Professional Documents

Culture Documents

Resume 11 12 2023 10 56 54 PM

Uploaded by

aswinkovilakamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Resume 11 12 2023 10 56 54 PM

Uploaded by

aswinkovilakamCopyright:

Available Formats

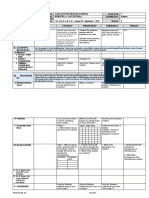

ASWIN KASTHURBAI ANDY INSTRUMENTATION ENGINEER

EDUCATION

University Of Calicut, Kerala 2007

B TECH in Applied Electronics And Instrumentation

Board of secondary Education, Kerala 2003

Higher secondary / Plus two

GVHSS Balussery 2001

SSLC

PROJECTS

CONTACT Data control system

Controling parameters like temperature, pressure using progammed chip and sensors

kozhikode, Kerala, India

Speed detector

+971 554472038 +91 9895536235 Identify speed, make alarm if it exceeds the speed limit

aswinkovilakam@gmail.com

EXPERIENCE

31-05-1986

BRIDGE AND ROOF CO INDIA LTD January 2019 - June

Electrical And Instrumentation Engineer 2023

Client: Oil and Natural Gas Corporation Ltd. (ONGC)

Passport No- M4662623

validity- 22.12.2024

Project: Up-gradation of Fire Fighting System at Cauvery Asset-Central

https://www.linkedin.com/in/aswin-k-a-568828201 Tank Farm (CTF), Narimanam Region, Nagapattinam District, Tamil Nadu.

India

OBJECTIVE Managed daily project operations, achieving a 95% success rate in

maintenance, troubleshooting, and equipment analysis.

A Results-driven instrumentation engineer with 8+ Ensured adherence to safety protocols, maintaining detailed

years' experience in pre-commissioning, equipment records with a 100% compliance rate.

commissioning, maintenance shutdown activities, Oversaw inventory management, contributing to a 90% accuracy in

QA/QC, and HSE. Seeking a role to leverage expertise in procurement planning and technical recommendations.

material management, statutory requirements, and Collaborated with clients and designers for design changes and as-

contractual services to drive safety, innovation, and built drawings, achieving a high client approval rate.

process improvements Coordinated with vendors for timely material deliveries and

equipment availability, resulting in a 97% on-time delivery rate.

SKILLS Supervised vendor management, contributing to an improvement in

equipment sourcing efficiency.

SOFT SKILLS Ensured compliance with engineering standards and codes for

equipment requisitions, achieving a 95% compliance rate.

- Leadership and team management Reviewed and analyzed fabrication drawings for quality and

compliance, resulting in a high accuracy rate.

-communication and Documentation Prepared and reviewed material inspection reports and relevant

-Strong problem-solving and analytical technical drawings with a high accuracy rate.

Coordinated with multiple stakeholders for job execution and

- Project management commissioning, contributing to a 95% on-time completion rate.

Maintained accurate records, including Daily Progress Reports and

- Attention to quality & safety standards material issuance, with a 100% completeness rate

- Adaptability and the ability to work under pressure

REVALATION AUTOMATION PVT LTD October 2017 -

Instrumentation Engineer (Field) december 2019

TECHNICAL SKILLS

Location - Kerala, Tamilnadu, Karnataka

-P&ID, loop diagrams, instrument mounting details,cable

routing layout Calibration and maintenance and calibration of various instruments

including:

-QA /QC, HSE practices Flow, pressure, temperature, and level transmitters, valves

Flow switches, temperature switches, pressure switches, and level

- Expertise in reviewing IFC packages construction, material

preparation, switches

Utilized test instruments such as:

- Calibration, Installataion BEAMEX MC-5, MC-4, MC-6, MC-2

- Root Cause Analysis & troubleshooting FLUKE PACE 5000, FLUKE 9144

YANTHRIKA DEAD WEIGHT TESTER

- DCS, SCADA, and PLC TK3 for calibration

- Meagering, termination, and testing Installed a range of instruments including:

