Professional Documents

Culture Documents

1 Investigations On The Development of Heated Build Platform 3

Uploaded by

Alireza Khodabandeh0 ratings0% found this document useful (0 votes)

3 views1 pageThis document discusses additive manufacturing (AM) processes and focuses on fused filament fabrication (FFF). It classifies AM processes into seven categories including material extrusion, powder bed fusion, and binder jetting. The document states that material extrusion has become a viable and economical manufacturing technology. It is used to deposit layers of material to build parts through movement of an extrusion tool or build platform. FFF is introduced as one of the most popular material extrusion processes, which fabricates plastic parts through extrusion of heated filament and is commonly used for prototyping due to its ease of use, low material waste, and design freedom without geometric restrictions.

Original Description:

Original Title

(Lecture Notes on Multidisciplinary Industrial Engineering) Vishal S. Sharma, Uday S. Dixit, Knut Sørby, Arvind Bhardwaj, Rajeev Trehan - Manufacturing Engineering _ Select Proceedings of CPIE 2019-Sp15

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses additive manufacturing (AM) processes and focuses on fused filament fabrication (FFF). It classifies AM processes into seven categories including material extrusion, powder bed fusion, and binder jetting. The document states that material extrusion has become a viable and economical manufacturing technology. It is used to deposit layers of material to build parts through movement of an extrusion tool or build platform. FFF is introduced as one of the most popular material extrusion processes, which fabricates plastic parts through extrusion of heated filament and is commonly used for prototyping due to its ease of use, low material waste, and design freedom without geometric restrictions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views1 page1 Investigations On The Development of Heated Build Platform 3

Uploaded by

Alireza KhodabandehThis document discusses additive manufacturing (AM) processes and focuses on fused filament fabrication (FFF). It classifies AM processes into seven categories including material extrusion, powder bed fusion, and binder jetting. The document states that material extrusion has become a viable and economical manufacturing technology. It is used to deposit layers of material to build parts through movement of an extrusion tool or build platform. FFF is introduced as one of the most popular material extrusion processes, which fabricates plastic parts through extrusion of heated filament and is commonly used for prototyping due to its ease of use, low material waste, and design freedom without geometric restrictions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

1 Investigations on the Development of Heated Build Platform … 3

Fig. 1.2 Categorization of AM processes

Manufacturing’ standard, AM processes can be classified into seven categories based

on different working principles, i.e., material extrusion, direct energy deposition,

powder bed fusion, binder jetting, vat photo-polymerization, material jetting, sheet

lamination, etc. [1] (Fig. 1.2).

Among these processes, material extrusion-based AM process has grown as viable

and economical manufacturing technology. Material extrusion is a process that con-

sists of mainly a material extrusion tool and build platform. Either of the material

extrusion tool or build platform is moved in usually z-direction that helps to deposit

material on top of layer previously deposited on build platform. After fabrication,

parts have to perform some post-processing, that is essential for functional use. The

AM system manufactures parts at reasonable cost with good quality in the short-

est time, which helps to compete with others in the current manufacturing world.

Manufacturing world witnessed evolution of new process since last three decades,

and earlier, AM process is only used for prototyping purpose, popularly known as

rapid prototyping (RP). Nowadays, many industries adopted AM to make functional

products of parts to minimize the product development cycle time [2–5].

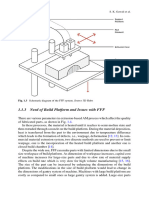

1.1.2 Fused Filament Fabrication (FFF)

Fused filament fabrication (FFF) is a one of the most popular material extrusion-based

AM processes which is used to fabricate prototypes and small end-use functional

products [6–8]. FFF is a process in which material in the filament form is processed

through extrusion principle to fabricate plastic parts, as shown in Fig. 1.3. FFF is

the most commonly used process for fabrication of parts among other AM processes

with ease, minimum wastage of material and easy material change. FFF is a typical

RP process that fabricates prototypes for visualization and validation of designs. FFF

process need not require a tooling for fabrication of parts and has design freedom

with no geometrical restriction [9–11].

