Professional Documents

Culture Documents

MAR DS SWC415 WeighModule EN1090

Uploaded by

Nhật Quang PhạmOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MAR DS SWC415 WeighModule EN1090

Uploaded by

Nhật Quang PhạmCopyright:

Available Formats

SWC415 PinMount ™EN1090

Cost Efficient Tank Weighing

Safe, Accurate, Service Friendly

Tank Weighing

SWC415 PinMount offers incomparable

value in weigh modules for all appli

cations including tank, hopper, and silo

weighing, and this is achieved without

sacrificing the well-established features

of the PinMount family.

Conveyors and Mixers

SWC415 PinMount™ weigh modules

are designed for dynamic-loading appli

cations such as conveyors, mixers,

and blenders. SWC415 PinMount™

provides 360 degree checking for ease SWC415 PinMount ™ EN1090

of installation and maximum safety.

The rocker pin load cell restores the

Cost Efficient Tank Weighing

top plate to its ideal position to maintain

accurate, repeatable weight. SWC415 PinMount™ EN1090 features ensure correct

scale system installation, right from the start. PinMount

Load Cells

The analog load cells have a rocker-pin does not compromise on safety – all safety features

design that automatically aligns load are provided as standard. The rocker pin design

forces for accurate weighing. These

hermetically sealed load cells are rated

provides the highest level of weighing accuracy.

IP68 / IP69K and can be used in all Installation features including SafeLock™ ensure easy

environments. The load cells are easy and trouble free installation. SWC415 PinMount™

to inspect or replace.

features include:

• Dual integrated lift-off protection

• Dual vertical safety down-stop

Stabilizers

An optional stabilizer can be applied to • Full 360 degree integrated checking

each weigh module to stabilize a scale • Ground strap – welding protection

subject to heavy vibration or high torque,

• SafeLock™ – Weigh module locked for installation

or used for in-motion weighing. With a

stabilizer installed, thermal expansion • SafeLock™ – Load cell protected for installation

is still possible, guaranteeing the best • Stabilizer option

weighing performance.

• Capacity range: 7.5 t – 100 t

• All load cells with IP68 and IP69K and fully

stainless steel

• Global approvals standard on each load cell

• Zinc plated or stainless steel mounting hardware

• CalFree™: Calibration without test weights

• EN1090 Conformity

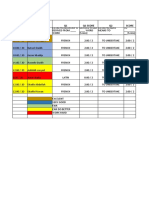

SWC415 PinMount™ EN1090 Weigh Module Specifications

Weigh Module Unit of measure Specification

Model No. SWC415 PinMount™ EN1090

Size 1 2 3

Rated Capacity (R.C.) t (klb, nominal) 7.5 (16.5) 15 (33) 22.5 (49.6) 30 (66) 50 (110) 100 (220)

Max. Rated Forces 1)

Max. Compressive Force, Rated kN (klb) 74 (16.5) 145 (33) 220 (50) 290 (65) 490 (110) 980 (220)

transverse

Max Horizontal Force, Rated kN (klb) 50 (11) 70 (15.4) 91 (20.5)

longitudinal

Max. Uplift Force, Rated kN (klb) 44 (9.7) 105 (23.1) 133 (30)

Max. horizontal force (longitudinal)

kN (klb) 22 (5) 35 (7.7) 60 (13.4)

per stabilizer option, Rated 6)

Max. Yield Forces 2) 4)

Max. Compressive Force, Yield kN (klb) 145 (33) 294 (67) 440 (97) 505 (110) 685 (190) 1715 (385)

transverse

Max. Horizontal Force, Yield kN (klb) 73 (16.1) 95 (20.9) 133 (30)

longitudinal

Max. Uplift Force, Yield kN (klb) 60 (13.2) 140 (30.8) 186 (42)

Max. Ultimate Forces 3) 4)

Max. Compressive Force, Ultimate kN (klb) 220 (50) 420 (94) 660 (147) 883 (194) 1470 (323) 2940 (647)

transverse

Max. Horizontal Force, Ultimate kN (klb) 145 (31.9) 250 (55) 300 (76)

longitudinal

Max. Uplift Force, Ultimate kN (klb) 140 (30.8) 275 (60.5) 340 (76)

Restoring Force %A.L./mm (../in) 5) 2.4 (61) 3.4 (87) 0.8 (19) 2 (51) 2(51)

