Professional Documents

Culture Documents

Ficha Tecnica Rociadores Montante Pendiente Share

Uploaded by

Jhon AltamarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ficha Tecnica Rociadores Montante Pendiente Share

Uploaded by

Jhon AltamarCopyright:

Available Formats

UPRIGHT, PENDENT AND RECESSED

PENDENT SPRINKLER(STANDARD & QUICK RESPONSE) HD FIRE PROTECT

PVT. LTD.

TECHNICAL DATA

STYLE Upright, Pendent and

Recessed Pendent

TEMPERATURE Standard Response - 5mm

RESPONSE glass bulb

Quick Response - 3mm glass bulb

COVERAGE Standard Coverage

K-FACTOR 5.6 US (80 metric)

NOMINAL THREAD SIZE ½” BSPT (NPT Optional)

MAXIMUM WORKING 175 psi (12 bar)

PRESSURE

FACTORY HYDROSTATIC 500 psi (35 bar)

TEST PRESSURE

MINIMUM OPERATING 7 psi (0.5 bar)

PRESSURE APPROVALS

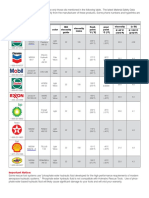

TEMPERATURE 57°C (135° F), 68°C (155° F), Orientation

Temperature Approval

Response

RATING 79°C (175° F), 93°C (200° F), Type

Type /

Rating

Code No

SIN No. UL FM

141°C (286°F),182°C (360°F)

SR PENDENT 57°C (135°F) √ √ T10021

APPROVALS Refer Table HD401 68°C (155°F) √ √ T10022

79°C (175°F) √ √ T10023

FINISH Brass, Chrome Plated, White

93°C (200°F) √ √ T10024

Painted. White shade is

RAL9010. For other shades, SR UPRIGHT 57°C (135°F) √ √ T10055

contact HD Sales. HD402 68°C (155°F) √ √ T10056

For SIN Nos.HD401/402/501/502, 79°C (175°F) √ √ T10057

chrome plating will not be done on 93°C (200°F) √ √ T10058

the threaded portion. QR PENDENT 57°C (135°F) √ √ T10050

HD501 68°C (155°F) √ √ T10002

ORDERING Style, Temperature Rating &

79°C (175°F) √ √ T10003

INFORMATION Response, Thread type,Finish, 93°C (200°F) √ √ T10004

Approval required- UL or UL & FM

QR UPRIGHT 57°C (135°F) √ √ T10051

SIN NUMBER HD401/ HD101 - Pendent, SR HD502 68°C (155°F) √ √ T10042

HD402/ HD102 - Upright, SR 79°C (175°F) √ √ T10043

HD501/ HD201 - Pendent, QR 93°C (200°F) √ √ T10044

HD502/ HD202 - Upright, QR SR PENDENT 57°C (135°F) √ √ T10021F

HD101 68°C (155°F) √ √ T10022F

DESCRIPTION 79°C (175°F) √ √ T10023F

93°C (200°F) √ √ T10024F

HD Pendent and Upright sprinklers are designed for

141°C (286°F) √ — T10035

use in light and ordinary hazards. The temperature

182°C (360°F) √ — T10037

response is standard response (5mm glass bulb)

SR UPRIGHT 57°C (135°F) √ √ T10055F

and quick response (3mm glass bulb). The sprinklers

HD102 68°C (155°F) √ √ T10056F

come with compact design, glass bulb type, available

79°C (175°F) √ √ T10057F

in several different finishes and temperature ratings.

93°C (200°F) √ √ T10058F

The pendent sprinklers must be installed in pendent

position, and upright sprinklers are to be installed in QR PENDENT 57°C (135°F) √ — T10001

HD201 68°C (155°F) √ √ T10002F

the upright position.

79°C (175°F) √ √ T10003F

Pendent Recessed Sprinklers are installed with 93°C (200°F) √ √ T10004F

adjustable or non-adjustable Escutcheon plates (also 141°C (286°F) √ — T10036

termed as Rosette plates). These are intended to

QR UPRIGHT 57°C (135°F) √ — T10041

be installed with finished ceilings. Escutcheon plate

HD202 68°C (155°F) √ √ T10042F

adjustment provides convenience in Pendent Sprinkler 79°C (175°F) √ √ T10043F

installation in case of areas with finished ceilings or 93°C (200°F) √ √ T10044F

walls.

