Professional Documents

Culture Documents

FO-SHE-01 Incident Investigation Report

Uploaded by

Neil OsenaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FO-SHE-01 Incident Investigation Report

Uploaded by

Neil OsenaCopyright:

Available Formats

FO-SHE-01

INCIDENT INVESTIGATION REPORT

INCIDENT №

INCIDENT TITLE

DATE OF INCIDENT WAREHOUSE/LOCATION

TIME OF INCIDENT DEP’T. INVOLVED

INCIDENT TYPE

Personal Injury Health Issues Environmental Vehicular Accident

Property Damage Affecting Company Property Damage Affecting 3rd Parties

Security / Theft Other, please specify

INCIDENT DESCRIPTION (report only facts & documented data)

WORK BEING UNDERTAKEN AT TIME OF INCIDENT (detail location, type of work& equipment involved and/or being worked on)

PERSONAL INJURY DETAILS

NAME: AGE HOURS INTO SHIFT

INJURED SEX EXPERIENCE IN ROLE

PARTY (IP)

COMPANY EMPLOYEE 3RD PARTY EMPLOYEE

INDICATE ON THE DIAGRAM AREAS THAT HAVE SUSTAINED INJURIES

WORK RELATED? YES NO

DETAILS OF

INJURIES

SUSTAINED

DETAILS OF

TREATMENT

GIVEN AT

SITE

OUTCOME OF INJURY FAC MTC RWC LTA FAT

FAC – First Aid Case / MTC – Medical Treatment Case / RWC – Restricted Work Case / LTA – Lost Time Accident / FAT - Fatality

Revision No.: 01 Effectivity Date: September 15, 2019

Date of Revision: May 31, 2023

FO-SHE-01

INCIDENT INVESTIGATION REPORT

VEHICULAR ACCIDENT

TRANSPORTATION Motorbike Car 6-Wheelers 10-wheelers Other,

TYPE

Specify:

Company Employee 3RD Party Employee Experience in Local Area,

DRIVER DETAILS

State in Weeks/Months/Years:

LOAD/CARGO BEING CARRIED:

IMMEDIATE CAUSES List ALL relevant Immediate Causes

(Warehouse Manager to complete

using List 1 on last page)

IMMEDIATE CORRECTIVE ACTIONS TAKEN COMPLETED BY

ADD MORE LINES ABOVE AS REQUIRED

SAFETY OFFICER’S COMMENTS

NAME: DATE: SIGNATURE:

SITE HEAD’S COMMENTS

NAME: DATE: SIGNATURE:

Revision No.: 01 Effectivity Date: September 15, 2019

Date of Revision: May 31, 2023

FO-SHE-01

INCIDENT INVESTIGATION REPORT

INVESTIGATION FEEDBACK

SYSTEM/ROOT CAUSES List ALL relevant System/Root Causes

(SHE Manager to complete using

List 2 on last page)

PRIORITY RESPONSIBLE TARGET COMPLETION

№ CORRECTIVE/PREVENTIVE ACTIONS

(H, M, L) PERSON/DEPT DATE DATE

ADD MORE LINES ABOVE AS REQUIRED

PRIORITY OF ACTIONS:

• High (H) - Requires immediate action;

• Medium (M) - Must be completed to an agreed plan;

• Low (L) - Should be considered by the Company but is not a priority.

SHE MANAGER’S COMMENTS

NAME: DATE: SIGNATURE:

INCIDENT CLOSED OUT

THIS INCIDENT SHALL ONLY BE SIGNED “CLOSED” UPON COMPLETION OF THE ACTION ITEMS IDENTIFIED ABOVE.

NAME: DATE: SIGNATURE:

Revision No.: 01 Effectivity Date: September 15, 2019

Date of Revision: May 31, 2023

FO-SHE-01

INCIDENT INVESTIGATION REPORT

THIS PAGE IS NOT REQUIRED TO BE SENT WITH THE INCIDENT INVESTIGATION

LIST 1 - COMPREHENSIVE LIST OF IMMEDIATE CAUSES

Did not Follow 1-1 Violation (by individual) 1-2 Violation (by group) 1-3 Violation (by Supervisor)

1

Existing Procedures 1-4 Procedure not available 1-5 Procedure was not understood 1-6 Other

PERSONAL ACTIONS

Use of Tools, Plant / 2-1 Plant/equipment/vehicle used incorrectly 2-2 Tools used in the wrong way 2-3 Use of equipment/vehicle with known defect

2 Equipment or 2-4 Use of tools with a known defect 2-5 Incorrect placement of tools / equipment 2-6 Operated at improper speed

Vehicle 2-7 Other

Use of Protective 3-1 Need for equipment/methods not recognized 3-2Equipment / methods not used 3-3 Incorrect use of equipment or methods

3 Equipment or 3-4Equipment or methods not available 3-5 Guards, warnings or safety devices disabled 3-6Guards, warnings or safety devices removed

Methods 3-7 Other

4-1 Distracted by other concerns 4-2 Inattention to surroundings 4-3 Inappropriate workplace behavior

Lack of Focus or

4 4-4 No warning provided 4-5 Unintentional human error 4-6 Routine activity without thought

Inattention 4-7 Other

5-1 Guards or protective devices not effective 5-2 Defective guards or protective devices 5-3 Incorrect personal protective equipment

5 Protective Systems 5-4 Defective personal protective equipment 5-5 Warning systems not effective 5-6 Defective warning systems

WORKING CONDITIONS

5-7 Safety devices were not effective 5-8 Defective safety devices 5-9 Other

Tools, Plant / 6-1 Plant / equipment malfunction 6-2 Preparation of plant / equipment 6-3 Tool malfunction

6 Equipment & 6-4 Preparation of tools 6-5 Vehicle malfunction 6-6 Preparation of vehicle

Vehicles 6-7 Other

7-1 Fire and explosion 7-2 Noise 7-3 Energized electrical systems

Unanticipated

7 7-4 Energized sources other than electrical 7-5 Temperature extremes 7-6 Hazardous chemicals

Exposure to 7-7 Mechanical hazards 7-8 Storms or acts of nature 7-9 Other

8-1 Congestion 8-2 Illumination 8-3 Ventilation

8 Workplace Layout 8-4 Unprotected height 8-5 Workplace displays 8-6 Other

LIST 2 - COMPREHENSIVE LIST OF SYSTEM CAUSES

9-1 Vision deficiency 9-2 Hearing deficiency 9-3 Other sensory deficiency

9 Physical Capabilities 9-4 Other permanent physical disabilities 9-5 Substance sensitivities or allergies 9-6 Size or strength limitations

9-7 Other

10-1 Previous Injury or illness 10-2 Fatigue 10-3 Diminished performance

10 Physical Condition

PERSONAL FACTORS

10-4 Impairment due to drugs or alcohol 10-5 Other

11-1 Memory failure 11-2 Poor coordination or reaction time 11-3 Emotional status

11 Mental Capability 11-4 Fears or phobias 11-5 Low mechanical aptitude 11-6 Low learning aptitude

11-7 Incorrect judgment 11-8 Other

12-1 Preoccupation with problems 12-2 Frustration 12-3 Confusing directions/demands

12 Mental Stress 12-4 Conflicting directions/demands 12-5 Extreme decision demands 12-6 Unusual concentration/perception demands

12-7 Other emotional overload 12-8 Other

13-1 Antecedent not present 13-2 Antecedent not effective 13-3 Incorrect behavior reinforced

13 Behaviour 13-4 Incorrect behavior not confronted 13-5 Proper behavior not rewarded 13-6 Behavioral analysis process not effective

13-7 Other

Skill Level / 14-1 Skills/competency assessment not effective 14-2 Practice of skill not effective 14-3 No coaching on skill

