Professional Documents

Culture Documents

28 Dec 2016 160300010GYGFUIJTAnnexure-Pre-feasibilityReportPFR

Uploaded by

Anshul MishraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

28 Dec 2016 160300010GYGFUIJTAnnexure-Pre-feasibilityReportPFR

Uploaded by

Anshul MishraCopyright:

Available Formats

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

1.0 EXECUTIVE SUMMARY

Hindustan Fertilizer Corporation Limited (HFCL) operated four fertilizer units namely

Barauni (Bihar), Haldia and Durgapur (West Bengal) and Namrup (Assam). HFCL

Barauni Unit was commissioned in November 1976. The installed capacities of the main

plants were 600 MTPD Ammonia and 2×500 MTPD Urea.

In addition to the main plants, fertilizer complex at Barauni has self contained utility and

off-site facilities including township. During mid eighties, Government of India (GoI)

constituted various committees to look into the causes of poor performance with no

outcome and the plant was shut down from January 1999 due to unviable cost of

operation. GoI declared the closure of all the fertilizer manufacturing units of HFCL

including Barauni.

The Barauni unit of HFCL was defunct since its closure. Therefore, the unit and other

associated facilities were lying unutilized. There is presently no functional urea unit in

the Eastern part of the country except two small units at Namrup (Assam).

Due to closure of all fertilizer units, a large gap between demand and supply of Urea in

India was experienced both by consumers and Government. In 2007, Govt. decided to

review the decision for revival of fertilizer units in view of the availability of huge

infrastructure facilities at plant locations and increasing gap between demand and supply

of urea.

Earlier, in 2015, Government had approved revival of three units i.e. FCIL Gorakhpur,

Sindri and HFCL Barauni through ‘bidding route’. The Union Cabinet in its meeting on

July 13, 2016 approved the revival of these three fertilizers units. A new Joint Venture

Company (JVC) in the name of Hindustan Urvarak and Rasayan Limited (HURL) has

been formed by means of Special Purpose Vehicle (SPV) comprising of PSUs viz.

National Thermal Power Corporation (NTPC), Coal India Limited (CIL), Indian Oil

Corporation Limited (IOCL) and FCIL/HFCL, through ‘nomination route’.

Projects & Development India Limited, Sindri 1 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

In pursuance to the above objectives, PDIL was entrusted to prepare the techno-economic

feasibility report for the closed Barauni unit with proposed annual production capacity of

1.27 MMTPA Urea.

1.1 PROJECT LOCATION

The proposed fertilizer plant of HURL shall be located at Latitude 25024'45" N and

Longitude 86001'40" E in the existing premises of HFC, village- Bishunpur Chand,

Begusarai, Bihar. The proposed location is well connected by rail and road. Broad gauge

Railway Station (Barauni Jn.) is located at a distance of 5 km from the proposed site.

National Highway No. 31 passes adjacent to the proposed site. The nearest airport is at

Patna about 120 km from Barauni. Nearby major industries include IOCL’s refinery &

Barauni Thermal Power plant.

1.2 PROJECT AT A GLANCE

Main features of proposed Ammonia-Urea Fertilizer Project are as follows:

Table-1.1

Details of Main Facilities

S.No. Parameters : Description

1.0 Name of the Project : Ammonia-Urea Fertilizer Project

2.0 Project Proponent : Hindustan Urvarak and Rasayan

Limited (HURL)

3.0 Project Location : Barauni, Dist-Begusarai, Bihar

4.0 End Product : Urea

5.0 Plant Capacity (MTPD)

- Ammonia : 2200 MTPD

- Urea (Neem coated) : 3850 MTPD

6.0 Plant Stream Days : 330

7.0 Annual Production (MT) : 12,70,500

8.0 Man Power Requirement (Nos.) : 460

9.0 Project Time Schedule(Months) : 36

10.0 Mode of Implementation : EPCM

11.0 Requirement of Raw Material

& Utilities

Natural Gas : 90,910 Nm3/hr

Treated Water : 1100 m3/hr

12.0 Project Capital Cost (Rs. Crore) : 5847.10

Projects & Development India Limited, Sindri 2 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

1.3 Environmental Consideration

HURL Barauni does not fall in the list of critically polluted area identified by CPCB as

per Comprehensive Environmental Pollution Index (CEPI). The proposed plant shall be

established based on new generation technology and inbuilt pollution abatement devices.

All the required civic amenities like School, College, Hospitals etc. are available within

10 km radius of project site.

1.4 Engineering Consultant

1.4.1 Ammonia Plant

The most prominent ammonia process licensors are as follows:

o Haldor Topsoe (HTAS), Denmark

o Kellogg Brown & Root (KBR), USA

o Uhde, Germany

1.4.2 Urea Plant

The current global leading licensors of Urea technology are as follows:

- Stamicarbon, Netherlands

- Saipem, Italy

- Toyo Engineering Corporation (TEC), Japan

1.5 RAW MATERIAL AND UTILITIES

The requirement of raw material and utilities for the proposed project has been worked

out on the basis of rated capacity of the proposed Ammonia-Urea plants and are

summarized in Table- 1.2:

Table-1.2

Hourly Raw Material & Utility Requirement

Sl. No. Raw Material/Utilities Unit Requirement

1.0 Natural Gas (LHV 8653 kcal/Nm3) Nm3 90910

2.0 Treated Water m3 1100

3.0 Neem Oil kg 56.15

4.0 Power MW 25

Projects & Development India Limited, Sindri 3 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

1.6 PROJECT IMPLEMENTATION PLAN & TIME SCHEDULE

1.6.1 Project Implementation Plan

Barauni unit of HFCL is to be revived through nomination route. HURL will make his

own strategy for technology selection, appointment of engineering

consultants/contractors, identifying and selecting the project team, organisational

structure, funding arrangement for implementing the project. EPC (Engineering,

Procurement and Construction) mode of implementation has been considered.

1.6.2 Time Schedule

The expected implementation time is around 36 (33 months mechanical completion and 3

months commissioning) months after the zero date i.e. from the date of environmental

clearance.

1.7 Estimated Project Capital Cost

The capital cost of the proposed project is estimated at Rs. 5847.10 Crores.

1.8 FINANCIAL ANALYSIS OF PROJECT

There will be overall saving in specific energy consumption for Urea production and the

financial analysis is as under:

Table-1.3

Financial Analysis

Urea Plant Capacity MTPD 3850

Post-tax IRR (Project) % 13.72%

IRR (Equity) % 16.21%

Estimated Investment Rs. Crore 5847.10

Profit % 61.19

Cash-break-even point % 73.44%

Payback Years 6.13

1.9 NEED & JUSTIFICATION

The need and justification of the proposed project is summarized as under:

It will bridge-up the overall demand - supply gap of Urea in the country especially in

the region.

It will maintain stability in indigenous / domestic market for Urea.

Projects & Development India Limited, Sindri 4 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

It will check the import possibility of fertilizers to some extent and yield national

savings

It will generate employment opportunity for the people in the region.

It will ease the availability of chemical fertilizers to farmers.

1.10 Conclusion

The proposal for ammonia/urea plant of HURL at Barauni in Begusarai district of Bihar

state can be seen as a corrective step towards reducing the growing supply gaps for

fertilizer urea in eastern zone and to minimize import dependency. Indirectly, by

producing the fertilizer within the consumption region, it will lessen the pressure on the

long distance transport network as well as the transport cost involved in long distance

movement between production units and the consumer points.

The proposed plant shall be implemented with new generation technology & in-built

pollution abatement devices with low specific energy consumption of 7.005 Gcal/Te for

ammonia and 4.904 Gcal/Te for Urea.

Projects & Development India Limited, Sindri 5 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

2.0 INTRODUCTION

2.1 Background

Hindustan Fertilizer Corporation Limited (HFCL) operated four fertilizer units namely

Barauni (Bihar), Haldia and Durgapur (West Bengal) and Namrup (Assam).

The ammonia-urea complex of HFCL located at Barauni in Begusarai district of Bihar

was one of the new generation fertilizer plant in that period based on classical

reformation technology from hydrocarbon feedstock. The complex comprised of

Naphtha based ammonia-urea plants with self contained utility and off-site facilities.

The plant declared commercial production in November 1976. The installed capacities

of the main plants were 600 MTPD ammonia and 2×500 MTPD urea.

The plant performance has never been in the line of expectations. The primary reason

was design deficiencies and poor quality of equipment supply. The other reasons were

lack of stability in operation, unstable external power supply, etc. Desired production

level of the plant, has never been achieved. Although many of the problems faced by the

plants were identified at that time, no meaningful remedial and revamping measures

were undertaken. HFCL, Barauni made huge losses due to continuous non-performance

of its ammonia-urea plant. These losses had their own cascading effect. The corporation

was declared sick and was referred to BIFR in 1992. The plant was shut down from

January 1999.

Decision was taken to close down the company in December 2002. Subsequently,

Barauni unit was closed down and all the employees, barring a few, were released under

Voluntary Separation Scheme.

2.2 Revival of Barauni Unit of HFCL

The Barauni unit of HFCL was lying defunct since its closure. Therefore, the unit and

other associated facilities were lying unutilized. There is presently no functional Urea

plant in the Eastern part of the country except two small units at Namrup (Assam).

Earlier in 2015, Government had approved revival of three units i.e. FCIL Gorakhpur,

Sindri & HFCL Barauni unit through ‘bidding route’. However, the bidding process

could not be carried forward due to receipt of only one application each against

Projects & Development India Limited, Sindri 6 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

‘Request for Qualifications’ (RFQs) for revival of Gorakhpur and Sindri units of FCIL.

The annual consumption of Urea in the country is approx. 320 LMT, out of which 245

LMT is produced indigenously and rest is imported. To enhance the production of Urea

indigenously, Govt. had earlier also approved the revival of Talcher (Odisha) &

Ramagundam (Telangana) units of FCIL by PSUs through ‘nomination route’.

The Union Cabinet in its meeting on July 13, 2016 approved the revival of three

fertilizers units i.e. FCIL Gorakhpur, Sindri & HFCL Barauni. A new Joint Venture

Company (JVC) in the name of Hindustan Urvarak and Rasayan Limited (HURL) has

been formed by means of Special Purpose Vehicle (SPV) comprising of PSUs like

National Thermal Power Corporation (NTPC), Coal India Limited (CIL), Indian Oil

Corporation Limited (IOCL) and FCIL/HFCL, through ‘nomination route’.

The setting up of new fertilizer unit at Barauni will bridge-up the growing demand of

Urea in Bihar, West Bengal and Jharkhand. It will also ease the pressure on railway and

road infrastructure due to long distance transportation of Urea from Western and

Central Regions and thereby savings in Govt. subsidy on freight. It will also accelerate

the economic development of the region. Apart from growth of regional economy, this

unit will create opportunities for direct and indirect employments.

2.3 Project Location

The proposed Ammonia-Urea project shall be located Latitude 25024'45" N and

Longitude 86001'40" E at an altitude of 45m from Mean Sea Level (MSL) in the

existing premises of HFC, village- Bishunpur Chand, Begusarai, Bihar. National

Highway, NH-31 passes nearby and Broad gauge Railway Station (Barauni Jn.) is

located at a distance of 5 km. Major industries adjacent to the proposed fertilizer plant

are IOCL refinery and Barauni Thermal Power plant. The nearest airport is located at

Patna about 120 km from Barauni. Location of project site in Google map and

Geographical map has been shown in Plate-1 & 2.

2.3.1 Connectivity

The project site is well connected by road and rail network and is located adjacent to

NH-31. Barauni Railway Station is located at the distance of 5 km (NW).

Projects & Development India Limited, Sindri 7 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

2.3.2 Site Characteristics

Site characteristic are given in Table 2.1.

Table 2.1

Site Characteristics

Sl. No. Particulars Details

1. Latitude 25024'45" N

2. Longitude 86001'40" E

3. Altitude 45 m above MSL

4. Topography Plain

5. Present land-use Industrial

6. Nearest highway NH-31

7. Nearest Railway station Barauni Junction, 5 Km

8. Nearest Airport Patna, 120 Km

9. Nearest Town / city Begusarai: 9 Km

10. Water body Papraur pond: 0.25 Km

Ganges River: 8.6 Km

11. Seismic Zone IV

2.3.3 Climate

Being part of the Gangetic plains of the Indian subcontinent, the district experiences

three climatic seasons - summer season from March to mid June, monsoon season from

mid June to October and winter season from November to February. The month of

February & March fall in the transitional season from winter to summer described as

Spring or “Basant”. Similarly the months of September & October falls in the

transitional season from the monsoon season to the winter season and described as

“Shishir”.

2.3.4 Soil

Soil of the district is generally alkaline and is most fertile soil suitable for cultivation of

rice, jute and sugarcane.

2.3.6 Infrastructure

The proposed project is within the premises of the HFCL Barauni unit. all the

infrastructural facilities need to be developed in the existing complex.

2.4 Facilities available at old & closed Barauni Fertilizer Complex

Land

Projects & Development India Limited, Sindri 8 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

The total land available under HFCL Barauni ownership is around 630 acres comprising

of

Factory area and Railway siding : 350 acres

Township : 280 acres

This land does not include the land of Barrow Pit which has been Transferred to Bihar

State Electricity Board after approval by the Cabinet.

Railway Siding

Existing railway siding is meant for coal, naphtha and bagged Urea transportation. Rails

are in place however deteriorated and may be used after refurbishing. For the proposed

project, coal and naphtha handling is not required. Moreover entire usable railway lines

has to be reinstalled after dismantling the existing tracks to suit the requirement of new

proposed Bagging Plant.

Availability of Raw Water

Raw water requirement for the plant and township was made available through ten

numbers of deep tube well. The condition of the pumps and tube well could not be

ascertained as they have not been in use since long time. For proposed project, new ten

nos. of tube wells have been envisaged to meet the water requirement and older may be

kept as stand-by after thorough refurbishment.

2.5 Proposed Project Facilities & Description

2.5.1 Project Facilities

The proposed project consists of new ammonia and urea plant of 2200 MTPD & 3850

MTPD capacity respectively and related offsite and utility facilities considering

utilization of the existing facilities to the maximum extent possible. The details of the

facilities of proposed Fertilizer Complex are given below in Table 2.2.

Table - 2.2

List of Facilities in the proposed Fertilizer Complex

SI.No. Facility Capacity

1.0 NG/LNG Receiving & Metering Corresponding to 2.2 MMSCMD

Natural Gas

2.0 Process Plants

Projects & Development India Limited, Sindri 9 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

SI.No. Facility Capacity

2.1 Ammonia Plant 2200 MTPD

2.2 Prilled Urea (Neem Coated) Plant 3850 MTPD

3.0. Offsite Facilities

3.1 Ammonia Storage (Atm.) (2x5000) MT & associated

facilities

3.2 Urea Storage & Handling Facilities

a] Silo 60000 MT

b] Empty Bag Storage 2.0 Million

c] Bagged Storage 1000 MT (on platform)

d] Bagging Plant (7+1) Slats of 60 MTPH each

3.3 ETP Provided

3.4 Waste water collection system Provided

3.5 Contaminated rain water /storm Provided

water storage

3.6 Process & utility interconnection Provided

4.0 Utility facilities

4.1 Raw water pipeline and pumping Corresponding to 1265 m3/hr

from source capacity

4.2 Raw water storage and pumping Corresponding to 1265 m3/hr

capacity

4.3 DM water system including (1+1) x100 m3/hr

storage and pumping

4.4 Condensate Polishing Unit (2+1) x250 m3/hr

4.5 Cooling Tower

a] Ammonia Plant & CPP (8+1) Cell of 3500 m3/hr each

b] Urea Plant (5+1) Cell of 3500 m3/hr each

4.6 Instrument & Plant Air System

a] Compressor (Centrifugal) (1+1)×3000 Nm3/hr

b] Drying Unit (1+1)×3000 Nm3/hr

c] Receiver Provided

4.7 Inert Gas System 600 Nm3/hr

Projects & Development India Limited, Sindri 10 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

4.8 Steam & Power Generation System

a] GTG 15 MW

b] STG 10 MW

c] Emergency D.G. Set 1 × 2000 kVA

d] HRSG 1 x 130 MTPH

4.9 Flare System Provided

5.0 Infrastructure Provided

5.1 Plant Buildings Provided

5.2 Non-plant Buildings Provided

5.3 Auxiliary & General Welfare Provided

Facilities

5.4 Fire Fighting facilities Provided

5.5 Township & related facilities Provided

5.6 Transport Facilities

a] Locomotive (1+1) of 1200 HP

b] Railway Siding and lead line Lead line available, Railway

siding renovated for new

provision.

c] Road Transport Provision made

5.7 Construction equipment Provided

2.6 DESCRIPTION OF PROJECT

2.6.1 Ammonia Plant

The Ammonia Plant will consist of single stream of 2200 MTPD capacity. The plant

will be designed to use NG/RLNG as feed and fuel. The modern high capacity plant has

the advantage of economy of scale as well as lower energy consumption thereby

resulting in lower production cost. The Ammonia Plant will be self-sufficient in steam.

Part of steam requirement for Urea Plant will be met from ammonia plant. The

remaining steam requirement to urea plant will be met from the steam generated in

HRSG of Gas Turbine (GT) driven captive power plant.

Projects & Development India Limited, Sindri 11 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

2.6.2 Urea Plant

The Urea plant will consist of single stream having nameplate capacity of 3850 MTPD

neem coated prilled urea plant with stripping process technology. High-pressure steam

imported from the Ammonia Plant will be used to drive the CO2 Compressor with

extraction arrangement for meeting the process requirements.

2.6.3 Ammonia Storage

The provision of two new 5000 MT atmospheric ammonia storage tank with all

associated facilities have been considered for the proposed Project.

2.6.4 Urea Storage, Handling and Bagging

The new urea silo of 60000 MT capacities has been envisaged keeping product

inventory of about 15 days. Provision of new automatic bagging plant has been

considered. For the proposed project, (7+1) bagging streams, each of 60 MTPH, have

been considered. Modern and automatic system has been conceived for bagging and

loading of product into railway wagons/trucks. The system broadly consists of lifting of

empty bags from the sack magazine, placement of empty bags on the bag holder,

stitching of filled bags and flattening of filled bags on subsequent flat belt conveyor,

loading of filled bags into rail wagons/trucks shall be completely automatic involving

very little manual labour.

2.6.5 Water Supply, Treatment and Distribution

Ten nos. of new deep tube wells have been envisaged for the proposed project to meet

the water requirement. Besides this, DM Water Plant (1+1) 100 m3/hr capacity catering

to the requirements of the DM Water to the Steam Generation and Process Units has

been considered.

Considering the minimum condensate recovery from the complex, condensate polishing

unit of capacity (2+1) 250 m3/hr has been considered.

Projects & Development India Limited, Sindri 12 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

2.6.6 Cooling Water System

The Cooling water system will cater to the cooling water requirements of all facilities of

the complex. The cooling water requirements of pumps, compressors etc. shall also be

met from cooling water system.

The cooling water system provides cooling water to all users and controls the chemical

composition of circulating cooling water to prevent corrosion, biological growth and

solid deposits in piping etc. Cooling water return from various units is to be routed to

the cooling tower.

2.6.7 Ammonia, CPP and OSBL Cooling Water System

This cooling water system will cater to the cooling water requirement of the following

main units:

Ammonia Unit

CPP

Other Misc. facilities

The rated capacity of the system is 28000 m3/h. Cooling tower will have nine (8+1)

cells each of capacity 3500 m3/hr.

2.6.8 Urea Cooling Water System

The cooling water demand of Urea plant will be met from Urea Cooling Water System.

The rated capacity of the system is 17500 m3/h. Cooling tower will have six (5+1) cells

each of capacity 3500 m3/hr.

2.6.9 Steam & Power Generation System [Captive Power Plant (CPP)]

In order to have best optimized energy consumption for the complex, the CPP has been

integrated with Ammonia unit. The CPP will meet all the power requirements of

ammonia unit for normal as well as start-up/emergency operations. In addition, CPP

shall supply the required power and steam to rest of the facilities of the complex.

Projects & Development India Limited, Sindri 13 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

CPP is the central unit supplying steam (HP/ MP/ LP) and power to all process units,

utility systems & offsites. It consists of GTG/ HRSG, Deaerators and other auxiliaries.

i) Steam System

Steam is consumed in the complex at three levels, viz. High Pressure (HP) Steam,

Medium Pressure (MP) Steam, Low Pressure (LP) Steam. Steam is also generated at all

three levels within process units / facilities of complex either in process steam

generators or through steam turbines for process pump / compressor turbine drives.

Steam is used in the fertilizer complex mainly for the following purposes besides the

internal demand of CPP:

Process use (Chemical reaction, stripping steam etc.)

Steam drives for some of the compressors/pumps

As heating medium for steam heated exchangers

Steam tracing of lines

De-aeration

Intermittent requirement like decoking, purging etc.

Power System

Power is used in the complex for following main purposes, besides the internal power

demand of captive power plant (CPP):

For driving motors to run various rotating machinery (pumps, compressors, blowers,

etc.)

For meeting the power demand of instruments

For operating electric heaters (like instrument air-dryer heater, electric tracing of

lines if specified, etc.)

For plant lighting and other miscellaneous purposes, etc.

To meet the power requirement of proposed fertilizer complex, provision of NG based

Gas Turbo Generator (GTG) set (1) of 15 MW ISO rating capacity and Steam Turbine

Generator (STG) of 10 MW capacity has been kept to ensure uninterrupted power

supply to the plant. The exhaust gas from the gas turbine (GT) shall be utilised for

Projects & Development India Limited, Sindri 14 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

generating HP steam required in urea plant and STG. Further, emergency DG set of

2000 KVA has also been considered.

Provision shall be made for emergency power back-up from Bihar State Electricity

Board (BSEB).

2.6.10 Instrument Air Facilities

The normal instrument air requirement for the plant will be met from the Process Air

Compressor. However, as instrument air is very vital for process control instruments,

(1+1) Centrifugal Air Compressors each having a capacity of 3000 Nm3/hr along with

air dryer and receiver units have been provided for the Project. This arrangement will

add to the fail-safe system of instrument control.

2.6.10 Fire Fighting System

Fire-fighting system including firewater storage, pumps etc. shall be provided which

will be adequate to meet the requirement of proposed plant. Provision has been made

for firewater ring and other fire & safety equipment including fire tenders.