You might also like

- Dies and MouldsDocument19 pagesDies and MouldsTomas Trojci TrojcakNo ratings yet

- Analyzing The Benefits of Lean Manufacturing and Value Stream Mapping Via Simulation A Process Sector Case StudyDocument14 pagesAnalyzing The Benefits of Lean Manufacturing and Value Stream Mapping Via Simulation A Process Sector Case StudyJamesNo ratings yet

- Automation in ManufacturingDocument12 pagesAutomation in ManufacturingAnonymous RaHCnzALNo ratings yet

- 16 Qiang Bai and Yong Bai: Pipeline InstallationDocument1 page16 Qiang Bai and Yong Bai: Pipeline InstallationAlireza KhodabandehNo ratings yet

- An Application of SMED MethodologyDocument4 pagesAn Application of SMED MethodologyIng Raul OrozcoNo ratings yet

- 20201019-Plant Layout and Material HandlingDocument78 pages20201019-Plant Layout and Material HandlingRavi KumarNo ratings yet

- 25 Material and Information Flow Chart MIFC Mapping For Lean Manufacturing Implementation in TH PDFDocument6 pages25 Material and Information Flow Chart MIFC Mapping For Lean Manufacturing Implementation in TH PDFIshwar RajputNo ratings yet

- Chapter 1: Introduction & Motivation: 1.1 BackgroundDocument13 pagesChapter 1: Introduction & Motivation: 1.1 Backgrounddarshan008No ratings yet

- A Review of Melt Extrusion Additive Manufacturing Processes I. Process Design and ModelingDocument13 pagesA Review of Melt Extrusion Additive Manufacturing Processes I. Process Design and ModelingFernando AraujoNo ratings yet

- Reconfigurable Tooling For Airframe AssemblyDocument21 pagesReconfigurable Tooling For Airframe AssemblyDennis Padec BwochengoNo ratings yet

- Rad o SMED UDocument9 pagesRad o SMED UAmiljkovicviNo ratings yet

- Additive ManufacturingDocument5 pagesAdditive ManufacturingIJRASETPublicationsNo ratings yet

- Impact of Fused Deposition Modeling (FDM) Process ParametersDocument13 pagesImpact of Fused Deposition Modeling (FDM) Process ParametersKenan MuhamedagićNo ratings yet

- Experimental Determination of Critical Orientation of Abs Parts Manufactured Using Fused Deposition Modelling TechnologyDocument12 pagesExperimental Determination of Critical Orientation of Abs Parts Manufactured Using Fused Deposition Modelling TechnologyAnand NagarajanNo ratings yet

- Materials 12 00895Document25 pagesMaterials 12 00895amol shindeNo ratings yet

- Paper 3Document38 pagesPaper 3nafayzaman03No ratings yet

- 3D Printed Prototyping Tools For Flexible Sheet Metal DrawingDocument15 pages3D Printed Prototyping Tools For Flexible Sheet Metal DrawingMina AdelNo ratings yet

- Rapid Prototyping - Lecture NotesDocument71 pagesRapid Prototyping - Lecture NotessreeshpsNo ratings yet

- Quantum Machine Learning and Support Vector MachineDocument16 pagesQuantum Machine Learning and Support Vector MachineBeatriz IzquierdoNo ratings yet

- Additive Manufacturing A Framework For ImplementationDocument8 pagesAdditive Manufacturing A Framework For Implementationnicero555No ratings yet

- Fused Deposition Modeling (FDM)Document3 pagesFused Deposition Modeling (FDM)Ahmed Khalid HussainNo ratings yet

- Materials 15 07954 v2Document19 pagesMaterials 15 07954 v2Mehmet Cemal ACARNo ratings yet

- Rapid Manufacturing JournalDocument12 pagesRapid Manufacturing JournalAdelina RomanNo ratings yet

- (Document Title) : Noor Abd Alrasoul AHMED-UNDER (Company Address)Document18 pages(Document Title) : Noor Abd Alrasoul AHMED-UNDER (Company Address)noor bayanNo ratings yet

- Additive Manufacturing Technology: The Status, Applications, and ProspectsDocument15 pagesAdditive Manufacturing Technology: The Status, Applications, and ProspectsImrul Kayes KhanNo ratings yet

- AM Tech Brief PolymerDocument9 pagesAM Tech Brief Polymermanoj smNo ratings yet

- Computer Integrated ManufacturingDocument6 pagesComputer Integrated ManufacturingSagar PawarNo ratings yet

- Just in TimeDocument19 pagesJust in TimeRadu ChisiuNo ratings yet

- 2.4.14.2 Final Report HIPARMSDocument9 pages2.4.14.2 Final Report HIPARMSVaibhav KaliaNo ratings yet

- Ghrce - Final Aip Lab Manual (Viii Sem)Document89 pagesGhrce - Final Aip Lab Manual (Viii Sem)Jyotiraman De100% (1)

