Professional Documents

Culture Documents

MSDS Glo Na Bromide LQ 1000

Uploaded by

Vikash Kumar0 ratings0% found this document useful (0 votes)

21 views2 pagesbromide liquid

Original Title

MSDS GLO NA BROMIDE LQ 1000

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentbromide liquid

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views2 pagesMSDS Glo Na Bromide LQ 1000

Uploaded by

Vikash Kumarbromide liquid

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Global Drilling Fluids

& Chemicals Limited

ISO 9001:2008

Corporate Office : Manufacturing Facility :

Drilling Fluid Division 33/1, Ghansar, Baska-Rameshra Road, Halol,

75, Mathura Road, Sector 27 C, Dist. Panchmahals, Gujarat – 389 350, India

Faridabad, New Delhi (NCR) -121 003, India Phone : +91 -2676 247170

Phones : +91-129-4271500, Fax : +91-129-4155502/03 TeleFax : +91 -2676 247236

E-mail : global@globaldrilling.in E-mail : contanct@globaldrilling.in

Website: www.globaldrilling.in

MATERIAL SAFETY DATA SHEET

GLO NA BROMIDE LQ 1000

Section 1: Product and Company Identification

Product Name GLO NA BROMIDE LQ 1000 Common Name Sodium Bromide

Product Use Drilling fluid additive Product Type Drilling Fluid

Company Identification: Section 2: Composition /Information On

Global Drilling Fluids and Chemicals Limited Ingredients

Corporate Office and Information Centre : Chemical Work over Completion Fluid

Characterization

For Product Information and MSDS Requests : Sodium Bromide 45%

75 Sector 27 C Mathura Road,

Faridabad (Delhi NCR)- 121 003, India

Phone: +91-129-4271500

Fax: +91-129-4155502

Email: info@globaldrilling.in

Section 3: Hazard Identification

Adverse human health effect No specific risk when handled in accordance with good occupational hygiene and safety

practices.

Environmental Effects Negligible

Physical and Chemical hazards Non flammable liquid

Other Hazards No specific hazard under normal condition of use

Section 4: First Aid Procedures

Eyes Hold eyelids apart and flush eyes with water for at least 15 minutes. Get medical attention if irritation persists.

Skin Wash thoroughly with soap and water. Remove contaminated clothing. If irritation develops, seek medical

attention.

Ingestion Drink water to dilute. Never give anything by mouth to an unconscious person. Seek medical attention.

Inhalation If exposed to a high concentration of dust, remove to fresh air and restore breathing. If not breathing give

artificial respiration. Seek medical attention.

Other Instructions Sensitive individuals should avoid further contact. If irritation persists, seek medical attention. Persons

seeking medical attention should carry a copy of this MSDS with them.

Section 5: Fire Fighting Measures

Extinguishing Media Carbon dioxide, dry chemical, foam and water spray or fog. Use water to cool fire-

exposed containers

Fire fighting procedures Normal fire fighting procedures may be used

Section 6: Accidental Spill / Release Measures:

Steps to be taken is the material Wear proper protective equipment. Contain the spill and minimize dust. Re-package or recycle

is released or spilled if possible, or place in a suitable waste container. Keep out of sewers and waterways.

Spill Management Avoid Creating a dust Cloud. Shovel Sweep or use industrial vacuum cleaner. Reduce airborne

dust or scattering by moistening by water

Reporting Please follow Local Laws

Disposal The material must be disposed as per the Regulations of the Local Laws

Section 7: Handling and Storage

Precautions Use caution to avoid dust and to prevent inhalation of dust. High Airborne dust contaminations may cause

dust explosion Hazard. Avoid Breathing material, Keep container closed. Use with adequate ventilation.

Avoid contact with eyes , Skin and clothing

General Information Keep away from oxidizing materials in a cool Dry well ventilated area

Regd. Office : 12, Friend’s Colony (West), New Delhi - 110065

Global Drilling Fluids

& Chemicals Limited

Section 8: Occupational Control Measures / Personal Protection

Respiratory Wear a high efficiency particulate respirator when exposure exceeds the recommended limits.

Ventilation Supply natural or mechanical ventilation adequate to keep exposures below the recommended exposure limits.

Skin Wear appropriate gloves and long protective clothing. Wash thoroughly after handling. Wash clothes and

clean shoes before reuse

Eyes Wear safety glasses with side guards. Insure proper fit for best Protection

Other Protective Ordinary measures of personal hygiene should be observed. Avoid contact with eyes, skin and clothing and

Equipment inhalation of dust.

