing old

has found that despite recent changes, heavy locomotives with new generation units on a three

trucks were still only paying marginal costs for for one basis, the numbers do not stack up.

the use of transport infrastructure whereas

freight rail pays average costs plus a profit 3. REBUILD/OVERHAUL OPTIONS

margin. Heavy vehicles also do not pay for

A standard locomotive overhaul typically involves

externality costs such as environmental emissions

the reconditioning of an old locomotive back to

and congestion delays.

original condition using new or reconditioned

With new locomotives costing between $6 million parts. Major components such as the engine,

- $7 million7, rail operators/asset owners need to alternator, traction motors, compressor, bogies,

earn in the order of $700,000 per year or $2000 draft gear/couplers and brake equipment are

per day capital charge for each locomotive to replaced or reconditioned on a like for like basis.

cover interest and an appropriate risk adjusted The performance of the locomotive after

return. From the author’s experience, overhaul is basically the same as when the

locomotive capital costs make up approximately locomotive was originally supplied.

half of total rolling stock capital costs, which in

AUSRAIL PLUS 2009

17 – 19 November 2009, Adelaide

Neil Buckley, CEO, RISP, B.E., M.B.A. Repowering of Old Locomotives

The advantage of this form of overhaul is that it developed the 710ECO Repower engine, which

improves reliability of the locomotive, costs less can be used to replace the old 645 engines in SD-

than a new locomotive or repowering and 40 series locomotives. EMD claims9 that these

involves less risk if the locomotive has already locomotives can achieve fuel savings of up to

proven to perform well in service. However, a 25%, meet EPA Tier 2 environmental emissions

standard locomotive overhaul does not offer any standards and have 90% parts commonality with

improvement in productivity of the locomotive in other EMD engines. Whilst the cost of this form

terms of power output or tractive effort nor does of repowering has not been published, a payback

it improve environmental emissions. In addition, period of 5 years is being quoted.

finding parts for some old locomotives is

becoming increasingly difficult and the question GE has also recently entered the repower

of how much is the asset owner prepared to market10 with its Evolution Series 2,350-hp shunt

spend on a 40 year locomotive is a burning locomotive. This locomotive is powered by a

question. This results in owners/operators taking version of GE's proven 12-cylinder GEVO engine

the detrimental approach to maintenance where used on the Evolution Series locomotives. The

the locomotives are virtually run until they fail unit is designed for shunting applications and is

and maintenance practices are centred around a planned to achieve improved fuel efficiency,

“fix when fail” mentality. This results in poor lower emissions, greater reliability, and extended

reliability of services using old locomotives, which life. Additional benefits of the design include

exacerbates rail’s competitiveness in certain parts commonality with GE's high horsepower

markets. Evolution Series locomotives.

The need for more reliable and productive The alternative to replacing an old locomotive

locomotives in the general freight market is engine with a modern derivative is to repower

apparent given competition from road. It is the locomotive with a medium speed, base

generally not possible to incrementally modify mounted diesel engine/alternator package.

existing traction equipment as its vital There are no freight locomotives in commercial

components are designed around a certain power use in Australia, which have been repowered

rating and tractive effort. However using this approach however, there are several

owner/operators of these locomotives can obtain overseas examples of repowered old locomotives

additional power/tractive effort through and some new locomotives using this technology.

repowering the locomotive.

There are two basic approaches to repowering A 36 year old Swedish NOHab t43 multipurpose

locomotives. The first is to replace the existing locomotive,11 which was originally powered by an

engine with a compatible but more EMD12-567-Di engine and generator was refitted

contemporary locomotive engine and traction with a modern 50-litre Cummins KV series diesel

package. The second approach is to repower the power pack, increasing output from 1065kW to

locomotive with a medium speed, base mounted 1268kW. After 3700 hours of heavy-duty

engine/alternator set, sometimes referred to as a operation since 1999, it is reported that the

“gen set” locomotive. This approach typically repowered locomotive has achieved impressive

involves retaining the original locomotive results in terms of operating costs (overall

structure and bogies but increasing its power. reduction of 20% including fuel savings of 26%),

Both repowering approaches typically improved environmental performance (60%

incorporate a full locomotive overhaul to ensure reductions in NOx and reduced noise emissions

the reliability of other critical components match from 94 to 86 dB (A)) and improved vehicle

the new engine/traction packages. availability (engine overhaul period of up to

30,000hrs).