2.6.11 Effluent Treatment

Urea plant shall be provided with in-built deep Urea Hydrolyser System, which will

generate condensate for re-utilization in the plant itself. Ammonia plant shall be

provided with Condensate Stripper for stripping and re-use of ammonia. Disc. oil

separator shall be provided for removal of oil from oil bearing effluents generated in

various compressors system.

The occasional effluent generated during plant upset conditions shall be stored in

effluent delay pond from where it shall be discharged to treated effluent pond at

controlled rate after treatment.

2.6.12 Auxiliary & General Welfare Facilities

The following facilities have been considered under this head.

Safety

Projects & Development India Limited, Sindri 15 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

Smoke detection system

Workshop Equipment

Communication System

NDT Equipment

Laboratory Equipment incld. Lab Chemicals

Weigh Bridges

Public address system

Computers & Software

Pollution Monitoring System

Furniture’s & Fittings (Plants & Township)

Office, Canteen, First Aid etc.

Hospital Equipments

2.6.13 Transport Facilities

Provision for (1+1) locomotives each of 1200 HP, two nos. of cars, two nos. of jeeps,

one ambulance and one bus, etc. shall be provided for the project. New railway siding

have been considered for the proposed Project. Development of parking area for truck

movement within the complex shall also be provided.

2.6.14 Construction Facilities

The following facilities have been considered:

400 Te Crane (1 no.)

75 Te Crane (1 no.)

12.5 Te tyre mounted crane (1 no.)

5 Te tyre mounted crane (2 nos.)

Tractor with trailer (2 nos.)

Fork Lift (4 nos.)

Bull dozer (2 nos.)

Projects & Development India Limited, Sindri 16 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

Fire Tenders (2 nos.)

Tools and Tackles

Hutments & Shelters

Shed yards

Fencing

2.6.15 Township and other facilities

As the Barauni unit is closed since more than 15 years, most of the facilities are not in

usable condition. Hence, a new township along with other facilities has been

considered.

2.7 Raw Material Consumption

The consumption of raw material of proposed project is as under:

Table-2.3

Hourly Raw Material & Utility Requirement

Sl. No. Raw Material/Utilities Unit Requirement

a) Natural Gas (LHV 8653 kcal/Nm3) Nm3 90910

b) Treated Water m3 1100

c) Neem Oil kg 56.15

2.8 Estimated Project Capital Cost

The Project Capital Cost of the proposed project 2200 MTPD ammonia and 3850

MTPD urea along with associated offsite & utility facilities is estimated at Rs. 584710

Lakh.

2.9 Need & Justification

The need and justification of the proposed project is summarized as under:

Projects & Development India Limited, Sindri 17 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

It will bridge-up the overall demand - supply gap of Urea in the country especially in

the region.

It will maintain stability in indigenous / domestic market for Urea.

It will check the import possibility of fertilizers to some extent and yield national

savings

It will generate employment opportunity for the people in the region.

It will ease the availability of chemical fertilizers to farmers.

The proposed project is based on recent technology with minimum energy

consumption per tonne of ammonia and urea which in-turn will facilitate low

emission from the proposed ammonia / urea plants.

2.10 MARKET SURVEY

2.10.1 Gap in Production and Consumption

Though the level of fertilizer consumption in India has all along been very low, the

indigenous production of Urea in has always been lagging behind the consumption

requirement except for the year 2000-01.

Table-2.4

Gaps between Consumption & Production of Urea

(‘000 tonnes of material)

Year Consumption Production Gap % of Gap to Consumption

2000-01 191.86 196.23 (+) 4.47 2.28

2005-06 222.95 200.85 (-)22.10 9.91

2006-07 233.38 203.10 (-)30.28 12.97

2007-08 259.63 198.60 (-)61.03 23.51

2008-09 266.49 199.22 (-)67.27 25.24

2009-10 266.73 211.12 (-)55.21 20.85

2010-11 281.13 218.72 (-)62.41 22.20

2011-12 295.65 219.92 (-)73.73 25.61

2012-13 300.02 225.86 (-)74.16 24.72

2013-14 304.54 227.18 (-)77.36 25.40

(-) deficit (+) surplus

Projects & Development India Limited, Sindri 18 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

It may be seen from the above table that gap increased from 22.10 Lakh MT in 2005-06

to 77.36 Lakh MT in 2013-14. Surplus availability of urea in the year 2000-01 has been

due to decline in consumption on one hand and excess domestic availability particularly

in view of high opening stock on the other.

2.10.2 Future Supply Estimates

2.10.2.1 Indigenous Existing Supply

To meet the domestic demand for urea, production from the existing units in the country

stood at 227.18 Lakh MT during 2013-14, an increase of 1.32 Lakh MT over 2012-13.

Almost 21 plants operated above 100 % capacity utilization. It is likely that the same

trend shall be continued in the near future.

2.10.3 Projected Demand-Supply Gap

The following table gives scenario of the demand-supply gaps that are likely to emerge

by the end of 2016-17.

Table-2.5

Projected Demand Supply Gap for Urea

(‘000 tonnes of material)

2011-12 2012-13 2014-15 2015-16 2016-17

Demand Estimates (FAI) 28755 29733 31789 32870 33987

Supply Estimates

Plants under Operation 20000 20000 20000 20000 20000

OMIFCO 1652 1652 1652 1652 1652

Revamp/ Debottlenecking 2560 2560 2560 2560 2560

Total Supply 24212 24212 24212 24212 24212

There is almost 3-4 lakh tones of Urea demand per annum for manufacturing of

complex fertilizers and for exports to neighbouring countries like Nepal, Myanmar etc.

This will increase the projected deficit level of Urea further.

Projects & Development India Limited, Sindri 19 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

2.10.4 Import of Urea

The policy objective of Government of India for fertilizer sectors, as reflected in the

past five year plans, has been directed towards achievement of maximum degree of self-

sufficiency in ‘N’ production, leaving only marginal quantities to be met through

imports.

In spite of very impressive growth in indigenous production, the gap between

consumption and availability from indigenous sources remained at a high level

necessitating high level of imports. However, the pragmatic approach of the

government towards achieving self-sufficiency helped in substantially narrowing the

gap. Imports of urea were brought down to almost negligible level during the seventh

plan period. Subsequently, the production could not keep its pace with the growth in

consumption, consequently imports of Urea, which had come down to nil during 2000-

01, has steadily risen back to a level of 18 Lakh MT of nutrient (Product 70.87 Lakh

MT) during 2013-14 in the country.

2.10.5 Demand Projections for Urea

All-India demand forecast of fertilizer nutrients and product Urea during 12th Plan &

onwards as projected in the Report of the Working Group on Fertilizer Industry for the

Twelfth Plan (2012-13 to 2016-17) based on Population Nutrition Method are presented

in Table 2.6.

Table-2.6

Demand Projections for Fertilizer

( Lakh MT)

Year Fertilizer Nutrients Demand Urea Demand

N P K Total

2016-17 198.61 95.17 41.38 335.16 336.77

2017-18 201.65 98.68 42.90 343.23 337.54

2018-19 206.32 100.96 43.90 351.18 345.36

2019-20 210.92 103.22 44.88 359.02 353.07

2020-21 215.45 105.43 45.84 366.72 360.64

2024-25 230.60 115.30 50.13 396.03 380.99

Projects & Development India Limited, Sindri 20 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

To ensure uninterrupted supply in the eventuality of break down and unforeseen

demand, buffer stock up to a limit of 5% of the seasonal requirement is to be

maintained. Also taking into consideration 10% of the supply in the pipeline, projected

production capacity should be 15% above the projected demand of Urea as indicated in

Table above. Thus the Projected Production Capacity of Urea in the terminal year of

12th Plan should be around 400 Lakh MT.

