0% found this document useful (0 votes)

526 views9 pagesPiping Supervisor

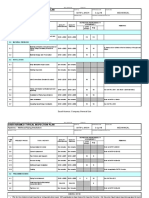

The document contains a 50 question multiple choice test on piping standards and specifications. The questions cover topics such as pipe material standards, dimensional standards for valves, flanges and fittings, piping codes, hydrotesting requirements, and piping symbols. The maximum number of choices given for each question is four.

Uploaded by

Ahmed HaridiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

526 views9 pagesPiping Supervisor

The document contains a 50 question multiple choice test on piping standards and specifications. The questions cover topics such as pipe material standards, dimensional standards for valves, flanges and fittings, piping codes, hydrotesting requirements, and piping symbols. The maximum number of choices given for each question is four.

Uploaded by

Ahmed HaridiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd