Professional Documents

Culture Documents

Ukanol Es 2018

Uploaded by

Muhammad Aasim HassanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ukanol Es 2018

Uploaded by

Muhammad Aasim HassanCopyright:

Available Formats

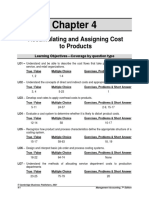

FIBRE UK ANOL ES

REACTIVE FL AME RETARDANT

ADDITIVE FOR POLYESTER

UK ANOL ES

ADDITIVE FOR PERMANENT FL AME RETARDANCY IN POLYESTER FIBRES

The trend towards the use of synthetic polymers in the Although halogenated flame retardant additives can

textile industry is increasing continuously. It is therefore meet these requirements, their use will raise questions

of major importance that the fire safety aspects of these about their effect on human health and the environment.

materials should not be ignored. The inflammability of UKANOL ES offers an alternative approach.

PET Fibres can be significantly reduced by the use of

flame retardants, which increase the resistance to Schill+Seilacher offer UKANOL ES as a halogen-free

ignition or decrease the rate of spread of flame. phosphorus based flame retardant additive, which

However, additives should not affect the physical provides PET Fibres with excellent, permanent flame

properties of the material and additional costs must retardant effects.

remain low.

FL AME RETARDANCY OF TEX TILES

COT TON

VISCOSE

LINEN

POLYACRYL POLYESTER

POLYPROPYLENE POLYAMID

WOOL

SILK UK ANOL ES-CoPET

ARAMID

Cotton PVC

Viscose GL ASS FIBRES

Linen METAL FIBRES

Polyacryl ASBESTOS

Polypropylene

HIGHLY FL AMMABLE FL AMMABLE HARDLY FL AMMABLE NON FL AMMABLE

THE TWO PRINCIPLES OF ESTABLISHED FL AME RETARDANCY IN TEX TILES

Flame retardants may be physically Reactive flame retardants

blended with or chemically bonded to are reactive components chemically built into a polymer chain.

the host polymer. Therefore a distinction

has been made between reactive and Additive flame retardants

additive flame retardants: are mixed with polymer or coated on a fabric. Additive flame

retardants can be removed easily after washing.

REACTIVE FL AME RETARDANT ADDITIVE FOR POLYESTER

UK ANOL ES

PROPERTIES AND PERFORMANCE

UKANOL ES is a halogen-free phosphorus based reactive flame retardant additive. It is incorporated into the

polymer chain during the polycondensation process by chemical bonding.

PROPERTIES AND PERFORMANCE

UKANOL ES is an efficient flame retardant system

with more than one mode of action and including free

HEAT RELEASE RATE/TEMPERATURE

radical scavenging. It does not simply rely on influencing

the melting behaviour of PET. In this way it can either

WITHOUT UK ANOL ES

prevent fires from growing or significantly slow the rate

of growth.

WITH

UK ANOL ES

IGNITION FL AME SPREAD FL ASH OVER FULL FIRE

TIME

WITHOUT UK ANOL ES

REACTIVE FL AME RETARDANT ADDITIVE FOR POLYESTER

UK ANOL ES

THE UNIQUE PROPERTIES OF UK ANOL ES-COPET ARE DUE TO THE POSITION

OF THE ACTIVE FL AME RETARDANT IN THE MACROMOLECULE

APPLICATION OF UK ANOL ES

■ UKANOL ES is applied after the ■ UKANOL ES-CoPET reaction parameters such as

esterification process. temperature and time in the polycondensation stage

are similar to those of standard PET production.

■ UKANOL ES is manufactured as a ready

usable 65 % solution in ethylene glycol. ■ Approx. 12 % UKANOL ES (based on the final

polymer) is required for a phosphorous content of

■ Due to the fact that no chemical interaction takes 6000 ppm, which is necessary to reach a flame

place, UKANOL ES may be combined with other retardant effect in PET.

additives (Sb2O3, TiO2, GeO2) and catalysts.