2.10.6 Employment Generation (Direct & Indirect)

It is envisaged that the proposed project would generate employment opportunity

during construction phase as well as operation phase. For carrying out construction

related activities, it is envisaged to engage skilled, semi-skilled and unskilled workers

from local area to the maximum extent.

2.10.7 Manpower Requirement

Based on the organizational pattern followed in the existing fertilizer plants, it is

envisaged that, the total number of personnel required for operating in different plants

and establishments during normal operation in three shifts and at full rated capacity

would be about 460 directly employed & 1500 indirectly employed. The breakup of

direct employment is given in Table-2.7.

Table- 2.7

Man Power Requirement

S. No. Description Estimated Manpower Requirement

1. Plant Head 10

2. Production / Operation 210

3. Maintenance 112

4. Technical Services 22

5. Materials Management 28

6. Safety & Fire Fighting 15

7. Finance & Accounts 13

8. Personnel, Admn. & Medical 40

9. Marketing 10

Total 460

Projects & Development India Limited, Sindri 21 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

3.0 PROJECT DETAILS

3.1 Type of Project

The proposed project is based on recent Best Available Technology (BAT) with an aim

to reduce the energy consumption per tonne of production by adopting the modern

proven, fail-safe technology. The proposed project fulfills the aims and objective of EIA

by reduction in energy and natural resources like NG & water. This is a part of “India’s

Low Carbon Strategy” and INTENDED NATIONALLY DETERMINED

CONTRIBUTION (INDC) under UNEPCCC Protocol.

The proposed project is an independent project and not interlinked with any other

project. Implementation of new technology which consumes approximately 7.005

Gcal/Te of ammonia and 4.904 Gcal/Te of Urea shall facilitate low emission from

proposed ammonia / urea plants. It will recover maximum energy due to

implementation of new technology.

3.2 Co-ordinates of the project

The Geo Co-ordinate of Barauni fertilizer complex is at Longitude 25024'45" N and

Longitude 86001'40" E at an elevation of 45 m above mean sea level (MSL).

3.3 Details of Alternate Site

The choice for selection of alternate site is not open as the proposed Ammonia / Urea

Plants shall be installed within plant premises of old existing Barauni fertilizer

complex.

3.4 Size & Magnitude

The proposed Ammonia-Urea project will include the following main units:

Single Stream Ammonia plant with capacity of 2200 MTPD

Single Stream Urea plant with capacity of 3850 MTPD

Urea bagging and loading facilities etc.

All offsite & Utilities (Power, steam, water, inert gas, instrument air, effluent

treatment, cooling tower, safety/fire fighting, Gas Metering and refurbishment of

Non-Plant building facilities).

Projects & Development India Limited, Sindri 22 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

The project shall be implemented within premises of existing closed Barauni fertilizer

complex.

5.0 Raw Material & Utilities

5.1 Raw Material Consumption

5.1.1 Consumption Norms

The requirement of raw material and utilities for the proposed project has been worked

out on the basis of rated capacity operation of the ammonia urea plants. The

requirement of various inputs for 2200 MTPD Ammonia and 3850 MTPD Urea plants

are summarized in Table- 5.1:

Table-5.1

Raw Material & Utility Requirement

Raw Material/Utilities Unit Requirement

Natural Gas (LHV 8653 kcal/Nm3) Nm3/hr 90910

Treated Water m3/hr 1100

Neem Oil Kg/hr 56.15

5.1.2 Natural Gas

NG / R-LNG will be made available for the proposed project from 18" & 922 Km long

(mainline) GAIL’s Jagdishpur-Phulpur-Haldia pipeline. The Cabinet Committee on

Economic Affairs has recently approved the viability gap funding for NG pipeline from

Jagdishpur to Haldia and Bokaro to Dhamra (JHBDPL). The project will cover states

like U. P., Bihar, Jharkhand, Odisha & WB.

5.1.3 Water

The total requirement of treated water for the complex is envisaged to be around 1100

m3/hr. Raw water requirement (1265 m3/hr) will be made available from proposed new

10 nos. of bore wells.

5.1.4 Bags

Urea will be sold in 50 kg bags. The provision has been made for use of polyethylene

bags. The delivered price of bag has been considered as Rs. 19.0/bag

Projects & Development India Limited, Sindri 23 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

5.1.5 Catalysts

The following catalysts would be required for the project:

1. Hydro-desulphurisation

2. Primary Reformation

3. Secondary Reformation

4. HT Co-Shift Conversion

5. LT Co-Shift Conversion

6. Methanation

7. Synthesis

5.2 Resource Recycling/Reuse

The proposed project envisages resource recycling and reuse. The entire amount of effluent

shall be treated and reused either in plant or in maintenance of green belt areas. Efforts

shall be made to adopt Zero Liquid Discharge (ZLD) concept.

5.3 Availability of Water, Energy & Power

Water

Raw water requirement of 1265 m3/hr will be made available from proposed 10nos. of

new bore wells.

Energy

To meet the requirement of proposed fertilizer complex, provision of NG based 1 no.

each of GTG of 15 MW ISO rating capacity and STG of 10 MW capacity has been kept

to ensure uninterrupted power supply to the plant. The exhaust gas from the GT shall be

utilised for HP steam generation required in Urea plant and STG.

5.4 Quantity of Waste (Solid & Liquid)

The main solid wastes to be generated will be spent catalysts, spent resins, activated

carbons, etc. Spent catalyst shall be stored, handled as per Hazardous & Other Wastes

(Management & Trans-boundary Movement) Rules 2016 and shall be disposed of

through SPCB authorized recyclers. The quantity of wastes are as under:

Spent catalyst (Non-ferrous): Approx. 800 MT in 4 - 5 years.

Spent oil: Approx. 1 KL per month (max.)

WTP sludge = 100 Kg/hr (max.)

ETP sludge =100 Kg/hr (approx.)

Projects & Development India Limited, Sindri 24 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

6.0 ENVIRONMENTAL CONSIDERATION

HURL Barauni does not fall in the list of critically polluted area identified by CPCB as

per Comprehensive Environmental Pollution Index (CEPI). The proposed plant shall be

established based on new generation technology and inbuilt pollution abatement devices.

All the required civic amenities like School, College, Hospitals etc. are available within

10 km radius of project site.

6.1 Waste Management & Disposal System

Waste Management & Disposal System for the proposed project is described below:

Gaseous Emissions During Combustion of Fuel

Fuel used in the proposed project is NG. Hence, SO2 emissions are not anticipated.

Ultra Low NOx burners will be installed to keep NOx emission at minimum.

Production Processes

Urea dust (less than 50 mg/m3) and ammonia (less than 150 mg/m3) emissions are

envisaged from Urea Prilling Tower (UPT) & Ammonia plant. Flare stack and vent stack

of adequate height shall be provided in the respective plants.

Material Handling

To control the emissions in the Urea bagging plant, the plant has been provided with de-

dusting system. Dust from various points will be collected and sent to Urea plant where it

will be dissolved in Urea solutions and reprocessed.

6.2 Liquid Effluents

Effluent generated from the process, shall be treated within the complex:

Ammonia plant process condensate will be treated in the process condensate stripper

and recycled to the process as Boiler Feed Water.

Urea plant process condensate shall be treated in in-built Urea hydrolyser and

recycled to the process as Boiler Feed Water.

Cooling tower and DM plant effluent shall be treated and re-used in the system.

Domestic effluent after treatment in the STP shall be used for green belt development,

to the extent possible.