- Pre Commissioning, commissioning, construction,

maintainnace and shutdown

Level switches,

LANGUAGE Level gauges,

Dosing pumps

Malayalam Flow indicators, totalizer

English Pessure gauges

Hindi

High-pressure pumps,

Tamil

pneumatic valves, and rotameters

Regulated power cylinders, air cylinders (on/off)

ACTIVITIES Air filter regulators, thermocouples, RTDs

Vibration sensors, vibration transmitters

Hiking Blood Donation Social Worker Butterfly valves, O2 analyzers, and more

Carried out calibration and loop checking of control valves and

REFERENCE accessories, as well as PH transmitters and conductivity transmitters

POWER INSTRUMENTATION AND ENGINEERING July 2014 - July 2017

submit on request

Instrumentation Engineer

Location - Kerala, Karnataka

Duties and Responsibilities

Cable measuring, gladding, and termination

Cold and hot loop checking

Field instrument installation and calibration

Collaboration with mechanical teams

Pneumatic hookup and tubing installation

Valve erection, installation, and connection

Temperature element calibration

Instrument hook-up and checking

Panel checking and installation with vendors

Fire system installation and commissioning

TECHNOSYS January 2011 -

Instrumentation Engineer December 2014

Client - Kensai nerolac Paints ltd, Hosur, Tamilnadu, India

Contractor- ABB Banglore

Project brief - Pre-commissioning and commissioning of new plants

Duties and Responsibilities:

Proficient in P&ID, instrument loop diagrams, mounting details, cable

routing layout, and cable & conduit schedules

Calibration and loop checking of control valves and accessories

Review of IFC packages for construction and material preparation

Installation and termination of electrical motors, pumps, level

instruments, dosing pumps, flow indicators, pressure instruments, high-

pressure pumps, and pneumatic valves

Installation and termination of analog junction box, digital junction

box, power panels, PLC panels, PH transmitters & sensors, conductivity

transmitters & sensors, TDS transmitters & sensors

Cable laying for instruments, power, control, and ground

Measurement of instrument and power cable and ground testing

Installation of cable tray and tubing for transmitters

activities

Advance systek March 2009 - January

Control Room Operator 2010

Site - HPCL Elatur, Calicut, Kerala

Duties and Responsibilities:

Continuous monitoring and reporting of control room activities

Fault finding, troubleshooting, and calibration of various systems

including DANLOAD, load cells, weighbridge strain gauges, thermal mass

flow meters, and Coriolis mass flow meters

Execution of preventive maintenance and preparation of reports

Collaborative fault finding of DCS and SCADA systems with vendors

Calibration of valves for export oil pipeline pumps and settling tank

valves (master valve

Signature:

Aswin Kasthurbai Andy

You might also like

- P&ID SymbolsDocument119 pagesP&ID SymbolsaswinkovilakamNo ratings yet

- One Touch SurgeryDocument12 pagesOne Touch SurgerySergio Uscamaita FloresNo ratings yet

- CWSB The ConfederacyDocument45 pagesCWSB The ConfederacyEd Franks Jr.100% (2)

- Mani San Resume FEB2013Document5 pagesMani San Resume FEB2013Manivannan PurushothamanNo ratings yet

- R.Madhavan: Curriculum VitaeDocument4 pagesR.Madhavan: Curriculum VitaeMadhavan RengarajNo ratings yet

- Dineshkumar Vidi Ravindran: Professional SummaryDocument4 pagesDineshkumar Vidi Ravindran: Professional SummaryvrdineshNo ratings yet

- Dineshkumar Vidi Ravindran: Electrical & Instrumentation EngineerDocument4 pagesDineshkumar Vidi Ravindran: Electrical & Instrumentation EngineervrdineshNo ratings yet

- Quiz Infection Prevention and Control MDocument3 pagesQuiz Infection Prevention and Control MGareth McKnight0% (1)

- Session 5Document3 pagesSession 5Sistine Rose Labajo100% (1)