Both Electro Motive Division (EMD) and General

Electric (GE) are offering new engine packages In North America a number of old locomotives

aimed at improving the fuel economy and have been repowered for use in shunting

emissions from old locomotives. EMD has operations. These include a recent project where

AUSRAIL PLUS 2009

17 – 19 November 2009, Adelaide

Neil Buckley, CEO, RISP, B.E., M.B.A. Repowering of Old Locomotives

Union Pacific and Progress Rail12 repowered five assembly and air compressor virtually

SD40-2 locomotives, which were originally built in eliminates frame-transmitted noise and

the 1970s. These locomotives have been vibration from these sources;

repowered with Caterpillar 3516 engines and will

meet Tier 2 emissions standards. The • The engine running at higher speed means it is

locomotives will be tested on intermediate-haul more compact than the traditional locomotive

routes in the Midwest and California. engine for the same or increased horsepower,

thus providing additional space and greater

MotivePower13 has developed a range of low flexibility for equipment and crew amenity

emission locomotives utilising medium speed layout;

diesel engines. The MP20B/C models are 2000hp

single engine locomotives fitted with MTUDD • Up to one third 20 reduction in lubricating oil

12V4000 or equivalent engines. Thirteen of the volume compared to that of a conventional

MP20C models are in operation for Pacific low speed engine with oil change intervals

Harbour Lines14 serving the Ports of Long Beach extended;

and Los Angeles. MotivePower is also

understood to have a multi engine (i.e. 3 x 700hp) • Modular equipment within the traction pack

demonstration shunt locomotive. and electrically driven auxiliaries allowing for

easier component replacement and better

National Rail Equipment Company in the United maintenance accessibility; and

States has developed its “N-ViroMotive”

locomotive15 which is a “genset” locomotive • Extended maintenance and overhaul periods

utilising up to 3 x 700hp medium speed diesel provided by the new diesel engine,

engines, which can be synchronised together or alternators, air compressor and cooling

used individually or in pairs depending on power system components provided in the proposed

requirements. The locomotives have primarily package will result in a 40% to 50%21

been constructed for shunting applications but reduction in maintenance costs on these

are being considered for regional operation. components and an overall reduction of some

Over 250 locomotives have been built or in the 40% of total locomotive maintenance costs.

process of being built for customers such as BNSF

Railway, the Canadian Pacific Railroad, CSX and Environmental considerations in terms of exhaust

Union Pacific. emissions (including greenhouse gases) and noise

levels are playing an increasing part with

In summary, the benefits of repowering old investment decisions in rail. In Australia,

locomotives with medium speed diesel transport contributes approximately 14% of the

engine/traction packages include: country’s total greenhouses emissions with rail

causing only 3% of the total transport

• Improved tractive effort of up to 60%16 emissions22. The inherent efficiency of steel

through the use of an integrated micro- wheels on steel rails, makes rail part of the

processer managed traction control systems solution rather than part of the problem with

coupled with the new engine/alternator; global greenhouse emissions. However,

repowering of old locomotives so that the old

• Improved fuel consumption of up to 20-35%17, engines are replaced with modern fuel and

depending on duty cycle due to more precise carbon efficient engines will improve rail’s green

control of fuel injection and combustion; credentials even further and maintain rail’s

natural competitive advantage over road with

• Reduced exhaust emissions (NOx and respect to greenhouse emissions.

particulates reduced by up to 80%18) and noise

emissions by over a half19, particularly in the Diesel locomotives produce a number of

low frequency, high energy range and tonality. emissions including nitrogen oxides,

Resilient mounting of the engine/alternator hydrocarbons, carbon dioxide and particulate

AUSRAIL PLUS 2009

17 – 19 November 2009, Adelaide

Neil Buckley, CEO, RISP, B.E., M.B.A. Repowering of Old Locomotives

matter. There are currently no emission The Mark I and Mark II 48 class Locomotives were

standards for locomotives in Australia, however, fitted with small fuel tanks and light draft gear

experience from overseas shows that a number and have mostly been withdrawn from revenue

of countries including the United States, Europe service. The locomotives have been dispersed

and Japan have introduced standards on and ownership is distributed between Pacific

emissions from locomotives. For example, the National, RailCorp, Junee Railway Workshops,

United States has introduced regulations for Silverton / Coote Industrial Rail and GrainCorp.

locomotives based on their age (or when they are The 48 class locomotives were last overhauled in

remanufactured) and the nature of operation the late 1980’s and are due for major overhaul in

(e.g. linehaul or shunting)23. “Tier 2” standards the near future if they are to remain in active

currently apply to locomotives and locomotive service. The 50 year old technology currently

engines originally manufactured or employed in these locomotives makes them

remanufactured in 2005 and later. extremely expensive to operate and maintain and

parts are getting difficult to come by.