- ObsCPMT PDFDocument14 pagesObsCPMT PDFrocaoNo ratings yet

- Advances in The Control of Sheet Metal Forming: Ifac Proceedings Volumes (Ifac Papers-Online) July 2008Document10 pagesAdvances in The Control of Sheet Metal Forming: Ifac Proceedings Volumes (Ifac Papers-Online) July 2008Rui MatiasNo ratings yet

- PLMH Notes PDFDocument78 pagesPLMH Notes PDFRossi AghdaNo ratings yet

- Polymers 14 05093Document15 pagesPolymers 14 05093KAVINNo ratings yet

- Fldvanced Itlanufacturin (I TechnoloouDocument7 pagesFldvanced Itlanufacturin (I TechnoloouDegaga KebedeNo ratings yet

- Design For AssemblyDocument6 pagesDesign For AssemblyRupesh SiyodiaNo ratings yet

- Additive Manufacturing UNIT-1Document11 pagesAdditive Manufacturing UNIT-1ENGINEERING MECHANICSNo ratings yet

- Dynamic Simulation and Neural Network Compliance Control of An Intelligent Forging CenterDocument19 pagesDynamic Simulation and Neural Network Compliance Control of An Intelligent Forging CenterDegaga KebedeNo ratings yet

- Changeover Process Improvement Based On Modified SMEDDocument18 pagesChangeover Process Improvement Based On Modified SMEDRoberto Ramirez GomezNo ratings yet

- Additive ManufacturingDocument13 pagesAdditive ManufacturingPrajwal ChatraNo ratings yet

- 3D Printing Study ExperimentDocument4 pages3D Printing Study Experimentkingsurya6091022No ratings yet

- Rapid Prototyping and Tooling (RPT)Document11 pagesRapid Prototyping and Tooling (RPT)Livia Ticu100% (1)

- Rapid Prototyping: (1) IntroductionDocument1 pageRapid Prototyping: (1) IntroductionkdsahooNo ratings yet

- Plant Lay Out PDFDocument14 pagesPlant Lay Out PDFLee BảoNo ratings yet

- Methodical Approach For Process Selection in Additive ManufacturingDocument10 pagesMethodical Approach For Process Selection in Additive ManufacturingRAVI KUMARNo ratings yet

- A Review On Additive ManufacturingDocument10 pagesA Review On Additive ManufacturingKamlesh RanaNo ratings yet

- Production Process Improvement Using VSMDocument15 pagesProduction Process Improvement Using VSMJames OrtegaNo ratings yet

- Screw Extrusion Based 3D Printing, A Novel Additive Manufacturing TechnologyDocument7 pagesScrew Extrusion Based 3D Printing, A Novel Additive Manufacturing TechnologyPaulo Canedo da SilvaNo ratings yet

- Bus 2C 12 Operations Management: Dr.A.Abirami / OmDocument17 pagesBus 2C 12 Operations Management: Dr.A.Abirami / OmBalujagadishNo ratings yet

- Assignment No-01 Machine Element: Fundamental Rules For The Selection and Planning of A Manufacturing ProcessDocument10 pagesAssignment No-01 Machine Element: Fundamental Rules For The Selection and Planning of A Manufacturing ProcessTushar PingateNo ratings yet

- Wear Assessment of 3-D Printed Parts of PLA (Polylactic Acid) Using Taguchi Design and Artificial Neural Network (ANN) TechniqueDocument16 pagesWear Assessment of 3-D Printed Parts of PLA (Polylactic Acid) Using Taguchi Design and Artificial Neural Network (ANN) TechniqueArturo CervantesNo ratings yet

- Simulacion 2Document8 pagesSimulacion 2Victor Barrios AlvarezNo ratings yet

- Abdulmalek, Rajgopal - 2007 - Analyzing The Benefits of Lean Manufacturing and Value Stream Mapping Via Simulation A Process Sector CaseDocument14 pagesAbdulmalek, Rajgopal - 2007 - Analyzing The Benefits of Lean Manufacturing and Value Stream Mapping Via Simulation A Process Sector CaseDragan DragičevićNo ratings yet

- PLMH NotesDocument78 pagesPLMH NotesbagumaNo ratings yet

- Advantages and Disadvantages of AMDocument11 pagesAdvantages and Disadvantages of AMSafwan Aszemi0% (2)

- Durão2019 Article OptimizingAdditiveManufacturinDocument23 pagesDurão2019 Article OptimizingAdditiveManufacturinAlamNo ratings yet

- 1.1.3 Need of Build Platform and Issues With FFF: 4 S. K. Gawali Et AlDocument1 page1.1.3 Need of Build Platform and Issues With FFF: 4 S. K. Gawali Et AlAlireza KhodabandehNo ratings yet

