0 ratings0% found this document useful (0 votes) 2K views23 pagesFit-Up Inspection

Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content,

claim it here.

Available Formats

Download as PDF or read online on Scribd

a

dhe A poy ieee UE eh tha et

eee ee tare beet com al be Aste styonrt Pjere 8 te

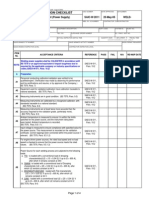

row DEranT weeny Pre FITTER TRAINONG PROGRAM OFT

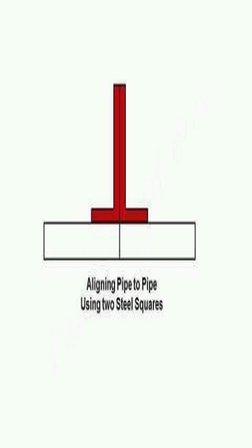

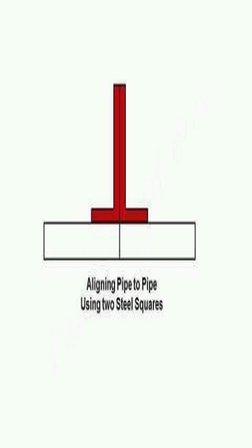

Bia ADMIRAL�Aligning Pipe to Pipe

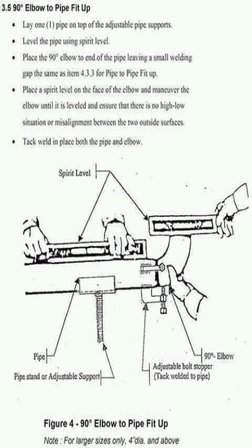

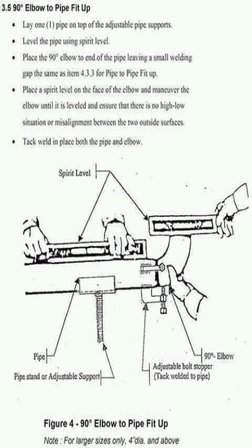

Using two Steel Squares�3.5 90° Elbow to Pipe Fit Up

Lay one (1) pipe on top of the adjustable pipe supports:

Level the pipe using: spirit level.

Place the 90° elbow to end of the pipe leaving a small welding

gap the same as item 4.3.3 for Pipe to Pipe Fit up,

Place a-spirit level on the face of the elbow and maneuver the

elbow until itis leveled and ensure that there 1s no Iigh-low

situation or misalignment-berween the two outside surfaces.

Tack weld in place both the pipe and elbow,

Spirit Level

90°- Elbow

Adjustable bolt stopper

Pipe-stand or Adjustable Support (Tack welded to pipe)