Such exhaust emission standards can be met in

repowered locomotives by means of technologies The upgrade of a 48 class locomotive to a higher

within the diesel engine envelope such as power output together with the installation of

common rail injection systems and electronic new a traction control system, to increase the

governors. This eliminates the need for adhesion level from the 18.7% current level to

expensive and power depleting exhaust after nominally 28%, will provide a number of

treatment such as exhaust scrubbers. extremely useful operational advantages. It will

permit a 50% increase in load hauling capacity for

Noise emission in built up areas is also a problem a single locomotive, with no significant loss of

for rail operations in Australia. In NSW the running time over a given haul. A modest 12.5%

maximum noise level for locomotives under all increase in fuel tank capacity will allow the same

service conditions is 87 dB(A), with specific operating range as the existing 48 class

tonality requirements24. This requirement is locomotives with the 50% load increase.

difficult to achieve in standard new locomotives,

let alone in older locomotives where noise levels The 50% increase in locomotive hauling capability

can be as high as 92 to 95 dB(A). As mentioned, would allow a 2 for 3 replacement within a 48

the noise level of repowered locomotives is in the class fleet. This equates to a direct reduction of

order of 86 dB (A), which is below the current 33% in overhaul and maintenance costs, without

standard and ideal for applications in noise taking the reduced maintenance requirements of

sensitive areas. the new equipment into account (e.g. oil

changes). The versatility of the upgraded

locomotive in substituting for a mainline

4. 48 CLASS REPOWER CASE STUDY locomotive would also prove extremely valuable.

For example, two upgraded 48 class locomotives

The following presents a case study on the cost

could be substituted for a single 81 class

and benefits of repowering 48 class locomotives.

locomotive or three upgraded 48 Class

The 48 Class locomotives were introduced during locomotives can substitute for a single NR class

the 1960’s to operate on the light rail branch locomotive. Trailing load versus speed for the

lines in NSW. A total of 165 locomotives were in existing 48 class, a repowered 48 class and the 81

the class, spread over four versions. Their light class locomotives are shown in Figure 3 below.

axle load of 13 TAL, made the 48 Class locomotive With the use of a medium speed, more compact

ideally suited for operation on lighter track diesel engine, it should be feasible to add

structures in country areas for haulage of grain dynamic brake to the 48 class.

and mineral commodities. The 48 class

locomotives were also used extensively to

perform shunting and trip train operations within

the Sydney metropolitan network.

AUSRAIL PLUS 2009

17 – 19 November 2009, Adelaide

Neil Buckley, CEO, RISP, B.E., M.B.A. Repowering of Old Locomotives

Figure 2 – Trailing Load vs Speed for a standard 48 cl, Repowered 48 cl and 81 cl Locomotives

The cost to repower a 48 class locomotive is in Although not factored into this analysis, a new,

the order of $1.9 million including a new 1500hp forward-facing cab costing approximately

medium speed diesel engine, traction $200,000 to improve the crew’s visibility and

alternator/rectifier and auxiliary alternator amenity could also be included in the scope.

compared with a standard overhaul cost of

approximately $1.2 million25. The scope of the The benefits of repowering the locomotives

repower includes overhauling the existing bogies include fuel and maintenance cost savings and

including traction motors to ensure they handle improved locomotive availability compared with

the increased horsepower and tractive effort. a non-overhauled unit. Other non quantifiable

The new engine is based on electrically driven benefits which include improved locomotive

auxiliary equipment. This approach is more reliability and improved environmental emissions

flexible and allows better use of available space. have not been factored into this analysis.

The auxiliaries include an AC motor driven air

The cost and benefits of a typical 48 class

compressor, AC driven radiator fans, AC driven

locomotive configuration are shown in Figure 3.

traction motor blowers and inertial filter dust

The analysis compares the relative cost and

extractor fans. This modification will include a

benefit differentials between operating non

complete high and low voltage rewire as well as

overhauled locomotives, standard overhauled

new air, fuel and cooling water pipe work. A

locomotives and repowered locomotives. The

microprocessor based control system is necessary

cumulative costs of the three options over a 10

to cover traction control, alternator excitation,

year period, showing the relative break even

and dynamic brake control, where fitted.

points are presented in Figure 4.