MARCH, 2022 PAGE 1 OF 4 HD 237

HD FIRE PROTECT

PVT. LTD.

Sprinkler Operation Sprinkler must never be painted, plated or coated

after they leave factory.

The Sprinkler operating device is state of the art heat

responsive frangible glass bulb supplied by a world The HD Sprinkler described herein must be installed

leader in this innovative technology. The glass bulb and maintained in accordance with the latest edition

contains fluid which expands when exposed to heat. of HD technical data, the latest standard of National

Fire protection Association (NFPA) and Factory Mutual

When rated temperature is reached, the bulb shatters

(FM) or to the standard of any other authorities

and water flows through the sprinkler and strikes

having jurisdiction. The owner is solely responsible for

deflector, forming a uniform water spray pattern to

maintaining their fire protection system and device in

control or extinguish fire.

proper operating condition.

Care and Handling Exposure to ultraviolet or direct sunlight for extended

Sprinklers must be handled with due care, they must period may cause the liquid dye in glass bulb to fade

be stored at ambient temprature for best results. or lose colour. Colourless or faded coloured bulbs are

Storage as well as any onward shipment is to be made not a problem, as long as the fluid level has not been

in original packing only. Sprinklers must be visually affected. The loss of colour in the liquid will not effect

inspected carefully before installation. Sprinklers sprinkler performance, as long as the bulb is intact

visibly damaged, dropped or exposed to temperature and not damaged. The loss of colour may be an issue

in excess of the maximum ambient temperature in identifying sprinkler temperature rating, but the

permitted, should never be installed. Never install temperature rating is still stamped on the sprinkler

any glass blub sprinkler if the bulb is cracked or if deflector.

there is a loss of liquid from the bulb. Sprinkler must

be installed after the piping is in place to prevent Inspection Testing and Maintenance

mechanical damage. Refer to NFPA 25 for inspection testing and

Use Teflon Tape or soft thread sealent on male thread maintenance requirement or to the authority having

of the Sprinkler for the leak tight Sprinkler joint. Use jurisdiction. For details of warranty, refer HD’s

proper wrench. A leak-tight 1/2 NPT/BSPT Sprinkler current price list, conditions of sale or contact HD

joint should be obtained by applying maximum torque directly.

of 19.0 N-m (14 lb-ft). Excessive tightening torque

may distort the Sprinkler inlet and cause leakage.

MATERIAL SPECIFICATION

Deflector Brass

Bulb Glass

Cap Copper

Frame Brass

Seal Teflon Coated Washer

Standard Response 5.0mm

Bulb Nominal Diameter

Quick Response 3.0mm

SPRINKLER RATINGS

SPRINKLER TEMP. NORMAL SPRINKLER NFPA MAX. CEILING GLASS BULB

CLASSIFICATION TEMP. RATING TEMP. ALLOWED COLOUR

Ordinary 57° C (135° F) 38° C (100° F) Orange

Ordinary 68° C (155° F) 38° C (100° F) Red

Intermediate 79° C (175° F) 66° C (150° F) Yellow

Intermediate 93° C (200° F) 66° C (150° F) Green

High 141° C (286° F) 107° C (225° F) Blue

Extra High 182° C (360° F) 149° C (300° F) Purple

As per Table 6.2.5.1 NFPA 13

MARCH, 2022 PAGE 2 OF 4 HD 237

HD FIRE PROTECT

PVT. LTD.

PENDENT & UPRIGHT SPRINKLER

SIN # HD401/HD501 SIN # HD402/ HD502

Ø32mm

HD

55mm

55mm

HD

Ø26mm

SIN # HD101/ HD201 SIN # HD102/ HD202

Ø33.7mm

HD

50mm

50mm

HD

Ø30mm

* For T10002F/T10003F/T10004F Deflector diameter is 25 mm.

RECESSED PENDENT

HOLE-Ø60 Max.

HOLE-Ø51 Min.

15mm

23.5mm

39mm

20mm

Maximum Recess

Ø75mm

Maximum Extension

MARCH, 2022 PAGE 3 OF 4 HD 237

HD FIRE PROTECT

PVT. LTD.