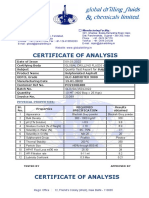

Section 9: Physical and Chemical Characteristics

Properties Value

Appearance Light to pale yellow

pH (45 % Sol) 6.0 - 8.0

SG @ 25 Deg C 1.40 – 1.60

Sodium Bromide Content 45%

Please also see attached Specification Sheet

Section 10: Stability and Reactivity

Stability Stable under normal conditions of use

Materials to avoid Strong oxididizers

Hazardous decomposition products No dangerous reaction , decomposition known with common products

Hazardous Polymerization Will not occur

Section 11: Toxicological Information

Acute Toxicity N/A

Eyes The material is dusty so may cause Irritation to the Eyes

Skin Skin irritation may occur in sensitive individuals after repeated or prolonged contact

Inhalation Excessive or repeated inhalation may cause respiratory irritation.

Ingestion Not to be swallowed.

Section 12: Ecological Information

Degradability This product is biodegradable

Effects on Aquatic Environment Detrimental effects only at very high concentrations.

Section 13: Disposal Considerations

In accordance with local and national regulations provided by the local authorities

Section 14: Transport Information

The material is not regulated for transport of Dangerous Goods: ADR, IATA

Section 15: Regulations Information

NO regulations applicable

Precautionary Labeling WARNING! Contains liquid material, inhalation of which may cause cancer.

May cause eye, skin and respiratory tract irritation.

Precautions for transportation handling and Storage Protect sacks from heat and excessive moisture. Minimize dust exposure

during use.

Section 16: Additional Information:

The statements, information, and data provided in this MSDS are believed reliable and accurate by Global Drilling

Fluids & Chemicals Limited and its responsible personnel

Regd. Office : 12, Friend’s Colony (West), New Delhi - 110065

You might also like

- Optigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLEFrom EverandOptigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLENo ratings yet

- MSDS Glo Drill Foam 1000Document7 pagesMSDS Glo Drill Foam 1000Vikash KumarNo ratings yet

- MSDS Sheet Glo TrollDocument5 pagesMSDS Sheet Glo TrollVikash KumarNo ratings yet

- MSDS Glo Organo Clay 1000Document5 pagesMSDS Glo Organo Clay 1000Vikash KumarNo ratings yet

- Material Safety Data Sheet: Product Name: CocodiethanolamideDocument3 pagesMaterial Safety Data Sheet: Product Name: CocodiethanolamideVRVNo ratings yet

- Material Safety Data Sheet Section 1: IdentificationDocument5 pagesMaterial Safety Data Sheet Section 1: IdentificationAfiq RahmadNo ratings yet

- ZenTreat D 100 (SDS)Document3 pagesZenTreat D 100 (SDS)Abhay BhoirNo ratings yet

- Cationic Polyelectrolyte UW-MSDS 412VSDocument4 pagesCationic Polyelectrolyte UW-MSDS 412VSBRAHMDEV KUSHWAHANo ratings yet

- Sodium Benzoate MSDSDocument6 pagesSodium Benzoate MSDSsayedtanzilNo ratings yet

- Dow Corning 200 Malaysia PDFDocument6 pagesDow Corning 200 Malaysia PDFLim BoniNo ratings yet

- MSDS for Thermal Transfer RibbonDocument4 pagesMSDS for Thermal Transfer Ribbonayrton carls zamora cardenasNo ratings yet

- Cocamide Dea MsdsDocument6 pagesCocamide Dea Msdsmaha muhammedNo ratings yet

- Cilajet Aviation Grade MSDS APR 2016Document4 pagesCilajet Aviation Grade MSDS APR 2016Hero ShadowNo ratings yet

- Global - BIOCIDEDocument1 pageGlobal - BIOCIDEjyoti duttaNo ratings yet

- Chemical Safety Data Sheet: Section 1: Chemical Product & Company IndentificationDocument7 pagesChemical Safety Data Sheet: Section 1: Chemical Product & Company IndentificationSyerifaizal Hj. MustaphaNo ratings yet

- Material Safety Data Sheet: (Acute and Chronic)Document4 pagesMaterial Safety Data Sheet: (Acute and Chronic)Ganjar Tri Gita AzhariNo ratings yet

- Safety Data Sheet Lithium Carbonate: Section 1: Identification of The Substance and of The CompanyDocument6 pagesSafety Data Sheet Lithium Carbonate: Section 1: Identification of The Substance and of The CompanyAndrianoNo ratings yet