AUSRAIL PLUS 2009

17 – 19 November 2009, Adelaide

Neil Buckley, CEO, RISP, B.E., M.B.A. Repowering of Old Locomotives

5. RESULTS

Figure 3 – 48 Cl Locomotive 10 Year Cost Comparison – No Overhaul, Std Overhaul and Repowered

Figure 4 – Cost Benefit Comparison of 48 Class Locomotive Overhaul and Repower Options

AUSRAIL PLUS 2009

17 – 19 November 2009, Adelaide

Neil Buckley, CEO, RISP, B.E., M.B.A. Repowering of Old Locomotives

The analysis shows that over a 10 year period 7. REFERENCES

there is a quantifiable benefit of $2.6 million to

$2.9 million of repowering two 48 class 1

locomotives compared with standard overhaul or Australian Government Department of Transport and

non overhaul options. The repowering option Regional Services, Auslink White Paper,

had a breakeven point of just less than 6 years Commonwealth of Australia, 2004, p. 4.

compared with the option to not overhaul the 2

National Transport Commission Australia, Scoping

locomotives.

Rail Environment Issues Discussion Document, 2004,

Whilst a repowered 48 class locomotive would be Appendix 2.

mainly used in regional freight operations and for 3

work and trip trains, the principles could be Review of locomotives listed on

extended to the development of a 4,000hp http://www.locopage.railpage.org.au.

single- engine, mainline locomotive. With an 4

For example, ATO TR 2009/4 Effective Life for

appropriate donor locomotive, the cost to

Depreciating Assets states an effective life of 20 years

repower and fully overhaul the locomotive is of

the order of $3 million. Depending on the duty for heavy haul diesel electric locomotives and 25 years

cycle and the characteristics of the original for general freight locomotives,

locomotive, the payback period on the www.law.ato.gov.au/atolaw/view.htm?docid=%22TXR

investment can be as little as three to four %2FTR20094%2FNAT%2FATO%2F00001%22#PB.

years26. 5

Phillips, M. 2009, Challenges Australia faces in the

6. CONCLUSION Development of our International Trades, AMSA

Conference, Sydney, 3 – 5 June 2009.

If rail in Australia is going to reach its potential

6

and play an increasing part in meeting the Productivity Commission, Road and Rail Freight

forecast doubling of the freight task over the next Infrastructure Pricing, Report no. 41, Canberra, 2006.

10 - 15 years, it needs a locomotive solution that 7

works economically where rail has to compete QR Media Release, Report on the Purchase of 12 x

with road transport. Repowering of old C44 Aci for Downer EDI for more than $70 million, 18

locomotives provides a solution where high January 2009.

productivity, reliability and environmental 8

advantage can be achieved at a fraction of the Asciano, ASX Announcement, Release of Financial

cost of new units. Ideal applications for Results for Full Year Ending 30 June 2008, 6 August

locomotive repowering solutions include low to 2008.

medium duty cycle hauls including intermodal, 9

Electro Motive, Press Release, KCS Rolls Out EMD

branch line, work train and short haul operations. TM

710ECO Repower Locomotives, 22 June 2009.

With the capital cost of a repowering solution,

including overhaul of non-replaced components, 10

Locomotive repowers: investing in the future; Railway

costing approximately half the cost of a new

Age, October 2008.

locomotive build, the estimated payback on the

cost of repowering a locomotive used for a 11

Repowering breathes new life into old locomotives –

typical operation is estimated to be around 4 - 6 Diesel Traction, International Railway Journal, April

years. The case study of a 48 class locomotive 2002.

application shows a payback period of less than 6

12

years for repowering these locomotives Locomotive repowers: investing in the future;

compared with a standard overhaul option. Railway Age, October 2008.

Additional to this are the environmental benefits

13 X

of reduced noise and emissions from repowered MPE Low Emissions Locomotives Data Sheet,

locomotives. www.motivepower-wabtec.com

AUSRAIL PLUS 2009

17 – 19 November 2009, Adelaide

Neil Buckley, CEO, RISP, B.E., M.B.A. Repowering of Old Locomotives

14 26

Pacific Harbour Lines Newsletter, Unpublished Rail Industry Service Providers P/L cost

www.anacostia.com, Summer 2008. and benefit analysis of a class of old locomotives

15

currently deployed on an intermodal operation in

N-ViroMotive: A New Locomotive Concept, Australia, 2009.

www.nationalrailway.com/nviro.asp.