REPRESENTATIVE IMAGES OF SPRINKLERS

HD401/HD501 HD402/HD502 HD101/HD201 HD102/HD202

T10002F/T10003F/T10004F RECESSED PENDENT HD101 (WHITE)

NOTE: These are representative images of sprinklers. Please contact HD Sales for any further details.

LIMITED WARRANTY

HD FIRE PROTECT PVT. LTD. hereby referred to as HD FIRE warrants to the original purchaser of the fire protection products manufactured by HD FIRE and to any other person

to whom such equipment is transferred, that such products will be free from defect in material and workmanship under normal use and care, for two (2) years from the date of

shipment by HD FIRE. Products or Components supplied or used by HD FIRE, but manufactured by others, are warranted only to the extent of the manufacturer’s warranty.

No warranty is given for product or components which have been subject to misuse, improper installation, corrosion, unauthorized repair, alteration or un-maintained.

HD FIRE shall not be responsible for system design errors or improper installation or inaccurate or incomplete information supplied by buyer or buyer’s representatives.

HD FIRE will repair or replace defective material free of charge, which is returned to our factory, transportation charge prepaid, provided after our inspection the material is

found to have been defective at the time of initial shipment from our works. HD FIRE shall not be liable for any incidental or consequential loss, damage or expense arising directly

or indirectly from the use of the product including damages for injury to person, damages to property and penalties resulting from any products and components manufactured

by HD FIRE. HD FIRE shall not be liable for any damages or labour charges or expense in making repair or adjustment to the product. HD FIRE shall not be liable for any

damages or charges sustained in the adaptation or use of its engineering data & services. In no event shall HD Fire’s product liability exceed an amount equal to the sale price.

The foregoing warranty is exclusive and in lieu of all other warranties and representation whether expressed, implied, oral or written, including but not limited

to, any implied warranties or merchantability or fitness for a particular purpose. All such other warranties and representations are hereby cancelled.

NOTICE :

The equipment presented in this bulletin is to be installed in accordance with the latest publication standards of NFPA or other similar organisations and also with the

provision of government codes or ordinances wherever applicable.

The information provided by us is to the best of our knowledge and belief, and consist of general guidelines only. Site handling and installation control is not in our scope.

Hence we give no guarantee for result and take no liability for damages, loss or penalties whatsoever, resulting from our suggestion, information, recommendation or

damages due to our product.

Product development is a continuous programme of HD FIRE PROTECT PVT. LTD. and hence the right to modify any specification without prior notice is reserved with

the company.

D-6/2, ROAD NO. 34, WAGLE INDUSTRIAL ESTATE, THANE 400 604, INDIA.

HD FIRE PROTECT PVT. LTD. • TEL: + (91) 22 2158 2600 • FAX: +(91) 22 2158 2602

Protecting What Matters Most to You • EMAIL: info@hdfire.com • WEB: www.hdfire.com

MARCH, 2022 PAGE 4 OF 4 HD 237

You might also like

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Upright, Pendent and Recessed Pendent Sprinkler: HD Fire Protect Pvt. Ltd. Technical DataDocument4 pagesUpright, Pendent and Recessed Pendent Sprinkler: HD Fire Protect Pvt. Ltd. Technical DataBhavin lodayaNo ratings yet

- Quartzoid Bulb DetectorDocument6 pagesQuartzoid Bulb DetectorKirankumar BoddalaNo ratings yet

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesFrom EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Upright, Pendent and Recessed Sprinkler Technical Data SheetDocument4 pagesUpright, Pendent and Recessed Sprinkler Technical Data SheetsureshkanuboyinaNo ratings yet

- Troubleshooting & Repairing Consumer Electronics Without a SchematicFrom EverandTroubleshooting & Repairing Consumer Electronics Without a SchematicNo ratings yet

- HD245 Side Wall SprinklerDocument2 pagesHD245 Side Wall Sprinklerrajjar010No ratings yet

- Non-Storage / Special Protection / Storage Sprinklers: General InformationDocument7 pagesNon-Storage / Special Protection / Storage Sprinklers: General InformationsakurageassNo ratings yet

- Ty4251 - FMDocument7 pagesTy4251 - FMRafael CardosoNo ratings yet

- PR 1422 Class BDocument2 pagesPR 1422 Class BHasan RazaNo ratings yet

- Aerospace Sealants: PR-1440 Class B Fuel Tank SealantDocument2 pagesAerospace Sealants: PR-1440 Class B Fuel Tank SealantVu NguyenNo ratings yet