14

Competency 14-4 Infrequent performance of skill 14-5 Other

Training / Knowledge 15-1 No training provided 15-2 Training effort not effective 15-3 Knowledge transfer not effective

15

Transfer 15-4 Training materials not recalled 15-5 Other

16-1 Behaviors not reinforced 16-2 Participation in safety efforts not effective 16-3 Staffing safety considerations not effective

Management/

16-4 Resourcing for safety not effective 16-5 Support of people not effective 16-6 Monitoring / auditing not effective

16 Supervision/ 16-7 Lessons learned not embedded 16-8 Leadership or accountability 16-9 Employee involvement not effective

Employee leadership 16-10 Risk analysis or tolerance not effective 16-11 Other

17-1 No pre-qualification process 17-2Pre-qualification process not effective 17-3 Use of a non-approved contractor

Contractor Selection

17 17-4 Contractor selection not effective 17-5 No job oversight process 17-6 Job oversight not effective

& Oversight 17-7 Other

18-1Incorrect technical design 18-2 Incorrect standards/specifications/criteria 18-3 Incorrect ergonomic or human factor design

18 Engineering / Design 18-4 Monitoring of construction not effective 18-5Ineffective assessment of readiness 18-6 Monitoring of initial operation not effective

JOB FACTORS

18-7 Technical analysis for risk not effective 18-8 Other

19-1 No planning or risk assessment performed 19-2 Risk assessment not effective 19-3 Required permit not obtained

Control of Work

19 19-4 Specified controls not followed 19-5 Change in job scope 19-6 Worksite not left safe

(CoW) 19-7 Other

Purchasing & 20-1 Incorrect item ordered 20-2 Incorrect item received 20-3 Handling or shipping not effective

20 Material 20-4 Storage of materials not effective 20-5 Labelling of materials not effective 20-6 Other

Handling/Control

21-1 Wrong tools/plant/equipment provided 21-2 Correct tools/plant/equipment not available 21-3 No inspection

Tools & Plant /

21 21-4 Incorrect adjustment/repair/maintenance 21-5Unsuitable items not removed 21-6 No preventative maintenance program

Equipment 21-7 Testing not performed 21-8 Other

Standards / Practices 22-1 Lack of SPP for the task 22-2 Development of SPP not effective 22-3 Communication of SPP not effective

22

/ Procedures (SPP) 22-4 Implementation of SPP not effective 22-5 Enforcement of SPP not effective 22-6 Other

23-1 Ineffective between peers 23-2 Ineffective between supervisor and staff 23-3 Ineffective between different organizations

23 Communication 23-4 Ineffective between work groups 23-5 Ineffective between shifts 23-6 Communication not received

23-7 Incorrect information 23-8 Information not understood 23-9 Other

Revision No.: 01 Effectivity Date: September 15, 2019

Date of Revision: May 31, 2023

You might also like

- Health and Safety Solutions Accident Investigation FormDocument2 pagesHealth and Safety Solutions Accident Investigation Formhussein aliNo ratings yet

- Incident Alert 001 - Incidente Operacional - Mina Islay - Ecosem HuaychaoDocument3 pagesIncident Alert 001 - Incidente Operacional - Mina Islay - Ecosem HuaychaoSEGURIDAD ECOSEM HNo ratings yet

- Near Miss or Incident InvestigationDocument4 pagesNear Miss or Incident InvestigationFahad AhmedNo ratings yet

- Incident - Investigation - Report (Fameco)Document9 pagesIncident - Investigation - Report (Fameco)sandy sandeepNo ratings yet

- APRIL 04Document3 pagesAPRIL 04roland magoNo ratings yet

- Accident and Incident ReportDocument7 pagesAccident and Incident ReportWafrika TechnologiesNo ratings yet

- 1-Accident l Incident Investigation Report FormDocument3 pages1-Accident l Incident Investigation Report Formroland magoNo ratings yet