Max. top plate travel transverse ± 5 (0.2)

± mm (in)

longitudinal 7) ± 5 (0.2)

Weight (including load cell), nominal kg (lb) 20 (44) 55 (120) 70 (154)

Material carbon steel / 304 stainless steel

Finish Zinc Plated / Electropolished

EN1090 approval Yes, execution class EXC2

LOAD CELL SLC611, 0782 Unit of measure Specification

Item No. 30058060 30058061 30058062 71201709 71201710 71201711

Model No. SLC611 0782

Rated Capacity (R.C.) t (klb, nominal) 7.5 (16.5) 15 (33) 22.5 (49.6) 30 (66) 50 (110) 100 (220)

Rated Output mV/V @R.C. 2 ± 0.1 %

Combined Error 8) 9) %R.C. ≤ 0.018

Min. Dead load Output %R.C./°C (../°F) ≤ 0.0018 (0.0010) ≤ 0.0021 (0.0011)

Temperature Effect on

Sensitivity 9) %A.L./°C (../°F) ≤ 0.001 (0.0006)

Compensated -10 ~ +40 (-14 ~ +104)

Temperature Range Operating °C (°F) -40 ~ +65 (-40 ~ +149)

Safe Storage -40 ~ +80 (-40 ~ +176)

Class C3

OIML / European Approval 10) nmax 3000

Y 7800 6666

Class III M III L M

NTEP Approval 10) nmax 5000 10000

Vmin kg (lb) 0.96 (2.12) 1.92 (4.24) 2.8 (6.36) 2.1 (4.5) 3.5 (7.5) 7.0 (15)

II 1 G Ex ia IIC T6...T4 Ga / II 1 D Ex ia IIIC T100°C Da II 2 G Ex ib IIC T4 … T6 / II 2 D Ex ibD 21 IP68 T60°C

ATEX Approval 10) Rating II 3 G Ex nA IIC T6…T4 Gc / II 3 G Ex ic IIC T6…T4 Gc II 3 G Ex ic IICT6 ..T4 Gc ; II 3 G Ex nA IIC T6 Gc ; II 3 G Ex

/ II 3 D Ex tc IIIC T100°C Dc ec IIC T6 Gc ; II 3 D Ex tc IIIC T60°C Dc

Ex ia IIC T6...T4 Ga / Ex ia IIIC T100°C Da Ex ib IIC T6 ...T4 Gb ; Ex ib IIIC T55°C … T60°C Db

IECEx Approval 10) Rating Ex nA IIC T6…T4 Gc / Ex ic IIC T6…T4 Gc / Ex ic IIC T6 … T4 Gc ; Ex nA IIC T6 Gc ; Ex ec IIC T6 Gc ;

Ex tc IIIC T100°C Dc Ex tc IIIC T60°C Dcc

Rating, USA IS / I, II, III / 1 / ABCDEFG / T5 IS / I, II, III / 1 / ABCDEFG / T4 Ta = -40°C to +50°C

NI / I, II, III / 2 / ABCDFG / T6 NI / I,II,III / 2 / ABCDFG / T4 Ta = -40°C to +50°C

Factory Mutual Approval 10) Rating, Canada IS / I, II, III / 1 / ABCDEFG / T5 TA= -40°C to +55°C; NI / IS / I,II,III / 1 / ABCDEFG / T4 Ta = -40°C to +50°C ; NI / I / 2 /

I / 2 / ABCD / T6 Ta = -40°C to +55°C, DIP/II,III/2/FG ABDC / T4 Ta = -40°C to +50°C, DIP/II,III/2/FG

Comply Class I, Division 1, Groups A, B, C and D; Class II, Groups E,

F and G; Class III

Recommended 5 ~ 15

Excitation Voltage V AC/DC

Max. 20

Excitation 1150 ± 50 1150 ± 25

Terminal Resistance Ω

Output 1000 ± 2 1000 ± 3

Material Spring Element stainless steel

Type welded

Protection IP Rating IP68, IP69K IP68

NEMA Rating NEMA 6/6P

Weight, nominal kg (lb) 1 (2.2) 3 (6.6) 3.3 (7.3) 4.5 (9.9)

Length m (ft) 12 (39.4) 13 (42.5)

Cable

Diameter mm (in) 5.2 (0.20) 5.8 (0.23)

1)

The weigh module is rated for these forces in normal operation, a Factor of Safety has been 5)

% of Applied Load (A.L.) per mm (in) displacement of the top plate (transverse & longitudinal).

applied by METTLER TOLEDO. 6)

1 per weigh module. Max permissible longitudinal force per stabIlizer.

