Professional Documents

Culture Documents

Ffu 0000534 01

Uploaded by

Karunia LestariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ffu 0000534 01

Uploaded by

Karunia LestariCopyright:

Available Formats

Safety checked

Chassis variant Document no.

Safety item

Division/Group Issuer, date

Quality checked 2079419

Mark yellow for updated

TEACO A v Tongeren 05/09/2011

497577

Symbols

Title Issue ECO

Task no

topline cab

Task duration

Beam airhorns on a topline 2 Total time 3.5 H

Search way

Task description Warning (if applicable)

Picture / Comments

1 Switch X

2 fitting wiring harness X

3 fitting wiring harness X

4 fitting 8 mm line X

5 Fitting magnetic valve X

6 fitting magnetic valve kitchen use a trapezium drill X

7 fitting magnetic valve acc and storage (panel beater drill) for X

8 fitting 6 mm line drilling the holes X

9 drilling holes X

9.1 measuring for fitting or not / glueing X

10 checking and glueing X

11 supplying

Parts list X

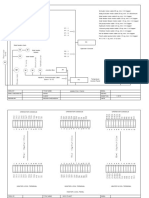

drawing 1 X

sypply sheet X

Affected products:

topline cab FPC 584B + not with rigid adapted FPC 3968B, 3969A

00:00

Version 1 FFU Standard Template MZ TEACO

ECO No. Document no. Issue

497577 2079419 2

Task number Chassis variant Issuer, date Symbols Real time

Safety Quality control Safety control

1 topline cab A v Tongeren 05/09/2011 sec

Task description Sy No Operation Important / notice consequences

Switch switch:

1 The switch goes into panel D. If no room in

D, then into panel F. If no room in F, then

into panel H.

2 Connect wiring harnesses according to

drawing 1428523, section B,C,D / 5,6,7.

Refer also to drawing 1.

Part and tool handling

Name Name Name Name Name Name Name Name Name Name Name Name Name Name Name

Version 1 FFU Standard Template MZ TEACO

ECO No. Document no. Issue

497577 2079419 2

Task number Chassis variant Issuer, date Symbols Real time

Safety Quality control Safety control

2 topline cab A v Tongeren 05/09/2011 sec

Task description Sy No Operation Important / notice consequences

fitting wiring harness Fitting cable harness:

1 Fit cable harness 1723015 in dashboard.

C274

2 Pull grey cable ( vis 78) from wiring

harness.

3 Pull grey cable (Vis78) from the visibility

ecu, (positioned next to the pedals),

connector E32 / B - pin 1.

4 Fit vis 78 from truck together with vis 40

from wiring harness in the same position.

Part and tool handling

E32/B - pin 1

Name Name Name Name Name Name Name Name Name Name Name Name Name Name Name

Version 1 FFU Standard Template MZ TEACO

ECO No. Document no. Issue

497577 2079419 2

Task number Chassis variant Issuer, date Symbols Real time

Safety Quality control Safety control

3 topline cab A v Tongeren 05/09/2011 sec

Task description Sy No Operation Important / notice consequences

fitting wiring harness Fitting cable harness:

1 Remove the upper cupboard and the Apillar

cover on passenger's side.

Ground rail

2 Route cable 1847032 through the Apillar

downwards, connect the black cable to the

ground rail in the upper cupboard.

C20-

pin18

Part and tool handling

Name Name Name Name Name Name Name Name Name Name Name Name Name Name Name

Version 1 FFU Standard Template MZ TEACO

ECO No. Document no. Issue

497577 2079419 2

Task number Chassis variant Issuer, date Symbols Real time

Safety Quality control Safety control

4 topline cab A v Tongeren 05/09/2011 sec

Task description Sy No Operation Important / notice consequences

fitting 8 mm air line Fitting 8 mm air line:

1 Route an 8 mm air line from the junction

block at the pedals through the dashboard,

passenger side A-pillar to the upper

cupboard.

Remove plug and fit 8 mm line for

air horns.

Part and tool handling

Name Name Name Name Name Name Name Name Name Name Name Name Name Name Name

Version 1 FFU Standard Template MZ TEACO

ECO No. Document no. Issue

497577 2079419 2

Task number Chassis variant Issuer, date Symbols Real time

Safety Quality control Safety control

5 topline cab A v Tongeren 05/09/2011 sec

Task description Sy No Operation Important / notice consequences

Fitting magnetic valve Fitting solenoid valve:

1 Fit the magnetic valve according to picture.

2 Drill 2 holes in the middle cupboard

according to picture and countersink holes.