Projects & Development India Limited, Sindri 25 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

6.3 Solid Waste

Hazardous waste generated in the Ammonia-Urea plants such Spent Catalyst, used Oil

etc. shall be sold to authorized vendors as per Hazardous & Other Waste (Management &

Trans-boundary) Rules, 2016.

7.0 EMPLOYMENT GENERATION

It is envisaged that the proposed project would generate sufficient employment

opportunity during construction phase as well as operation basis. For carrying out

construction related activities, it is envisaged to engage skilled, semi-skilled and unskilled

workers from local area to the maximum extent.

7.1 Manpower Requirement

Based on the organizational pattern followed in the existing fertilizer plants, it is

envisaged that total number of personnel required for operation of the proposed plants in

three shifts and at full rated capacity would be about 460 nos. directly employed & 1500

nos. indirectly employed. The break-up is as under:

Table- 7.1

Man Power Requirement

Sl. No. Description Estimated Manpower

Requirement

1. Plant Head 10

2. Production / Operation 210

3. Maintenance 112

4. Technical Services 22

5. Materials Management 28

6. Safety & Fire Fighting 15

7. Finance & Accounts 13

8. Personnel, Admn. & Medical 40

9. Marketing 10

Total 460

Projects & Development India Limited, Sindri 26 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

8.0 REHABILITATION & RESETTLEMENT PLAN

Old & closed Barauni fertilizer complex is spread over an area of 630 acres of land and is

under the administrative possession of HFCL, which is also one of the members of JVC.

The proposed fertilizer project of HURL shall be implemented within the plant premises

of HFCL, Barauni. Hence, any planning with respect to rehabilitation & resettlement is

not applicable.

9.0 PROJECT SCHEDULE & COST ESTIMATES

9.1 Project Schedule

The project completion scheduled shall be 36 months after issuance of EC.

9.2 Cost Estimates

The capital cost of the proposed project 2200 MTPD ammonia and 3850 MTPD urea

along with associated offsite & utility facilities is estimated to be Rs. 5847.10 Crores.

Details of the requirement are as under:

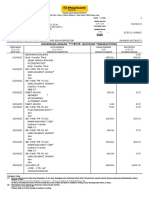

Table-9.1

Project Capital Cost Estimates

(Rs. Lakhs)

1.0 Main Plants 111894 189310 301204

2.0 Off-Site Facilities 3816 89603 93419

3.0 Spares 5758 10789 16547

4.0 Project Management Charges 70 11294 11364

5.0 Engineering fee & Services 21803 27896 49699

6.0 Non Plant Building 0 4000 4000

7.0 Township 0 6000 6000

8.0 Piling 0 5000 5000

9.0 Land Development 0 2976 2976

10.0 Total Manufacturing Facilities 143341 346868 490209

11.0 Working Capital Margin 0 17272 17272

12.0 Contingency 7167 15220 22387

13.0 Net Commissioning Expenses 0 7000 7000

14.0 Land/Usable Assets of HFCL 0 21439 21439

14.0 Interest During Construction 0 26403 26403

Total Project Cost 150508 434202 584710

Note: FC - Foreign Currency, IC- Indian Currency

Assumptions are provided in Annexure – I.

Projects & Development India Limited, Sindri 27 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

10.0 COST OF PRODUCTION

10.1 Capacity and Level of Production

The capacities of proposed Ammonia and Urea plants have been considered as 2200

MTPD and 3850 MTPD respectively. The conversion of total Ammonia will be about

3850 MTPD Urea and there will not be any surplus ammonia. The cost of production of

Urea has been worked out assuming operation at rated capacity and 330 days stream

efficiency. The annual production of Urea on these assumptions will be 12.70 Lakh MT.

10.2 Cost of Production

The cost of production of Neem coated Urea has been worked out at 95% and rated

production (100%) levels and presented below:

Table- 10.1

Cost of Production of Neem Coated Urea

Sl.No. Level of Production COP of Urea (Rs./MT)

1.0 95% level 18445

2.0 100% level 18113

10.3 Input Prices

The cost of production has been calculated based on the following prices of raw material,

utilities and packing material as given as under:

Table- 10.2

Input Prices

Sl.No. Item Unit Unit Price (Rs.)

3 3

1.0 NG/RLNG (LHV=8653 kcal/Nm ) 1000Nm 17254

3

2.0 Water Cess 100 m 60

3.0 Neem Coating Cost MT of Urea 143

4.0 Bags 1 No. 19.0

Projects & Development India Limited, Sindri 28 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

11.0 ANALYSIS OF PROPOSAL

The final analysis of proposal may be briefed as under:

a) The revival of Barauni Fertilizer Complex will narrow the gap between demand and

supply of Urea in eastern zone of India.

b) Proposed project site as well as area in Bihar State has never been identified as

“CRITICALLY POLLUTED AREA/ ZONE” by CPCB.

c) The implementation of recently developed Best Available Technology (BAT) which

is a reliable and reproducible in different environment throughout the globe will

reduce the carbon load of the country.

d) The proposed project fulfills aims & objectives of EIA to save & conserve the natural

resources like NG, Water etc., in compliance to the resources conservation and reuse

act.

e) The proposed project is a part of “India Low Carbon Strategy” and INTENDED

NATIONALLY DETERMINED CONTRIBUTION (INDC) under UNEPCCC

Protocol.

f) The policy for revival of Barauni fertilizer complex is based on the recommendation

of Cabinet Committee on Economic Affairs (CCEA) of Government of India held on

4.8.2011.

10.0 CONCLUSION

Based on the facts mentioned above, the proposed project proposal of HURL for

installation of new Ammonia-Urea fertilizer complex deserves a sincere consideration on

priority basis for implementation of project in time.

Projects & Development India Limited, Sindri 29 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

Plate-1

Location of Old Closed Barauni Fertilizer Complex of HFCL on Google Map

Projects & Development India Limited, Sindri 30 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

Plate-2

Location of Old Closed HFCL Barauni fertilizer complex on Geographical Map

Projects & Development India Limited, Sindri 31 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

PLATE-3

PLOT PLAN OF PROPOSED BARAUNI UNIT OF HURL

Projects & Development India Limited, Sindri 32 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

PLATE-1.4

BLOCK DIAGRAM OF PROCESS OF PROPOSED AMMONIA PLANT

Projects & Development India Limited, Sindri 33 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

PLATE-1.5

BLOCK DIAGRAM OF PROCESS OF PROPOSED UREA PLANT

Projects & Development India Limited, Sindri 34 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

PLATE-1.6

BLOCK DIAGRAM OF RAW MATERIAL & UTILITY BALANCE

Projects & Development India Limited, Sindri 35 of 36

Feasibility report for EC of Ammonia/ Urea Project of HURL at Barauni, Begusarai (Bihar)

Note: Zero date will start after issuance of EC from MoEF&CC

PLATE-1.7

BAR CHART SHOWING PROJECT COMPLETION SCHEDULE

Projects & Development India Limited, Sindri 36 of 36

You might also like

- Pre-Feasibility R E P O R T: Ammonia / Urea Fertilizer ProjectDocument37 pagesPre-Feasibility R E P O R T: Ammonia / Urea Fertilizer ProjectAyman RiyadhNo ratings yet

- Pre-Feasibility R E P O R T: Ammonia / Urea Fertilizer ProjectDocument37 pagesPre-Feasibility R E P O R T: Ammonia / Urea Fertilizer Projectsagar das guptaNo ratings yet

- 09 Aug 2016 184316203KN27MVMPAnnexure-Pre-FeasibilityReport (PFR) File PDFDocument43 pages09 Aug 2016 184316203KN27MVMPAnnexure-Pre-FeasibilityReport (PFR) File PDFAyman RiyadhNo ratings yet

