Professional Documents

Culture Documents

Saic A 1005

Uploaded by

pradeepthalava97Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic A 1005

Uploaded by

pradeepthalava97Copyright:

Available Formats

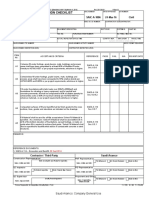

#

SAUDI ARAMCO ID/PIEU-31-Dec-2020 - REV.2020.12.00 (Standards Cutoff - Dec 31,2020) Rev 62 31-Dec-20

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Compaction Testing SAIC-A-1005 31-Jan-21 CIVIL-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Note: To verify that the area/ material being inspected was tested by SA

approved third party testing agency, the test results attached with this RFI

shall be verified by the relevant PID inspection unit if copy of the test

results had been received directly from the third party lab. If not available

in the PID Inspection Unit, the inspector shall contact the third party

laboratory representative and request for an explanation. If the

explanation is not reasonable, NCR shall be issued to the third party lab

through the Batch Plant and Civil Testing Group.

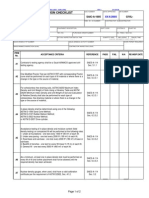

Contractor's testing agency shall be a Saudi ARAMCO-approved SAES-A-114

A1

independent civil testing agency. Sec. 5.1.1

One Modified Proctor Test per ASTM D1557 with corresponding Proctor

SAES-A-114

A2 curve shall be performed for each type of fill material or where there is a

Sec. 6.4.1.1

change in the type or the source of material.

For cohesionless free draining soils, ASTM D4253 Maximum Index

Density and Unit Weight of Soils Using a Vibratory Table and ASTM

D4254 Minimum Index Density and Unit Weight of Soil and Calculation of SAES-A-114

A3

Relative Density shall also be performed for each type of cohesionless, Sec. 6.4.1.1

free draining material or where there is a change in the type or the source

of material..

In-place density shall be determined using one of the following:

ASTM D-1556 Sand Cone Method;

SAES-A-114

A4 ASTM D-2167 Rubber Balloon Method;

Sec. 6.4.2.1

ASTM D-6938 Nuclear Method;

or ASTM D-2937 Drive-cylinder.

Acceptance testing of in-place density and moisture content (field density

testing) on compacted fill will be performed at the following rates:

1. Under all foundations - one test every 1077 ft² (100 m²) of each lift.

2. Under area paving - one test every 2153 ft² (200 m²) of each lift. SAES-A-114

A5

3. Road base and sub-base - one test every 2153 ft² (200 m²) of base or Sec. 6.4.2.3

sub-base.

4. Backfill of trenches - one test for every 50 linear ft (15 m) of each lift.

5. General fill - one test every 5382 ft² (500 m²) of each lift.

As a minimum, at least one in-place density test must be performed on

SAES-A-114

A6 every lift of fill and further placement shall not be allowed until the required

Sec. 6.4.2.4

density has been achieved.

Nuclear density gauges, when used, shall have a valid calibration SAES-A-114

A7

certificate per the requirement of ASTM D6938, Sec. 8. Sec. 3.2

Saudi Aramco: Company General Use

# Saudi Aramco: Company General Use

#

Fill or backfill placed beneath footings, grade beams, mats, buildings or

SAES-A-114

A8 process areas shall be compacted to at least 90% of the maximum

Sec. 6.3.6.1

Modified Proctor density as determined by ASTM D1557.

For cohesionless free draining soils, 70% relative density as determined

SAES-A-114

A9 by ASTM D4253 and ASTM D4254 shall be achieved under footings,

Sec. 6.3.6.4

grade beams, mats, buildings or process areas.

Under foundations with static loads over 320kPa and foundations for

vibrating or heavy machinery and pavements, 85% of relative density SAES-A-114

A10

(ASTM D4253/ASTM D4254) for cohesionless soils or 95% of of the Sec. 6.3.6.2

maximum density as determined by ASTM D1557 for cohesive materials.

When the backfill material cannot clearly be classified as cohesive or

SAES-A-114

A11 cohesionless both relative density and Proctor density tests must be

Sec. 6.4.1.1

performed. The backfill shall then be compacted to the greater density.