- SW - Ci - Const - Fillable CsirDocument10 pagesSW - Ci - Const - Fillable CsirJaycee Bareng PagadorNo ratings yet

- Property Damage Incident Report - Sub0Document7 pagesProperty Damage Incident Report - Sub0medleminNo ratings yet

- Incident Investigation Report-LBernacer Car Crash IncidentDocument6 pagesIncident Investigation Report-LBernacer Car Crash IncidentNelz PelaezNo ratings yet

- Incident Report: Please Print Confidential InformationDocument2 pagesIncident Report: Please Print Confidential InformationMuhammad Aulia RahmanNo ratings yet

- HSE-PRO-03-INR 0.3 - Incident ReportDocument2 pagesHSE-PRO-03-INR 0.3 - Incident ReportSoufian BahmadNo ratings yet

- MSP-INR-2024-0369 incident notofication reportDocument2 pagesMSP-INR-2024-0369 incident notofication reportlukmanNo ratings yet

- HSE Incident Report RevDocument2 pagesHSE Incident Report RevBee100% (1)

- Foot Pursuit Report Officer Ruiz FP 2023 - Reginald Clay, Jr.Document1 pageFoot Pursuit Report Officer Ruiz FP 2023 - Reginald Clay, Jr.John KuglerNo ratings yet

- Incident Report FormDocument2 pagesIncident Report FormHamzaNoumanNo ratings yet

- Incident Detail Report HSE-Incident-04-2021Document6 pagesIncident Detail Report HSE-Incident-04-2021fasilNo ratings yet

- 01 - IMS TMT 27 HSE Incident NotificationDocument3 pages01 - IMS TMT 27 HSE Incident NotificationIbrahim EsmatNo ratings yet

- IBSPL-HSE-F01 Accident Notification FormDocument1 pageIBSPL-HSE-F01 Accident Notification FormAbdul RaheemNo ratings yet

- Incident & Accident ReportDocument7 pagesIncident & Accident ReportleganzaNo ratings yet

- HAZARD AND INCIDENT REPORTDocument2 pagesHAZARD AND INCIDENT REPORTAnku Kingsley Etornam100% (1)

- GUT-HSE-FM-05 First Information ReportDocument1 pageGUT-HSE-FM-05 First Information ReportAjith Pillerkatill AntonyNo ratings yet

- Incident FormDocument5 pagesIncident FormMurtadda Mohammed100% (1)

- LUS-HSE-FM4-453-003.01 - Incident Investigation ReportDocument11 pagesLUS-HSE-FM4-453-003.01 - Incident Investigation ReportamalNo ratings yet

- Elegancia Incident ReportDocument3 pagesElegancia Incident ReportFarouk Abd El HalimNo ratings yet

- Accident Incident Report (TLS)Document2 pagesAccident Incident Report (TLS)jonesNo ratings yet

- Accident/Incident Report: Health, Safety and Environmental PlanDocument2 pagesAccident/Incident Report: Health, Safety and Environmental PlanjonesNo ratings yet

- Incident Report Form Final PDFDocument2 pagesIncident Report Form Final PDFMary Jane Gamale100% (1)

- Lamp Sesi 8.2 Investigasi SCATDocument2 pagesLamp Sesi 8.2 Investigasi SCATaab kanayaNo ratings yet

- Incident Notification Report - SAG3 - Personal Injury - Edi Widodo Laceration Right Pinky Finger 15 Jun 23Document3 pagesIncident Notification Report - SAG3 - Personal Injury - Edi Widodo Laceration Right Pinky Finger 15 Jun 23Muhammad Fachrizal SyarifNo ratings yet

- JSP For SS 9013 No. JSP#05 Concrete Breaking Work Using EquipmentDocument10 pagesJSP For SS 9013 No. JSP#05 Concrete Breaking Work Using EquipmentAbdul Rasheed Mangrio50% (2)