16

For example, National Railway Equipment Company

claim tractive effort enhancements of 60%, N-

ViroMotive: A New Locomotive Concept,

www.nationalrailway.com/nviro.asp.

17

For example, MotivePower quote 35% fuel saving.

MPEX Low Emissions Locomotives Data Sheet,

www.motivepower-wabtec.com).

18

For example, National Railway Equipment Company

claim 80% reduction in NOx and particular emission,

www.nationalrailway.com/nviro.asp and Cummins

claim 60% reduction in NOx, International Railway

Journal April 2002.

19

For example, Cummins claim a reduction in external

noise levels from 94 to 86 dB (A), International Railway

Journal, April 2002.

20

For example, 165 litres of lubricating oil in the

MTUDD 12V 4000 R41 engine compared with 520

litres in an Alco 6-251B engine, is a considerable

maintenance cost saving.

21

Unpublished analysis by Rail Industry Service

Providers P/L, 2009.

22

Department of Climate Change, Transport Sector

Greenhouse Gas Emissions Projects, Canberra p3 &

p11, 2007.

23

Emission Standards – United States - Locomotives,

http://www.dieselnet.com/standards/us/loco.php

24

ARTC’s Environmental Protection Licence under

Section 55 of the Protection of the Environment

Operations Act 1997 (NSW)

http://www.environment.nsw.gov.au/prpoeo/licences

/L3142.pdf.

25

Unpublished Rail Industry Service Providers P/L cost

estimates, 2009.

AUSRAIL PLUS 2009

17 – 19 November 2009, Adelaide

You might also like

- Multi-Engine Submarine Power SuppliesDocument14 pagesMulti-Engine Submarine Power Suppliesdavid2404100% (2)

- Hyster J40xnt Parts and Service User Interface 1688879 2200SRM1336 (12 2011) US ENDocument106 pagesHyster J40xnt Parts and Service User Interface 1688879 2200SRM1336 (12 2011) US ENJahir Frutos100% (2)

- World Bank Report On The Standard Gauge RailwayDocument5 pagesWorld Bank Report On The Standard Gauge RailwayMaskani Ya Taifa100% (2)

- CPC KersDocument13 pagesCPC KersandrewgeorgecherianNo ratings yet

- Pounder's Marine Diesel Engines and Gas TurbinesFrom EverandPounder's Marine Diesel Engines and Gas TurbinesRating: 4 out of 5 stars4/5 (15)

- Operator'S: NoticeDocument56 pagesOperator'S: NoticeGabriela100% (2)

- Azure Dynamics Emergency Response Guide PDFDocument32 pagesAzure Dynamics Emergency Response Guide PDFwopontourNo ratings yet

- Alco Locomotive Usa - EmissionsDocument11 pagesAlco Locomotive Usa - EmissionsharisimhanNo ratings yet

- CVT2010 - Mech Hybrid Paper PDFDocument7 pagesCVT2010 - Mech Hybrid Paper PDFSurendra SainiNo ratings yet

- Techno-Economic Analysis of Fuel Cell Auxiliary Power Units As Alternative To IdlingDocument11 pagesTechno-Economic Analysis of Fuel Cell Auxiliary Power Units As Alternative To IdlingDaniel CruzNo ratings yet

- Four-Pass Loading - Must-Have or Myth PDFDocument9 pagesFour-Pass Loading - Must-Have or Myth PDFRobert KnightNo ratings yet

- Diesel Electric PropulsionDocument77 pagesDiesel Electric PropulsionAnuraag Diyya100% (1)

- Diesel Vs Electrical LocoDocument2 pagesDiesel Vs Electrical LocomajjisatNo ratings yet

- 1998 - March - 03. Shuard - National Rail NR Class LocomotiveDocument8 pages1998 - March - 03. Shuard - National Rail NR Class LocomotiveБорис Грищенко100% (2)

- 2013 Kevin Ludlum Thesis PDFDocument24 pages2013 Kevin Ludlum Thesis PDFPranaya NahakNo ratings yet

- Propeller Cap TurbineDocument4 pagesPropeller Cap TurbineKapil VermaNo ratings yet