The compaction requirement for base coarse shall not be less than(98%

SAES-Q-006

A12 for the base and 95% for the subbase)of the maximum laboratory dry

Sec. 5.2.2.2

density as determined by ASTM D1557 or AASHTO T180..

The compaction requirement for subbase shall not be less than 95% of

SAES-Q-006

A13 the maximum laboratory dry density as determined by ASTM D1557 or

Sec. 5.2.2.2

AASHTO T180..

Compacted surfaces of fill and backfill shall be finish graded to the cross SAES-A-114

A14

sections, lines, grades, and elevations as indicated on the drawings. Sec. 6.3.7

The depth of the test holes shall be no greater than 300mm (12 inches) SAES-A-114

A15

deep. (ASTM D 2922, Sec. 1.1) Sec. 6.4.2

REMARKS:

REFERENCE DOCUMENTS:

1- SAES-A-114 -- Excavation and Backfill, 18 April , 2019

2- SAES-Q-006 -- Asphalt Concrete Pavement,18 February 2018

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

# Saudi Aramco: Company General Use

You might also like

- Saic A 1005Document2 pagesSaic A 1005munibbarcaNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005Niel TanedoNo ratings yet

- Saudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 31-Nov-2019 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 31-Nov-2019 CivilyazNo ratings yet

- Saic A 1005Document3 pagesSaic A 1005Naushad AlamNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005Son AbanadorNo ratings yet

- Saic A 1005Document3 pagesSaic A 1005mohammadNo ratings yet

- SAUDI ARAMCO COMPACTION INSPECTION CHECKLISTDocument3 pagesSAUDI ARAMCO COMPACTION INSPECTION CHECKLISTkarthi51289No ratings yet

- Saic A 1005Document2 pagesSaic A 1005Rauf ChaudharyNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005Ansar Ali VemmullyNo ratings yet

- Saic-A-1005 Compaction TestingDocument2 pagesSaic-A-1005 Compaction TestingZia ur RehmanNo ratings yet

- SAIC A 1005 Compaction TestDocument3 pagesSAIC A 1005 Compaction TestAbdul HannanNo ratings yet

- Saic A 1005.Document5 pagesSaic A 1005.Fazal HaqNo ratings yet

- Saudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 1-Nov-09 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 1-Nov-09 CivilNaushad AlamNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistMuhammadNo ratings yet

- Saudi Aramco Compaction Testing ChecklistDocument3 pagesSaudi Aramco Compaction Testing ChecklistJeffrey Lipata Jr.No ratings yet

- Saudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 29-Jun-17Document2 pagesSaudi Aramco Inspection Checklist: Compaction Testing SAIC-A-1005 29-Jun-17Zia ur RehmanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistJagdishNo ratings yet

- Compaction Testing Inspection ChecklistDocument3 pagesCompaction Testing Inspection ChecklistShazab NawazNo ratings yet

- SAIC A 1005 Compaction TestingDocument2 pagesSAIC A 1005 Compaction TestingwalidNo ratings yet

- SAUDI ARAMCO FILL PLACEMENT INSPECTION CHECKLISTDocument2 pagesSAUDI ARAMCO FILL PLACEMENT INSPECTION CHECKLISTyazNo ratings yet

- Saic A 1004Document2 pagesSaic A 1004usmanNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005Afzal HussainNo ratings yet

- Saic A 1004Document2 pagesSaic A 1004Son AbanadorNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005Hussain Nasser Al- Nowiesser0% (1)

- Saudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 8-Nov-15 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 8-Nov-15 CivilAhsaan MughalNo ratings yet

- Saic A 1001Document3 pagesSaic A 1001Ansar Ali VemmullyNo ratings yet

- Saudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 8-Nov-15 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 8-Nov-15 CivilAhsaan MughalNo ratings yet

- Saic A 1004Document2 pagesSaic A 1004pradeepthalava97No ratings yet

- Saudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 30-Apr-13 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 30-Apr-13 CivilJeffrey Lipata Jr.No ratings yet