- EIA AkzoDocument23 pagesEIA AkzoRavi PanaraNo ratings yet

- Hindustan Petroleum Corporation2016Document18 pagesHindustan Petroleum Corporation2016Ngô Mạnh CườngNo ratings yet

- Vardhinni Fuels PVT LTD 120 KLPD Grain Ethanol Ec Granted by Moef&cc On 03.04.2023Document12 pagesVardhinni Fuels PVT LTD 120 KLPD Grain Ethanol Ec Granted by Moef&cc On 03.04.2023SRINIVASAN TNo ratings yet

- 20 - Feb - 2019 - 170439480IDKL5X0QAnnexPFRDocument44 pages20 - Feb - 2019 - 170439480IDKL5X0QAnnexPFRGavoutha BisnisNo ratings yet

- Capacity Expansion at BPCL Aonla POLDocument37 pagesCapacity Expansion at BPCL Aonla POLKalai SelvanNo ratings yet

- Acbi IndiaDocument43 pagesAcbi IndiaPriyankaNo ratings yet

- Ruchi Soya IndustriesDocument8 pagesRuchi Soya IndustriesAkhilesh KumarNo ratings yet

- GGHGLGLLGDocument20 pagesGGHGLGLLGInder RatheeNo ratings yet

- CEMENTDPRDocument142 pagesCEMENTDPRasnsuresh025No ratings yet

- Writereaddata EIA 25012019N4DFNOK8ALLCHAPTERSOFEIAREPORT PDFDocument223 pagesWritereaddata EIA 25012019N4DFNOK8ALLCHAPTERSOFEIAREPORT PDFKundan ShandilyaNo ratings yet

- NFL Project ReportDocument24 pagesNFL Project ReportAsaraf Ali50% (2)

- Title / Link To Download Bidding DocumentDocument24 pagesTitle / Link To Download Bidding Documentarjun SinghNo ratings yet

- Bhadrawati Project Information Memorandum (PIM)Document33 pagesBhadrawati Project Information Memorandum (PIM)Arpita GuptaNo ratings yet

- EIA MatixsadfsDocument11 pagesEIA MatixsadfsMudassir FarooqNo ratings yet

- Gujarat Narmada Valley Fertilizers and Chemicals Limited BRCH86 Exe Summ EngDocument13 pagesGujarat Narmada Valley Fertilizers and Chemicals Limited BRCH86 Exe Summ EngMeet ArdeshnaNo ratings yet

- 0 0 26 Feb 2015 1405391401PFR PDFDocument17 pages0 0 26 Feb 2015 1405391401PFR PDFKedar YadavNo ratings yet

- KGSInfra Corporation LTD Nasik Exe Summ 2015Document20 pagesKGSInfra Corporation LTD Nasik Exe Summ 2015prakash.chdNo ratings yet

- Hurl G Ed C00 Sta SPC 000 D123 - 2Document68 pagesHurl G Ed C00 Sta SPC 000 D123 - 2Darshan PanchalNo ratings yet

- Proj Desc 599Document47 pagesProj Desc 599Priya MathurNo ratings yet

- Food ProcessingDocument201 pagesFood ProcessingMohan P100% (1)

- AVISA FOODS AND FUELS - Ethanol & Cogen EC Report - Moefcc - 19.04.23Document14 pagesAVISA FOODS AND FUELS - Ethanol & Cogen EC Report - Moefcc - 19.04.23SRINIVASAN TNo ratings yet

- Project Report - MFG of Specialty Chemicals by Krishna Antioxidants PVT LTDDocument8 pagesProject Report - MFG of Specialty Chemicals by Krishna Antioxidants PVT LTDAshok PatilNo ratings yet

- 191021Mn Alloy Sinter Plant, BMPLDocument19 pages191021Mn Alloy Sinter Plant, BMPLravibelavadiNo ratings yet

- PFD FileDocument40 pagesPFD FileAbhishek ChaudhariNo ratings yet

- Background:: Project Location: Aditya Aluminium Is Located in Sambalpur District of Odisha State. TheDocument10 pagesBackground:: Project Location: Aditya Aluminium Is Located in Sambalpur District of Odisha State. TheNitanshu ChavdaNo ratings yet

- PDD Roura PDFDocument57 pagesPDD Roura PDFChakradhar BabuNo ratings yet

- Site HSE Plan (TOYO) (R)Document200 pagesSite HSE Plan (TOYO) (R)STG INSTRUMENT100% (1)

- 20 Jul 2018 210804070R6TNR0QZExidePrefeasibilityReportDocument13 pages20 Jul 2018 210804070R6TNR0QZExidePrefeasibilityReportayaanNo ratings yet

- 2G ICT Bathinda PFRDocument18 pages2G ICT Bathinda PFRNanasaheb PatilNo ratings yet

- BORL HCU-DHT APC Scoping Study Report (Final)Document45 pagesBORL HCU-DHT APC Scoping Study Report (Final)AnilKumarNo ratings yet

- Ethanol Plant From PSA Off Gases Ex HGU-Installation-Panipat Refinery-IOCL-EIA ReportDocument354 pagesEthanol Plant From PSA Off Gases Ex HGU-Installation-Panipat Refinery-IOCL-EIA ReportSRINIVASAN TNo ratings yet

- FACT ProjectsDocument6 pagesFACT ProjectsPritesh RoyNo ratings yet

- Capacity Expansion of POL DepotDocument16 pagesCapacity Expansion of POL DepotKalai SelvanNo ratings yet

- 2 PE Just RPT - Chambi Khal (F)Document42 pages2 PE Just RPT - Chambi Khal (F)nasif fattahNo ratings yet

- Project Feasibility: M/S. Radhey Foam Pvt. LTDDocument16 pagesProject Feasibility: M/S. Radhey Foam Pvt. LTDKarthikeyan100% (1)

- EIA ReportDocument188 pagesEIA ReportChan KianNo ratings yet

- Eg Gnind98g34 CBM Termeval 0Document65 pagesEg Gnind98g34 CBM Termeval 0sameer bakshiNo ratings yet

- Analyst BriefingDocument14 pagesAnalyst BriefingAnsarNo ratings yet

- Pre-Feasibility Report CCCR PlantDocument13 pagesPre-Feasibility Report CCCR Plantadelafuente2012No ratings yet

- Pre Feasibility Report: Prior Environment ClearanceDocument44 pagesPre Feasibility Report: Prior Environment ClearanceElio barrios ibarraNo ratings yet

- EIL - EIA Study - Refinery Unit DesalinationDocument24 pagesEIL - EIA Study - Refinery Unit DesalinationSwapnil WankhedeNo ratings yet

- Detailed Project Report (DPR) : Integrated Sugar (5000 TCD), Cogen Power (30 MW) & Ethanol Plant (60 KLPD)Document78 pagesDetailed Project Report (DPR) : Integrated Sugar (5000 TCD), Cogen Power (30 MW) & Ethanol Plant (60 KLPD)Vaibhav AgrawalNo ratings yet

- Ban02 01Document6 pagesBan02 01TasfikNo ratings yet

- EMPcompDocument21 pagesEMPcompMohit BhatiaNo ratings yet

- Project Design DocumentDocument39 pagesProject Design DocumentPrachurya SharmaNo ratings yet

- Vol 2Document559 pagesVol 2erbhaveshparmarNo ratings yet

- PFD FileDocument3 pagesPFD FileMedha MishraNo ratings yet

- Alumina PFR PDFDocument309 pagesAlumina PFR PDFMudit KediaNo ratings yet

- FS Dri 01Document50 pagesFS Dri 01فردوس سليمان100% (1)