2)

Warning: if loaded statically one time in excess of these forces, the weigh module may yield 7)

0 with Stabilizer.

and need replacing. The Max. Yield Forces do not consider fatigue/cyclic loading and should be 8)

Error due to the combined effect of non-linearity and hysteresis.

approached only in exceptional circumstances. 9)

Typical values only. The sum of errors due to Combined Error and Temperature Effect on Sensi-

3)

Warning: if loaded statically one time in excess of these forces, the weigh module may break tivity comply with the requirements of OIML R60 and NIST HB44.

with potential for serious injury and/or property damage. 10)

See certificate for complete information.

4)

Warning: apply a Factor of Safety appropriate to the application.

2 METTLER TOLEDO Data Sheet SWC415 PinMount™ EN1090

© 06/2020

SWC415 PinMount™ EN1090 Weigh Module Dimensions mm (in)

Size 1 Size 2 , Size 3

Dimensions and Locations Tank Leg Plate

Size Capacity D H HS2) HP1) H1 H2 H3 L4) L1 L2 L3 L4 L5 L64) L74) W Thickness Dimensions

7.5, 15, 22.5 t 22 152 167 192.4 11 18 51 300 200 155 255 22.5 50 205 min 25 200 x 200

1 – –

(16.5, 33, 49.6 klb) (0.87) (5.98) (6.57) (7.57) (0.43) (0.71) (11.8) (11.8) (7.87) (6.1) (10.04) (0.89) (1.97) (8.1) (1.0) (7.87 x 7.87)

20, 30, 50 t 26 235 268 293.4 23 25 69.5 365 250 200 315 25 55 27.5 47.5 261.5 min 50 250 x 250

2

(44, 66, 110 klb) (1.02) (9.25) (10.55) (11.55) (0.91) (0.98) (2.75) (14.37) (9.84) (7.87) (12.4) (0.98) (2.16) (1.08) (1.87) (10.29) (2.0) (9.84 x 9.84)

100t 32 263 301 326.4 27 28 86.5 440 300 235 375 32.5 70 40 52.5 313 min 60 300 x 300

3

(220klb) (1.26) (10.35) (11.85) (12.85) (1.08) (1.1) (3.4) (17.32) (11.81) (9.25) (14.75) (1.28) (2.75) (1.57) (2.07) (12.3) (2.4) (11.8 x 11.8)

1)

Height when using thermal isolation pad or shock / vibration pad

2)

Height when using spacer plate

3)

Shipping / Installation height is 2 mm (0.08 inches) taller

4)

Designed for square tank leg plate above top plate

METTLER TOLEDO Data Sheet SWC415 PinMount™ EN1090 3

© 06/2020

SWC415 PinMount™ EN1090 Weigh Module Arrangements

2L 2L

See 1)

See 1)

L L

2L

See 1)

1)

Provides equal load distribution, but the stability of this arrangement must

L

be assured.

4 METTLER TOLEDO Data Sheet SWC415 PinMount™ EN1090

© 06/2020

Order Information SWC415 PinMount™ EN1090 – Weigh Module

Order Information, Weigh Module Assembly Item No.

Material, Weigh Module

Size Rated Capacity Description Class Cable, Material /Lenght

Zinc Plated 304

7.5 t / 16.5 klb 30315457 30315458

15 t / 33 klb Weigh Module Assembly C3/III M n:5 PU / 12 m (39.4ft) 30315459 30315480

22.5 t / 49.6 klb 30315481 30315482

Stabilizer 1) 72205444 72205445

1 Spacer Plate 72245532 72206153

Dead Stand 72206154 72206155

7.5 - 22.5 t / 16.5 - 49.6 klb – –

Shock/Vibration Pad 2) 72246646 72207262

Thermal Isolation Pad 80°C 2) 72246647 72207263

Thermal Isolation Pad 170°C 2) 72246648 72207264

30 t / 66 klb 30315483 30315484

Weigh Module Assembly C3/IIIL M n:10 PVC / 13 m (42.5ft)