- Saic A 1004Document3 pagesSaic A 1004Ansar Ali VemmullyNo ratings yet

- Saic A 1004Document2 pagesSaic A 1004Hussain Nasser Al- Nowiesser0% (1)

- Saic A 1004Document3 pagesSaic A 1004Rauf ChaudharyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistZia ur RehmanNo ratings yet

- Saudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 30-Apr-17 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Fill Placement and Compaction Inspection SAIC-A-1004 30-Apr-17 Civilkarthi51289No ratings yet

- Saic A 1001Document3 pagesSaic A 1001Rauf ChaudharyNo ratings yet

- Saudi Aramco: Soil Sampling ChecklistDocument2 pagesSaudi Aramco: Soil Sampling ChecklistyazNo ratings yet

- Saic A 1004Document3 pagesSaic A 1004Saragadam DilsriNo ratings yet

- Saudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 24-Mar-16 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 24-Mar-16 CivilSajid ShaikhNo ratings yet

- SAUDI ARAMCO SOIL TESTING CHECKLISTDocument2 pagesSAUDI ARAMCO SOIL TESTING CHECKLISTMuhammadNo ratings yet

- Saic A 1001Document2 pagesSaic A 1001pradeepthalava97No ratings yet

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Document3 pagesSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Abdul HannanNo ratings yet

- Saic A 1001Document3 pagesSaic A 1001Shazab NawazNo ratings yet

- Saic A 1001Document3 pagesSaic A 1001QCI MYOUSIFNo ratings yet

- Quality control of foamed stabilized materialsDocument3 pagesQuality control of foamed stabilized materialsWaleed MedhatNo ratings yet

- Saic A 1001Document3 pagesSaic A 1001ansar aliNo ratings yet

- Saudi Aramco Soil Sampling ChecklistDocument3 pagesSaudi Aramco Soil Sampling ChecklistTayyab KhanNo ratings yet

- Saic A 1006Document1 pageSaic A 1006Saragadam DilsriNo ratings yet

- Refractory Installation Qualification ChecklistDocument3 pagesRefractory Installation Qualification ChecklistSUNIL RAJPUTNo ratings yet

- Saic Q 1011Document2 pagesSaic Q 1011Hussain Nasser Al- NowiesserNo ratings yet

- Saic A 1006Document1 pageSaic A 1006munibbarcaNo ratings yet

- SAIC-Q-1036 Raw Materials Sampling, Testing & Asphalt Mix Design ReviewDocument7 pagesSAIC-Q-1036 Raw Materials Sampling, Testing & Asphalt Mix Design ReviewAbdul HannanNo ratings yet

- SAIC-A-1005 Rev 3 Compaction TestingDocument2 pagesSAIC-A-1005 Rev 3 Compaction Testingimrankhan22No ratings yet

- Saudi Aramco Inspection Checklist: Geotechnical Field Works Inspection SAIC-A-1008 30-Nov-17 CivilDocument4 pagesSaudi Aramco Inspection Checklist: Geotechnical Field Works Inspection SAIC-A-1008 30-Nov-17 CivilMD SHARIQUENo ratings yet

- Saic A 1001Document2 pagesSaic A 1001Son AbanadorNo ratings yet

- SAUDI ARAMCO INSPECTION CHECKLISTDocument1 pageSAUDI ARAMCO INSPECTION CHECKLISTJagdishNo ratings yet

- Saic A 1006Document1 pageSaic A 1006QCI MYOUSIFNo ratings yet

- SAICbDocument2 pagesSAICbAfzal HussainNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistMainuddin AliNo ratings yet

- SAIC-Q-1036 Raw Materials Sampling, Testing & Asphalt Mix Design ReviewDocument8 pagesSAIC-Q-1036 Raw Materials Sampling, Testing & Asphalt Mix Design ReviewAbdul HannanNo ratings yet

- Nissan Magnite - Mobile BrochureDocument18 pagesNissan Magnite - Mobile BrochureAnoop KavirajanNo ratings yet

- Irc Gov in 079 2019Document24 pagesIrc Gov in 079 2019ARAVIND PATILNo ratings yet