- UREA Data 1Document8 pagesUREA Data 1simaproindia4958No ratings yet

- Feasibility Report On Diesel Hydro-Treater (DHT) Unit and Associated FacilitiesDocument29 pagesFeasibility Report On Diesel Hydro-Treater (DHT) Unit and Associated FacilitiesDivyansh Singh ChauhanNo ratings yet

- 02 May 2019 160030223F9D5GNRMPFRDocument46 pages02 May 2019 160030223F9D5GNRMPFRSwami PrabhuNo ratings yet

- Clean Development Mechanism Project Design Document Form (CDM-PDD) Version 03 - in Effect As Of: 28 July 2006Document44 pagesClean Development Mechanism Project Design Document Form (CDM-PDD) Version 03 - in Effect As Of: 28 July 2006smh1678No ratings yet

- DownloadPfdFile AspxDocument13 pagesDownloadPfdFile Aspxfirozr249No ratings yet

- Guidebook for Demand Aggregation: Way Forward for Rooftop Solar in IndiaFrom EverandGuidebook for Demand Aggregation: Way Forward for Rooftop Solar in IndiaNo ratings yet

- Carbon Capture, Utilization, and Storage Game Changers in Asia and the Pacific: 2022 Compendium of Technologies and EnablersFrom EverandCarbon Capture, Utilization, and Storage Game Changers in Asia and the Pacific: 2022 Compendium of Technologies and EnablersNo ratings yet

- Waste to Energy in the Age of the Circular Economy: Compendium of Case Studies and Emerging TechnologiesFrom EverandWaste to Energy in the Age of the Circular Economy: Compendium of Case Studies and Emerging TechnologiesRating: 5 out of 5 stars5/5 (1)

- DFL DD ApproachDocument3 pagesDFL DD ApproachAnshul MishraNo ratings yet

- Financial Management E BookDocument4 pagesFinancial Management E BookAnshul MishraNo ratings yet

- Edit SheetDocument3 pagesEdit SheetAnshul MishraNo ratings yet

- Student Hand BookDocument59 pagesStudent Hand BookAnshul MishraNo ratings yet

- Title: Business Model Study of Sharekhan LimitedDocument1 pageTitle: Business Model Study of Sharekhan LimitedAnshul MishraNo ratings yet

- Afm ProjectDocument11 pagesAfm ProjectAnshul MishraNo ratings yet

- Performance Management & AppraisalDocument25 pagesPerformance Management & AppraisalAnshul MishraNo ratings yet

- HRMDocument50 pagesHRMAnshul MishraNo ratings yet

- Leak Off Test: - Procedure - Maasp - Maximum Allowable Mud WeightDocument5 pagesLeak Off Test: - Procedure - Maasp - Maximum Allowable Mud Weighteng20072007No ratings yet

- Utilities User Guide: Caefatigue Software (CF)Document38 pagesUtilities User Guide: Caefatigue Software (CF)Oliver RailaNo ratings yet

- Common Hydraulic Problems - Symptoms and Causes - Hydraproducts - Hydraulic Systems - Hydraulic Power Packs - BlogDocument3 pagesCommon Hydraulic Problems - Symptoms and Causes - Hydraproducts - Hydraulic Systems - Hydraulic Power Packs - BlogLacatusu MirceaNo ratings yet

- SWFP66D Series Fine-Grinding Hammer Mill: Operation ManualDocument65 pagesSWFP66D Series Fine-Grinding Hammer Mill: Operation ManualDanielDeFrancescoNo ratings yet

- RouterOS by Example Stephen Discher PDFDocument236 pagesRouterOS by Example Stephen Discher PDFAntonioNo ratings yet

- TW Ebook Product Thinking Playbook Digital2pdfDocument172 pagesTW Ebook Product Thinking Playbook Digital2pdfgermtsNo ratings yet

- SD) Relay Settings CalculationsDocument8 pagesSD) Relay Settings CalculationsElectrical RadicalNo ratings yet

- BT-FPFF - Read To Find Questions For Asynchronous LearningDocument2 pagesBT-FPFF - Read To Find Questions For Asynchronous Learningjaredlimson1129No ratings yet

- Huawei FusionServer RH8100 V3 Data SheetDocument4 pagesHuawei FusionServer RH8100 V3 Data Sheetpramod BhattNo ratings yet

- Emhart Inspection Defect GuideDocument1 pageEmhart Inspection Defect GuideBryan Nadimpally75% (4)

- Ibs Kota Bharu 1 30/06/22Document7 pagesIbs Kota Bharu 1 30/06/22Nik Suraya IbrahimNo ratings yet

- The Power of Social MediaDocument3 pagesThe Power of Social MediaTIGER CHEETANo ratings yet

- FB156Document14 pagesFB156Hoangvinh DuongNo ratings yet

- Analytics-Based Investigation & Automated Response With AWS + Splunk Security SolutionsDocument37 pagesAnalytics-Based Investigation & Automated Response With AWS + Splunk Security SolutionsWesly SibagariangNo ratings yet

- Ps10ex Pressure Switch PresostatoDocument1 pagePs10ex Pressure Switch PresostatoJULIO AREVALONo ratings yet

- Supply Chain ManagementDocument16 pagesSupply Chain ManagementHaider AyyNo ratings yet

- Construction Cost Estimation SystemDocument5 pagesConstruction Cost Estimation SystemURBANHIJAUNo ratings yet

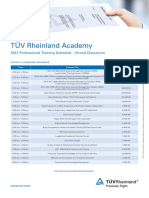

- TÜV Rheinland Academy: 2021 Professional Training Schedule - Virtual ClassroomDocument3 pagesTÜV Rheinland Academy: 2021 Professional Training Schedule - Virtual ClassroomAaron ValdezNo ratings yet

- NAVEEN Final Project 2Document83 pagesNAVEEN Final Project 2syed bismillahNo ratings yet

- Schengen Visa Application 2021-11-26Document5 pagesSchengen Visa Application 2021-11-26Edivaldo NehoneNo ratings yet

- 4MATION SAM Module IO-IDocument54 pages4MATION SAM Module IO-IIkhuosho AbodeNo ratings yet

- Problem Tutorial: "Erase Nodes": 1 CNT (U, V)Document6 pagesProblem Tutorial: "Erase Nodes": 1 CNT (U, V)Roberto FrancoNo ratings yet

- Flashattention: Fast and Memory-Efficient Exact Attention With Io-AwarenessDocument34 pagesFlashattention: Fast and Memory-Efficient Exact Attention With Io-AwarenessMarcos CostaNo ratings yet

- Perilaku Masyarakat Terhadap Kesehatan Lingkungan (Studi Di Pantai Desa Ketong Kecamatan Balaesang Tanjung Kabupaten Donggala)Document11 pagesPerilaku Masyarakat Terhadap Kesehatan Lingkungan (Studi Di Pantai Desa Ketong Kecamatan Balaesang Tanjung Kabupaten Donggala)Ali BaktiNo ratings yet

- Excel NotesDocument9 pagesExcel NotesAhnNo ratings yet

- Decision Support For Blockchain PlatformDocument20 pagesDecision Support For Blockchain PlatformgianniNo ratings yet

- Blast Resistant Buildingppt - CompressDocument35 pagesBlast Resistant Buildingppt - CompressAmal RobeenNo ratings yet

- Forensic Ballistics Reviewer - ScribdDocument589 pagesForensic Ballistics Reviewer - ScribdMelcon S. Lapina96% (25)

- Principles of Electric Circuits - FloydDocument40 pagesPrinciples of Electric Circuits - FloydhdjskhdkjsNo ratings yet

- Satellite TTC Module 4Document21 pagesSatellite TTC Module 4AmitNo ratings yet