- Training Report On Diesel LocomotivesDocument34 pagesTraining Report On Diesel LocomotivesAashish Singhal75% (4)

- 1 s2.0 S221313881930548X MainDocument7 pages1 s2.0 S221313881930548X MainNurrahma Salsabila HadimaNo ratings yet

- S123Document6 pagesS123RudanekNo ratings yet

- Energies 16 00286Document17 pagesEnergies 16 00286Jalil EmadiNo ratings yet

- Achieving Fuel Savings For Anchor Handling Tug Supply Vessels Through Electric Propulsion - ABBDocument4 pagesAchieving Fuel Savings For Anchor Handling Tug Supply Vessels Through Electric Propulsion - ABByw_oulalaNo ratings yet

- A Comparative Study of Fuel-Cell-Battery, Fuel-Cell-Ultracapacitor, and Fuel-Cell-Battery-Ultracapacitor VehiclesDocument10 pagesA Comparative Study of Fuel-Cell-Battery, Fuel-Cell-Ultracapacitor, and Fuel-Cell-Battery-Ultracapacitor Vehiclesangel.silvaNo ratings yet

- Ahmadi Munib - Indonesia - Gas Turbine Used As Future Propulsion SystemDocument9 pagesAhmadi Munib - Indonesia - Gas Turbine Used As Future Propulsion SystemAhmadi MunibNo ratings yet

- Modelling and Simulation of The Fuel CellBattery Hybrid Electric Vehicle Drive TrainDocument14 pagesModelling and Simulation of The Fuel CellBattery Hybrid Electric Vehicle Drive TrainInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- CRP Azipod For Ultra Large Container Ships-An Advanced Cost-Effective SolutionDocument17 pagesCRP Azipod For Ultra Large Container Ships-An Advanced Cost-Effective SolutionEhab Gamal Eldin BarakatNo ratings yet

- Energies: The Effect of Fuel Cell and Battery Size On Efficiency and Cell Lifetime For An L7e Fuel Cell Hybrid VehicleDocument18 pagesEnergies: The Effect of Fuel Cell and Battery Size On Efficiency and Cell Lifetime For An L7e Fuel Cell Hybrid Vehiclesyed hasan 19210064No ratings yet

- Introduction To DLWDocument20 pagesIntroduction To DLWSuraj YadavNo ratings yet

- Article Hydrogen Movility PDFDocument21 pagesArticle Hydrogen Movility PDFJeilson Bravo GonzálezNo ratings yet

- Car ProjectDocument6 pagesCar ProjectnarimantattNo ratings yet

- 2013 CIMAC Zou Et AlDocument9 pages2013 CIMAC Zou Et AlMario KrstovicNo ratings yet

- Design and Optimization of A Drivetrain With Two-Speed Transmission For Electric Delivery Step VanDocument8 pagesDesign and Optimization of A Drivetrain With Two-Speed Transmission For Electric Delivery Step VanPrafulla DandgeNo ratings yet

- Gyro DriveDocument16 pagesGyro DriveVara LakshmiNo ratings yet

- Pro Revue MDCR TransactionsDocument12 pagesPro Revue MDCR Transactionsolim owletNo ratings yet

- Effect of Transmission Design On Electric Vehicle (EV) PerformanceDocument6 pagesEffect of Transmission Design On Electric Vehicle (EV) PerformanceSwati NikamNo ratings yet

- Electric Warship IDocument17 pagesElectric Warship IEduarda BusnardoNo ratings yet

- Indian Railways and Hybrid Electric Vehicle: September 2015Document10 pagesIndian Railways and Hybrid Electric Vehicle: September 2015Karthik spNo ratings yet

- Mechanical Engineering Page No 1Document30 pagesMechanical Engineering Page No 1Syed SaadNo ratings yet

- Powering Decarbonisation With Trolley Assist SystemDocument11 pagesPowering Decarbonisation With Trolley Assist Systemmanager gayatriNo ratings yet

- Energy: Yanbiao Feng, Zuomin DongDocument14 pagesEnergy: Yanbiao Feng, Zuomin DongdinkuinkuNo ratings yet

- AusRAILPLUS 2019 - Spiryagin - WuDocument12 pagesAusRAILPLUS 2019 - Spiryagin - Wumuj_aliNo ratings yet

- Diesel Pollution UICDocument17 pagesDiesel Pollution UICBrijendra SinghNo ratings yet