- A Review of Assembly Line Changes For Lean Manufacturing: Awasare Anant Dattatray, M.V.KavadeDocument5 pagesA Review of Assembly Line Changes For Lean Manufacturing: Awasare Anant Dattatray, M.V.KavadeAeyrul KhairulNo ratings yet

- IAM3D ReportDocument11 pagesIAM3D Reportsiva shankarNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- 23Document1 page23Alireza KhodabandehNo ratings yet

- Finite Element Analysis: Pipeline Installation by Tow or PullDocument1 pageFinite Element Analysis: Pipeline Installation by Tow or PullAlireza KhodabandehNo ratings yet

- Wall Thickness and Material Grade Selection: GeneralDocument1 pageWall Thickness and Material Grade Selection: GeneralAlireza KhodabandehNo ratings yet

- Bending Loads. External Impact Loads.: 24 Qiang Bai and Yong BaiDocument1 pageBending Loads. External Impact Loads.: 24 Qiang Bai and Yong BaiAlireza KhodabandehNo ratings yet

- References: 20 Qiang Bai and Yong BaiDocument1 pageReferences: 20 Qiang Bai and Yong BaiAlireza KhodabandehNo ratings yet

- Untitled 3Document1 pageUntitled 3Alireza KhodabandehNo ratings yet

- Rec Erc 84 329Document1 pageRec Erc 84 329Alireza KhodabandehNo ratings yet

- Pipe Laying by Lay Vessel: Mode 1 Buckle Mode 2 Buckle Mode 3 Buckle Mode 4 BuckleDocument1 pagePipe Laying by Lay Vessel: Mode 1 Buckle Mode 2 Buckle Mode 3 Buckle Mode 4 BuckleAlireza KhodabandehNo ratings yet

- Untitled 1Document1 pageUntitled 1Alireza KhodabandehNo ratings yet

- Untitled 6Document1 pageUntitled 6Alireza KhodabandehNo ratings yet

- Rec Erc 84 332Document1 pageRec Erc 84 332Alireza KhodabandehNo ratings yet

- Untitled 2Document1 pageUntitled 2Alireza KhodabandehNo ratings yet

- Rec Erc 84 313Document1 pageRec Erc 84 313Alireza KhodabandehNo ratings yet

- Rec Erc 84 334Document1 pageRec Erc 84 334Alireza KhodabandehNo ratings yet

- Rec Erc 84 315Document1 pageRec Erc 84 315Alireza KhodabandehNo ratings yet

- Rec Erc 84 317Document1 pageRec Erc 84 317Alireza KhodabandehNo ratings yet

- Rec Erc 84 36Document1 pageRec Erc 84 36Alireza KhodabandehNo ratings yet

- Rec Erc 84 311Document1 pageRec Erc 84 311Alireza KhodabandehNo ratings yet

- Rec Erc 84 33Document1 pageRec Erc 84 33Alireza KhodabandehNo ratings yet

- Rec Erc 84 38Document1 pageRec Erc 84 38Alireza KhodabandehNo ratings yet

- Rec Erc 84 322Document1 pageRec Erc 84 322Alireza KhodabandehNo ratings yet

- CERTILAS EN Edition2023 317Document1 pageCERTILAS EN Edition2023 317Alireza KhodabandehNo ratings yet

- 1.2.1 Design Methodology: 6 S. K. Gawali Et AlDocument1 page1.2.1 Design Methodology: 6 S. K. Gawali Et AlAlireza KhodabandehNo ratings yet

- 1.1.3 Need of Build Platform and Issues With FFF: 4 S. K. Gawali Et AlDocument1 page1.1.3 Need of Build Platform and Issues With FFF: 4 S. K. Gawali Et AlAlireza KhodabandehNo ratings yet

- 14 S. K. Gawali Et AlDocument1 page14 S. K. Gawali Et AlAlireza KhodabandehNo ratings yet

- 2 S. K. Gawali Et Al.: 1.1.1 Additive ManufacturingDocument1 page2 S. K. Gawali Et Al.: 1.1.1 Additive ManufacturingAlireza KhodabandehNo ratings yet

- CERTILAS EN Edition2023 315Document1 pageCERTILAS EN Edition2023 315Alireza KhodabandehNo ratings yet

- PAINT22Document5 pagesPAINT22Alireza KhodabandehNo ratings yet

- Ni SiC AISI 304Document9 pagesNi SiC AISI 304Alireza KhodabandehNo ratings yet