TPA / DMT ESTERIFICATION EG

UK ANOL ES MIXING OTHER ADDITIVE

POLYCONDENSATION

UK ANOL ES-CoPET

REACTIVE FL AME RETARDANT ADDITIVE FOR POLYESTER

UK ANOL ES

HYDROLYTIC STABILITY OF UK ANOL ES-CoPET AND COMPETITOR FR-CoPET

% 100

PET

90

UK ANOL ES-CoPET

80

COMPETITOR FR-CoPET

70

60

0 1 2 3 4 5 6

HYDROLYSIS TREATMENT (h)

THERMAL RESISTANCE OF UK ANOL ES-CoPET AND COMPETITOR FR-CoPET

% 100

PET (standard)

80

UK ANOL ES-CoPET

60

40

COMPETITOR FR-CoPET

20

0

0 1 2 3 4 5

TIME OF THERMAL TREATMENT OF PET-FILM AT 140 °C (DAY)

THE ACTIVE PART OF THE FL AME RETARDANT MOLECULE IS AT TACHED TO THE PET POLYMER

CHAIN BY SIDE CHAIN BONDING. BOND BREAKING BY THERMAL REARRANGEMENT OR

HYDROLYSIS IN THE FL AME RETARDANT DOES NOT AFFECT THE INTEGRITY OF THE PET

POLYMER ITSELF. THE UNIQUE CHARACTERISTICS OF UK ANOL ES-CoPET PROVIDE A FIBRE

WITH HYDROLYSIS RESISTANCE AND THERMAL STABILITY TO MATCH STANDARD POLYESTER

FIBRE.

REACTIVE FL AME RETARDANT ADDITIVE FOR POLYESTER

UK ANOL ES

FIELDS OF APPLICATION OF UK ANOL ES-CoPET

■ POY, FDY TEXTILE DENIER ■ INDUSTRIAL YARN, BCF, CF

■ STAPLE FIBRE, SHORT CUT ■ NONWOVENS

FINAL ENDUSES IN

■ HOSPITALS ■ HOTELS

■ SCHOOLS ■ TRAINS, AIRPL AINES, FERRIES

■ CINEMAS/THEATERS ■ MILITARY

■ RESTAURANTS

KEY PROPERTIES OF UK ANOL ES-CoPET

FL AME RETARDANCY EXCELLENT

HYDROLYTIC STABILITY VERY HIGH

THERMAL RESISTANCE EXCELLENT *

TOXICITY AND ENVIRONMENTAL BEHAVIOR HARMLESS

*Thermal stability allows solid state polycondensation (SSP).

REACTIVE FL AME RETARDANT ADDITIVE FOR POLYESTER

S C H I L L + S E I L A C H E R AT A G L A N C E

BOEBLINGEN

SPECIALITY CHEMICALS FOR: FIBRES

TEXTILES

LEATHER

PAPER

DIN EN ISO 9001:2015 COSMETICS

DIN EN ISO 14001:2015 FINE CHEMICALS

DIN EN ISO 50001:2011

RSPO CERTIFICATION MASS BALANCE

HAMBURG

SPECIALITY CHEMICALS FOR: RUBBER ADDITIVES

ANTIFOAMS

EPOXY PREPOLYMERS

AND FL AME RETARDANTS

L ATEX ADDITIVES

DIN EN ISO 9001:2015 SILICONES

DIN EN ISO 14001:2015 RELEASE AGENTS

DIN EN ISO 50001:2011

PIRNA

SPECIALITY CHEMICALS FOR: SILICONES

PU INDUSTRY

PAPER

TEXTILES

COSMETICS

FIBRES

DIN EN ISO 9001:2015 LEATHER

(ONLY FOR BOEBLINGEN PRODUCTS)

HUDSON / OHIO / USA

PRODUCER OF: NANOFIBRE MATRICES

DIN EN ISO 9001:2015

DIN EN ISO 13485:2003

STOW / OHIO / USA

VILL A RICA / GEORGIA / USA PL ASTICS

SPECIALITY CHEMICALS FOR: WOOD COMPOSITES

RUBBER

LEATHER

DIN EN ISO 9001:2008

Any Questions?

Our service team will be pleased to answer any questions

and to assist you with advice and information at all times.

We can also advise you of the contact data of our local

offices and agencies. Data sheets and samples of our

products are available upon request.