- New Roads and Challenges For Fuel Cells in Heavy-Duty TransportationDocument13 pagesNew Roads and Challenges For Fuel Cells in Heavy-Duty TransportationJoão Gabriel Ferreira ArgondizziNo ratings yet

- Kinetic Energy Recovery System (Kers)Document15 pagesKinetic Energy Recovery System (Kers)Rohan SahniNo ratings yet

- Diesel Locomotive: How It Works.: Oliver Keating LexcieDocument4 pagesDiesel Locomotive: How It Works.: Oliver Keating LexcieLokesh NarasimhaiahNo ratings yet

- Diesel Vs ElectricDocument76 pagesDiesel Vs ElectricchidukNo ratings yet

- High-Speed TransformationDocument4 pagesHigh-Speed Transformationcosty_transNo ratings yet

- Towards The Electric Propulsion: Mihai Victor Pricop INCAS, Vpricop@incasDocument5 pagesTowards The Electric Propulsion: Mihai Victor Pricop INCAS, Vpricop@incasVidhyaNo ratings yet

- ERR Issue 1 2011Document3 pagesERR Issue 1 2011marzia84No ratings yet

- Deconstructing The Propulsion ConundrumDocument13 pagesDeconstructing The Propulsion ConundrumNajmul Puda PappadamNo ratings yet

- Kinetic Energy Recovery System KersDocument15 pagesKinetic Energy Recovery System Kersasif shaikhNo ratings yet

- Part 5 Optimal Wheel and Rail Performance (M.roney - IHHA 2001) PDFDocument45 pagesPart 5 Optimal Wheel and Rail Performance (M.roney - IHHA 2001) PDFDylkanWingsNo ratings yet

- Techno-Economic Comparison of Series Hybrid, Plug-In HybridDocument16 pagesTechno-Economic Comparison of Series Hybrid, Plug-In HybridHenrique Neiva GuimaraesNo ratings yet

- Chapter 8 MotorsDocument28 pagesChapter 8 MotorsDeepak GuptaNo ratings yet

- Refueling Automated and Autonomous Trucks - Challenges and OpportunitiesDocument14 pagesRefueling Automated and Autonomous Trucks - Challenges and OpportunitiesSylvie PerronNo ratings yet

- Hybrid VehicleDocument11 pagesHybrid VehicleShaviqNo ratings yet

- Diesel Electric Locomotive ComponentsDocument10 pagesDiesel Electric Locomotive Componentssimbairvine23No ratings yet

- Renius 3Document18 pagesRenius 3ManuelNo ratings yet

- Diesel-Electric Loco-Reference List enDocument24 pagesDiesel-Electric Loco-Reference List enRodrigo Hernández Abarzúa100% (2)

- Research Article Tailored Centrifugal Turbomachinery For Electric Fuel Cell TurbochargerDocument14 pagesResearch Article Tailored Centrifugal Turbomachinery For Electric Fuel Cell TurbochargerBharath kumarNo ratings yet

- Gyro Bus - The Fly Wheel Powered BusDocument22 pagesGyro Bus - The Fly Wheel Powered BusRam Kumar Gogada71% (14)

- The Privatisation Classes: A Pictorial Survey of Diesel and Electric Locomotives and Units Since 1994From EverandThe Privatisation Classes: A Pictorial Survey of Diesel and Electric Locomotives and Units Since 1994No ratings yet

- Reducing Business Jet Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemFrom EverandReducing Business Jet Carbon Footprint: Using the Power of the Aircraft Electric Taxi SystemNo ratings yet

- Motor Truck Logging Methods Engineering Experiment Station Series, Bulletin No. 12From EverandMotor Truck Logging Methods Engineering Experiment Station Series, Bulletin No. 12No ratings yet

- Lubricattng Oil For Marine EnginesDocument5 pagesLubricattng Oil For Marine Enginesemmsh71No ratings yet

- Electro-Motive DFVLSTQ?D - : Gemera Motors Corporation L A Gramge, Ltw4Oll, U. $. &, - Aftnjt - L - LR - I - .Document2 pagesElectro-Motive DFVLSTQ?D - : Gemera Motors Corporation L A Gramge, Ltw4Oll, U. $. &, - Aftnjt - L - LR - I - .emmsh71No ratings yet