50 t / 110 klb 30315485 30315486

Stabilizer 1) 72248968 72248969

Spacer Plate 72249203 72249206

2

Dead Stand 72249173 72249174

30 - 50 t / 66 - 110 klb – –

Shock/Vibration Pad 2) 72255072 72255075

Thermal Isolation Pad 80°C 2) 72255073 72255076

Thermal Isolation Pad 170°C 2) 72255074 72255077

100 t / 220 klb Weigh Module Assembly C3/IIIL M n:10 PVC / 13 m (42.5ft) 30396064 30396065

Stabilizer 72248970 72248971

Spacer Plate 1) 72249213 72249214

3 Dead Stand 72249175 72249176

100 t / 220 klb - -

Shock/Vibration Pad 2)

72255078 72255081

Thermal Isolation Pad 80°C 2)

72255079 72255082

Thermal Isolation Pad 170°C 2) 72255080 72255083

Bolded entries are stocked

1)

1 per weigh module.

Order Information SWC415 PinMount™EN1090 – Weigh Module without Load Cell

– SafeLock™ allows installation of weigh module hardware without load cell to avoid sensor damage

– Combine weigh module with other load cells (special cable lengths, etc.)

– Use weigh module with dummy load cell for level detection systems

Order Information, Weigh Module Kit Item No. Suitable Load Cells

Item No.

Material, Weigh Module

Cable, Material / Length

Size Rated Capacity Class Dummy

PU / 12 m PU / 20 m FEP / 12 m FEP / 20 m PVC / 13m

Zinc Plated 304 Load Cell

(39.4ft) (65.6ft) (39.4ft) (65.6ft) (42.5ft)

7.5 t / 16.5 klb C3/III M n:5 30058060 30058064 30105781 30105786

1 15 t / 33 klb 30295847 30295848 C3/III M n:5 30058061 30058065 30105783 30105788 – 30238196

22.5 t / 49.6 klb C3/III M n:5 30058062 30058066 30105784 30105789

30 t / 66 klb C3/IIIL M n:10 71201709

2 30295849 30295850 – – – – 72188111

50 t / 110 klb C3/IIIL M n:10 71201710

3 100 t / 220 klb 30396060 30396061 C3/IIIL M n:10 - - - - 71201711 72188112

Bolded entries are stocked

METTLER TOLEDO Data Sheet SWC415 PinMount™ EN1090 5

© 06/2020

SLC611 Cable Colour Code 0782 Cable Colour Code

Colour Function Colour Function

Green + Excitation Green + Excitation

Black – Excitation Black – Excitation

White + Signal White + Signal

Red – Signal Red – Signal

Yellow Shield Yellow + Sense

Blue – Sense

Yellow (long) Shield

Full Connectivity Weighing Electronics

METTLER TOLEDO supplies various data communication interfaces METTLER TOLEDO offers a complete family of electronics from simple

that enable our sensors and instruments to communicate with your weighing to application solutions for filling, stock control, batching,

PLC, MES, or ERP systems. formulation, counting, and checkweighing.

Our extensive service network is among the best in the world and

ensures maximum availability and service life of your product.

Quality certificate ISO 9001

Environment certificate ISO 14001

www.mt.com

Visit for more information

Mettler-Toledo GmbH

CH-8606 Greifensee

Switzerland

Tel. +41 44 944 22 11

Fax +41 44 944 30 60

Subject to technical changes

© 06/2020 Mettler-Toledo GmbH

MarCom Switzerland

MTSI Document-No: 30395284

You might also like

- Manual Grúa N65aDocument8 pagesManual Grúa N65aSaúlBorlandGalindoNo ratings yet

- National Crane 1100Document12 pagesNational Crane 1100ramon0% (1)

- MAR DS SWC415 WeighModule ENDocument6 pagesMAR DS SWC415 WeighModule ENhelobaezamorenoNo ratings yet

- Mar Ds Swc515 Pinmount enDocument6 pagesMar Ds Swc515 Pinmount enMuchamad Fajar NugrohoNo ratings yet

- Hệ Loadcell MT - brochureDocument6 pagesHệ Loadcell MT - brochureVănPhùngLươngNo ratings yet

- DS - SWB505 MultiMountDocument7 pagesDS - SWB505 MultiMountTenday Agus Setya WibawaNo ratings yet