- He - 02 - 2020 PDFDocument92 pagesHe - 02 - 2020 PDFMarco Antonio Guevara MartínezNo ratings yet

- Fayol General and Industrial Management PDFDocument2 pagesFayol General and Industrial Management PDFJennifer33% (6)

- Competitive Profile Matrix (CPM)Document17 pagesCompetitive Profile Matrix (CPM)AaaaaaNo ratings yet

- Resume 07 12 2023 03 45 31 PMDocument2 pagesResume 07 12 2023 03 45 31 PMaswinkovilakamNo ratings yet

- Sagar AliDocument2 pagesSagar Alisagarhussain1235789No ratings yet

- Asif Muhammad (QC Lead Engineer)Document5 pagesAsif Muhammad (QC Lead Engineer)Hello GuysNo ratings yet

- Saravana - CVDocument1 pageSaravana - CVKirubhakar.pNo ratings yet

- Sunil Kumar T Resume PDFDocument4 pagesSunil Kumar T Resume PDFskf BoilersNo ratings yet

- Bejoy ResumeDocument4 pagesBejoy ResumebejoyNo ratings yet

- Sagar Resume1Document3 pagesSagar Resume1Sagar DeodharNo ratings yet

- Kevalkumar PatelDocument1 pageKevalkumar PatelAftabur RahmanNo ratings yet

- Sathiyaraj .V: Summary of SkillsDocument4 pagesSathiyaraj .V: Summary of SkillsMano BalaNo ratings yet

- Akhil Suresh: Synthite Industries LimitedDocument2 pagesAkhil Suresh: Synthite Industries LimitedAkhil Suresh (Synthite Biotech)No ratings yet

- Anuraj A M CV 1-1Document2 pagesAnuraj A M CV 1-1Ramamanikanta DondapatiNo ratings yet

- Arun V Pillai: Profile Summary Core CompetenciesDocument3 pagesArun V Pillai: Profile Summary Core CompetenciesAlok TiwariNo ratings yet

- Aftab CV ShortDocument2 pagesAftab CV ShortNoor Muhammad Lab Engineer USPCASENo ratings yet

- Muhammad Sharif: (Electronics & Electrical Engineer) Pak Arab Housing Society House No 443, Ferozpur Road LahoreDocument3 pagesMuhammad Sharif: (Electronics & Electrical Engineer) Pak Arab Housing Society House No 443, Ferozpur Road LahoreSyed Muhammad Sharif NaqviNo ratings yet

- Ahamed Sheik Darwesh M: Professional SummaryDocument3 pagesAhamed Sheik Darwesh M: Professional SummaryNitesh SrivastavaNo ratings yet

- Danish Tatari - Manager Ops & MaintDocument3 pagesDanish Tatari - Manager Ops & MaintMisbhasaeedaNo ratings yet

- Russal CVDocument3 pagesRussal CVRussal MullappallyNo ratings yet

- Suresh Kumar K: QA/QC Engineer-MEPDocument4 pagesSuresh Kumar K: QA/QC Engineer-MEPVipin Kumar ParasharNo ratings yet

- CV Ingenieur Ensem Casablanca Iliass BoumzebraDocument2 pagesCV Ingenieur Ensem Casablanca Iliass BoumzebraIlyassBoumzebraNo ratings yet

- Mujahid Corporate QAQC Engineer CVDocument9 pagesMujahid Corporate QAQC Engineer CVKshama RaiNo ratings yet

- Ahsen CV 4.0Document1 pageAhsen CV 4.0Ahsen AbidNo ratings yet

- Zahoor Ud Din: ObjectiveDocument4 pagesZahoor Ud Din: ObjectiveAnas ZakaNo ratings yet

- CHETANKUMARMELINAMANI ET 6years InnovaDocument2 pagesCHETANKUMARMELINAMANI ET 6years InnovaRajesh ExperisNo ratings yet

- Resumes A Rath KrishnaDocument2 pagesResumes A Rath KrishnaAmanNo ratings yet

- CV Engr. Gravides 1Document4 pagesCV Engr. Gravides 1jherson gravidesNo ratings yet