- Guide For VictaulicDocument29 pagesGuide For VictaulicMohamed AAmerNo ratings yet

- Automatic Sprinkler Systems: 2006 Approval GuideDocument554 pagesAutomatic Sprinkler Systems: 2006 Approval GuideRAJESHNo ratings yet

- Technical Data: P/S 890 Class B Fuel Tank SealantDocument2 pagesTechnical Data: P/S 890 Class B Fuel Tank Sealantsaid PalaoNo ratings yet

- Service Bulletin: CautionDocument8 pagesService Bulletin: CautiondfmolinaNo ratings yet

- SPECIFICATIONS For Constant Temperature and Humidity ChamberDocument5 pagesSPECIFICATIONS For Constant Temperature and Humidity Chamber彭以和No ratings yet

- HKS Camshaft Specifications for RB26DETT EnginesDocument1 pageHKS Camshaft Specifications for RB26DETT EnginesОлег СадовскийNo ratings yet

- Vamac G AemDocument4 pagesVamac G AemZENGJIAQINo ratings yet

- Bimetal Disc Thermostats for Appliances and HVACDocument2 pagesBimetal Disc Thermostats for Appliances and HVACBuitinės Technikos RemontasNo ratings yet

- Automatic SprinklersDocument638 pagesAutomatic SprinklersRendani VeleNo ratings yet

- AV138M Araldite HV998 HardDocument6 pagesAV138M Araldite HV998 HardFilipe Alberto De MagalhãesNo ratings yet

- (TDB) DVM Chiller For America (R410A, 60Hz, HP) - Ver.1.0Document23 pages(TDB) DVM Chiller For America (R410A, 60Hz, HP) - Ver.1.0Jean Carlos SanchezNo ratings yet

- Alarm Trip Set Points For VHP EnginesDocument1 pageAlarm Trip Set Points For VHP EnginesCristianNo ratings yet

- Ficha Técnica sc15g Secop DanfossDocument4 pagesFicha Técnica sc15g Secop DanfossCamilo CarreñoNo ratings yet

- Victrex TDS WG101Document2 pagesVictrex TDS WG101matteo.gaggioliNo ratings yet

- Clay Softening Temperature ChartDocument2 pagesClay Softening Temperature ChartgpawkennelNo ratings yet

- Topic: Ident No: Supersedes: Date: SUBJECT: Engine Protection Shutdown MODELS AFFECTED: All Waukesha EnginesDocument4 pagesTopic: Ident No: Supersedes: Date: SUBJECT: Engine Protection Shutdown MODELS AFFECTED: All Waukesha EnginesMarco Antonio Cruz MéndezNo ratings yet

- TE Series of Temperature Controller: An Economical Temperature Controller with Digital Displaying, Alarm and Adjust FunctionsDocument4 pagesTE Series of Temperature Controller: An Economical Temperature Controller with Digital Displaying, Alarm and Adjust FunctionsAlejandro Saravia AlcócerNo ratings yet

- Informacion Tecnica Sprinklers Upright y Pendent K8.0Document6 pagesInformacion Tecnica Sprinklers Upright y Pendent K8.0Raul ToledoNo ratings yet

- Am Braycote 601 EF Micronic US Eng 04 08 PdsDocument2 pagesAm Braycote 601 EF Micronic US Eng 04 08 PdsGrégory EcalleNo ratings yet

- Datasheet 1279 Pressure DuragaugeDocument5 pagesDatasheet 1279 Pressure Duragaugealfredo cedeñoNo ratings yet

- Lubricantes QX - 3200 - Series 60 HPDocument1 pageLubricantes QX - 3200 - Series 60 HPYeisson Javier Beltran AquinoNo ratings yet

- SF109EDocument13 pagesSF109EJosé SánchezNo ratings yet

- Thermostat Specifications 2011 AU NZDocument22 pagesThermostat Specifications 2011 AU NZJeff LuoNo ratings yet

- TPR Temperature Switch: Series TPR High Accuracy Nema 4X & Ip 65 UL, CSA and CE Approved Compact, Economical DesignDocument4 pagesTPR Temperature Switch: Series TPR High Accuracy Nema 4X & Ip 65 UL, CSA and CE Approved Compact, Economical DesignargaNo ratings yet