3 50 mm from the hole to the right and

45 mm to the front is centre of first

magnetic valve hole.

Part and tool handling

Name Name Name Name Name Name Name Name Name Name Name Name Name Name Name

Version 1 FFU Standard Template MZ TEACO

ECO No. Document no. Issue

497577 2079419 2

Task number Chassis variant Issuer, date Symbols Real time

Safety Quality control Safety control

6 topline cab A v Tongeren 05/09/2011 sec

Task description Sy No Operation Important / notice consequences

fitting magnetic valve kitchen Fitting solenoid valve:

Topline with “kitchen module”:

1 With this variant the magnetic valve is fitted

in the outer corner behind the storage bin.

Part and tool handling

Name Name Name Name Name Name Name Name Name Name Name Name Name Name Name

Version 1 FFU Standard Template MZ TEACO

ECO No. Document no. Issue

497577 2079419 2

Task number Chassis variant Issuer, date Symbols Real time

Safety Quality control Safety control

7 topline cab A v Tongeren 05/09/2011 sec

Task description Sy No Operation Important / notice consequences

fitting magnetic valve acc and storage Fitting solenoid valve:

Topline with ACC and storage module

1 On this variant the magnetic valve right

front is fitted in the storage module.

Part and tool handling

Name Name Name Name Name Name Name Name Name Name Name Name Name Name Name

Version 1 FFU Standard Template MZ TEACO

ECO No. Document no. Issue

497577 2079419 2

Task number Chassis variant Issuer, date Symbols Real time

Safety Quality control Safety control

8 topline cab A v Tongeren 05/09/2011 sec

Task description Sy No Operation Important / notice consequences

fitting 6 mm line Fitting 6 mm air line:

1 Remove the roof hatch surround and the

rivets from the ceiling.

2 Route two 6 mm lines from the magnetic

valve to the roof hatch.

Part and tool handling

Name Name Name Name Name Name Name Name Name Name Name Name Name Name Name

Version 1 FFU Standard Template MZ TEACO

ECO No. Document no. Issue

497577 2079419 2

Task number Chassis variant Issuer, date Symbols Real time

Safety Quality control Safety control

9 topline cab A v Tongeren 05/09/2011 sec

Task description Sy No Operation Important / notice consequences

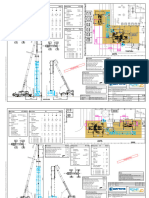

Drilling Drilling holes for air horn:

1 See drawing 2 for measurements.

2 Use the horn as a template for marking off

the front bracket hole.

3 Ensure that no drilling swarf remains,

remove carefully!!

Part and tool handling

If truck with 4.5 metre spoilers, supply the horns and the nipples in the cab.

Do not drill holes in the roof, only preparation in the cab.

Name Name Name Name Name Name Name Name Name Name Name Name Name Name Name

Version 1 FFU Standard Template MZ TEACO

ECO No. Document no. Issue

497577 2079419 2

Task number Chassis variant Issuer, date Symbols Real time

Safety Quality control Safety control

9.1 topline cab A v Tongeren 05/09/2011 sec

Task description Sy No Operation Important / notice consequences

Drilling Measure the heigth of the cab according to

document 2111233.

If the total heigth is more than 4 meters, the horns

and the last page of the instructions must be

supplied and the holes should be masked

according tot document 2111233 and instruction

Part and tool handling

Name Name Name Name Name Name Name Name Name Name Name Name Name Name Name

Version 1 FFU Standard Template MZ TEACO

ECO No. Document no. Issue

497577 2079419 2

Task number Chassis variant Issuer, date Symbols Real time

Safety Quality control Safety control

10 topline cab A v Tongeren 05/09/2011 sec

Task description Sy No Operation Important / notice consequences

checking and glueing checking and glueing:

1 Route a 6 mm line on each side, ± 10 cm

must be left protruding from the roof.

Ensure both lines are the same length.

2 Check if the magnetic valve is operational

and if air is blown from the valve through

the 6 mm lines.