- Safe, Accurate, Service-Friendly: Right-the-First-Time IntegrationDocument8 pagesSafe, Accurate, Service-Friendly: Right-the-First-Time IntegrationJayesh GawadNo ratings yet

- Gruas Bohme, Inbolcranes, Salfa MLC650 8-19-2015Document65 pagesGruas Bohme, Inbolcranes, Salfa MLC650 8-19-2015Felipe Schönffeldt TorresNo ratings yet

- Ficha TécnicaDocument8 pagesFicha TécnicaLUIS PABLO SALVADOR NUÑEZNo ratings yet

- Safe, Accurate, Service Friendly: Right The First TimeDocument10 pagesSafe, Accurate, Service Friendly: Right The First TimeSiewkuan LeeNo ratings yet

- Norsepower Rotor Sail Solution Brochure 2018-10-30Document2 pagesNorsepower Rotor Sail Solution Brochure 2018-10-30immortalbeast0% (1)

- Xforce PDocument6 pagesXforce PRAB HFRNo ratings yet

- Ac45e-127s 45 ToneladasDocument4 pagesAc45e-127s 45 Toneladasdavand publicidadNo ratings yet

- Goodrich Rescue Hoist 44311 DatasheetDocument2 pagesGoodrich Rescue Hoist 44311 DatasheetpucaracharlieNo ratings yet

- 900H Product Guide ImperialDocument12 pages900H Product Guide ImperialHeron HerreraNo ratings yet

- CSU 160 UnitDocument4 pagesCSU 160 Unitgustavo rivasNo ratings yet

- MLC250 Metric FlyerDocument2 pagesMLC250 Metric Flyerkeerthiphotography1992No ratings yet

- All Offerings 2017Document8 pagesAll Offerings 2017Andres SanchezNo ratings yet

- Hardness Tester Machine Rockwell 600MRDDocument2 pagesHardness Tester Machine Rockwell 600MRDĐào Trường AnNo ratings yet

- HSMARINE Products AkcDocument5 pagesHSMARINE Products AkcBoruida MachineryNo ratings yet

- Tank Weighing SystemDocument72 pagesTank Weighing SystemPur ChandruNo ratings yet

- Shock & Vibration Solutions Product InformationDocument146 pagesShock & Vibration Solutions Product InformationKaharul Afandi100% (1)

- Kongsberg Electricmooringcapstans-002Document2 pagesKongsberg Electricmooringcapstans-002SRARNo ratings yet

- Series E: Product GuideDocument8 pagesSeries E: Product GuideFrank Felipe Cruz ChavezNo ratings yet

- AC40-152S LiteratureDocument4 pagesAC40-152S LiteraturePKM MoniruzzamanNo ratings yet

- Impact-Test & Radial Impact-Test - MAKRA DatasheetDocument8 pagesImpact-Test & Radial Impact-Test - MAKRA Datasheetpezz07No ratings yet

- 2018 RLTMDocument2 pages2018 RLTMRenzo Ticona OlazabalNo ratings yet

- Aidco 450E BRDocument4 pagesAidco 450E BRFRANCISCO NIWTON BEZERRANo ratings yet

- DUCO Stab PlateDocument4 pagesDUCO Stab PlateProcurement PardisanNo ratings yet

- ActuatorDocument8 pagesActuatorsebastianNo ratings yet

- PR 6201 (500kg 50t) Precision Compression Load CellDocument4 pagesPR 6201 (500kg 50t) Precision Compression Load CellGM HerbalsNo ratings yet

- LK Rockwell Machines Brochure PDFDocument2 pagesLK Rockwell Machines Brochure PDFArun SasiNo ratings yet

- ROV Tooling 3Document41 pagesROV Tooling 3siswout100% (1)

- Ficha Tecnica Polipasto Electrico Yale CPV (Vego)Document12 pagesFicha Tecnica Polipasto Electrico Yale CPV (Vego)Fabio NieraNo ratings yet

- 200SFMTDocument11 pages200SFMTsubidubi99No ratings yet

- National Boom Trucks Spec Ef6a51Document8 pagesNational Boom Trucks Spec Ef6a51Juan Carlos Torres MartinezNo ratings yet

- SPETECH KammprofilesDocument2 pagesSPETECH KammprofilesabasakNo ratings yet

- Siemens Sivacon s8 - Part2Document8 pagesSiemens Sivacon s8 - Part2Mohamed NasrNo ratings yet