- SP-9888® Tank Lining: Selection & Specification DataDocument4 pagesSP-9888® Tank Lining: Selection & Specification DataSatees KrishnanNo ratings yet

- Technical Information: Cyclo® 6000 SeriesDocument16 pagesTechnical Information: Cyclo® 6000 SeriesAnonymous VWLxwfxgZMNo ratings yet

- Santoprene™ 121-75M100: Thermoplastic VulcanizateDocument3 pagesSantoprene™ 121-75M100: Thermoplastic VulcanizateBrian García AguirreNo ratings yet

- Dadfo Onoai Lajnioqja ÇliDocument6 pagesDadfo Onoai Lajnioqja ÇliAmy BoothNo ratings yet

- Chalice - 96642305Document2 pagesChalice - 96642305ShiHong KuangNo ratings yet

- TSW TTDocument2 pagesTSW TTPankaj RamoleNo ratings yet

- Gefran 1000 1101 Pid Controller ManualDocument19 pagesGefran 1000 1101 Pid Controller ManualCristian Godoy VargasNo ratings yet

- Calibration Certificate SampleDocument1 pageCalibration Certificate Samplefarid noor JusufNo ratings yet

- Calibration Certificate SampleDocument1 pageCalibration Certificate SampleAbdul Wahaab Khokhar100% (3)

- Rated Functioning Temperatures, Fusing-off Points, and Safety Approvals for Thermal Cutoffs A1-F to A8-FDocument11 pagesRated Functioning Temperatures, Fusing-off Points, and Safety Approvals for Thermal Cutoffs A1-F to A8-FNobreak ServiceNo ratings yet

- DS P5500-P6500-Low-press-gauge PDFDocument6 pagesDS P5500-P6500-Low-press-gauge PDFSukarim ChainkNo ratings yet

- Temperature Limit of Drift EliminatorsDocument1 pageTemperature Limit of Drift Eliminatorsparsiti unnesNo ratings yet

- Thermopop Operating Instructions Web BDocument2 pagesThermopop Operating Instructions Web BMirskymanNo ratings yet

- Chalice Pro-96642626Document2 pagesChalice Pro-96642626ShiHong KuangNo ratings yet

- Holmatro Oil Recommendations and MSDS Contact InfoDocument1 pageHolmatro Oil Recommendations and MSDS Contact InfoBraulio Mujica AguileraNo ratings yet

- Heat Detector Brosur..Document2 pagesHeat Detector Brosur..pitzuchiNo ratings yet

- Firelock™ V34, K8.0 Models V3401, V3402, V3405, V3406: 1.0 Product DescriptionDocument6 pagesFirelock™ V34, K8.0 Models V3401, V3402, V3405, V3406: 1.0 Product Descriptiongabriel240371No ratings yet

- 2004 Infiniti G35 Coupe Quick Reference SpecsDocument17 pages2004 Infiniti G35 Coupe Quick Reference Specsnikkon1100% (2)

- Eaton Fire Addressable Detector Range Datasheet 2019 PDFDocument2 pagesEaton Fire Addressable Detector Range Datasheet 2019 PDFAmol GoreNo ratings yet

- Installation and Operation ManualDocument19 pagesInstallation and Operation Manualciornei7romicaNo ratings yet

- 3496445985Document2 pages3496445985yosep gomezNo ratings yet

- Tenaris Proprietary Matlr Temperature SSC-NACE (I)Document1 pageTenaris Proprietary Matlr Temperature SSC-NACE (I)jainendra_ismNo ratings yet

- FLUXOGRAMA DE TODA REFINARIADocument19 pagesFLUXOGRAMA DE TODA REFINARIAMário Silva NetoNo ratings yet

- Ficha Tecnica Rociadores Montante Pendiente 3 4 1Document6 pagesFicha Tecnica Rociadores Montante Pendiente 3 4 1Javier Alba ArmestoNo ratings yet

- 2 - Pouch - Storage Shelf life-ST79Document2 pages2 - Pouch - Storage Shelf life-ST79Panthita Srisumran100% (1)

- Water Mist FundamentalsDocument24 pagesWater Mist Fundamentalsاحمد الجزار2007100% (2)