For more information please contact:

Schill+Seilacher GmbH

Schoenaicher Strasse 205

71032 Boeblingen (Germany)

Phone: +49 7031 282-297

Fax: +49 7031 282-9277

E-Mail: ctv@schillseilacher.de

Visit also our site:

www.schillseilacher.de

CHM08.2018

You might also like

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Macromolecular Chemistry: Session Lectures Presented at the Twentysixth International Congress of Pure and Applied Chemistry, Tokyo, Japan, 4-10 September 1977From EverandMacromolecular Chemistry: Session Lectures Presented at the Twentysixth International Congress of Pure and Applied Chemistry, Tokyo, Japan, 4-10 September 1977A. NakajimaNo ratings yet

- PC1 53Document148 pagesPC1 53bharatsehgal00@gmail.comNo ratings yet

- Lummus - EBOne Process PDFDocument2 pagesLummus - EBOne Process PDFJungmuk Lee0% (1)

- Product Selection Guide: To Corrosion Resistant Vipel ResinsDocument6 pagesProduct Selection Guide: To Corrosion Resistant Vipel ResinsChristian HinostrozaNo ratings yet

- Mike-Banach-UOP-2016 Presentation On Oleflex Operating UnitsDocument20 pagesMike-Banach-UOP-2016 Presentation On Oleflex Operating Unitsagarwalashwin32100% (1)

- SKFP COEXTRUSION SOLUTIONS Jan 31 2022Document26 pagesSKFP COEXTRUSION SOLUTIONS Jan 31 2022李万福No ratings yet

- LEVACO - Agrochemicals ProductsDocument6 pagesLEVACO - Agrochemicals Productsmercurius100% (1)

- Chemistry and Composition of Epn ResinsDocument6 pagesChemistry and Composition of Epn ResinsDiana AndreiNo ratings yet

- The Application of Ethylene Propylene RubberDocument4 pagesThe Application of Ethylene Propylene RubberJohn Patrick DagleNo ratings yet

- 10EPDM16Aug2012 PDFDocument4 pages10EPDM16Aug2012 PDFTaranom SpNo ratings yet

- Fomrez Brochure - InddDocument16 pagesFomrez Brochure - InddEdgar hernandezNo ratings yet

- Presentation On PET NewDocument117 pagesPresentation On PET NewJAWAD AHMEDNo ratings yet

- Liquids & Semisolids - Jul 2022Document37 pagesLiquids & Semisolids - Jul 2022Astrid Carolina Gutierrez ShimabukuroNo ratings yet

- Elevating Polymeric Compounds With Enhanced Scratch and Abrasion Resistance Using Silicon Additives OCTOBER 2023Document24 pagesElevating Polymeric Compounds With Enhanced Scratch and Abrasion Resistance Using Silicon Additives OCTOBER 2023enbuscadepalabrasbookNo ratings yet

- DSM GuideChemicalResistance - DurabilityProtection New 2012Document28 pagesDSM GuideChemicalResistance - DurabilityProtection New 2012Dustin SalasNo ratings yet

- Article FRDocument5 pagesArticle FRThu Trang NguyenNo ratings yet

- Exolit-FR-Clariant 2014Document6 pagesExolit-FR-Clariant 2014xy2zjgNo ratings yet

- Product Capsule Cumene/Phenol/Acetone: MarketworksDocument7 pagesProduct Capsule Cumene/Phenol/Acetone: MarketworksKevin L. BoyleNo ratings yet

- Wu 2019Document11 pagesWu 2019thủy caoNo ratings yet

- 5 UOP. Honeywell Egypt - Olefins - Mike BanachDocument17 pages5 UOP. Honeywell Egypt - Olefins - Mike Banachharaldno1No ratings yet

- Stabilization of Asphaltenes by Phenolic Compounds Extracted From Cashew-Nut Shell Liquid Moreira1999Document6 pagesStabilization of Asphaltenes by Phenolic Compounds Extracted From Cashew-Nut Shell Liquid Moreira1999Alfonso DominguezNo ratings yet

- Pekasol L Datenblatt GB 4S 11 2015Document4 pagesPekasol L Datenblatt GB 4S 11 2015tungxuanbrNo ratings yet

- Resistance: Guide To ChemicalDocument32 pagesResistance: Guide To ChemicaleragornNo ratings yet

- Epikote Resin 828lvelDocument2 pagesEpikote Resin 828lvelLê TiếnNo ratings yet

- EthyleneDocument4 pagesEthyleneAlejandro Giraldo ZuluagaNo ratings yet

- Document 3Document1 pageDocument 3leoNo ratings yet

- PBE 1 Flyer Lug09 PDFDocument8 pagesPBE 1 Flyer Lug09 PDFchantran90No ratings yet

