Professional Documents

Culture Documents

Heating Methodologies of Impact Crusher's Rotor Gearbox Coupling

Uploaded by

Dan Go0 ratings0% found this document useful (0 votes)

3 views2 pagesThe document compares two methods for heating the couplings of impact crusher rotor gearboxes: the oil bath method and the torch method. The oil bath method involves submerging the coupling in heated oil to reach 150C, then installing it onto the shafting. The torch method uses heating torches applied directly to the coupling to heat it and expand its diameter to the required size of 272mm, then a fast installation onto the cleaned and oiled shafting. Both methods aim to expand and install the coupling without damage, but the torch method may allow for faster, more efficient installation while avoiding potential overheating or smoke issues of the oil bath approach. Proper safety planning and PPE are important for both methods due to fire hazards

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document compares two methods for heating the couplings of impact crusher rotor gearboxes: the oil bath method and the torch method. The oil bath method involves submerging the coupling in heated oil to reach 150C, then installing it onto the shafting. The torch method uses heating torches applied directly to the coupling to heat it and expand its diameter to the required size of 272mm, then a fast installation onto the cleaned and oiled shafting. Both methods aim to expand and install the coupling without damage, but the torch method may allow for faster, more efficient installation while avoiding potential overheating or smoke issues of the oil bath approach. Proper safety planning and PPE are important for both methods due to fire hazards

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views2 pagesHeating Methodologies of Impact Crusher's Rotor Gearbox Coupling

Uploaded by

Dan GoThe document compares two methods for heating the couplings of impact crusher rotor gearboxes: the oil bath method and the torch method. The oil bath method involves submerging the coupling in heated oil to reach 150C, then installing it onto the shafting. The torch method uses heating torches applied directly to the coupling to heat it and expand its diameter to the required size of 272mm, then a fast installation onto the cleaned and oiled shafting. Both methods aim to expand and install the coupling without damage, but the torch method may allow for faster, more efficient installation while avoiding potential overheating or smoke issues of the oil bath approach. Proper safety planning and PPE are important for both methods due to fire hazards

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

COMPARATIVE PRESENTATION OF HEATING METHODOLOGIES OF IMPACT CRUSHER’S ROTOR GEARBOX

COUPLING

PARTICULARS OIL BATH METHOD TORCH METHOD

1. Eqpt & Tools - Crane, 45 tonner, 1 unit - Chain Block, 3 tonner, 3 units

- Chain Block, 3 tonner, 3 sets - Heating Torch (for LPG), 3 sets

- Gas burner, 3 units - Vernier Caliper (16”), 1 unit

- Gas tank (LPG, 50kg), 6pcs - Inside Caliper, 1 unit

- Oil 68, 3 drums - Oxygen tank, 3 sets

- Thermometer (dipstick type), 1

unit

- Vernier caliper (16”), 1 unit

- Inside Caliper , 1 unit

- Heating Torch, 3 sets

- Heating Pan, 1 pc

- Oxygen Tank, 3 pcs

2. Procedure a. Simulation a. Using A-frame, platform and

– set first the couplings (centering & mounted on a pedestal (as drawn),

leveling) position the coupling aligned

- Measure the bore dia. of coupling respectively with the shafting

& shafting b. Measure the shaft diameter and the

- Set the right expansion inside bore diameter of coupling

measurement of coupling c. Before heating, set the target

b. Put the coupling inside the pan expansion of the coupling (from

and start heating 269.7mm to 272mm)

c. Monitor the temp of oil bath every d. Start heating the coupling using 2

20 mins. heating torches

d. Upon reaching the desired 150C, e. Every 5 mins. monitor the inner

soak for 30 min to 1hr diameter of the coupling until it

e. After soaking take the coupling reaches the required expansion to

out to measure the target avoid overheating.

