Professional Documents

Culture Documents

Api 579 FFS PTR 4 & 5

Api 579 FFS PTR 4 & 5

Uploaded by

RAJNIKANT KAUSHIK0 ratings0% found this document useful (0 votes)

3 views1 pageThis document summarizes key points from API 579 Fitness for Service and ASME B31.3 training in Dammam, Saudi Arabia from December 17-21, 2005. [1] Fitness for brittle fracture assessment is required if the carbon equivalent or service/environment changes. [2] Figure II outlines general metal loss assessment. [3] Figure IIIA details local metal loss assessment. [4] Groove flaws can be analyzed as local thinning or cracks per Figure IIIB. [5] Laminations are acceptable if criteria are met.

Original Description:

Api579

Original Title

API_579_FFS_PTR_4_&_5

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes key points from API 579 Fitness for Service and ASME B31.3 training in Dammam, Saudi Arabia from December 17-21, 2005. [1] Fitness for brittle fracture assessment is required if the carbon equivalent or service/environment changes. [2] Figure II outlines general metal loss assessment. [3] Figure IIIA details local metal loss assessment. [4] Groove flaws can be analyzed as local thinning or cracks per Figure IIIB. [5] Laminations are acceptable if criteria are met.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views1 pageApi 579 FFS PTR 4 & 5

Api 579 FFS PTR 4 & 5

Uploaded by

RAJNIKANT KAUSHIKThis document summarizes key points from API 579 Fitness for Service and ASME B31.3 training in Dammam, Saudi Arabia from December 17-21, 2005. [1] Fitness for brittle fracture assessment is required if the carbon equivalent or service/environment changes. [2] Figure II outlines general metal loss assessment. [3] Figure IIIA details local metal loss assessment. [4] Groove flaws can be analyzed as local thinning or cracks per Figure IIIB. [5] Laminations are acceptable if criteria are met.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 1

Professional Training and Consultation

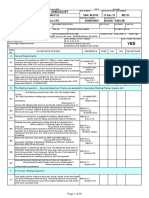

API 579 Fitness for Piping & ASME B31.3

17th upto 21st December 2005, Dammam, Saudi Arabia

API 579 Fitness for Service

Points to Recall (Day 4 & 5)

1. Whenever there is reduction in CET due to change of service

or change of environment (say new location), Fitness for

brittle fracture shall be performed as per Figure I.

2. For General metal loss assessment follow Figure II.

3. Local metal loss assessment shall be performed as per

assessment procedure of Fig. – III A.

4. Groove – like flaw can be analysed as locally thin area or as

per crack – like flaw according to Fig. – III - B

5. Laminations within pipe wall thickness are acceptable if.

a. component is not operating in hydrogen charging

service.

b. Distance from the edge of lamination to a major

structure discontinuity is greater than or equal to 1.8

tnom. (tnom is actual wall thickness)

6. Weld mis-alignment shall be cheeked whether it is within

tolerances of Original Code.

7. Crack – like flaw shall be analysed as given in Figure – IV.

8. For Fire damage, there are various zones of fire exposure

(Zones 1 to 6). In Level 1 Analysis Zones 1 to 4 are included

and shall be assessed as per table.

9. The benefits of API 579 include.

1. Reliable and safe operation of piping.

2. Possibility of break-down and damage is reduced.

3. Possible life extension of equipment and piping.

4. Overall Economics of plant operation will improve.

------------ End ------------

8th Floor, Al-Subeaei Towers, King Abdulaziz cor. Prince Faisal Bin Fahd Streets, Al-Khobar, Saudi Arabia 1

● TEL (966) 3 887 6633 ● FAX (966) 3 887 6565 ● info@gotoitc.com ● www.gotoitc.com

You might also like

- MEI - Aluminium MIG WeldDocument56 pagesMEI - Aluminium MIG WeldSaravana Kumar100% (1)

- Marriot Grand Ballroom Concrete Works: Project Title: Contract Package No. 02Document9 pagesMarriot Grand Ballroom Concrete Works: Project Title: Contract Package No. 02Imho TepNo ratings yet

- Astm A780Document4 pagesAstm A780Raúl Venegas Munita100% (5)