- Safety Audit NDocument24 pagesSafety Audit NAbdulSamad100% (1)

- Air Pockets: Invisible Threat to Sprinkler SystemsDocument3 pagesAir Pockets: Invisible Threat to Sprinkler SystemsvhlactaotaoNo ratings yet

- Sprinkler Systems Design Report 04302018 PDFDocument71 pagesSprinkler Systems Design Report 04302018 PDFShauvik Das100% (1)

- 750 Double Interlock Preaction System, Type D, 2 To 8 InchesDocument30 pages750 Double Interlock Preaction System, Type D, 2 To 8 InchesAhmad SalahNo ratings yet

- Name of The Student Class/ Section Topic of Thesis: Synopsis-1Document4 pagesName of The Student Class/ Section Topic of Thesis: Synopsis-1sunandNo ratings yet

- NBC 2005 - HighlightsDocument9 pagesNBC 2005 - Highlightsbijnor officeNo ratings yet

- Fire Sprinklers Hydraulic CalculationsDocument27 pagesFire Sprinklers Hydraulic CalculationsIlham Kelana100% (1)

- Water DemandDocument8 pagesWater DemandmehdiNo ratings yet

- 1574 - 03 Vol 2B - DS Package PDFDocument69 pages1574 - 03 Vol 2B - DS Package PDFanjnaNo ratings yet

- 012 SPP Presentation Oslo 2018Document44 pages012 SPP Presentation Oslo 2018Svetla KolevaNo ratings yet

- 7 Safety SystemsDocument61 pages7 Safety SystemsngtchungNo ratings yet

- Obstruction TableDocument1 pageObstruction Tableali faragallahNo ratings yet

- Fire Protection and Design AlarmsDocument33 pagesFire Protection and Design Alarmssarsan nedumkuzhi maniNo ratings yet

- 27,30 - The Saudi Building Code (SBC) - PDF - 87-87Document1 page27,30 - The Saudi Building Code (SBC) - PDF - 87-87heshamNo ratings yet

- Reliable Deluge Valve Model DDXDocument8 pagesReliable Deluge Valve Model DDXmanbkk100% (1)

- Sprinkler Training ManualDocument118 pagesSprinkler Training ManualChristine May CagaraNo ratings yet

- Fire Protection: Presentation by Vikram SinghDocument29 pagesFire Protection: Presentation by Vikram SinghShubham KumarNo ratings yet

- Flexible Sprinkler Hose Installation GuideDocument7 pagesFlexible Sprinkler Hose Installation GuideSopi LabuNo ratings yet

- Hotel Services: Case StudiesDocument37 pagesHotel Services: Case StudiestejaswiniNo ratings yet

- REGULATIONS FOR NAGPUR CITY DEVELOPMENTDocument158 pagesREGULATIONS FOR NAGPUR CITY DEVELOPMENTVirendra Kumar GajbhiyeNo ratings yet

- Bag HouseDocument40 pagesBag HousemahaveenNo ratings yet

- Engineering Standart For Fire Fighting PDFDocument33 pagesEngineering Standart For Fire Fighting PDFHans HanantaNo ratings yet

- Interfacing Fire Alarm and ElevatorsDocument76 pagesInterfacing Fire Alarm and ElevatorsFrancisco M. Ramos100% (1)

- Shipboard Firefighting: CODE FT0012Document17 pagesShipboard Firefighting: CODE FT0012Luis Fernando HRNo ratings yet

- A S M GL4110 & GL4910 P R P: Utomatic Prinklers Odel Endent Ecessed EndentDocument2 pagesA S M GL4110 & GL4910 P R P: Utomatic Prinklers Odel Endent Ecessed EndentAnwar SyedNo ratings yet

- Inspection Testing and Maintenance of Fire Protection SystemsDocument65 pagesInspection Testing and Maintenance of Fire Protection SystemsArfah Mp100% (1)

- Garbage and Linen Chutes: Specialized Factory For Steel Products Sigma Factory For Steel ProductsDocument8 pagesGarbage and Linen Chutes: Specialized Factory For Steel Products Sigma Factory For Steel ProductsAshraf RushdyNo ratings yet

- MEP Contractor Pre Qualification Document - SamppleDocument62 pagesMEP Contractor Pre Qualification Document - SamppleKaustubh Bidkar0% (1)