- SOR-IFM-Fire Safety-22 Nov. 2020Document1 pageSOR-IFM-Fire Safety-22 Nov. 2020haniNo ratings yet

- Emp Warning NoteDocument1 pageEmp Warning NoteJohn A MerlinoNo ratings yet

- Jha IbfDocument4 pagesJha Ibfgopal kumarNo ratings yet

- Accident and Incident ReportDocument6 pagesAccident and Incident ReportCharles DoriaNo ratings yet

- Purple Innovations Grantsville 2-5-21 - RedactedDocument1 pagePurple Innovations Grantsville 2-5-21 - RedactedAlyssa RobertsNo ratings yet

- Notification of Incident/Hazard: Incident Report Ref: MLE/HSE/IRF/-03Document3 pagesNotification of Incident/Hazard: Incident Report Ref: MLE/HSE/IRF/-03Abdul-kadiri SulleyNo ratings yet

- JSP For SS No. 3 Lifting of Heavy Equipment Using CraneDocument14 pagesJSP For SS No. 3 Lifting of Heavy Equipment Using CranemohammedtofiqahmedNo ratings yet

- Accident, Incident Investigation Report BlankDocument6 pagesAccident, Incident Investigation Report BlankHari NairNo ratings yet

- MSP-IFR-2023-0321 incident final report crane tireDocument3 pagesMSP-IFR-2023-0321 incident final report crane tirelukmanNo ratings yet

- Accident Incident Report (Promat)Document2 pagesAccident Incident Report (Promat)jonesNo ratings yet

- HSE Plan Accident ReportDocument2 pagesHSE Plan Accident ReportjonesNo ratings yet

- Winthrox Laboratories (PVT) Ltd. Ehs DepartmentDocument4 pagesWinthrox Laboratories (PVT) Ltd. Ehs Departmentanoushia alviNo ratings yet

- Dole BQF WairDocument5 pagesDole BQF Wairbeng acosta100% (1)

- Site safety report for Al Shaya cleaning projectDocument1 pageSite safety report for Al Shaya cleaning projecthaniNo ratings yet

- 52 Near Miss Report Form 1903Document3 pages52 Near Miss Report Form 1903SamuelNo ratings yet

- Report & Investigation PencurianDocument3 pagesReport & Investigation PencurianIchsan Yusran MareNo ratings yet

- Injury Incident Report FormDocument3 pagesInjury Incident Report FormDave Joseph Conde100% (1)

- FRM-SLC-001 Safety Incident ReportDocument3 pagesFRM-SLC-001 Safety Incident ReportJNo ratings yet

- Property Damage from Strong WindsDocument2 pagesProperty Damage from Strong WindsjonesNo ratings yet

- ACCIDENT INCIDENT REPORT (Al Omran)Document2 pagesACCIDENT INCIDENT REPORT (Al Omran)jonesNo ratings yet

- Accident Reporting Form - V4Document2 pagesAccident Reporting Form - V4numair khanNo ratings yet

- Accident & Incident Report: and ContractingDocument10 pagesAccident & Incident Report: and ContractingCharles DoriaNo ratings yet

- Accident Incident Investigation FormDocument5 pagesAccident Incident Investigation FormJaine GalvãoNo ratings yet

- Part 1 - Initial Incident Report FormDocument7 pagesPart 1 - Initial Incident Report FormNajeeb HashimNo ratings yet

- accident-incident-investigation-form-for-rtasDocument6 pagesaccident-incident-investigation-form-for-rtasJaine GalvãoNo ratings yet

- FIB-AL-NOY-01-Damage ReportDocument5 pagesFIB-AL-NOY-01-Damage ReportAhsanNo ratings yet

- Accident Near Miss Reporting FormDocument4 pagesAccident Near Miss Reporting FormharryNo ratings yet

- JSP For SS No. 5 Tower Crane InstallationDocument15 pagesJSP For SS No. 5 Tower Crane InstallationmohammedtofiqahmedNo ratings yet