- 3 msds-LANOTEX CS-105Document5 pages3 msds-LANOTEX CS-105saddamNo ratings yet

- MSDS Benzalkonium Chloride SolutionDocument4 pagesMSDS Benzalkonium Chloride SolutionPan SoapNo ratings yet

- Silica Fume: Section 1: Chemical Product and Company IdentificationDocument5 pagesSilica Fume: Section 1: Chemical Product and Company IdentificationMahmoud AbouzeidNo ratings yet

- Material Safety Data Sheet Kaolin MsdsDocument3 pagesMaterial Safety Data Sheet Kaolin MsdsNura Alam SiddiqueNo ratings yet

- Goodrich Shine Master MSDSDocument4 pagesGoodrich Shine Master MSDSSkySupplyUSANo ratings yet

- SDS Admix Gel A 50Document4 pagesSDS Admix Gel A 50adelsaqqaNo ratings yet

- MSDS Sodium Hypochlorite SolutionDocument4 pagesMSDS Sodium Hypochlorite SolutionPan SoapNo ratings yet

- QSR QUARRY TILE FLOOR CLEANER - PHILIPPINES-A-1-phil-en-900612-06-qsr Quarry Tile Floor CleanerDocument4 pagesQSR QUARRY TILE FLOOR CLEANER - PHILIPPINES-A-1-phil-en-900612-06-qsr Quarry Tile Floor CleanerPaulyn ParejaNo ratings yet

- Safety Data Sheet for Aquafin-IC Admix PowderDocument5 pagesSafety Data Sheet for Aquafin-IC Admix PowderJitendra ShahNo ratings yet

- Blue Herd MsdsDocument6 pagesBlue Herd MsdsChessa SalsabellaNo ratings yet

- Sds-Flor KlenDocument3 pagesSds-Flor KlenConnie SoonNo ratings yet

- Material Safety Data Sheet for Butyl StearateDocument3 pagesMaterial Safety Data Sheet for Butyl StearateTushar GuptaNo ratings yet

- Safety Data Sheet: Metalcrete IndustriesDocument4 pagesSafety Data Sheet: Metalcrete IndustriesCarlos Alberto Luyo BuendíaNo ratings yet

- Resolve-8Document5 pagesResolve-8Isaac MartinezNo ratings yet

- 1. CT-BENTO S9 - BENTONITE API - MSDSDocument1 page1. CT-BENTO S9 - BENTONITE API - MSDSMustafa AlrikabiNo ratings yet

- DOLPHIN Duct - MSDSDocument4 pagesDOLPHIN Duct - MSDSanwarNo ratings yet

- Premalube Red Material Safety Data SheetDocument3 pagesPremalube Red Material Safety Data Sheetfreddy william montalban palaciosNo ratings yet

- Epoxy ResinDocument3 pagesEpoxy Resinocta aldyNo ratings yet

- New SDS-FoamSMART Standard PU Chemical (Part A)Document3 pagesNew SDS-FoamSMART Standard PU Chemical (Part A)Dear ShamNo ratings yet

- ISO MSDS OXYGEN SCAVENGERDocument1 pageISO MSDS OXYGEN SCAVENGERjyoti duttaNo ratings yet

- Armix HyyeCrete PC 20Document4 pagesArmix HyyeCrete PC 20santaram.No ratings yet

- MSDS - Hydrex 5914 (Cleaning Chemical) - CO2 PlantDocument4 pagesMSDS - Hydrex 5914 (Cleaning Chemical) - CO2 PlantFAREEDNo ratings yet

- Material Safety Data Sheet (MSDS) : Coconut Fatty Acid DiethnolamideDocument3 pagesMaterial Safety Data Sheet (MSDS) : Coconut Fatty Acid DiethnolamideMezo MezoNo ratings yet

- ZenTreat D-302 Safety Data Sheet (SDSDocument3 pagesZenTreat D-302 Safety Data Sheet (SDSAbhay BhoirNo ratings yet

- ATTACHMENT 2Document12 pagesATTACHMENT 2WASSIM SUNNANo ratings yet

- SDS CarbopolPolymerDocument5 pagesSDS CarbopolPolymeramir hosenNo ratings yet

- Berger EmultionDocument4 pagesBerger EmultionFrancisco M. RamosNo ratings yet

- ZenTreat D 201 (SDS)Document3 pagesZenTreat D 201 (SDS)Abhay BhoirNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument7 pagesSafety Data Sheet: 1. IdentificationmahmoudNo ratings yet