- Holrl RK C!i Q Umy: Electro-Magnetic Power Contactor - . DescriptionDocument4 pagesHolrl RK C!i Q Umy: Electro-Magnetic Power Contactor - . Descriptionemmsh71No ratings yet

- ', Sec'I'Ioni Wlalntenanceanddlsasse: Arg-D14'Traction GeneratorDocument8 pages', Sec'I'Ioni Wlalntenanceanddlsasse: Arg-D14'Traction Generatoremmsh71No ratings yet

- 115-03 Operator Manual 1158071001EN 03-2009 PDFDocument210 pages115-03 Operator Manual 1158071001EN 03-2009 PDFLuis MironNo ratings yet

- Ee6801 PDFDocument53 pagesEe6801 PDFHarini KarthikeyanNo ratings yet

- Customised Drive Solutions For All Applications: Product Range of The VEM GroupDocument16 pagesCustomised Drive Solutions For All Applications: Product Range of The VEM Groupthiyagarajan vNo ratings yet

- OBDII C Code DefinitionsDocument23 pagesOBDII C Code DefinitionspriyonoNo ratings yet

- Heinrich Maximilian TE Finalsubmission2015august MAScDocument213 pagesHeinrich Maximilian TE Finalsubmission2015august MAScWilliam Jaldin CorralesNo ratings yet

- Bulox Equipment CatalogDocument24 pagesBulox Equipment CatalogIulian MurariuNo ratings yet

- Technical Data: Designed To WorkDocument6 pagesTechnical Data: Designed To WorkDarko Marjanovic0% (1)

- TIP Assignment 2Document16 pagesTIP Assignment 2HARSH MATHURNo ratings yet

- DLW ReportDocument40 pagesDLW ReportNilotpal Kumar RaiNo ratings yet

- Ref 1Document9 pagesRef 1Dwiky PurbacNo ratings yet

- 5581 Ie3 Catalogue enDocument76 pages5581 Ie3 Catalogue enmejri merinNo ratings yet

- Experiment No: 2: AIM: To Study and Simulate Single Phase Semi Control of DC Separately Excited MotorDocument29 pagesExperiment No: 2: AIM: To Study and Simulate Single Phase Semi Control of DC Separately Excited MotorPratik K AnandparaNo ratings yet

- 1535 e G 1885 eDocument24 pages1535 e G 1885 eaaaa100% (1)

- Vendor List Version 12 (Electrical) W.E.F 01-04-2019Document94 pagesVendor List Version 12 (Electrical) W.E.F 01-04-2019aniruthNo ratings yet

- Shakurbasti Diesel Shed Report NewDocument25 pagesShakurbasti Diesel Shed Report NewDeepak Chandhok100% (1)

- How Do Hybrid Electric Cars WorkDocument4 pagesHow Do Hybrid Electric Cars Workfootball clubNo ratings yet

- Indian Railways Diesel Locomotive Works: Technical Training CrntreDocument36 pagesIndian Railways Diesel Locomotive Works: Technical Training CrntreUtkarsh Singh100% (1)

- Gen - Elk.sxsrsp Fault CodesDocument86 pagesGen - Elk.sxsrsp Fault CodesFatih YÜKSELNo ratings yet

- Vertical Transportation: Elevators & EscalatorsDocument16 pagesVertical Transportation: Elevators & EscalatorsGeorge IskanderNo ratings yet

- Energy Storage Devices For Future Hybrid Electric VehiclesDocument10 pagesEnergy Storage Devices For Future Hybrid Electric VehiclesNavaneeth KedlayaNo ratings yet

- Dynamic BrakingDocument6 pagesDynamic BrakingKumar shantanu BasakNo ratings yet

- ALCO Loco RelaysDocument16 pagesALCO Loco RelaysMuhammathali JNo ratings yet

- Summer Training Report On DLW Workshop, VaranasiDocument15 pagesSummer Training Report On DLW Workshop, Varanasijatinshukla431No ratings yet

- Tech Data - Dulevo 6000 HD TIER3Document4 pagesTech Data - Dulevo 6000 HD TIER3Matias Contreras KöbrichNo ratings yet

- Operating InstructionsDocument49 pagesOperating InstructionsLada LabusNo ratings yet

- Materi SARANA - FreeportDocument79 pagesMateri SARANA - FreeportMuhammad Basir Biyantoro100% (1)

- B.tech 7th Sem SyllabusDocument7 pagesB.tech 7th Sem SyllabusVIKASH MALIKNo ratings yet