Professional Documents

Culture Documents

Saic A 1001

Uploaded by

pradeepthalava97Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic A 1001

Uploaded by

pradeepthalava97Copyright:

Available Formats

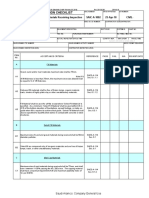

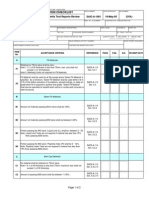

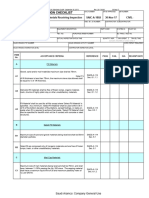

#

SAUDI ARAMCO ID/PIEU-31-Dec-2020 - REV.2020.12.00 (Standards Cutoff - Dec 31,2020) Rev 62 31-Dec-20

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 31-Jan-21 CIVIL-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A Laboratory Testing

The Contractor's quality control testing requirements shall be performed

by either Saudi Aramco-approved independent testing agency or by the SAES A-114

A1

Contractor's own laboratory, approved by Saudi Aramco Inspection Section 5.1.1

Department

The laboratory's Quality Personnel assigned to the Work must be

technically competent to perform their duties and shall have a Schedule "Q"

A2

recommendation for approval from Saudi Aramco to perform applicable Section 5.5

Tests.

Tests are performed in accordance to applicable Standards in the Schedule "Q"

A3

presence of Contractor and Saudi Aramco Representatives. Section 1.4

Gradation, density and moisture content control test are performed at the

following frequencies: one standard sieve analysis (ASTM C 136, ASTM

SAES-A-114

A4 D 422 or ASTM D 1140) and one Modified Proctor Test per ASTM D 1557

Sec. 6.4.1.1

with corresponding Proctor curve for each type of fill material or where

there is a change in the type or source of the material.

For cohesionless free draining soils, ASTM D4253 Maximum Index

Density and Unit Weight of Soils Using a Vibratory Table and ASTM D SAES-A-114

A5

4254 Minimum Index Density and Unit Weight of Soil & Calculation of Sec. 6.4.1.1

Relative Density shall also be performed.

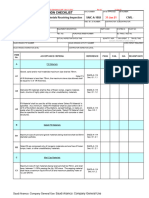

B Fill Materials

SAES-A-114

B1 Fill materials shall consist of gravel, sand and/or marl.

Sec. 6.1.1.1

The maximum size of fill materials shall be one-half (½ ) the lift thickness SAES-A-114

B2

or 75mm (3 inches), whichever is less. Sec. 6.1.1.1

C Select Fill Materials

SAES-A-114

C1 The amount of material passing the 50mm sieve shall be 100%.

Sec. 6.1.2.1

The amount of material passing the No. 200 sieve shall be between 0- SAES-A-114

C2

20%. Sec. 6.1.2.1

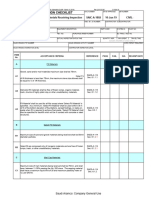

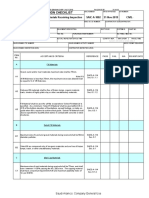

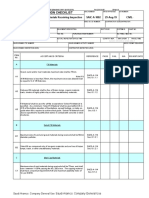

Saudi Aramco: Company General Use

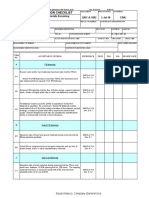

# Saudi Aramco: Company General Use

#

The portion of the material passing the No. 40 sieve shall have a

maximum Liquid Limit (LL) of 35 and Plasticity Index of 12 as per ASTM D

4318.

SAES-A-114

C3

Sec. 6.1.2.2

Note: Liquid Limit and plastic limit tests are not required if material has

less than 15% passing the No.200 sieve.

The maximum size of fill materials shall be one-half (½ ) the lift thickness SAES-A-114

D1

or 75mm, whichever is less. Sec. 6.1.1.1

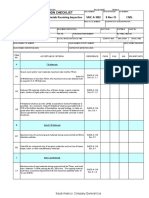

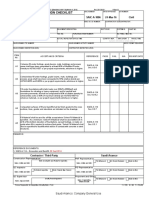

REMARKS:

REFERENCE DOCUMENTS:

1- SAES-A-114 - Excavation and Backfill, 18 April 2019

2- Schedule Q -

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

# Saudi Aramco: Company General Use

You might also like

- Saudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 31-Nov-2019 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 31-Nov-2019 CivilyazNo ratings yet

- Saic A 1001Document2 pagesSaic A 1001Son AbanadorNo ratings yet

- Saic A 1001Document3 pagesSaic A 1001Ansar Ali VemmullyNo ratings yet

- Saic A 1001Document3 pagesSaic A 1001Rauf ChaudharyNo ratings yet

- Saic A 1001Document3 pagesSaic A 1001QCI MYOUSIFNo ratings yet

- Saic A 1001Document3 pagesSaic A 1001ansar aliNo ratings yet

- Saudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 8-Nov-15 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 8-Nov-15 CivilAhsaan MughalNo ratings yet

- Saudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 24-Mar-16 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 24-Mar-16 CivilSajid ShaikhNo ratings yet

- Saic A 1001Document3 pagesSaic A 1001Tayyab KhanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistZia ur RehmanNo ratings yet

- Saudi Aramco Inspection Checklist: South Ghawar UR - Early Works 10-14331 AM Tamimi Partners CoDocument2 pagesSaudi Aramco Inspection Checklist: South Ghawar UR - Early Works 10-14331 AM Tamimi Partners CoMuhammadNo ratings yet

- Saic A 1001Document3 pagesSaic A 1001Shazab NawazNo ratings yet

- Saic A 1002Document2 pagesSaic A 1002Sajid ShaikhNo ratings yet

- Saic A 1002Document2 pagesSaic A 1002Rauf ChaudharyNo ratings yet

- Saic A 1002Document2 pagesSaic A 1002pradeepthalava97No ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistAhsaan MughalNo ratings yet

- Saic A 1002Document2 pagesSaic A 1002ansar aliNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistJeffrey Lipata Jr.No ratings yet

- Saic A 1001Document2 pagesSaic A 1001Hussain Nasser Al- NowiesserNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005Hussain Nasser Al- Nowiesser0% (1)

- Saic A 1002Document2 pagesSaic A 1002Son AbanadorNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistyazNo ratings yet

- Saic A 1002Document2 pagesSaic A 1002munibbarcaNo ratings yet

- Saic A 1002Document2 pagesSaic A 1002mohammadNo ratings yet

- SAIC-A-1002 Fill, Select-Fill and Marl Cap Materials Receiving InspectionDocument2 pagesSAIC-A-1002 Fill, Select-Fill and Marl Cap Materials Receiving InspectionhussniosmanNo ratings yet

- Saic A 1005.Document5 pagesSaic A 1005.Fazal HaqNo ratings yet

- Saudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 30-Apr-13 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 30-Apr-13 CivilJeffrey Lipata Jr.No ratings yet

- SAIC A 1005 Compaction TestingDocument2 pagesSAIC A 1005 Compaction TestingwalidNo ratings yet

- Saudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 1-Nov-09 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 1-Nov-09 CivilNaushad AlamNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005Ansar Ali VemmullyNo ratings yet

- SAIC-Q-1036 Raw Materials Sampling, Testing & Asphalt Mix Design ReviewDocument8 pagesSAIC-Q-1036 Raw Materials Sampling, Testing & Asphalt Mix Design ReviewAbdul HannanNo ratings yet

- Saic A 1002Document2 pagesSaic A 1002karthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 30-Apr-17 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 30-Apr-17 Civilkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistMuhammadNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005Rauf ChaudharyNo ratings yet

- SAIC-Q-1036 Raw Materials Sampling, Testing & Asphalt Mix Design ReviewDocument7 pagesSAIC-Q-1036 Raw Materials Sampling, Testing & Asphalt Mix Design ReviewAbdul HannanNo ratings yet

- SAIC A 1005 Compaction TestDocument3 pagesSAIC A 1005 Compaction TestAbdul HannanNo ratings yet

- Saic A 1005Document3 pagesSaic A 1005Naushad AlamNo ratings yet

- Saic A 1006Document1 pageSaic A 1006munibbarcaNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005pradeepthalava97No ratings yet

- Saic A 1005Document2 pagesSaic A 1005Niel TanedoNo ratings yet

- Saic A 1005.Document3 pagesSaic A 1005.Shazab NawazNo ratings yet

- Saic A 1005Document3 pagesSaic A 1005mohammadNo ratings yet

- Saic A 1006Document1 pageSaic A 1006Niel TanedoNo ratings yet

- Saic A 1006Document1 pageSaic A 1006Saragadam DilsriNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005munibbarcaNo ratings yet

- Saic-A-1005 Compaction TestingDocument2 pagesSaic-A-1005 Compaction TestingZia ur RehmanNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005Afzal HussainNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistJagdishNo ratings yet

- Saudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 31-Nov-2019 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 31-Nov-2019 CivilyazNo ratings yet

- Saic A 1011Document4 pagesSaic A 1011Naushad AlamNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005Son AbanadorNo ratings yet

- Saic H 2024Document2 pagesSaic H 2024usmanNo ratings yet

- Saic A 1011Document4 pagesSaic A 1011jerinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- SAIC-S-1001 Rev 8 (Final) Clean Sand and Aggregate Base Course Sampling, Testing - Review of Test Reports FinalDocument2 pagesSAIC-S-1001 Rev 8 (Final) Clean Sand and Aggregate Base Course Sampling, Testing - Review of Test Reports FinalGOSP3 QC MechanicalNo ratings yet

