Professional Documents

Culture Documents

WhitePaper4 A Case For Sidetrack Campaign With Motor BHA

Uploaded by

Josh SabimanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WhitePaper4 A Case For Sidetrack Campaign With Motor BHA

Uploaded by

Josh SabimanCopyright:

Available Formats

What To Do When RSS Is Not An

Option Due To Tight Budget

A Case For Side-track Campaign with Motor BHA

Issued: July 12, 2018

By: Erwan de Boisjolly

WhitePaper4 - A Case For Sidetrack Campaign with Motor BHA

I. Context

An Operator is planning a side-track campaign on approximately 20 wells. As they want to reduce equipment’s costs

-avoiding expensive RSS- they want to assess if these wells can be drilled with steerable motor BHA. The Operator

contacted DrillScan to perform some advanced engineering, considering both Directional and Mechanical aspects.

The Operator also asked DrillScan to provide recommendations for drill pipes selection, to optimize drillstring

design in terms of Hydraulics and Torque & Drag.

A complete Trajectory screening had been performed by DrillScan beforehand, to identify the most challenging well

trajectories to be drilled during this campaign.

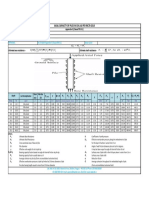

II. Directional challenges

The objective is to assess if the

complex 3D trajectory could be

drilled using a steerable motor

BHA despite high DLS

(10deg/30m) in soft formation.

DrillScan proposed a BHA

design that can deiver build,

drop and slant sections in a

single run, simulating with our

WellScan® software its

sensitivity to Weight On Bit

(WOB) and Hole Overgauge.

DrillScan was able to estimate a slide and

rotate pattern (respectively 80%/20%) Impact of Hole Overgauge and VGS activation

for both build and drop sections, on Build rate (rotating mode)

providing optimized bend angle of 1.5°

2

based on standard 6 3/4’’ hole drilling

equipment. 1,5

Build rate (deg/30m)

DrillScan also recommended to use a 1

Variable Gauge Stabilizer to get 0,5

inclination control while drilling slant

section in soft formation in case WOB is 0

limited and Hole Overgauge (OVG) is 0 10 20 30 40 50 60

-0,5

uncontrolled.

-1

Inclination (deg)

VGS 6" - OVG 1/2" VGS 6" - OVG 3/4"

VGS 6 1/2" - OVG 1/2" VGS 6 1/2" - OVG 3/4"

White paper – DrillScan - 2018 Page 2/3

WhitePaper4 - A Case For Sidetrack Campaign with Motor BHA

III. Torque and Drag and Buckling limits

III.1 - Drilling: The following questions were raised by the Operator:

• Ability to apply WOB while sliding,

• Ability to transfer torque at bit while rotating,

• Ability to back-ream from TD and derive rig power capacities.

DrillScan performed some

Torque and Drag and Buckling

analyses using its unique stiff

string model with contact

management. Sensitivities were

performed on the drillstring

composition: 3 ½” or 4” DP.

Buckling

margin

Looking at Hookload, tension

and torque profiles, the

simulations confirmed that the

sections could be safely drilled,

with comfortable margins to

apply the necessary torque and

weight at the bit. Besides, no

buckling was expected for the two types of drill pipes even while drilling with high WOB in a tortuous wellbore.

III.2 - RIH with 5 ½” liner: some simulations were performed using the WellScan® software to:

• Predict potential liner buckling and lock-up,

• Evaluate rotating torque while cementing the liner,

• Evaluate hook load capacity while POOH the liner.

The simulations confirmed that the 5 ½” liner can be run to

TD without buckling and approx. 35 tf of margin on

hookload. The maximum expected torque (~3330 lb.ft) and

the maximum expected hookload while POOH the liner (50

tf) were used to confirm rig power capacities as well.

In addition, DrillScan engineers investigated several centralisation programs along the liner, to optimize the stand-

off profile before the cementation, without compromising the ability to reach TD using too many centralisers.

IV. Hydraulics Analyses

Some hydraulics analyses were eventually performed to confirm good hole cleaning, ensuring sufficient annulus

velocity without compromising borehole quality through borehole erosion. The hydraulics simulations helped the

client in the choice of drill pipes diameter and evaluating ECD margins to frac pressure at side track depth.

V. Conclusion

Even if your budget is tight, it doesn’t mean you can not drill profitable campaigns. When you look closer at the

fundamentals of the drilling process, you may very well spot some golden opportunities. More often than not, the

most expensive or advanced equipment is NOT what you really need to unlock the reservoir. If you are in a penny-

pinching situation with you drilling campaign, and you want to find that fittest solution to make it work, we’re here

to help just like we did for the client in this case study. You can contact regis.studer@drillscan.com to set up a meeting

for discussion in more details.