- Material Safety Data Sheet: Section 1 Chemical Product and Company IdentificationDocument4 pagesMaterial Safety Data Sheet: Section 1 Chemical Product and Company IdentificationqwaszxcdeNo ratings yet

- Gojo Multi Green Hand Cleaner MsdsDocument13 pagesGojo Multi Green Hand Cleaner MsdsRichard PannNo ratings yet

- MSDS BlueDocument4 pagesMSDS BlueNaeem AhmadNo ratings yet

- MSDS RBD PoDocument3 pagesMSDS RBD PoAnggunNo ratings yet

- Safety Data Sheet Machine Rinse AidDocument2 pagesSafety Data Sheet Machine Rinse Aidmondeor1No ratings yet

- Vision SDS TitleDocument3 pagesVision SDS TitleSophie TranNo ratings yet

- Material Safety Data Sheet: (Acute and Chronic)Document3 pagesMaterial Safety Data Sheet: (Acute and Chronic)Sudharshan RamakrishnanNo ratings yet

- MSDS Hec en 3.3Document6 pagesMSDS Hec en 3.3Mohammed Tanjil Morshed remonNo ratings yet

- Glozee Dish Wash Lemon - 2019Document4 pagesGlozee Dish Wash Lemon - 2019Ashok KumarNo ratings yet

- Ptei Estocure P - Sds - 190405Document5 pagesPtei Estocure P - Sds - 190405Denis nataliaNo ratings yet

- MSDS Bloomfield Hand SanitizerDocument3 pagesMSDS Bloomfield Hand SanitizerKutay UyanikNo ratings yet

- SDS for ZI-CHEM 1630 boiler blend chemicalDocument4 pagesSDS for ZI-CHEM 1630 boiler blend chemicalwaskito_agusNo ratings yet

- SipPol Material Safety Data SheetDocument6 pagesSipPol Material Safety Data SheetMudzofar SofyanNo ratings yet

- Vicatan VB6 - MSDSDocument6 pagesVicatan VB6 - MSDSJohnraphelNo ratings yet

- Coa Glo Obm Semul 1000Document1 pageCoa Glo Obm Semul 1000Vikash KumarNo ratings yet

- Coa Glo Ca Retarder LQ 4000Document1 pageCoa Glo Ca Retarder LQ 4000Vikash KumarNo ratings yet

- GLO CFTHIN 1000 - Chrome Free ThinnerDocument2 pagesGLO CFTHIN 1000 - Chrome Free ThinnerVikash KumarNo ratings yet

- Glo Ca WGHT 1000Document2 pagesGlo Ca WGHT 1000Vikash KumarNo ratings yet

- Coa Glo Ben 1000 Api 13a Sec 9Document1 pageCoa Glo Ben 1000 Api 13a Sec 9Vikash KumarNo ratings yet

- COA (Inv 21089, KCH)Document6 pagesCOA (Inv 21089, KCH)Vikash KumarNo ratings yet

- Skala Perilaku Seks PranikahDocument6 pagesSkala Perilaku Seks PranikahRiska amaliaNo ratings yet

- Sample of A Comprehensive Narrative ReportDocument7 pagesSample of A Comprehensive Narrative ReportJanessa Andrei Perez FresnidoNo ratings yet

- Wa0002.Document9 pagesWa0002.SojiNo ratings yet

- 의약품동등성시험기준 해설서 요약Document137 pages의약품동등성시험기준 해설서 요약Travis JeonNo ratings yet

- Adime 2Document13 pagesAdime 2api-496164982No ratings yet

- LanoLip Power Point PresentationDocument12 pagesLanoLip Power Point PresentationWalter Sanchez EscobarNo ratings yet

- Benefits of Intermittent FastingDocument3 pagesBenefits of Intermittent FastingSaurabh PandeyNo ratings yet

- Revised - Ie18 Final UpdatedDocument120 pagesRevised - Ie18 Final UpdatedLUCAS AndrewsNo ratings yet

- Details Received From Collectorate - Excellent Dedicated Work - During Pandemic COVID - 19Document2 pagesDetails Received From Collectorate - Excellent Dedicated Work - During Pandemic COVID - 19Vimal kumarNo ratings yet

- ANSI Respiratory Protection PDFDocument40 pagesANSI Respiratory Protection PDFSagarKolachinaNo ratings yet

- Checklist Using Nasopharengeal and Oropharengeal SuctioningDocument4 pagesChecklist Using Nasopharengeal and Oropharengeal SuctioningKristine Louise JavierNo ratings yet

- Types of Oral Communication NDocument34 pagesTypes of Oral Communication NYen AduanaNo ratings yet

- Planeacion Preoperatoria Artroplastia CaderaDocument8 pagesPlaneacion Preoperatoria Artroplastia Caderamontserrat santiago sanchezNo ratings yet

- Bihar Jharkhand Lab ScrapDocument27 pagesBihar Jharkhand Lab ScrapOFC accountNo ratings yet

- 6 135Document6 pages6 135Ashok LenkaNo ratings yet

- Muscle Strength TestingDocument3 pagesMuscle Strength TestingGiselle Chloe Baluya ico100% (1)

- Test Bank For Burtons Microbiology For The Health Sciences 9 North Americanth Edition Paul G EngelkirkDocument10 pagesTest Bank For Burtons Microbiology For The Health Sciences 9 North Americanth Edition Paul G Engelkirkraphaelsophiep9f9100% (22)

- English Passion Project 2Document9 pagesEnglish Passion Project 2api-462335192No ratings yet

- PAE STAGE 2 EXAM PRACTICE With Answer Key and TapescriptDocument39 pagesPAE STAGE 2 EXAM PRACTICE With Answer Key and TapescriptaagNo ratings yet

- Galway All Products Price ListDocument3 pagesGalway All Products Price ListRishikesh Kumar Ray madhaipurNo ratings yet

- )Document6 pages)nuraninarunNo ratings yet

- Erba Lisawash Service ManualDocument9 pagesErba Lisawash Service ManualEricj Rodríguez100% (1)

- DNHS SHS Exam in PE and Health 11 (Midterm Exam SY 2017-2018) Answer SheetDocument2 pagesDNHS SHS Exam in PE and Health 11 (Midterm Exam SY 2017-2018) Answer SheetArangote Glenn92% (91)

- Identification: Infosafe No.: LPSIZ Issued Date: 30/03/2015 Issued By: Sibelco Australia LimitedDocument7 pagesIdentification: Infosafe No.: LPSIZ Issued Date: 30/03/2015 Issued By: Sibelco Australia Limitedsentient.bean8226No ratings yet

- Rcads-Child TemplateDocument3 pagesRcads-Child TemplateHome Sweet100% (1)

- Pandemic Learning: Migrant Care Workers and Their Families Are Essential in A Post-COVID-19 WorldDocument18 pagesPandemic Learning: Migrant Care Workers and Their Families Are Essential in A Post-COVID-19 WorldThe Wilson CenterNo ratings yet

- Relationship of Mothers' Knowledge and Socio-Culture to Motivation for MR ImmunizationDocument10 pagesRelationship of Mothers' Knowledge and Socio-Culture to Motivation for MR ImmunizationHanaNo ratings yet

- A Case Report of Acute Severe Necrotizing Pancreatitis FollowingDocument4 pagesA Case Report of Acute Severe Necrotizing Pancreatitis FollowingalexNo ratings yet

- Frist Aid PPT For Pharm PDFDocument257 pagesFrist Aid PPT For Pharm PDFAbdulwhab MohammedNo ratings yet

- Daily Diary Stress and Mood Variation/TITLEDocument103 pagesDaily Diary Stress and Mood Variation/TITLEFilsa Putri AnwarNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryFrom EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryRating: 4 out of 5 stars4/5 (5)

- The User's Journey: Storymapping Products That People LoveFrom EverandThe User's Journey: Storymapping Products That People LoveRating: 3.5 out of 5 stars3.5/5 (8)

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- The Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorFrom EverandThe Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorRating: 4 out of 5 stars4/5 (7)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsFrom EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNo ratings yet

- Design Is The Problem: The Future of Design Must Be SustainableFrom EverandDesign Is The Problem: The Future of Design Must Be SustainableRating: 1.5 out of 5 stars1.5/5 (2)

- Iconic Advantage: Don’t Chase the New, Innovate the OldFrom EverandIconic Advantage: Don’t Chase the New, Innovate the OldRating: 4 out of 5 stars4/5 (1)

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)

- Top-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsFrom EverandTop-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsNo ratings yet

- Reciprocating Compressors:: Operation and MaintenanceFrom EverandReciprocating Compressors:: Operation and MaintenanceRating: 4 out of 5 stars4/5 (7)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)