- Disaster Dollars: Financial Preparation and Recovery for Towns, Businesses, Farms, and IndividualsFrom EverandDisaster Dollars: Financial Preparation and Recovery for Towns, Businesses, Farms, and IndividualsNo ratings yet

- FO-SHE-19 Alcohol Test LogDocument1 pageFO-SHE-19 Alcohol Test LogNeil OsenaNo ratings yet

- FO-SHE-17 Pallet Jack Daily Inspection ChecklistDocument1 pageFO-SHE-17 Pallet Jack Daily Inspection ChecklistNeil OsenaNo ratings yet

- How To Analyse IncidentDocument3 pagesHow To Analyse IncidentNeil OsenaNo ratings yet

- FO-SHE-07 Weekly H&H Inspection ChecklistDocument2 pagesFO-SHE-07 Weekly H&H Inspection ChecklistNeil OsenaNo ratings yet

- 004-18 - Forklift HazardsDocument2 pages004-18 - Forklift HazardsNeil OsenaNo ratings yet

- FO-SHE-02 Risk Assessment FormDocument2 pagesFO-SHE-02 Risk Assessment FormNeil OsenaNo ratings yet

- Hermesone Warehouse Layout PDFDocument1 pageHermesone Warehouse Layout PDFNeil OsenaNo ratings yet

- Fire Code of The Philippines 2008Document475 pagesFire Code of The Philippines 2008RISERPHIL89% (28)

- Safety & Health Inspection FormDocument4 pagesSafety & Health Inspection FormNeil OsenaNo ratings yet

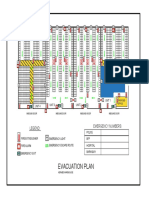

- Evacuation Plan: Legend: Emergency NumbersDocument1 pageEvacuation Plan: Legend: Emergency NumbersNeil OsenaNo ratings yet

- Hermes Warehouse Layout PDFDocument1 pageHermes Warehouse Layout PDFNeil OsenaNo ratings yet

- Identifying Incidents TechniquesDocument1 pageIdentifying Incidents TechniquesNeil OsenaNo ratings yet

- OGP Life-Saving Rules Protect YourselfDocument1 pageOGP Life-Saving Rules Protect YourselfNeil OsenaNo ratings yet

- Warehouse Layout PDFDocument1 pageWarehouse Layout PDFNeil OsenaNo ratings yet

- Fundamentals of Occupational Safety and HealthDocument11 pagesFundamentals of Occupational Safety and HealthSubbu JsrNo ratings yet

- Evacuation Plan: Legend: Emergency NumbersDocument1 pageEvacuation Plan: Legend: Emergency NumbersNeil OsenaNo ratings yet

- Fundamentals of Occupational Safety and HealthDocument11 pagesFundamentals of Occupational Safety and HealthSubbu JsrNo ratings yet

- 042 Practical Problems ... Part 1Document16 pages042 Practical Problems ... Part 1Lowie Torres TonioNo ratings yet

- OGP Life-Saving Rules Protect YourselfDocument1 pageOGP Life-Saving Rules Protect YourselfNeil OsenaNo ratings yet

- OGP Life-Saving Rules Protect YourselfDocument1 pageOGP Life-Saving Rules Protect YourselfNeil OsenaNo ratings yet

- Unit 4 Unit 3 Unit 1: Crossdock AreaDocument1 pageUnit 4 Unit 3 Unit 1: Crossdock AreaNeil OsenaNo ratings yet

- User list of chemistry analyzerDocument1 pageUser list of chemistry analyzerHussain Amir AliNo ratings yet

- CHAP2 Bioavailability of Metals David Jhon LeventhalDocument9 pagesCHAP2 Bioavailability of Metals David Jhon LeventhalCrisThian PaucaNo ratings yet

- English Task "Analytical Exposition": Smoking BansDocument7 pagesEnglish Task "Analytical Exposition": Smoking BansFirda RazaqNo ratings yet