- Astm d1418Document17 pagesAstm d1418cnrk777No ratings yet

- Ethylene-Propylene Rubbers & ElastomersDocument4 pagesEthylene-Propylene Rubbers & ElastomersrenebarreiroNo ratings yet

- Exolit AP 740, AP 750 (F (EXOLITAP) GB)Document2 pagesExolit AP 740, AP 750 (F (EXOLITAP) GB)Maximiliano MackeviciusNo ratings yet

- Common Uses of Alkene: Polythylene PolyisopreneDocument4 pagesCommon Uses of Alkene: Polythylene PolyisopreneZsarena G. BautistaNo ratings yet

- Polypropylene (PP)Document8 pagesPolypropylene (PP)julioNo ratings yet

- Daniel Zweifel, Dow - Argus Europe Fertilizer 2017Document29 pagesDaniel Zweifel, Dow - Argus Europe Fertilizer 2017vzgscribdNo ratings yet

- 08-The Orthoflow WayDocument12 pages08-The Orthoflow WayAbhimanyu SharmaNo ratings yet

- Alcohol Ethyoxylates As An Alternative To NonylPhenolsDocument3 pagesAlcohol Ethyoxylates As An Alternative To NonylPhenolsChristian Patrick FernandezNo ratings yet

- Pom, Pet, PC, TpuDocument81 pagesPom, Pet, PC, TpuPreksha AgrawalNo ratings yet

- Solbin A Tds 3.2014rsDocument2 pagesSolbin A Tds 3.2014rsGarvit GuptaNo ratings yet

- New Fire Protective Intumescent CoatingsDocument8 pagesNew Fire Protective Intumescent CoatingsBernathTurnipNo ratings yet

- Polyolefins 170917074212 PDFDocument26 pagesPolyolefins 170917074212 PDFTrinh Đình VũNo ratings yet

- Flame Retardants For Fire Protection SystemsDocument8 pagesFlame Retardants For Fire Protection SystemsMaximiliano MackeviciusNo ratings yet

- Dic Epoxy enDocument18 pagesDic Epoxy enSoonwook JangNo ratings yet

- Bermocoll Ebs 451fq CCD 3214Document1 pageBermocoll Ebs 451fq CCD 3214Liliana Higuera NítolaNo ratings yet

- World RefiningDocument7 pagesWorld RefiningmarraezNo ratings yet

- 419 - Composites Catalogue-AtulDocument12 pages419 - Composites Catalogue-AtulVaittianathan Mahavapillai100% (1)

- Grs Compliant: Products List - 2020, May 20Document9 pagesGrs Compliant: Products List - 2020, May 20Rezoanul HaqueNo ratings yet

- Clariant Brochure Exolit Flame Retardants For Thermoplastics 201306 EN PDFDocument24 pagesClariant Brochure Exolit Flame Retardants For Thermoplastics 201306 EN PDFxy2zjgNo ratings yet

- Polymer AbbreviationsDocument9 pagesPolymer AbbreviationsFernando GuerreroNo ratings yet

- Introduction TRAPYLEN EnglishDocument3 pagesIntroduction TRAPYLEN EnglishHoai thu NguyenNo ratings yet

- PE GrapheneDocument9 pagesPE Graphenechaminda nayanajithNo ratings yet

- Agentes AntiescalaDocument7 pagesAgentes AntiescalaFabian ArboledaNo ratings yet

- Metathesis: Refinery and Ethylene Plant ApplicationsDocument6 pagesMetathesis: Refinery and Ethylene Plant ApplicationsArash AbbasiNo ratings yet

- Two Component Aliphatic Polyurea Coatings For High Productivity Applications PDFDocument6 pagesTwo Component Aliphatic Polyurea Coatings For High Productivity Applications PDFsriatul2006No ratings yet

- Hunstman B&PC IngredientsDocument14 pagesHunstman B&PC IngredientsHadyan Adli100% (1)

- 2 6. Alkanes Alkenes and PolymersDocument17 pages2 6. Alkanes Alkenes and PolymersAmber MichaelsNo ratings yet

- Agentes Dispersante para Negro de HumoDocument11 pagesAgentes Dispersante para Negro de HumoMauricio LombanaNo ratings yet