expansion (from 269.7mm to f. Upon reaching the required

272mm) expansion, the coupling maybe

f. Transfer the coupling from the installed already making sure that

pan to A-frame using a 40-tonner the face of coupling and shafting are

crane and set it up with 3-tonners properly aligned

chain blocks as drawn g. Upon full installation of coupling,

g. After the chain block set up use oxygen to perform cooling of the

measure again the inside diameter gearbox shafting. This should be

of coupling while maintaining the done fast to avoid damage of oil

heated parts with heating torches. seal.

h. Install the coupling carefully,

properly and fast, making sure

that the face of coupling and

shafting are both aligned

3. Special Note a. Clean the shafting a. Clean the coupling and shafting

b. Required min. temp of oil bath is b. Apply oil on the shafting only

150C c. The target expansion of coupling

- The max. temp is 180C ranges from the original 269.7mm to

c. The target expansion of coupling 272mm

ranges from the original 269.7mm d. The measurement of temperature

to 272mm may optionally be done and that the

basis of commencement of

installation can be with reference to

the required expansion while

heating up is done

4. Safety Aspects a. Since this approach is using a. 3 fire extinguishers should be made

heated oil bath, a more intensive available in close range

hazard analysis and stricter safety b. PPEs – face shield, high heat

measures have to be imposed resistant gloves, welding apron,

b. Very dangerous jacket

c. 3 fire extinguishers should be c. The execution of works should be

made available in close range detailed and properly planned in

d. PPEs – face shield, high heat writing so that the most suitable

resistant gloves, welding apron, safety plan can be made

jacket

e. The execution of works should be

detailed and properly planned in

writing so that the most suitable

safety plan can be made

5. Quality Aspects a. Being heated up by oil, the a. Having mounted on pedestal

succeeding procedures of ungrouted, poses a bigger challenge

installing the coupling might or difficulty on alignment

produce undesirable smoky b. Addressing a uniform distribution of

working environment which may heat may not be as perfect as oil

affect the effectivity of the bath but since the area to be heated

installation up can easily be reached and applied

b. Overheating of coupling may with by heating torches this concern

accidentally happen of heat distribution is being replaced

c. Having mounted on pedestal by a careful determination of

ungrouted, poses a bigger desired and required expansion

challenge or difficulty on c. Since the heating-up process is done

alignment very close already to the shafting,

d. Undetermined length of heating- the installation procedure may be

up time may bring some troubles done more efficiently and effectively

like accidental running out of fuel compare to oil bath procedures

e. The execution of works should be d. The execution of works should be

properly planned in writing properly planned in writing

You might also like

- 1997 Factory Service ManualDocument1,724 pages1997 Factory Service ManualJose Herrera100% (1)

- 4 BenderScoreDocument1 page4 BenderScoreAnton Henry Miaga0% (1)

- True HealthDocument112 pagesTrue Healthmarianaluca100% (2)

- WRT 114: Writing CultureDocument11 pagesWRT 114: Writing CulturePatrick W. BerryNo ratings yet

- Orange BookDocument43 pagesOrange BookbiosiriNo ratings yet

- How To Track Macros in 3 Simple Steps - EditedDocument21 pagesHow To Track Macros in 3 Simple Steps - EditedTilak Raj100% (1)

- Cement Mill ReportDocument13 pagesCement Mill ReportYhaneNo ratings yet

- The Greater Heaven Meditation - Meridian Qigong - Energy Gates QigongDocument9 pagesThe Greater Heaven Meditation - Meridian Qigong - Energy Gates Qigongspiraldao100% (1)

- Kiln Start Up Procedures PDFDocument12 pagesKiln Start Up Procedures PDFfaheemqc100% (2)

- Shell Welding ProcedureDocument7 pagesShell Welding ProcedurePravesh Modi100% (2)

- 02-Specification Mock ExamDocument9 pages02-Specification Mock ExamCRISTIAN SILVIU IANUC100% (1)

- Urine AnalysisDocument69 pagesUrine AnalysisAffan ElahiNo ratings yet

- Prepare A Boiler For SurveyDocument9 pagesPrepare A Boiler For SurveyLakshmikanthNo ratings yet