- Resume Chethan PDFDocument5 pagesResume Chethan PDFchakramsNo ratings yet

- Jaiganesh Murugaiyan - CVDocument2 pagesJaiganesh Murugaiyan - CVAl GHANMINo ratings yet

- Adnan HSE SepDocument3 pagesAdnan HSE SepSajid0% (1)

- Mechanical Engineer: Career ObjectiveDocument2 pagesMechanical Engineer: Career ObjectiveEr Sahil KhanNo ratings yet

- CV - Saravana Kumar PothirajDocument3 pagesCV - Saravana Kumar PothirajSaravana KumarNo ratings yet

- Resume Jegatheeshwaran PalanisamyDocument2 pagesResume Jegatheeshwaran PalanisamyNithish KuttanNo ratings yet

- Eng Nasser ResumeDocument1 pageEng Nasser Resumeisomekan11No ratings yet

- Engr. Salman Amir: Professional SummaryDocument3 pagesEngr. Salman Amir: Professional SummarysalmanNo ratings yet

- Gavin Chui: Professional ProfileDocument3 pagesGavin Chui: Professional ProfileMarkoNo ratings yet

- Sample Resume For Instrumentation EngineerDocument4 pagesSample Resume For Instrumentation Engineersherin josephNo ratings yet

- Proactive Reliability Services: T /C A PDocument10 pagesProactive Reliability Services: T /C A PHamza AshrafNo ratings yet

- CV - Kushal B CDocument3 pagesCV - Kushal B Ckushal B CNo ratings yet

- Salamuddin: QA/QC EngineerDocument3 pagesSalamuddin: QA/QC Engineercrm 2No ratings yet

- Instrument HH BDDocument4 pagesInstrument HH BDZain RehmanNo ratings yet

- Djahid Zaidi CVDocument5 pagesDjahid Zaidi CVZaidiNo ratings yet

- Farhan Baig: 19+ Years of Experience in The Field of Instrument and Control (I&C), ElectricalDocument9 pagesFarhan Baig: 19+ Years of Experience in The Field of Instrument and Control (I&C), Electricalfarhanbaig125319No ratings yet

- Junaid CV 16-04-2022Document6 pagesJunaid CV 16-04-2022prabhat2000.kNo ratings yet

- CV - Imran AhmadDocument3 pagesCV - Imran AhmadABID AKHTERNo ratings yet

- Emmanuel Santhanasamy: ContactDocument1 pageEmmanuel Santhanasamy: ContactEmmanuel SanthanasamyNo ratings yet

- Muhammed Fayiz PK Resume 1Document2 pagesMuhammed Fayiz PK Resume 1engrsaidnawab2020No ratings yet

- Atif Jabbar: BE (Electronics), ME (Mechatronics)Document2 pagesAtif Jabbar: BE (Electronics), ME (Mechatronics)atif jabbarNo ratings yet

- Praveen Rajeev: Service EngineerDocument3 pagesPraveen Rajeev: Service EngineerNagarajNo ratings yet

- Venkata - Ramana - Sas Engineer - ResumeDocument2 pagesVenkata - Ramana - Sas Engineer - ResumeKiran KumarNo ratings yet

- shabbi20@InstEnger - CV New-1Document18 pagesshabbi20@InstEnger - CV New-1Ishtiyak KhanNo ratings yet

- Ketul ResumeDocument2 pagesKetul ResumeketulNo ratings yet

- Rakesh Resume PDFDocument2 pagesRakesh Resume PDFrakukulappullyNo ratings yet

- Syed Ashar Hussain CVDocument3 pagesSyed Ashar Hussain CVShergul KhanNo ratings yet

- QC Inspector - LKDocument3 pagesQC Inspector - LKEngineering Affairs Dept.No ratings yet

- Vivek Kumar (Site)Document3 pagesVivek Kumar (Site)Dayanand WasateNo ratings yet