- Light Alkane Dehydrogenation To Light Olefin Technologies: A Comprehensive ReviewDocument24 pagesLight Alkane Dehydrogenation To Light Olefin Technologies: A Comprehensive ReviewAnupama D. MishraNo ratings yet

- Lesson 8 AlkenesDocument10 pagesLesson 8 AlkenesSideka ResalsinghNo ratings yet

- Polymer Fundamentals For CoatingsDocument18 pagesPolymer Fundamentals For CoatingsAmritanshu BanerjeeNo ratings yet

- AOX Poly CompendiumDocument12 pagesAOX Poly CompendiumBobNo ratings yet

- Asim Hassan 4Document1 pageAsim Hassan 4Muhammad Aasim HassanNo ratings yet

- Detergent Formulation IngredientsDocument2 pagesDetergent Formulation IngredientsMuhammad Aasim Hassan100% (2)

- BASF XL SeriesDocument9 pagesBASF XL SeriesMuhammad Aasim HassanNo ratings yet

- Material Safety Data Sheet Formic AcidDocument9 pagesMaterial Safety Data Sheet Formic AcidMuhammad Aasim HassanNo ratings yet

- Mastercard Credit Card Discount List Dec 2022Document7 pagesMastercard Credit Card Discount List Dec 2022Muhammad Aasim HassanNo ratings yet

- Haval Brochure H6 HEVDocument12 pagesHaval Brochure H6 HEVMuhammad Aasim HassanNo ratings yet

- MID - Credit Card Statement Via JS BOTDocument4 pagesMID - Credit Card Statement Via JS BOTMuhammad Aasim HassanNo ratings yet

- Private-Banking-Signature-July-Dec-23 JS BankDocument4 pagesPrivate-Banking-Signature-July-Dec-23 JS BankMuhammad Aasim HassanNo ratings yet

- H2so4 MSDSDocument6 pagesH2so4 MSDSMuhammad Aasim HassanNo ratings yet

- FCMC ProfileDocument3 pagesFCMC ProfileMuhammad Aasim HassanNo ratings yet

- BASF Customer Presentation Formic-AcidDocument17 pagesBASF Customer Presentation Formic-AcidMuhammad Aasim HassanNo ratings yet

- Important DyesDocument20 pagesImportant DyesHitz9925No ratings yet

- Formic Acid Manufacturing ProcessDocument29 pagesFormic Acid Manufacturing ProcessMuhammad Aasim HassanNo ratings yet

- BASF Formic AcidDocument11 pagesBASF Formic AcidMuhammad Aasim HassanNo ratings yet

- COA Formic AcidDocument1 pageCOA Formic AcidMuhammad Aasim HassanNo ratings yet

- Aluminum Sulfate COADocument1 pageAluminum Sulfate COAMuhammad Aasim Hassan0% (1)

- Belfasin 44Document2 pagesBelfasin 44Muhammad Aasim HassanNo ratings yet

- Superclear X-TRADocument4 pagesSuperclear X-TRAMuhammad Aasim HassanNo ratings yet

- Stabitex WFDocument2 pagesStabitex WFMuhammad Aasim HassanNo ratings yet

- AMRESCO Buffers PDFDocument10 pagesAMRESCO Buffers PDFMuhammad Aasim HassanNo ratings yet

- Important DyesDocument20 pagesImportant DyesHitz9925No ratings yet

- Stabitex ETR UndetailedDocument3 pagesStabitex ETR UndetailedMuhammad Aasim HassanNo ratings yet

- Primasol Level FF-AM Conc.Document4 pagesPrimasol Level FF-AM Conc.Muhammad Aasim Hassan100% (1)

- Stabicryl 1009Document3 pagesStabicryl 1009Muhammad Aasim HassanNo ratings yet

- Stabilol PDocument2 pagesStabilol PMuhammad Aasim HassanNo ratings yet

- Stabilol ZMDocument3 pagesStabilol ZMMuhammad Aasim HassanNo ratings yet

- Stabitex ETRDocument5 pagesStabitex ETRMuhammad Aasim HassanNo ratings yet

- Stabitex ETR UndetailedDocument3 pagesStabitex ETR UndetailedMuhammad Aasim HassanNo ratings yet

