Professional Documents

Culture Documents

Dor - 24 09 2022 - WQ1 223 - Idc 143 3

Dor - 24 09 2022 - WQ1 223 - Idc 143 3

Uploaded by

kareemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dor - 24 09 2022 - WQ1 223 - Idc 143 3

Dor - 24 09 2022 - WQ1 223 - Idc 143 3

Uploaded by

kareemCopyright:

Available Formats

IRAQI DRILLING COMPANY DAILY REPORT

INTEGRATED MANGEMENT SYSTEM (IDCWI-1-F5)

Daily Operation Report Date: 24-09-2022 Project: EXXON MOBIL Location: WEST QURNA/1 ROW : 95 Country : IRAQ

Rig: IDC-143 Well No.: WQ1:223 Conductor :20" RT - GL: 5.8 Activity: WORKOVER Spud Date: 23/09/2022 Obj: RIH NEW

ESP&PKR Planned Depth: 2484 m POB: 43 Report No.: 3 . Planned Days: 20 GL Elev: 1.8M Start Of Moving Date :

06/09/2022 End Of Moving Date : 08/09/2022 Days Of Acc : 12 .

Depth MD (m) TVD (m) Bit current previous BHA Amount ID (in) OD (in) Total (m)

00:00 hrs Make

Serial #

18:00 hrs

Run #

24:00 hrs

Meterage Diameter(in)

Lithology Top(m) Bottom(m) Model

Dibdibba

Nozzles (in)

L-faris

GHAR Mts Drilled

Dammam Oper. hrs

RUS

IADC

UM RADHUMA

TAYARAT Depth in

RTKP

shiranish DULL Grading

Bit no.

BHA

SaDI

0.00

24 PM situation R/D HSL equipment. K.D

06 AM situation Keep the well open to the waste tank for the flow checking, no flow. T.D TON MILE = 358

Casing Depth (m) F.C (m) D.V (m) TVD (m) Angle Azimuth Closure (m) Severity (deg/30m)

pre.

Current

Mud Type: Density In : g/cc Density Out: Temp. In : degC Formation Tests Material tons Stock

Sand : ECD : g/cm3 Ca= Temp. Out: degC EMW Test g/cm3 Camp fuel(L)

Gel 0: Gel = API Cake: PP EMW g/cm3

600 / 300 = API Vol. Cm3 AV = Choride: mg/L FP EMW g/cm3

Viscosity = sec. PV YP = Water:

RIG FUEL: 15.3 M³/CONSUMER FUEL: 900 L

pH = Fil Sand : Solids : oil :

Weight on Bit : ton. SPM1 = SPM2 =

Achievement Ratio For Workover OPS. 5 %

R.P.M =. Liner Size1: 5"

Stand pipe Pressure = psi Liner Size2: 5''

DRILL DATE : 24-09-2022 TIME: 04:00 PM

Torque: AMP Flow Rate: L/m

Koomy: Manifold: 1500psi Accumulator:3000psi Annular: 1000psi

Wt. of string: Ton Annular Velocity: Rental Crane 30 TON 0 Hrs 1 ALI HABEEB

pump press. = psi

Rental Fork Lift 10 ton 0 Hrs 1 KADIM OBEADI

RIG ACCEPTANCE, PJSM, L/U&P/T, RWCP, P/T,P/T,KILL WELL, MONITORING, WOWH,P/T,P/U KELLY, RELEASE BOLTS, PJSM,RELEASE

Summary of Previous Day:

ANCHER, N.CIR.

TIME H CODE Operations

00:00 - 02:30 2.5 22.1 Trying for several attempts to re-latch the anchor , it was unsuccessful.

02:30 - 03:30 1 22.1 R/D kelly.

03:30 - 06:00 2.5 19 Waiting on IDC to bring X.O.S 3 1/2" NV X 3 1/2" VT.

Next steps discussion:

-PJSM with the day shift.

-House keeping for the rig floor.

06:00 - 08:00 2 22.1

-Meeting the RM and discuss a plan for the next steps.

-Hold the FOD morning meeting and discuss next plan that to relatch anchor with kelly.

-Meanwhile IDC made cross overs NV -VT.

Re-latch with kelly:

-PJSM with the IDC team.

-P/U and M/U 3.5" NV landing joint .

-Pull out and disconnect the TBG hanger and 3.5" NV joint (9.54 m length) below it.

-P/U and M/U following bellow the kelly: 1.5 m of NV-VT XOS + 9.29 m 3.5" VT TBG joint + 0.3 m VT-IF XOS.

-P/U and M/U kelly on the string, RIH and tag with 1 ton, the kelly down was 4.68 m (0.67 cm needed to be added with string to relatch).

08:00 - 13:30 5.5 22.1

-After 3 time we, it was engaged, Pull out string to the 31.5 tons ( 2 tons over pull), ok.

-Trying to release by pull 29.5 tons (string weight), made 12 turns with 30-80 amps torque, released.

-Disconnect kelly and kelly hose, L/D kelly.

-P/U and M/U three 3.5" pup joint(8 ft length), connect on the string.

-Trying to engage anchor again, Pull out string to the 31.5 tons ( 2 tons over pull), ok.

-Pumped 5 m3 of fresh water insde TBG.