- Heat Treatment Procedure.Document15 pagesHeat Treatment Procedure.Vijay ShamNo ratings yet

- Emd-Mi927 IntercoolerDocument8 pagesEmd-Mi927 IntercoolerVictor Raul Tobosque MuñozNo ratings yet

- Standard Procedure of Steam Blowing TestDocument4 pagesStandard Procedure of Steam Blowing TestDennis B. YapNo ratings yet

- Manufactouring Agreement Semiconductors Template - 1Document21 pagesManufactouring Agreement Semiconductors Template - 1David Jay MorNo ratings yet

- Haramase Simulator Achievement GuideDocument3 pagesHaramase Simulator Achievement GuideRisdiansyah 08633% (9)

- Sample Heat Treatment ProcedureDocument13 pagesSample Heat Treatment ProcedureAnonymous uXdS9Y7100% (1)

- Heat Loss Through TankDocument56 pagesHeat Loss Through Tankinamdar_sameerNo ratings yet

- MFD Part2 Pastpapers According To SubjectsDocument255 pagesMFD Part2 Pastpapers According To SubjectsEnea Nastri100% (3)

- Chapter 1Document6 pagesChapter 1kenetic0186% (7)

- E. Steam Power Plant - Pe - ExamDocument4 pagesE. Steam Power Plant - Pe - ExamallovidNo ratings yet

- Procedure of Bearing and Coupling Installation Using Conventional Heating MethodDocument2 pagesProcedure of Bearing and Coupling Installation Using Conventional Heating MethodFranco Angelo RegenciaNo ratings yet

- Conventional Heating Method For Bearing and Coupling InstallationDocument2 pagesConventional Heating Method For Bearing and Coupling InstallationFranco Angelo RegenciaNo ratings yet

- Thermal Expansion of Wingwall SuperheaterDocument3 pagesThermal Expansion of Wingwall Superheaterbeh XulNo ratings yet

- Wingwall SH Distortion in CFBC Boilers by K.K.parthiban Jan 2018Document3 pagesWingwall SH Distortion in CFBC Boilers by K.K.parthiban Jan 2018parthi20065768No ratings yet

- Maintenance Manual For BG Coaches of ICF Design Rolling GearDocument9 pagesMaintenance Manual For BG Coaches of ICF Design Rolling GearChandra BhaskarNo ratings yet

- Furnace ProceduresDocument6 pagesFurnace ProceduresArunNo ratings yet

- AP BOE-2013 Paper-1 SolutionDocument9 pagesAP BOE-2013 Paper-1 SolutionAlok Doshi50% (2)

- PG Test of BTGDocument7 pagesPG Test of BTGO&E CeplNo ratings yet

- Me Me 2102Document20 pagesMe Me 2102Ariyan Abrar SaifNo ratings yet

- Expansion or Contraction of Coal by The Sole-Heated Oven: Standard Test Method ForDocument5 pagesExpansion or Contraction of Coal by The Sole-Heated Oven: Standard Test Method Formohamed fathiNo ratings yet

- 155-157 Bilge System - 1Document3 pages155-157 Bilge System - 1ParthivNo ratings yet

- Boufarik Generator Equipment Serial # 324X045: Reference: Rev.: - SectionDocument6 pagesBoufarik Generator Equipment Serial # 324X045: Reference: Rev.: - SectionFEKO56No ratings yet

- T122 TorsionalDocument6 pagesT122 Torsionalprabin kumar ashishNo ratings yet

- Distorsion Corrective TechniquesDocument4 pagesDistorsion Corrective TechniquesMathew RodriguezNo ratings yet

- Method of Test For Density and Air Voids of Asphalt Concrete by The Gyratory MethodDocument9 pagesMethod of Test For Density and Air Voids of Asphalt Concrete by The Gyratory MethodIbrahim FawwazNo ratings yet