- Securon 540Document2 pagesSecuron 540Muhammad Aasim HassanNo ratings yet

- Stabifix AFBDocument3 pagesStabifix AFBMuhammad Aasim HassanNo ratings yet

- Introduction To Discourse Analysis PDFDocument20 pagesIntroduction To Discourse Analysis PDFShobade Christianah Temitope100% (1)

- Chap 3Document40 pagesChap 3eshbliNo ratings yet

- AccountingDocument45 pagesAccountingAfia ZaheenNo ratings yet

- Sample Waste Management Tracking FormDocument3 pagesSample Waste Management Tracking FormSreekumarNo ratings yet

- Joshi - Quant Job InterviewDocument329 pagesJoshi - Quant Job InterviewPiciBivNo ratings yet

- Kidstone Mines Start UpDocument5 pagesKidstone Mines Start UpCraftychemistNo ratings yet

- Stsgroup 1Document13 pagesStsgroup 1Wenalyn Grace Abella LlavanNo ratings yet

- Journal Innovation Knowledge: Indicators Used To Measure Service Innovation and Manufacturing InnovationDocument16 pagesJournal Innovation Knowledge: Indicators Used To Measure Service Innovation and Manufacturing InnovationHj SuhaimiNo ratings yet

- Gynecological Examination Table: Order Number: 11.1047Document1 pageGynecological Examination Table: Order Number: 11.1047yosra MedicalNo ratings yet

- MKTED208071EN CatalogueDocument618 pagesMKTED208071EN Cataloguecarlos augustoNo ratings yet

- Remote Sensing GeologyDocument438 pagesRemote Sensing GeologyStalin Bryan100% (2)

- FC9170 02Document14 pagesFC9170 02ВладимирNo ratings yet

- Phase Locked LoopDocument17 pagesPhase Locked LoopPaulo Toro OlivosNo ratings yet

- Conditions For Effective Innovation On The MacroDocument3 pagesConditions For Effective Innovation On The MacroWinesha U. Smith100% (2)

- Nursing ResumeDocument2 pagesNursing Resumeapi-655558844No ratings yet

- CitiBank ApplicationDocument15 pagesCitiBank ApplicationJordan P HunterNo ratings yet

- tf00001054 WacDocument22 pagestf00001054 WacHritik RawatNo ratings yet

- Business Partner and Master DataDocument5 pagesBusiness Partner and Master DataPamela PerezNo ratings yet

- 2b FLUID STATIC - Pressure MeasurementDocument27 pages2b FLUID STATIC - Pressure Measurement翁绍棠No ratings yet

- CIRPs Ending in Resolution - 30sept 2022Document10 pagesCIRPs Ending in Resolution - 30sept 2022dip downNo ratings yet

- Cablemaster RLC - ManualDocument8 pagesCablemaster RLC - ManualGlendinning Products, LLC.No ratings yet

- Prosperity Power Signature PDFDocument31 pagesProsperity Power Signature PDFOscar NygrenNo ratings yet

- Proforma - Attendance PercentageDocument6 pagesProforma - Attendance Percentageraja93satNo ratings yet

- Ian Robb a.M.I.struct.E. (Auth.) - Steel Frame Design Examples-Macmillan Education UK (1961)Document216 pagesIan Robb a.M.I.struct.E. (Auth.) - Steel Frame Design Examples-Macmillan Education UK (1961)GT100% (1)

- Shadowfinder - Big Damn HeroesDocument30 pagesShadowfinder - Big Damn HeroesSteampunkObrimos100% (1)

- Jmu Honors Thesis ProposalDocument4 pagesJmu Honors Thesis Proposalwbrgaygld100% (2)

- Gas Cutting - by KiranDocument40 pagesGas Cutting - by KiransridharchebroluNo ratings yet

- Schoolwide Plan Worksheet: School Name: Pioneer Elementary Principal Name: Brenda Lopresto School Planning TeamDocument10 pagesSchoolwide Plan Worksheet: School Name: Pioneer Elementary Principal Name: Brenda Lopresto School Planning TeamChauncey Mae TanNo ratings yet

- Er9000en 21204 1.00Document106 pagesEr9000en 21204 1.00Alexandru AnghelNo ratings yet

- Highlands FM: Jacqueline LawrenceeDocument14 pagesHighlands FM: Jacqueline LawrenceeLydia LaizaNo ratings yet