- Objective: Lifting Gear InspectorDocument2 pagesObjective: Lifting Gear InspectorMohamed YasirNo ratings yet

- INEOS UK Application Form-1Document4 pagesINEOS UK Application Form-1aswinkovilakamNo ratings yet

- Industrial Hydraulic CircuitsDocument43 pagesIndustrial Hydraulic CircuitsaswinkovilakamNo ratings yet

- cv20023464 Aswin-Kasthurbai Andy Instrumentation-EngineeringDocument2 pagescv20023464 Aswin-Kasthurbai Andy Instrumentation-EngineeringaswinkovilakamNo ratings yet

- Tri Review Turbidity Fact Sheet 01-08-15Document2 pagesTri Review Turbidity Fact Sheet 01-08-15Shyla Fave EnguitoNo ratings yet

- Panasonic IP CameraDocument77 pagesPanasonic IP CameraEtc EtcNo ratings yet

- Fashion - February 2014 CADocument144 pagesFashion - February 2014 CAAlmaMujanovićNo ratings yet

- LP Unsung Heroes PDFDocument3 pagesLP Unsung Heroes PDFzfmf025366No ratings yet

- DAILY LESSON LOG Week 2 Science 7Document3 pagesDAILY LESSON LOG Week 2 Science 7Matet GenerosaNo ratings yet

- Elements of Workshop Technology by Hajra Choudhary PDFDocument4 pagesElements of Workshop Technology by Hajra Choudhary PDFShakeel Mohmand25% (12)

- Academic CV Working DraftDocument3 pagesAcademic CV Working Draftapi-548597996No ratings yet

- Shipping and Spiel (AutoRecovered)Document5 pagesShipping and Spiel (AutoRecovered)jb1929835No ratings yet

- Time in Porphyry Cu - Au Development Corbett - Pacrim 2019 - BDocument5 pagesTime in Porphyry Cu - Au Development Corbett - Pacrim 2019 - BHumberto SalvadorNo ratings yet

- Cae Letter of RecommendationDocument4 pagesCae Letter of RecommendationsimonaNo ratings yet

- 03-17-08 CP-The Fed's Wall Street Dilemma by PAM MARTENSDocument4 pages03-17-08 CP-The Fed's Wall Street Dilemma by PAM MARTENSMark WelkieNo ratings yet

- Supplies Inventory Monitoring SheetDocument10 pagesSupplies Inventory Monitoring Sheetmharaynel.afableNo ratings yet

- Igc1 PDFDocument11 pagesIgc1 PDFDavid Akatsa50% (2)

- Sample Reciprocity LetterDocument1 pageSample Reciprocity LetterRrichard Prieto MmallariNo ratings yet

- Tigist Berhanu Supply ChainDocument73 pagesTigist Berhanu Supply Chainmissy advinculaNo ratings yet

- Cereal RecipeDocument21 pagesCereal RecipeMaynard Pascual100% (1)

- MarketingDocument73 pagesMarketingAse SharewNo ratings yet

- At The Pool TSM RedDocument4 pagesAt The Pool TSM RedSarah StevensNo ratings yet

- Annex 4 - Testing Centers - Amtec Cemtre & LatlDocument17 pagesAnnex 4 - Testing Centers - Amtec Cemtre & LatlHarvy LucinadaNo ratings yet

- Chapter 4: Redemption of Pref Share & Debentures Topic: Redemption of Debentures. Practice QuestionsDocument53 pagesChapter 4: Redemption of Pref Share & Debentures Topic: Redemption of Debentures. Practice QuestionsMercy GamingNo ratings yet

- BIR Form No GuidlineDocument11 pagesBIR Form No GuidlineFernando OrganoNo ratings yet

- Cooper Form 6 Control ManualDocument3 pagesCooper Form 6 Control ManualReinhad HutabaratNo ratings yet

- 1st Fraserburgh Boys' Brigade: World War One 1914-19Document31 pages1st Fraserburgh Boys' Brigade: World War One 1914-19Michael Strachan100% (1)