- RP-01-05 - Retread Heat and Thermocouple SDocument31 pagesRP-01-05 - Retread Heat and Thermocouple SGustavo PomaqueroNo ratings yet

- Determine The Material Flow Behavior AZ31B MG Alloy by Changing It Into A Conical ShapeDocument5 pagesDetermine The Material Flow Behavior AZ31B MG Alloy by Changing It Into A Conical ShapeInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Providing Sustainable Energy Solutions Worldwide: Installation-And Maintenance InstructionDocument20 pagesProviding Sustainable Energy Solutions Worldwide: Installation-And Maintenance Instructioncristian villegasNo ratings yet

- Bringing A Boiler On-Line From Cold AR PWIR KS - V3 170816Document5 pagesBringing A Boiler On-Line From Cold AR PWIR KS - V3 170816cadhoaNo ratings yet

- Bentone Burner Operating InstructionsDocument20 pagesBentone Burner Operating InstructionsVikk Suriya100% (2)

- RME Practice ExamDocument12 pagesRME Practice ExamKaiser CarloNo ratings yet

- Drying Out Process For TransformerDocument4 pagesDrying Out Process For TransformerAradhana Ray100% (1)

- Astm D 2014 - 97 (2010)Document5 pagesAstm D 2014 - 97 (2010)alexander guerraNo ratings yet

- Installation and Removal of Interference Compressor Drive Coupling Hubs, Edit BMDocument3 pagesInstallation and Removal of Interference Compressor Drive Coupling Hubs, Edit BMjose luis rattiaNo ratings yet

- Brazing Pipe: Apply Alloy Here Heat Draws Alloy UpwardDocument6 pagesBrazing Pipe: Apply Alloy Here Heat Draws Alloy UpwardWilly UioNo ratings yet

- B30a Oil BurnerDocument20 pagesB30a Oil BurnerPiyush DhimanNo ratings yet

- TECHNOLOGY4 Answer 2Document7 pagesTECHNOLOGY4 Answer 2ابومحمد الكنانيNo ratings yet

- Instr Bentone B40a en 0 PDFDocument13 pagesInstr Bentone B40a en 0 PDFमेनसन लाखेमरूNo ratings yet

- Bomb CalorimeterDocument3 pagesBomb CalorimeterDeeptanu DattaNo ratings yet

- Use of Electric Downhole Heaters To Improve Production and Recovery of Heavy, Viscous Oil in California and VenezuelaDocument10 pagesUse of Electric Downhole Heaters To Improve Production and Recovery of Heavy, Viscous Oil in California and VenezuelaJonathan FariasNo ratings yet

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocument5 pagesModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaNo ratings yet

- Action To Taken During Scavange FireDocument7 pagesAction To Taken During Scavange FireVinothen RajNo ratings yet

- Burner 52Document2 pagesBurner 52ynmoihcppwlkaizbciNo ratings yet

- OMB Alorimetry: ReparationDocument5 pagesOMB Alorimetry: ReparationrajmehaNo ratings yet

- EKM Engineering Knowledge MotorDocument22 pagesEKM Engineering Knowledge MotorMc Den Al BakryNo ratings yet

- Compact Installation ManualDocument20 pagesCompact Installation Manualasjoben1002No ratings yet

- BoilerDocument42 pagesBoilerakram husseinNo ratings yet

- Questionaire Requested PIPEDocument7 pagesQuestionaire Requested PIPERhizhailNo ratings yet

- Cooker Hood Hotte Dunstabzugshaube Dampkap Cappa Campana ExaustorDocument5 pagesCooker Hood Hotte Dunstabzugshaube Dampkap Cappa Campana ExaustorAleksander RzeczyckiNo ratings yet

- CB CBLE HW SpecsDocument11 pagesCB CBLE HW SpecsDiogenes Rafael TorresNo ratings yet

- Sample QuestionsDocument3 pagesSample QuestionsRAJKUMARNo ratings yet

- Softening Point Test ApparatusDocument1 pageSoftening Point Test ApparatusUsman HasanNo ratings yet