Figure 4 - 90° Elbow to Pipe Fit Up

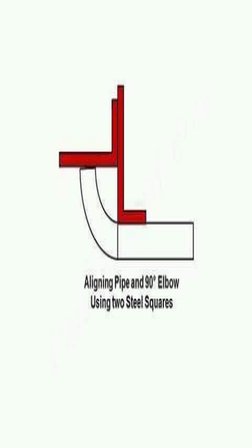

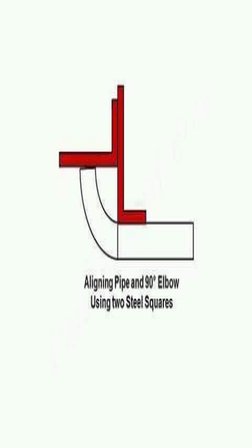

Note : For larger sizes only, 4dia. and above�Aligning Pipe and 90° Elbow

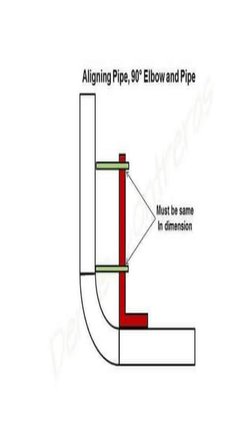

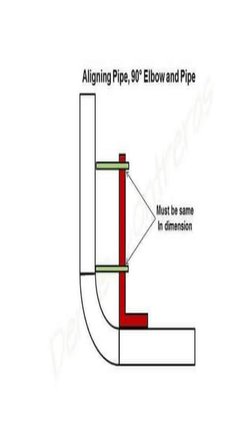

Using two Stee! Squares�Aligning Pipe, 90° Elbow and Pipe

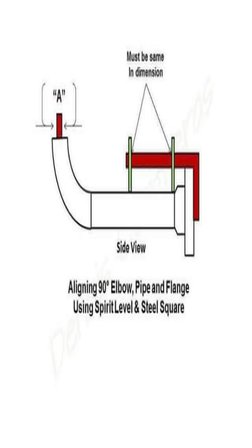

Must be same

In dimension�ALIGNING PIPE TO 90° ELBOW

PIPING/NDT/WELDING.COM.PH

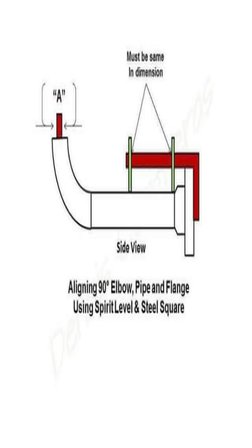

www.fb.com/pipingNDTwelding.com.ph�Must be same

In dimension

{yl

Side View

Aligning 90° Elbow, Pipe and Flange

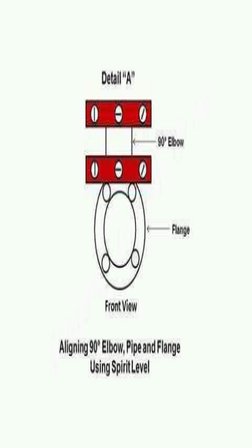

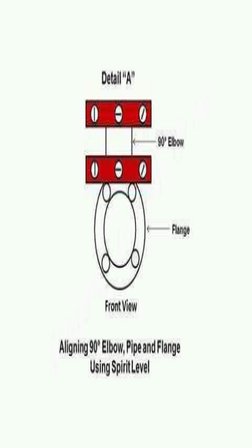

Using Spirit Level & Stee] Square�Detail “A”

Front View

Aligning 90° Elbow, Pipe and Flange

Using Spirit Level�3.7 Flange to Pipe Fit-Up

* Lay one (1) pipe on top of the adjustable pipe suppor.

* Level the pipe using spint level.

® Bring the flange at the end of the pipe leaving a small

welding gap the same-as item 4.3.3 for Pipe to Pipe fit-up (In

casea Weld neck type of flange is-used). Ifa slip-on type of

flange is to be used, insert the pipe to the flange bore upto

5mm depth from the flange. face to give enough space for a

fillet weld.

+ Align the top two (2) holes of the flange with the spirit level,

* Tack weld in place the pipe and flange

Spirit Level

Pipe

Lo

\

Figure 6 - Flange to Pipe Fit Up�Step 2, .

quare ffi . Center rule on top of pipe.

kane, dingo pr ato and pipe are parallel. Tack weld

bottom. *

- Step 3.

r on face of flange. Center rule on side of pipe

p 2. Tack both sides. ; ia�3.6 Tee to Pipe Fit-Up

Pipe stand or Roller support

Lay one (1) pipe on top of the on the adjustable

Pipe supports

Level the pipe using spirit level.

Place the tee at the end of the pipe leaving a small

welding gap the same as item 4.3.3 for Pipe to Pipe fit up.

Place aspint level on the face of the tee and maneuver the

tee until leveled and ensure that there is no high-low

situation or misalignment between the nwo outside

surfaces

Tack weld in place both the pipe-and tec.