3 Ensure the nipples fit through the 26 mm

holes and that the holes match the rivet

nuts.

4 Treat the holes with tectyle and fit bolt Supply horns if

812502 with washer 1379223 to the rivet necessary.

nuts. Mask everything with tape Tesa 4688

or similar, additional masking on 26 mm

hole.

Part and tool handling

Name Name Name Name Name Name Name Name Name Name Name Name Name Name Name

Version 1 FFU Standard Template MZ TEACO

ECO No. Document no. Issue

497577 2079419 2

Task number Chassis variant Issuer, date Symbols Real time

Safety Quality control Safety control

11 topline cab A v Tongeren 05/09/2011 sec

Task description Sy No Operation Important / notice consequences

supplying Supply:

1 Supply the horns in the original box and put Supply horns if

the box in the cab. necessary.

2 Supply also: 2x stainless steel plate, 2x Supply horns if

elbow insert nipple, 2x rubber for stainless necessary.

steel plate, 6x M6 bolt and 6x M6 washer.

3 Switch off the switch and stick the last page Supply horns if

to the inside of the window. necessary.

Part and tool handling

Name Name Name Name Name Name Name Name Name Name Name Name Name Name Name

Version 1 FFU Standard Template MZ TEACO

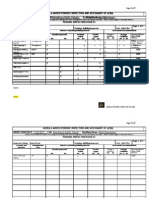

ECO number 497577

Part number Number Description Conditions

2079419 1 Document number

2 Air horn

1736470 8 Rivet nut

2 Elbow insert nipple

2038654 1 Solenoid valve

1886105 1 Cable

1847032 1 Cable

1321155 1 T-nipple

812957 1 45º nipple

1371197 1 Insert nipple

1369863 2 Nipple

813202 1 Plug

1452625 2 M6X25 Allen screw

1108763 2 Blind rivet

1483543 2 x 2000 mm Air line 6 mm

1483544 1 x 4000 mm Air line 8 mm

1421841 1 Switch

801992 8 Bolt

802995 8 Washer

1443344 1 Cable shoe

812502 8 Bolt

1379223 8 Washer

807351 1 Lock nut M6 Ground

2 stainless steel base plate

2 rubber for base plate

drawing 1

drawing 2

Do not operate the air horns.

because of

loose lines on the roof.

Do not operate the airhorns

There are loose lines on the roof

You might also like

- Ffu 0000053 01Document9 pagesFfu 0000053 01Karunia LestariNo ratings yet

- Valves 600 MMDocument3 pagesValves 600 MMjaseelNo ratings yet

- Ffu 0000058 01Document8 pagesFfu 0000058 01Karunia LestariNo ratings yet

- 1.0 Fitting 2.0 Fitting Parts List Affected Products: Safety Checked Document No. Safety ItemDocument5 pages1.0 Fitting 2.0 Fitting Parts List Affected Products: Safety Checked Document No. Safety ItemRodolfo Alberto Muñoz CarcamoNo ratings yet

- KBL 6800 New Circuit Diagram (JanDocument11 pagesKBL 6800 New Circuit Diagram (JanPaulmanke0% (1)

- Ffu 0000002 01Document7 pagesFfu 0000002 01Karunia LestariNo ratings yet

- Spare Part Upgradable Optionals 1/10th 4WD Nitro Power R/C Off-Road TruckDocument1 pageSpare Part Upgradable Optionals 1/10th 4WD Nitro Power R/C Off-Road TruckEka RoksNo ratings yet

- Hse 24 Ppe MappingDocument1 pageHse 24 Ppe MappingBa N Nhim100% (1)

- 11 5365A 2 HRS: 1.0 Positioning 2.0 Fitting 3.0 Checking Parts List Affected ProductsDocument6 pages11 5365A 2 HRS: 1.0 Positioning 2.0 Fitting 3.0 Checking Parts List Affected ProductsRodolfo Alberto Muñoz CarcamoNo ratings yet

- Angular Gripper-FUA-63M-Food Gripper SeriesDocument2 pagesAngular Gripper-FUA-63M-Food Gripper SeriesBe HappyNo ratings yet

