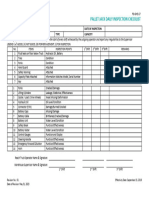

FO-SHE-06

MONTHLY SAFETY, HEALTH, & ENVIRONMENT (SHE) INSPECTION CHECKLIST

WAREHOUSE/SITE ELISCO LOCATION KALAWAAN, PASIG

INSPECTION FOR THE MONTH OF DECEMBER 2023 DATE INSPECTED DECEMBER 01, 2023

Mark each check point with "X" OR "✓" as appropriate

I. LEGAL REQUIREMENTS YES NO NA REMARKS

1 Copy of ECC/CNC is available ✓ Certificate of Non-Coverage (CNC) needs to ba applied

2 LLDA Clearance available ✓ This needs to be verified with the lessor if available

3 A valid Discharge Permit available ✓ This needs to be verified with the lessor if available

4 SMR & CMR are submitted regularly and on time ✓ This needs to be verified with the lessor if available

5 A valid genset PTO is available ✓ To be applied, a CNC is required for the application

6 A valid Fire Safety Inspection Certificate available ✓ On process

II. GENERAL WAREHOUSE AREA YES NO NA REMARKS

8 Are aisles clear and open for material transfer ✓

9 Are floor and rack storage limits properly posted ✓

10 Are racks upright and beams in good condition ✓

11 Are all emergency exits clear of blockage ✓

12 Are the exit signs in good condition ✓

13 Are all fire fighting equipment up to date for inspections, in good ✓

condition, and unobstructed

14 Is there adequate natural or mechanical ventilation to control any ✓

potential atmospheric hazards

15 Are overhead lightings, skylights, and roofs in good condition ✓

16 Loose/unboxed materials which might fall from a stack are properly ✓

stored by blocking, interlocking or limiting the height of the pile to

prevent from falling

17 Guardrails and/or covers are provided to protect personnel from ✓

the hazards of the open sides of the stairs, platforms, floor

openings, floor holes, mezzanines, equipment pits, and other

possible fall hazards

18 Elevators and hoists used for lifting items are properly used, have ✓

adequate/safe clearances, no obstructions, appropriate signals and

directional warning signs. Documented annual inspections by

licensed inspector are posted on the equipment and on file

19 All hazardous materials containers are properly labeled ✓

20 MSDS book is up to date ✓ No MSDS available

21 Employees use proper personal protective equipment (PPE) when ✓ No PPE available for chemical handling such as safety goggles,

handling chemicals chemical/rubber gloves, masks (N95), face shields, aprons, etc.

22 All chemicals are stored according to the manufacturer’s ✓ Cleaning chemicals only, properly arranged in a shelves

recommendations and local or national fire codes (i.e. flammable

cabinets, cans, etc.)

23 Employees use proper lifting technique for the materials being ✓

handled

24 Products that are most frequently moved by hand are stored at ✓

rack heights that minimize bending/stooping or excess reach to

pick up or place

III. DOCK/LOADING BAY AREAS YES NO NA REMARKS

25 Are approach roads and staging areas clear for maneuvering and ✓

are all signs in place and legible

26 Is the approach to the dock free from obstructions ✓

27 Are dock positions clearly marked with painted lines that the ✓

drivers can see to help them spot their trucks accurately

28 Are all exterior lights working properly ✓

29 Are wheel chocks and/or trailer restraint systems working properly ✓

30 Are visitors and drivers remaining in designated safe areas and ✓

walkways

31 Are all interior overhead lights properly working ✓

32 Do dock doors work properly and closed when not in use ✓

33 Is there sufficient room to maneuver materials ✓

Revision No. 01

Date of Revision: August 08, 2023 Effectivity Date: September 15, 2019

� FO-SHE-06

34 Are there sufficient waste cans for the area and are properly ✓

labeled and emptied on a regular basis

IV. EQUIPMENT YES NO NA REMARKS

35 Ladders and hand tools are in good condition ✓ No ladder found during the inspection

36 MHE operators have valid NC2 certificates ✓

37 Are forklifts being operated safely and inspected at the start of ✓ No record of inspection was found

every shift

38 Do forklifts have functioning warning devices such as back-up ✓

alarms, strobes, or horns

39 Are battery charging/changing areas designated for that purpose ✓

and contain appropriate emergency flushing facilities (i.e. eyewash)

40 Are guards in place for any hazard points on moving equipment ✓

such as belt guards on compressors or conveyors

41 Are all fire sprinkler control valves in their “OPEN” position ✓

42 The original capacity, operation and maintenance instruction ✓

plates, tags or decals on powered industrial trucks are in place and

legible

43 Carboy tilters or siphons rated for the specific corrosive material ✓

are used for electrolytes and are stored in appropriate area (i.e.

corrosives cabinet or other protected, designated and segregated

area)

44 Battery vent caps are in place, in good working condition with vents ✓

open and clear

45 Hot work permit process or other documented/dedicated ✓

processes are in place to prevent welding, grinding or other ignition

sources from battery charging functions and other flammable

material areas

46 Tools and other spark producing metallic objects are kept away ✓

from the top of uncovered batteries

47 Are gensets & pumps regularly tested and documented ✓ no evidence that genset has been recently tested

V. SANITATION YES NO NA REMARKS

48 Are aisles, wall perimeters, and exterior areas near the building ✓

free of loose trash and debris

49 Is the trash disposed on a daily basis ✓

50 Is there a dedicated Material Recovery Facility, MRF ✓

51 Are the storage areas free of pests ✓ Cat poop found on the extension warehouse - strong smel was

observed

52 Are Washrooms & toilets rooms are well maintained & cleaned ✓ Toilet intended for truckers is poorly maintained. An unpleasant

regularly odour of urine can be smell all over once inside the toilet.