- Saic A 1011Document4 pagesSaic A 1011mohammadNo ratings yet

- SAIC-A-1006 - Final Fill InspectionDocument1 pageSAIC-A-1006 - Final Fill InspectionwalidNo ratings yet

- A A A A A A: Saudi Aramco Inspection ChecklistDocument2 pagesA A A A A A: Saudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Airman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BFrom EverandAirman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BNo ratings yet

- Daily Tracking Sheet - PCPL G1 - 08 Aug 23Document4 pagesDaily Tracking Sheet - PCPL G1 - 08 Aug 23ali burhanNo ratings yet

- DLFDocument58 pagesDLFgsingh_105No ratings yet

- AISE Anchor Bolt Details PDFDocument1 pageAISE Anchor Bolt Details PDFYash PaulNo ratings yet

- Group 5 - Construction Methods and Operations-1Document6 pagesGroup 5 - Construction Methods and Operations-1Donna Cece MelgarNo ratings yet

- Metal Comany Products DiscreptionDocument22 pagesMetal Comany Products DiscreptionAjinkya BhujbalNo ratings yet

- Plinth Area For Rough Cost Est TN Pwd. 2021-2022Document15 pagesPlinth Area For Rough Cost Est TN Pwd. 2021-2022Golden KingNo ratings yet

- 334.3R-05 Construction of Concrete Shells Using Inflated FormsDocument13 pages334.3R-05 Construction of Concrete Shells Using Inflated FormsYaser ShabasyNo ratings yet

- Action Plan in Brigada Eskwela: Jamoyaon Elementary SchoolDocument2 pagesAction Plan in Brigada Eskwela: Jamoyaon Elementary SchoolResa Consigna Magusara100% (2)

- Performance of RFP Wrapped RC Column Under Combined Axial Flexural LoadingDocument10 pagesPerformance of RFP Wrapped RC Column Under Combined Axial Flexural LoadingCu ToànNo ratings yet

- Perfil de Riel 115 AremaDocument1 pagePerfil de Riel 115 AremaJorge Cruz RodriguezNo ratings yet

- Critical Regionalism - 1Document26 pagesCritical Regionalism - 1NikhilNo ratings yet

- Cold Formed Steel SectionsDocument37 pagesCold Formed Steel SectionsurhenNo ratings yet

- AZURINSULATIONDocument20 pagesAZURINSULATIONtitaNo ratings yet

- Product Summary Guide: Constructive SolutionsDocument17 pagesProduct Summary Guide: Constructive SolutionsShridhar VaidyaNo ratings yet

- BSW - Whitworth Thread Chart - British MetricsDocument1 pageBSW - Whitworth Thread Chart - British Metricsdeni pedroNo ratings yet

- Foundation Plan For StorageDocument4 pagesFoundation Plan For StoragePia LagmanNo ratings yet

- 4 Common Types of Construction ContractsDocument12 pages4 Common Types of Construction Contractsharshit sorthiyaNo ratings yet

- Andrew Mayne - RazorwireDocument12 pagesAndrew Mayne - RazorwireChristophe BenhaimNo ratings yet

- Dremel TrioDocument56 pagesDremel TrioSean Mclaren100% (1)

- Facade Issues - GRC ScreenDocument12 pagesFacade Issues - GRC Screenmohamed rafiNo ratings yet

- Hassan FathyDocument11 pagesHassan FathySheshu KNo ratings yet

- Concrete Pavements in Germany Eurotour92-6Document18 pagesConcrete Pavements in Germany Eurotour92-6جميل عبد الله الحماطيNo ratings yet

- FoundationsDocument23 pagesFoundationsAyaz ShaikhNo ratings yet

- Kode Uraian Satuan Harga Satuan (RP.)Document1 pageKode Uraian Satuan Harga Satuan (RP.)saepul mgNo ratings yet

- Preferred Practices For Steel Bridge Design, Fabrication, and ErectionDocument64 pagesPreferred Practices For Steel Bridge Design, Fabrication, and ErectionmojgfdNo ratings yet

- C823-3-DOC-PRQ-CIV-016 - Pre-Qualification For Ms REDCO For GRC WorksDocument202 pagesC823-3-DOC-PRQ-CIV-016 - Pre-Qualification For Ms REDCO For GRC Works721917114 47No ratings yet

- Boq National Library Timor LesteDocument24 pagesBoq National Library Timor Lestekrisna kingNo ratings yet

- 1735 - 1737 - 1745 - Barral VaultDocument15 pages1735 - 1737 - 1745 - Barral VaultPriya ChauhanNo ratings yet

- 1867772461CBF SHADING DEVICES - Compressed PDFDocument14 pages1867772461CBF SHADING DEVICES - Compressed PDFAagney Alex RobinNo ratings yet

- Project List 2020 (En)Document12 pagesProject List 2020 (En)Arun SasiNo ratings yet