- Check ListDocument3 pagesCheck ListGUSTAVO RAFAEL MESA HERNANDEZNo ratings yet

- Ffu 0000043 01Document19 pagesFfu 0000043 01Karunia LestariNo ratings yet

- System BreakdownDocument16 pagesSystem BreakdownYousuf Nasser ALAbriNo ratings yet

- Inspection Report Part ADocument12 pagesInspection Report Part Aramon coss lopezNo ratings yet

- Ffu 0000027 01Document4 pagesFfu 0000027 01Karunia LestariNo ratings yet

- PANASONIC FAN - fv-x0vq3 - en - OmDocument8 pagesPANASONIC FAN - fv-x0vq3 - en - OmbbeisslerNo ratings yet

- Hanwha Q Cells Data Sheet Qpeak Duo L-g5.2 380-395 2018-04 Rev04 AuDocument2 pagesHanwha Q Cells Data Sheet Qpeak Duo L-g5.2 380-395 2018-04 Rev04 AuAnonymous vDSlQGNo ratings yet

- Sheer Strake 1200x8.5: Principle Particulars Loa 82M 78m LBPDocument1 pageSheer Strake 1200x8.5: Principle Particulars Loa 82M 78m LBPmohammad shihabNo ratings yet

- Brief Information: Sharp Tone Horn Set M26SDocument2 pagesBrief Information: Sharp Tone Horn Set M26SDhimas NNo ratings yet

- AttH1 Fundao Dam TailingDocument39 pagesAttH1 Fundao Dam TailingOscar Labarca AlvaradoNo ratings yet

- U 140 PDFDocument163 pagesU 140 PDFTaymazNo ratings yet

- Ffu 0000767 01Document4 pagesFfu 0000767 01Omar ScaniaNo ratings yet

- CPSI - Safe and Efficient Inspection: Core Module Trainer Manual T181 Edition 2012-02Document13 pagesCPSI - Safe and Efficient Inspection: Core Module Trainer Manual T181 Edition 2012-02Ali DiabNo ratings yet

- INSTALLATION GUIDE (ON-SITE) - ModelDocument1 pageINSTALLATION GUIDE (ON-SITE) - ModelPaul De La CruzNo ratings yet

- Meyer Burger White 390 - Datasheet - ENDocument2 pagesMeyer Burger White 390 - Datasheet - EN25hyunseor20No ratings yet

- Chapter 3 Testbank Topic Grid: Garrison/Noreen/Brewer, Managerial Accounting, Twelfth Edition 3-1Document6 pagesChapter 3 Testbank Topic Grid: Garrison/Noreen/Brewer, Managerial Accounting, Twelfth Edition 3-1Ivern BautistaNo ratings yet

- PlanosDocument14 pagesPlanosMarco Salazar JachillaNo ratings yet

- Ffu 0000360 01Document4 pagesFfu 0000360 01Omar ScaniaNo ratings yet

- Ffu 0000034 01Document8 pagesFfu 0000034 01Karunia LestariNo ratings yet

- AMAN - Sico PlastDocument5 pagesAMAN - Sico PlastNaveen PatelNo ratings yet

- Masoneilan BrochureDocument32 pagesMasoneilan Brochurenurfara39No ratings yet

- Bolt and Weld Capacity - Red Book 1999 PDFDocument2 pagesBolt and Weld Capacity - Red Book 1999 PDFWhite_rabbit2885764No ratings yet

- Glulam - Service Class 1Document3 pagesGlulam - Service Class 1ikanyu79No ratings yet

- S-18-13306 - DR7050 - A - V-169AB-01 Stack (Max.31t)Document3 pagesS-18-13306 - DR7050 - A - V-169AB-01 Stack (Max.31t)Hanif Nur Fauzi MargonoNo ratings yet

- AsbestosPERIODICIS 7-10Document2 pagesAsbestosPERIODICIS 7-10idahssNo ratings yet

- Skid Packages - TQ-4-Consolidated - Alshirawi UpdatedDocument6 pagesSkid Packages - TQ-4-Consolidated - Alshirawi Updatedyadav yadavNo ratings yet

- FPC-2 - Solution With LHD For Electrical CabinetsDocument1 pageFPC-2 - Solution With LHD For Electrical CabinetsMạnh HùngNo ratings yet

- EPSON WF-C20590 Service Manual Page101-150Document50 pagesEPSON WF-C20590 Service Manual Page101-150ion ionNo ratings yet