- Palfinger PK 6001Document6 pagesPalfinger PK 6001luis gonzalezNo ratings yet

- AUW-D/AUW/AUX/AUY SeriesDocument8 pagesAUW-D/AUW/AUX/AUY SeriesВиктория VNo ratings yet

- 1100 Product Guide ImperialDocument16 pages1100 Product Guide ImperialReynaldo Caballero100% (1)

- MoogDocument5 pagesMoogRajashekarNo ratings yet

- Torsion Testing SystemDocument3 pagesTorsion Testing Systemsrinath.gajapathy5478No ratings yet

- Stability of A Floating Body: Fluid MechanicsDocument2 pagesStability of A Floating Body: Fluid MechanicsDr.Anmar Hamid AliNo ratings yet

- TWA Assembly BrochureDocument2 pagesTWA Assembly BrochureNaqib FuadNo ratings yet

- SBMO Swivel Stack Original 2159Document12 pagesSBMO Swivel Stack Original 2159joNo ratings yet

- SM1004 Beam DatasheetDocument3 pagesSM1004 Beam Datasheetsinghmanjinder8872No ratings yet

- Lr100Kplus 100 KN Universal Materials Testing Machine: FeaturesDocument2 pagesLr100Kplus 100 KN Universal Materials Testing Machine: FeaturesSoup PongsakornNo ratings yet

- SM1005 Euler Buckling Datasheet PDFDocument3 pagesSM1005 Euler Buckling Datasheet PDFSuranga DilshanNo ratings yet

- R P Jacking SystemDocument2 pagesR P Jacking Systemgrupa2904No ratings yet

- R P Jacking SystemDocument2 pagesR P Jacking Systemanang WahjudiNo ratings yet

- National Crane Series 1400H: Product GuideDocument12 pagesNational Crane Series 1400H: Product GuideTomas HernandezNo ratings yet

- 14 ElectronicsDocument16 pages14 Electronicsedark2009No ratings yet

- Bauer Load Cells For Anchor Force MeasurementsDocument1 pageBauer Load Cells For Anchor Force MeasurementsCatherine Nur KomaraNo ratings yet

- Keystone Actuators and Controls PDFDocument8 pagesKeystone Actuators and Controls PDFMostafa NabilNo ratings yet

- Training P IDDocument139 pagesTraining P IDNhật Quang PhạmNo ratings yet

- LNG Process OverviewDocument59 pagesLNG Process OverviewNhật Quang PhạmNo ratings yet

- LMV enDocument10 pagesLMV enNhật Quang PhạmNo ratings yet

- Regulators For Gas With Filter and Safety DiaphragmDocument11 pagesRegulators For Gas With Filter and Safety DiaphragmNhật Quang PhạmNo ratings yet

- 6817-PR-CN-0601 Att 2 - RevADocument1 page6817-PR-CN-0601 Att 2 - RevANhật Quang PhạmNo ratings yet

- Catalogue van điều áp C-10A-1Document2 pagesCatalogue van điều áp C-10A-1Nhật Quang PhạmNo ratings yet

- DriveTechnology p174 p193 Steel Laminae CouplingsDocument20 pagesDriveTechnology p174 p193 Steel Laminae CouplingsNhật Quang PhạmNo ratings yet

- SKF FY 60 TFSquare Flanged Ball Bearing Unit With Set Screw Locking, Cast Iron Housing, ISO SpecificationDocument6 pagesSKF FY 60 TFSquare Flanged Ball Bearing Unit With Set Screw Locking, Cast Iron Housing, ISO SpecificationNhật Quang PhạmNo ratings yet

- Power Transmission Component Couplings KTR Germany E0214 Radex N Steel Laminae Couplings CatalogueDocument2 pagesPower Transmission Component Couplings KTR Germany E0214 Radex N Steel Laminae Couplings CatalogueNhật Quang PhạmNo ratings yet

- Translating Isaac Bashevis SingerDocument4 pagesTranslating Isaac Bashevis SingerDavid StrombergNo ratings yet

- MATH 223 Spring 20 Course OutlineDocument6 pagesMATH 223 Spring 20 Course OutlineJames JonesNo ratings yet

- Entrepreneurship Development Test 2 Assessment SheetDocument7 pagesEntrepreneurship Development Test 2 Assessment SheetHaseeb ShaikhNo ratings yet