- Hkie Paper 2020Document24 pagesHkie Paper 2020Sol TianNo ratings yet

- SB 1289a NavajoDocument7 pagesSB 1289a NavajoDiego LlNo ratings yet

- Exxon IP 10-10-2 General Purpose Gear UnitsDocument3 pagesExxon IP 10-10-2 General Purpose Gear UnitsGilvan SilvaNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Final Exam (Closed) : Professional Training and ConsultationDocument12 pagesFinal Exam (Closed) : Professional Training and ConsultationGeorge KudiaborNo ratings yet

- Painting SpecificationDocument40 pagesPainting SpecificationIkram Syed100% (4)

- Ford ABS Plating Spec.Document7 pagesFord ABS Plating Spec.Pieter100% (2)

- 1 API 653 Memories Sept 2012Document20 pages1 API 653 Memories Sept 2012majid100% (1)

- Bench - Mark Ouiz: ASME B 31.3 Process PipingDocument4 pagesBench - Mark Ouiz: ASME B 31.3 Process PipingMichael AlbuquerqueNo ratings yet

- SAIC M 2012 (Structural Welding)Document30 pagesSAIC M 2012 (Structural Welding)rubda11100% (1)

- GP 03 19 01Document12 pagesGP 03 19 01Anonymous fvO1W3100% (2)

- Permanent FormworkDocument13 pagesPermanent FormworkjimmydomingojrNo ratings yet

- BOQ (Structural & Archetectural)Document222 pagesBOQ (Structural & Archetectural)pdkprabhath_66619207No ratings yet

- 7 ASME B31.3 Final Exam Open BookDocument2 pages7 ASME B31.3 Final Exam Open BookMichael Albuquerque100% (1)

- Daily Points To Recall (Day 4) : Professional Training and ConsultationDocument3 pagesDaily Points To Recall (Day 4) : Professional Training and ConsultationGeorge KudiaborNo ratings yet

- API 510 PC 05mar05 Bench MarkDocument5 pagesAPI 510 PC 05mar05 Bench MarkKommula Narayana SwamyNo ratings yet

- RFP - 2023 02 16 17 14 06Document53 pagesRFP - 2023 02 16 17 14 06Barun kumar paridaNo ratings yet

- API 653 PC 26feb05 PTR 5Document3 pagesAPI 653 PC 26feb05 PTR 5Nuwan RanaweeraNo ratings yet

- Asphalt Installn ProcedureDocument5 pagesAsphalt Installn ProcedureNoel Delos SantosNo ratings yet

- Work Procedure For Maintenance Painting of Installations With Inlet Pressures Not Exceeding 7 Barg (Free From Pitting Corrosion)Document12 pagesWork Procedure For Maintenance Painting of Installations With Inlet Pressures Not Exceeding 7 Barg (Free From Pitting Corrosion)James TaylorNo ratings yet

- Engineering Material Specification: Printed Copies Are UncontrolledDocument6 pagesEngineering Material Specification: Printed Copies Are UncontrolledChandrajeet ShelkeNo ratings yet

- BMW Technical Guideline Corrosion ProtectionDocument5 pagesBMW Technical Guideline Corrosion ProtectionJiahui WuNo ratings yet

- Chapter 3 Volume 2 Section 3 General BA 36/90: GRC Flat Single SkinDocument8 pagesChapter 3 Volume 2 Section 3 General BA 36/90: GRC Flat Single SkinchatxxnoirNo ratings yet

- FM2 & Ashford ObservationDocument9 pagesFM2 & Ashford ObservationshubhNo ratings yet

- Procedure For Repairing The Defective Welds of Transformers Rdso - CompressDocument4 pagesProcedure For Repairing The Defective Welds of Transformers Rdso - CompressSuraj JadhavNo ratings yet

- API 510 PC 20 31 Aug05 Bench MarkDocument5 pagesAPI 510 PC 20 31 Aug05 Bench MarkCss SfaxienNo ratings yet

- Daily Points To Recall (Day 5) : Professional Training and ConsultationDocument3 pagesDaily Points To Recall (Day 5) : Professional Training and Consultationraobabar21No ratings yet

- Maharashtra State Electricity Distribution Co. LTDDocument8 pagesMaharashtra State Electricity Distribution Co. LTDraj_stuff006No ratings yet