- SheetfgffgfDocument1 pageSheetfgffgfapi-331456142No ratings yet

- Asd Tug 3212 FactsheetDocument1 pageAsd Tug 3212 FactsheetRoda NiagaNo ratings yet

- 2014 05 Turbine Generator PKG EreDocument8 pages2014 05 Turbine Generator PKG EretpplantNo ratings yet

- Grid 03Document6 pagesGrid 03Lloyd Vincent O. TingsonNo ratings yet

- P27-1040 Switch - Eaton PNsDocument3 pagesP27-1040 Switch - Eaton PNsDiego LiraNo ratings yet

- Mono 345wDocument1 pageMono 345wmiedlchristian03No ratings yet

- R4T-S-Seriesrev.01 UL EDocument1 pageR4T-S-Seriesrev.01 UL EHiểu TuyếtNo ratings yet

- Ffu 0000243 01Document10 pagesFfu 0000243 01Karunia LestariNo ratings yet

- Propeller Shaft: SectionDocument16 pagesPropeller Shaft: SectionJBNo ratings yet

- Outline-Bare Unit: DWN by CK'D by Third Angle ProjectionDocument1 pageOutline-Bare Unit: DWN by CK'D by Third Angle ProjectionHelder ChavezNo ratings yet

- 7.4 (附件二十三) List of the primary structuresDocument6 pages7.4 (附件二十三) List of the primary structuresTsung-Ching LinNo ratings yet

- Supplier Award 1st Quarterly 2019 (Jan-Mar) - Rev.01Document39 pagesSupplier Award 1st Quarterly 2019 (Jan-Mar) - Rev.01Wiratama PratamaNo ratings yet

- Bosch Tca5201 El ShemaDocument1 pageBosch Tca5201 El Shemanechal2008No ratings yet

- Cor-Acc890kp Cor-Acc890bioDocument8 pagesCor-Acc890kp Cor-Acc890biojuan david mendez tellezNo ratings yet

- Scala: Service InstructionsDocument16 pagesScala: Service Instructionsmario_turbinadoNo ratings yet

- Fuel Tank Assy: ComponentsDocument3 pagesFuel Tank Assy: Componentsdmc constructionNo ratings yet

- TF100-20C - Rynglok PosterDocument1 pageTF100-20C - Rynglok PosterLorenzoTanNo ratings yet

- Generator Assy (1Gr Fe) : ComponentsDocument1 pageGenerator Assy (1Gr Fe) : ComponentsIslam AttiaNo ratings yet

- Programming in COBOL: Library of Computer EducationFrom EverandProgramming in COBOL: Library of Computer EducationRating: 5 out of 5 stars5/5 (2)

- Ffu 0001108 01Document6 pagesFfu 0001108 01Karunia LestariNo ratings yet

- Ffu 0000574 01Document8 pagesFfu 0000574 01Karunia LestariNo ratings yet

- Ffu 0001110 01Document9 pagesFfu 0001110 01Karunia LestariNo ratings yet

- Ffu 0001108 01Document6 pagesFfu 0001108 01Karunia LestariNo ratings yet

- Ffu 0001102 01Document12 pagesFfu 0001102 01Karunia LestariNo ratings yet

- Ffu 0001108 01Document6 pagesFfu 0001108 01Karunia LestariNo ratings yet

- Ffu 0000046 01Document13 pagesFfu 0000046 01Karunia LestariNo ratings yet

- Ffu 0001115 01Document38 pagesFfu 0001115 01Karunia LestariNo ratings yet

- Ffu 0001110 01Document9 pagesFfu 0001110 01Karunia LestariNo ratings yet

- Ffu 0000061 01Document4 pagesFfu 0000061 01Karunia LestariNo ratings yet

- Ffu 0000034 01Document8 pagesFfu 0000034 01Karunia LestariNo ratings yet

- Document No.: 374679 Fitting Mudguards On CA4x2Document5 pagesDocument No.: 374679 Fitting Mudguards On CA4x2Rodolfo Alberto Muñoz CarcamoNo ratings yet

- Aw60 40leDocument3 pagesAw60 40leCESARALARCON1No ratings yet

- Replacement Parts Diagrams HBF600 (Series A)Document3 pagesReplacement Parts Diagrams HBF600 (Series A)Claudio VerdeNo ratings yet

- TM-5-2350-262-10 M9 AceDocument304 pagesTM-5-2350-262-10 M9 AceIce82100% (1)

- Followers Can Be Classified Based On - Type of Surface Contact Between Cam and Follower - Type of Follower Motion - Line of Motion of FollowersDocument25 pagesFollowers Can Be Classified Based On - Type of Surface Contact Between Cam and Follower - Type of Follower Motion - Line of Motion of FollowersN NandiniNo ratings yet

- Laporan Hasil Shipping Inspection: Nomor Produk 48500 61J70 Nama ProdukDocument4 pagesLaporan Hasil Shipping Inspection: Nomor Produk 48500 61J70 Nama ProdukBrata IvanNo ratings yet

- Massey Ferguson Baler Parts Manual PDFDocument15 pagesMassey Ferguson Baler Parts Manual PDFisa0% (1)

- Spare Parts Manual CP18 - March 2012Document234 pagesSpare Parts Manual CP18 - March 2012Sunny Sethi67% (3)

- Genuine Brunswick Parts CatalogDocument172 pagesGenuine Brunswick Parts CatalogAbror ArtukmetovNo ratings yet

- Bicykle EbikecgctfDocument2 pagesBicykle Ebikecgctfbotanyalloy4No ratings yet

- Sab 330Document8 pagesSab 330Manuel perezNo ratings yet

- Value Wise (More Then 2 Years)Document16 pagesValue Wise (More Then 2 Years)Saurabh Kumar SinghNo ratings yet

- Saab 9-5Document12 pagesSaab 9-5Roberto Ortega MicalizziNo ratings yet

- 96 Blazer All Wiring DiagramsDocument44 pages96 Blazer All Wiring Diagramsjcox414958% (12)

- Maruti 800 Maintenance ScheduleDocument5 pagesMaruti 800 Maintenance Schedulemikegrace100% (1)

- Replacing The Fuel FilterDocument5 pagesReplacing The Fuel FilterLuis San Emeterio ArgumosaNo ratings yet

- R 2t-2.5t PARTS CATALOGDocument5 pagesR 2t-2.5t PARTS CATALOGjm empilhadeirasNo ratings yet

- Hyster Ut Series: Electric Walkie Pallet TruckDocument4 pagesHyster Ut Series: Electric Walkie Pallet TruckAlbertoNo ratings yet

- Comercial Vehicle BrochureDocument8 pagesComercial Vehicle BrochureCloudNo ratings yet

- File 4626Document3 pagesFile 4626jansjansNo ratings yet

- Zack Casha - Bachelor of Engineering (Honours) in Mechanical Engineering (Plant)Document25 pagesZack Casha - Bachelor of Engineering (Honours) in Mechanical Engineering (Plant)Zack CashaNo ratings yet

- Bleeding Your Cherokee BrakesDocument4 pagesBleeding Your Cherokee BrakesBlueSkyMasterNo ratings yet

- ZOOMLION Scissor+LiftsDocument2 pagesZOOMLION Scissor+LiftsPM XieNo ratings yet

- Fanuc Oi Data Input Output PDFDocument38 pagesFanuc Oi Data Input Output PDFnam buiNo ratings yet

- Design and Analysis of Rear Axle CasingDocument8 pagesDesign and Analysis of Rear Axle CasingMassive MindsNo ratings yet

- Peterbilt Pb362 Cab Wiring Schematic Sk14799Document1 pagePeterbilt Pb362 Cab Wiring Schematic Sk14799brian100% (31)

- Shell Omala S4 GXV 460 - TDSDocument2 pagesShell Omala S4 GXV 460 - TDSDENNY BAYUAJINo ratings yet

- ASME B18.3.2M-1979 Metric Series Hexagon Keys and BitsDocument11 pagesASME B18.3.2M-1979 Metric Series Hexagon Keys and Bitshcsharma1967No ratings yet

- Tailift FD-FG 15-35 Parts ManualDocument100 pagesTailift FD-FG 15-35 Parts ManualAlfredo Leal Jr.100% (1)

- Hasaaan Order ListDocument10 pagesHasaaan Order ListArif MamunNo ratings yet

- StackPack 300 TechsheetDocument2 pagesStackPack 300 TechsheetmanishNo ratings yet