- Medical Equipment List for District HospitalDocument60 pagesMedical Equipment List for District Hospitalramesh100% (1)

- Imagicle Solutions Available On Cisco DcloudDocument4 pagesImagicle Solutions Available On Cisco Dcloudchindi.comNo ratings yet

- Sixth CommandmentDocument26 pagesSixth CommandmentJewel Anne RentumaNo ratings yet

- Service Manual: Side by Side S20B RSB21-A/GDocument16 pagesService Manual: Side by Side S20B RSB21-A/GjicutuNo ratings yet

- SGS-GIS-RFC - Combined Version-A4 - v8 - Mar 16 2018Document3 pagesSGS-GIS-RFC - Combined Version-A4 - v8 - Mar 16 2018Refresh CornerNo ratings yet

- Comp Carlyle Torque PDFDocument125 pagesComp Carlyle Torque PDFjsnavarro1o100% (2)

- Diagnostic Test Science 5Document7 pagesDiagnostic Test Science 5Rex Russel SalemNo ratings yet

- Respiratory Care Anatomy and Physiology 3rd Edition Will Beachey Test BankDocument12 pagesRespiratory Care Anatomy and Physiology 3rd Edition Will Beachey Test BankOcean0% (1)

- Amal ResumeDocument2 pagesAmal ResumeMunaNo ratings yet

- PDFDocument218 pagesPDFRague MiueiNo ratings yet

- New Grad RN Resume ObjectiveDocument5 pagesNew Grad RN Resume Objectiveafjzcgeoylbkku100% (2)

- Connectwell Price List 2018 - W.E.F. 20.06.2018 PDFDocument110 pagesConnectwell Price List 2018 - W.E.F. 20.06.2018 PDFArun KumarNo ratings yet

- Literature Review Sustainable DevelopmentDocument5 pagesLiterature Review Sustainable DevelopmentJade NelsonNo ratings yet

- De Thi Thu Vao 10 Mon Tieng Anh Quan Dong Da Ha NoiDocument5 pagesDe Thi Thu Vao 10 Mon Tieng Anh Quan Dong Da Ha NoiTrang VuongNo ratings yet

- A Review of Bempedoic Acid - A New Drug For Old ProblemDocument6 pagesA Review of Bempedoic Acid - A New Drug For Old ProblemVõ Ngọc Bích VânNo ratings yet

- NCM 120Document5 pagesNCM 120Tiffany AdriasNo ratings yet

- Water Hardness Case StudyDocument15 pagesWater Hardness Case StudyTaima GhNo ratings yet

- Multiple Reactions Assignment Problems 2 To 5Document2 pagesMultiple Reactions Assignment Problems 2 To 5DechenPemaNo ratings yet

- Divine Intervention Episode 5 Cardio A Physiology1Document18 pagesDivine Intervention Episode 5 Cardio A Physiology1Swisskelly1No ratings yet

- 1st Dec'09 - DPRDocument325 pages1st Dec'09 - DPRasad8111No ratings yet

- Condensate Drain Calculation - Lab AHU PDFDocument1 pageCondensate Drain Calculation - Lab AHU PDFAltaf KhanNo ratings yet

- Nanostrength Block Copolymers For Epoxy TougheningDocument5 pagesNanostrength Block Copolymers For Epoxy TougheningRonald GeorgeNo ratings yet

- Sage Yb October2015Document460 pagesSage Yb October2015olopNo ratings yet

- The Declaration of Alma-Ata at 40Document19 pagesThe Declaration of Alma-Ata at 40Nicole MedinaNo ratings yet

- Predictor PlatesDocument40 pagesPredictor PlatesrambabuNo ratings yet

- Solid Phase ExtractionDocument16 pagesSolid Phase ExtractionDAVID VELEZNo ratings yet

- General Catalogue 2019: UNIOR D.DDocument401 pagesGeneral Catalogue 2019: UNIOR D.DjinpoeNo ratings yet