- 3PS Gaw 005 - 06Document46 pages3PS Gaw 005 - 06Viveck VivekNo ratings yet

- API 653 PC 26feb05 PTR 4Document3 pagesAPI 653 PC 26feb05 PTR 4Nuwan RanaweeraNo ratings yet

- UntitledDocument11 pagesUntitledRodrigo LeanosNo ratings yet

- UAA10Document17 pagesUAA10abhishek_modemNo ratings yet

- (TM F QQT) : Indian StandardDocument14 pages(TM F QQT) : Indian StandardSubodh SontakkeNo ratings yet

- Carmagen 02 13 PDFDocument3 pagesCarmagen 02 13 PDFAARON HERRERANo ratings yet

- Mahalaxmi Quality Plan For FabricationDocument1 pageMahalaxmi Quality Plan For FabricationAnonymous RXXdbl36ANo ratings yet

- G I Wire No. 8 & 10Document5 pagesG I Wire No. 8 & 10Dharmendra KumarNo ratings yet

- Cor 2Document113 pagesCor 2Yazhisai SelviNo ratings yet

- Irst 19Document12 pagesIrst 19krischaeverNo ratings yet

- 2690 1 2023 PDFDocument12 pages2690 1 2023 PDFDevesh Kumar PandeyNo ratings yet

- IAB - Quinn-Lite BlocksDocument13 pagesIAB - Quinn-Lite BlocksCormac DooleyNo ratings yet

- Daily Points To Recall (Day 2) : Professional Training and ConsultationDocument4 pagesDaily Points To Recall (Day 2) : Professional Training and Consultationraobabar21No ratings yet

- Scope: Volume 2 Section 3 BA 36/90 ScopeDocument10 pagesScope: Volume 2 Section 3 BA 36/90 ScopechatxxnoirNo ratings yet

- CZ 859 TS Bulletin On Excessive Anchor ProfileDocument1 pageCZ 859 TS Bulletin On Excessive Anchor ProfilehuycongvuNo ratings yet

- Norma FiatDocument15 pagesNorma FiatmirosekNo ratings yet

- 2009FDocument26 pages2009FdaimaheshNo ratings yet

- Chapter - 1: Industrial Training ReportDocument27 pagesChapter - 1: Industrial Training Reportreloaded63No ratings yet

- Asme Section Ii A-2 Sa-836 Sa-836mDocument4 pagesAsme Section Ii A-2 Sa-836 Sa-836mdavid perezNo ratings yet

- RS Pile Fesability ReportDocument19 pagesRS Pile Fesability ReportAbilaash VNo ratings yet

- 3PS Gaw 006 - 03Document53 pages3PS Gaw 006 - 03Viveck VivekNo ratings yet

- Industrial Slab Flooring ReportDocument31 pagesIndustrial Slab Flooring ReportChirag Chikmagalur VenkateshNo ratings yet

- API 570 PC 2apr05 Daily Exam 3A ClosedDocument6 pagesAPI 570 PC 2apr05 Daily Exam 3A ClosedSSKNo ratings yet

- Iffi' RR R: Equipment Data Equipment TypelconfigurationDocument2 pagesIffi' RR R: Equipment Data Equipment TypelconfigurationJanakiraman Malliga0% (1)

- Product Manual 398 5 - V2Document7 pagesProduct Manual 398 5 - V2Puneet ChaurasiaNo ratings yet

- API Standard 620 - Design and Construction of Large, Welded, Low-Pressure Storage TanksDocument12 pagesAPI Standard 620 - Design and Construction of Large, Welded, Low-Pressure Storage TanksEC BaloncestoNo ratings yet

- API Standard 620 - Design and Construction of Large, Welded, Low-Pressure Storage TanksDocument12 pagesAPI Standard 620 - Design and Construction of Large, Welded, Low-Pressure Storage TanksEC BaloncestoNo ratings yet

- API Standard 620 - Design and Construction of Large, Welded, Low-Pressure Storage TanksDocument12 pagesAPI Standard 620 - Design and Construction of Large, Welded, Low-Pressure Storage TanksEC BaloncestoNo ratings yet