- Colo Gas Curing Oven enDocument14 pagesColo Gas Curing Oven ensharklink blackNo ratings yet

- Principles of Refrigeration Job Report INDocument5 pagesPrinciples of Refrigeration Job Report INAlexsander JacobNo ratings yet

- Service RSVP Post Weld Heat TreatDocument2 pagesService RSVP Post Weld Heat Treat1339979No ratings yet

- MEP112 Thermal Power Engneering Sp21 V01Document3 pagesMEP112 Thermal Power Engneering Sp21 V01Mohamed AliNo ratings yet

- 8 Series Steam or Hot Water Boiler-Burner Unit Installation & Operating InstructionsDocument24 pages8 Series Steam or Hot Water Boiler-Burner Unit Installation & Operating Instructionsmanuals1121No ratings yet

- Corrosion Protection Solutions For Oil, Gas and Water Transmission PipelinesDocument6 pagesCorrosion Protection Solutions For Oil, Gas and Water Transmission PipelinesAntonio RamirezNo ratings yet

- AIA Boiler Specification CM2 v1.2 Master Spec PDFDocument11 pagesAIA Boiler Specification CM2 v1.2 Master Spec PDFbotosionNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Nestle Project AssignmentDocument21 pagesNestle Project AssignmentAwais AfzalNo ratings yet

- MSDS ProkleenDocument6 pagesMSDS ProkleenDesta Eka PrasetyaNo ratings yet

- PEOPLE vs. NONOY EBET CRIMDocument2 pagesPEOPLE vs. NONOY EBET CRIMKayee KatNo ratings yet

- Assignment4-2023 For Numerical AnalysisDocument3 pagesAssignment4-2023 For Numerical AnalysisPratyush Kumar SinghNo ratings yet

- Scarlett Ball - Wicreflecttemp23Document3 pagesScarlett Ball - Wicreflecttemp23api-665569952No ratings yet

- Polybond PVA: PVA Based Bonding Agent and AdmixtureDocument2 pagesPolybond PVA: PVA Based Bonding Agent and AdmixtureHtun ZarniNo ratings yet

- Semisolid Dosage Forms - Ointments, Pastes and JelliesDocument46 pagesSemisolid Dosage Forms - Ointments, Pastes and JelliesKhushbooNo ratings yet

- Improving Food Security and Market Linkages For SmallholdersDocument45 pagesImproving Food Security and Market Linkages For SmallholdersRicardo SotoNo ratings yet

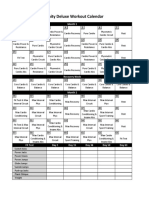

- Insanity Workout Deluxe Calendar SimpleDocument1 pageInsanity Workout Deluxe Calendar SimpleCristian Manuel GonzálezNo ratings yet

- Exercise 2Document9 pagesExercise 2Meryem LamhamdiNo ratings yet

- Update CV Hse Engineer SlimaniDocument3 pagesUpdate CV Hse Engineer SlimanialiouecheNo ratings yet

- Jared Hunter ResignationDocument1 pageJared Hunter ResignationAnna BeahmNo ratings yet

- Best Practices For Trauma-Informed InstructionDocument11 pagesBest Practices For Trauma-Informed InstructionColectivo de Formación Docente Samuel RobinsonNo ratings yet

- Starters: Please Ask Our Waiting Staff For Our Today'S Special MenuDocument2 pagesStarters: Please Ask Our Waiting Staff For Our Today'S Special MenuAdrian HartantoNo ratings yet

- Bill D External Works FormatDocument189 pagesBill D External Works FormatJoanna YunusNo ratings yet

- ! 19 Organic Rankine CycleDocument14 pages! 19 Organic Rankine Cyclesapcuta16smenNo ratings yet

- 2 Infectious Disease EpidemiologyDocument62 pages2 Infectious Disease Epidemiologykindness jawoNo ratings yet