13:30 - 16:30 3 22.1 R/U Hall slick line on the 3.5"VT-4.5" VT XOS, pressure test Hall PCE equipment with 500psi/5min and 2000psi/10min , test was OK.

16:30 - 18:00 1.5 22.1 Start RIH with 2.75" GC, tagged at 2265m, POOH to surface.

RIH with 2.75" plug, set at 2265 RTKP m, POOH to 2000m, P/T through TBG with 1000 psi for one minute got drop to zero ,P/T the annulas with 1000 psi

18:00 - 22:30 4.5 22.1

for 10 min test was ok, POOH to the surface then ,P/T hold 1000 psi on the CSG and TBG in the same time, test ok for 15 min.

22:30 - 00:00 1.5 22.1 R/D SL equipment.

24

TIME H CODE 6 AM Operations For The Day 25-09-2022

00:00 - 01:00 1 22.1 Open the TBG to the waste tank, It was some gas flowing (without pressure), stopped flowing, OK.

Release the anchor:

-Disconnect the TBG hose and L/D 4.5" VT FOSV.

-While trying to pull the string, got a well kick from the TBG side, Secured the well by connect 3.5" VT FOSV and close it, close the pipe ram.

01:30 - 03:00 2.5 22.1 -L/U the surface line to the TBG, read pressure, zero psi, open to the waste, it was gas and crude oil flowing.

-Open the pipe ram, pumped from TBG (zero SPP), returned from BOP, close BOP.

-PT TBG side with 1000 psi, the annulus held the pressure in the same time, no pressure dropping for the both sides, bleed to zero.

-Discuss with the SL supervisor, Hall was not okay with release plug prong.

Forward circulation:

-pumped 3 m3 of 85 sec high vis.

03:00 - 05:00 1.5 22.1 -Pumped 45 m3 of fresh water.

-SPP= zero psi.

-Return was clean and same the pumped weight (8.33 PPG).

05:00 - 06:00 1 22.1 Keep the well open to the waste tank for the flow checking, no flow and both sides = ZERO.

Remaining M³ Item Received Accumulate M3 Safety Coord.

Quantity Of

Liquids In Mud : Ind. WATER R.O water 0 50

Medic

Tanks

You might also like

- BOP Configuration 9.625inch Mud CrossDocument2 pagesBOP Configuration 9.625inch Mud CrosskareemNo ratings yet

- Dor - 25 09 2022 - WQ1 223 - Idc 143 4Document1 pageDor - 25 09 2022 - WQ1 223 - Idc 143 4kareemNo ratings yet

- Po 4510089832Document2 pagesPo 4510089832kareemNo ratings yet

- Daily Operation Report Date: 02/ 06 / 2021 Project: Exxon Mobil Location Area: WQ1 - 053 ROW: 82 Country: IraqDocument18 pagesDaily Operation Report Date: 02/ 06 / 2021 Project: Exxon Mobil Location Area: WQ1 - 053 ROW: 82 Country: IraqkareemNo ratings yet

- Waiting On Daylight Waiting On Mast Leg Pad InspectionDocument1 pageWaiting On Daylight Waiting On Mast Leg Pad InspectionkareemNo ratings yet

- Workover Daily Report WQ1-039Document3 pagesWorkover Daily Report WQ1-039kareem100% (1)

- IDC-30 Report 02-11-2023Document4 pagesIDC-30 Report 02-11-2023kareemNo ratings yet

- IDC SOP # 13 POOH With DP, DC's and BitDocument4 pagesIDC SOP # 13 POOH With DP, DC's and BitkareemNo ratings yet

- Waiting On Daylight Waiting On Mast Leg Pad InspectionDocument1 pageWaiting On Daylight Waiting On Mast Leg Pad InspectionkareemNo ratings yet

- Dor 19-11-2019 FH#5 Idc45 18Document1 pageDor 19-11-2019 FH#5 Idc45 18kareemNo ratings yet

- Iraqi Drilling Company Daily Report Integrated Mangement System (IDCP08F4)Document1 pageIraqi Drilling Company Daily Report Integrated Mangement System (IDCP08F4)kareemNo ratings yet

- IDC SOP # XX Laying Down Drill Pipe From DerrickDocument4 pagesIDC SOP # XX Laying Down Drill Pipe From DerrickkareemNo ratings yet

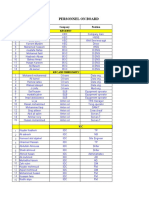

- Personnel On Board: No. Full Name Company Position LocationDocument4 pagesPersonnel On Board: No. Full Name Company Position LocationkareemNo ratings yet

- IDC SOP # 10 Operation of The Pipe SpinnerDocument2 pagesIDC SOP # 10 Operation of The Pipe SpinnerkareemNo ratings yet

- IDC SOP # 10 RIH With DC's and Drill Pipe (Bit On Bottom)Document4 pagesIDC SOP # 10 RIH With DC's and Drill Pipe (Bit On Bottom)kareemNo ratings yet

- IDC SOP # 11 POOH With DP, DC's and BitDocument3 pagesIDC SOP # 11 POOH With DP, DC's and Bitkareem100% (1)

- IDC SOP #2 Pressure Test of The StandpipeDocument5 pagesIDC SOP #2 Pressure Test of The StandpipekareemNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)