53 Are locker rooms clean and tidy and that no evidence food is being ✓

consumed

54 Foot-operated trash bins are provided on toilets & kitchen ✓

VI. SAFETY, HEALTH, & ENVIRONMENT YES NO NA REMARKS

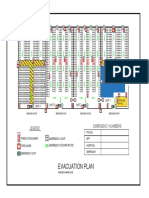

55 There is a designated emergency assembly area ✓

56 No fire hazards are observed ✓

57 At least two exits are provided in every floor of every workplace ✓

58 Electrical outlets are in safe condition ✓

59 No octupus wire connections that could cause fire ✓

60 Electrical power tools are in good conditions and guards are in ✓

place

61 Are fire extinguishers available, maintained in good condition, & ✓

regularly inspected?

62 Non-routine jobs are controlled by Permit-to-Work ✓

Revision No. 01

Date of Revision: August 08, 2023 Effectivity Date: September 15, 2019

� FO-SHE-06

63 No evidence of oil spill is observed ✓ A small of oil spill was observed in the battery charging station

64 All trucks have oil pans and are being used ✓

65 Tire chocks available and are used correctly ✓

66 Appropriate PPE are available and are used correctly ✓ Most of the warehouse presonnel do not have issued safety shoes

67 Certified first aider is available ✓

68 List of first aiders with contact numbers posted ✓

69 Medicines as per DOLE standards available ✓ No medicines and medical supplies provided - please see email

dated: October 13, 2023

70 Logbook for medicines provided ✓

71 Treatment Logbook is available ✓

72 Medical supplies as per DOLE standard is available ✓

VII. KITCHEN/DINING AREA/PANTRY YES NO NA REMARKS

74 Cooks and food servers has a valid food handling certificate ✓

75 Cooks and food handlers have no open wounds ✓

76 Staffs do not have signs of cold or flu ✓

77 Are fire Extinguishers & Blankets available - accessible, free from ✓

obstructions, and regularly checked

78 Is the food warmer in good working condition to control food ✓

temperature

79 Is the kitchen waste bins cleaned orderly and free of odor & away ✓

from food preparation areas

80 Are spoiled & rotten foods, vegetables discarded regularly ✓

81 Is there a hand sanitizer available in the area ✓

82 A small amount of food samples taken and kept for 8 hours ✓

83 Oil-water separator is available and regularly cleaned ✓

VIII. DRIVERS' LOUNGE/ACCOMMODATIONS YES NO NA REMARKS

84 The area is properly ventilated ✓

85 The area is clean and tidy ✓

86 Garbage are properly stored, segregated, and regularly disposed ✓

87 Phone chargers are unplugged when not in use ✓

88 Electrical outlets and appliance cords are in good condition ✓

89 No octopus wiring connections are observed ✓

90 Washroom & toilets are provided and maintained in good, sanitary ✓

condition

91 No signs of rodents or cockroaches are present ✓

92 No feeding of animals ✓

93 No clothes are hanging outside around or near the ✓

accommodations

OTHER COMMENTS (List other findings/observations for improvement which are not covered above but required to be rectified):

Truckers common toilet needs to be improved such as:

- Installing additional water supply to clean toilet bowls/urinals better to eliminate odour - smell of urine intensifies during hot days that makes

people avoid using them. We do not want them to urinate anywhere around the warehouse premises.

- Provide water hose, long enough, for water spraying during cleaning.

Revision No. 01

Date of Revision: August 08, 2023 Effectivity Date: September 15, 2019

� FO-SHE-06

Genset do not have roof to protect it from rain and sunlight - install roofings in order to avoid parts of it from getting inoperable and corroded

through time.

Damage on loading dock floors, and some areas inside the warehouse, were observed - recommended for repair in order to avoid from getting worse

when ran over by heavy equipment (to prevent dust as well).

Thorough cleaning needs to be implemented paying particular attention on wall corners and behind equipment, rackings, tables or furnitures, etc.

ADD ADDITIONAL LINES AS NECESSARY

I hereby certify that this inspection was done in the presence INSPECTED BY

of the warehouse Manager/Supervisor who's signature

appears below. Name/Position Signature/Date

The undersigned Manager/Supervisor acknowledges that ACKNOWLEDGED BY

he/she has personally witnessed the inspection and accepted

the score above. Name/Position Signature/Date

Revision No. 01

Date of Revision: August 08, 2023 Effectivity Date: September 15, 2019