- Energy Tech - 2016 - WesterhoffDocument11 pagesEnergy Tech - 2016 - WesterhoffMario CastilloNo ratings yet

- Copy Math9 Q4 Mod6 ProblemsInvolvingRightTriangles v3Document20 pagesCopy Math9 Q4 Mod6 ProblemsInvolvingRightTriangles v3txbi nariiNo ratings yet

- Semi Detailed Lesson PlanDocument2 pagesSemi Detailed Lesson Plankaren bacquialNo ratings yet

- Unit 35 Explanatory Texts. Structure and CharacteristicsDocument9 pagesUnit 35 Explanatory Texts. Structure and CharacteristicsMiriam Reinoso SánchezNo ratings yet

- Volumen 4Document7 pagesVolumen 4Willians MariscalNo ratings yet

- Hill Criterion and Von MisesDocument10 pagesHill Criterion and Von MisesSiva PrasadNo ratings yet

- Pedagogical Practice in Teaching - Learning Mathematics in Secondary in School LevelDocument8 pagesPedagogical Practice in Teaching - Learning Mathematics in Secondary in School LevelapfgNo ratings yet

- Gecolea, ME143-2 Sample QuestionsDocument25 pagesGecolea, ME143-2 Sample QuestionsJazztine Andrei GecoleaNo ratings yet

- Theoretical Computer Science: Yi Hong, Jiandong Liu, Deying Li, Chuanwen Luo, Mengjie ChangDocument11 pagesTheoretical Computer Science: Yi Hong, Jiandong Liu, Deying Li, Chuanwen Luo, Mengjie ChangDinda AisyNo ratings yet

- GLR - CT Lesson PlanDocument4 pagesGLR - CT Lesson PlanMARY JOY DELAROSANo ratings yet

- Research Proposal Template APADocument8 pagesResearch Proposal Template APASameen FaisalNo ratings yet

- Unisonic Technologies Co., LTD: 9A, 700V N-CHANNEL Power MosfetDocument4 pagesUnisonic Technologies Co., LTD: 9A, 700V N-CHANNEL Power MosfetJoshi Joseph JoyNo ratings yet

- Cyclone Separator Expt No:9 AimDocument10 pagesCyclone Separator Expt No:9 AimsampathkumarNo ratings yet

- Functions of Parts of An Animal CellDocument2 pagesFunctions of Parts of An Animal CellashuraqueenNo ratings yet

- Shs SLM-CNF Melc5Document26 pagesShs SLM-CNF Melc5Jean RamosNo ratings yet

- Appendix A. Code Generators For BCH CodesDocument28 pagesAppendix A. Code Generators For BCH CodesBereket TarikuNo ratings yet

- BSE-ODISHA Result of HSC EXAMINATION SA-I RESULT 2022-2023 - Board of Secondary Education, OdishaDocument2 pagesBSE-ODISHA Result of HSC EXAMINATION SA-I RESULT 2022-2023 - Board of Secondary Education, OdishaPrasanta KaruaNo ratings yet

- Conclusion HDFCDocument2 pagesConclusion HDFCSudeep MallNo ratings yet

- Trees That Count West Coast Regional GuideDocument3 pagesTrees That Count West Coast Regional GuideJohn MurdochNo ratings yet

- Finals Module3Document29 pagesFinals Module3John RivasNo ratings yet

- Full Report-Oil Skimmer Cum Metal Chip CollectorDocument55 pagesFull Report-Oil Skimmer Cum Metal Chip Collectorrajkumar100% (1)

- Experiment No. 1 - AnthropometryDocument8 pagesExperiment No. 1 - AnthropometryBai MustaphaNo ratings yet

- AOL 2 Mod 4Document41 pagesAOL 2 Mod 4Canlas Aniel Jesper C.No ratings yet

- Smart GoalsDocument3 pagesSmart Goalsapi-527878842No ratings yet

- MAT1175Document7 pagesMAT1175Naruto UwzumakiNo ratings yet

- Seminar Presentation1Document27 pagesSeminar Presentation1devrajNo ratings yet

- Composite Deck Technical Manual: 3WH-36 Hi FormDocument33 pagesComposite Deck Technical Manual: 3WH-36 Hi FormVinod Kumar ReddyNo ratings yet