- Road Section Analysis: KSBP Park to CSIBER CollegeDocument7 pagesRoad Section Analysis: KSBP Park to CSIBER CollegeØmkär PowarNo ratings yet

- Highway Engineering Drainage and Slope ProtectionDocument3 pagesHighway Engineering Drainage and Slope ProtectionscrNo ratings yet

- Manitou MT 14 18 (EN)Document16 pagesManitou MT 14 18 (EN)Manitou100% (3)

- Nebraska Pavement Maintenance ManualDocument72 pagesNebraska Pavement Maintenance ManualAlya SalmasariNo ratings yet

- DC Bike Law Pocket Guide Jan2014Document36 pagesDC Bike Law Pocket Guide Jan2014wabadcNo ratings yet

- Irc 6 2010Document82 pagesIrc 6 2010suvraNo ratings yet

- How to Display Registration Numbers on Motor VehiclesDocument2 pagesHow to Display Registration Numbers on Motor VehiclesSudheepNo ratings yet

- Brickell Citycentre Legal Description Development Agreement Design Guidelines Regulating PlanDocument102 pagesBrickell Citycentre Legal Description Development Agreement Design Guidelines Regulating Planthe next miamiNo ratings yet

- Overview of HDM-4: Volume OneDocument53 pagesOverview of HDM-4: Volume Oneattiori fabriceNo ratings yet

- Temporary Traffic Management Manual-Abu DhabiDocument176 pagesTemporary Traffic Management Manual-Abu DhabiyasirNo ratings yet

- Equivalent Single Axle Load - Pavement InteractiveDocument6 pagesEquivalent Single Axle Load - Pavement InteractiveClaire RuizNo ratings yet

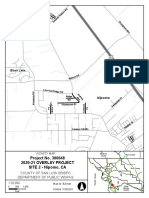

- Vicinity MapsDocument2 pagesVicinity MapsKatherine WorshamNo ratings yet

- Mini Project On Entrepreneur of T. v. Sundaram IyengarDocument25 pagesMini Project On Entrepreneur of T. v. Sundaram IyengarHarikrishna Malla100% (1)

- Bike Battles: A History of Sharing The American RoadDocument34 pagesBike Battles: A History of Sharing The American RoadUniversity of Washington PressNo ratings yet

- Modes of Transport in IndiaDocument18 pagesModes of Transport in IndiaJinny SebastianNo ratings yet

- Camping Information KarrathaDocument2 pagesCamping Information Karratha2tqchnw8j9No ratings yet

- Audi Q7 PDFDocument2 pagesAudi Q7 PDFMuguthanNo ratings yet

- 34-BMW F10 EmfDocument9 pages34-BMW F10 EmfJJ H FalconNo ratings yet

- Pavement Management System Text BookDocument44 pagesPavement Management System Text BookGoutham AthemNo ratings yet

- Talegaon Dabhade DpproposalDocument108 pagesTalegaon Dabhade DpproposalHemant Chandravanshi92% (12)

- Volume 3 - Tech Schedules - Dwarka Exp - PAC-3NH-248BBDocument50 pagesVolume 3 - Tech Schedules - Dwarka Exp - PAC-3NH-248BBPradeep KaplaNo ratings yet

- Benjamin Button curso de colisiónDocument3 pagesBenjamin Button curso de colisiónmonica rojas100% (1)

- Boomer's Legacy: IslandGals - Ca Volume 2 Issue 2Document2 pagesBoomer's Legacy: IslandGals - Ca Volume 2 Issue 2Pieter VorsterNo ratings yet

- Omm ForkliftDocument151 pagesOmm Forkliftlittle khansa100% (1)

- PTV Vision Traffic Suite Innovation - 2018Document42 pagesPTV Vision Traffic Suite Innovation - 2018Saduddin NsNo ratings yet

- Concrete Equipment CatalogueDocument117 pagesConcrete Equipment Cataloguetata_77No ratings yet

- Pavement Design Kiran BiradarDocument18 pagesPavement Design Kiran BiradarSudipto PaulNo ratings yet

- DP Report 1Document263 pagesDP Report 1Satyaja InfratechNo ratings yet