Spirit Level

Adjustable bolt stopper

l2mmt MS plate

(Tack welded to pipe)

Figure 5 - Tee to Pipe Fit Up

Note : For larger sizes only, 4"dia. and above�are on ad of pipe. Blas second sate oneen ;

putes Move tee until squ: 7�HOW TO FIT UP PIPE TO TEE

2. TACK WELD

3. CENTER SQUARE F ON TOP

ON TOP OF PIPE Ff

\ 4. CENTER SQUARE ON

\ / CENTER OF BRANCH

4 i

= MOVE TEE UNTIL

HAVE AT LEAST 3MM ~~

SQUARES ARE ALIGNED

GAP FORWELDING _

PIPING/NOT/WELDING.COM.PH

www.fb.com/pipingNDTwelding.com.ph�x Must be same

in dimonsion

Aligning Pipe and 45° Elbow

Using two Steel Squares�45° Elbow-To-Pipe

Follow procedure 90° elbow-to-pipe as

described previously except squares will

cross. To obtain correct 45° angle, align the

same numbers on the inside scale of the titlted

square.�Aligning Pipe, 45° Elbow and Pipe

Must be same

In dimension

Must be same

in dimension�45° ELBOW-TO-PIPE

Follow procedure described above except aquares will ©

cross. ‘To obtain correct 45° angle, align the same numbers

on the inaide scale of the tilted square (note: The numbers

4 and 7 are used in the illustration.)�Remove the adjustable bolt stoppers after fit up and grind flush all

tack welded points making sure that there is no over grinding of

the base metal.

Place the spirit level over both pipes as shown on Figure 2 and

maneuver until both pipes are leweled, Adjusting the pipe support

can casily do this, Ensure that there is no high-low situation or

misalignment between the wo ourstde surfaces,

Tack weld at the top and bottom.

Rotate the pipes 90°,

Repeat the same procedure.

3.4 45° Elbow to Pipe Fit Up

.

*

Lay one (1) pipe on top of the adjustable pipe suppor,

Level the pipe using spirit level.

Place the 45° elbow to the end of the pipe leaving a small welding

Sap, similar to item 4.3.3 for Pipe to Pipe fit up.

Place a 45°-spint level on the face of the elbow umtil bubble is

centered and ensure that there is no high-low situation of misalignment

berween the two outside surfaces:

Tack weld in place both the pipe and the elbow,

| sspieit oval with 45° nae

Adjuswlle alt stopper

L2mmmt MS plate

(Tacks sehted to pipe)

Spiric Lavel |-— 43*-Eibow

Pipe |

Pipe stand or Adjugtaliés } _:

Support

Figure 3 - 45° Elbow to Pipe Fit Up

Note : For larger sizes only, 4"dia. and above�‘SET = (ary number) buse 100

RUM = 777

Gap = 72?

How to Check the Squareness of a 30° Pipe Run?

(Using Steel Squares)

“The Pipe Fitter's Corer”�(b)

JON DE RAMEN NT APE FITTER TAUNTNG. PROGRAM ETT

find annesetraat�sapanosaneT of TiO 49" ELCICE

Up chet DU ote: fet gure le ati fi ants a OT Aiewen, Oa

Parenv anne remem enna tat Te acge

tarp ttm pac in whee nus LL

seceed Ra

peor para tetra fen nena cheers mar on) Foe

A should be equal to 4

Aunizotesin oe a tet hana AD A PIER IN OPLAESNE PoET SR

ns om tp she regen a pape erecicn chen or we FIA cp peewee Keset eaeh waiat, ‘There

ree ere gemacht te wo Ae Do Thee the SOD eepeas coped. arte Pe

se oe tak esi apc the pret cer oa aei9 BE vs Pom for anryetn, the erie) Bop Wo aE

ar a eajrane trey Pom seca x? 4 — NO) With We CUNT nae eaeg. Pe OTAcor

etigrete Pye eta i piegeed nowe! tht Pulte several ee

Tabich w prctea a

———<$—

po - protractor tevel

* -

see Una . stool plate

og ARMAAESE RATIOS RALANTMENT A FITTE TRAINS reg etry�+ oa a seen ema REAM TTY�tas) nese ONT rediy 7atd STIL NOLLLLEENIY FH

i

}

‘a a es wat mar 88

ales

perry to eee SE ens

ee a To al “Te re

0 ee a ec pa fan cares at ROA SETS