White paper – DrillScan - 2018 Page 3/3

You might also like

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Pump DecokingDocument8 pagesPump Decokingrohl55No ratings yet

- Screwcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsFrom EverandScrewcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsNo ratings yet

- BHA StabilizationDocument14 pagesBHA StabilizationenantioagaNo ratings yet

- Spe Rss Workshop Brisbane21oct15-Distribution Version - HoanvluuDocument47 pagesSpe Rss Workshop Brisbane21oct15-Distribution Version - HoanvluuNestorMenesesPinto100% (2)

- Crane Proof Testing & LAG Revisions 2020 PDFDocument26 pagesCrane Proof Testing & LAG Revisions 2020 PDF朱峰No ratings yet

- Chapter 09 Procedures and Laboratory Equipment (Document67 pagesChapter 09 Procedures and Laboratory Equipment (محمد أحمد عبداللطيفNo ratings yet

- Choke ManifoldDocument5 pagesChoke ManifoldscrbdgharaviNo ratings yet

- Advanced Wireline Operations CourseDocument75 pagesAdvanced Wireline Operations CourseIbad sNo ratings yet

- JarPro Jarring Analysis SoftwareDocument4 pagesJarPro Jarring Analysis Softwareeleceron7919No ratings yet

- SPE/IADC 119446 High Angle Directional Drilling With 9 5/8-In. Casing in Offshore QatarDocument10 pagesSPE/IADC 119446 High Angle Directional Drilling With 9 5/8-In. Casing in Offshore QatarJulio BenitezNo ratings yet

- Extended Reached DrillingDocument34 pagesExtended Reached DrillingAhmad Advin100% (4)

- Rendering TestDocument7 pagesRendering TestDwiky syamcahyadi rahman100% (1)

- Spe 209846 MsDocument10 pagesSpe 209846 MsCavidan IbrahimliNo ratings yet

- DD Ops Guidelines 1 - IPMDocument8 pagesDD Ops Guidelines 1 - IPMEmre Cengiz100% (1)

- BS 128 - Load Testing of Steel Girder Bridges PDFDocument9 pagesBS 128 - Load Testing of Steel Girder Bridges PDFSAURAV SRIVASTAVANo ratings yet

- BHA Design CalculationDocument26 pagesBHA Design CalculationRema OmarNo ratings yet

- Rotary Bha Ingold r3xDocument56 pagesRotary Bha Ingold r3xUsama Bin Sabir100% (2)

- DVA Well SystemsDocument12 pagesDVA Well SystemsfdoppelNo ratings yet

- Directional DrillingDocument23 pagesDirectional DrillingConstantino Danilo Zapata Mogollon100% (1)

- On FALLING WEIGHT DEFLECTOMETERDocument30 pagesOn FALLING WEIGHT DEFLECTOMETERParvez100% (1)

- ERD RecommendationsDocument25 pagesERD Recommendationsvictor_n333100% (2)

- SEPCo 20hole Cleaning 20manual 1Document240 pagesSEPCo 20hole Cleaning 20manual 1Orathai Toy100% (8)

- SPE 30462 Application of A Highly Variable Gauge Stabilizer at Wytch Farm To Extend The ERD EnvelopeDocument11 pagesSPE 30462 Application of A Highly Variable Gauge Stabilizer at Wytch Farm To Extend The ERD EnvelopeAliNo ratings yet

- Adapt PT Training Manual PDFDocument22 pagesAdapt PT Training Manual PDFbvm013_502268804No ratings yet

- Design Analysis of Parts of Francis Turbine: Provision of Features To Blend Some Reaction Into ImpulseDocument35 pagesDesign Analysis of Parts of Francis Turbine: Provision of Features To Blend Some Reaction Into ImpulseMarcelo DelgadoNo ratings yet

- Drill Bench 5Document12 pagesDrill Bench 5Abdalla Magdy DarwishNo ratings yet

- Advanced Wireline Operations Course: Mahmoud Farag RadwanDocument75 pagesAdvanced Wireline Operations Course: Mahmoud Farag RadwanNadjibe LatracheNo ratings yet

- Chapter 5-ADocument23 pagesChapter 5-AMahrouz MadoNo ratings yet

- A Project Report On SonalikaDocument76 pagesA Project Report On SonalikaRohan Jain0% (2)

- Robert Allan - Escort Tug StabilityDocument28 pagesRobert Allan - Escort Tug Stabilitycarlos ivan carvajal ortiz100% (1)

- Single Stage Sag-Ag Milling DesignDocument11 pagesSingle Stage Sag-Ag Milling DesignrobigedNo ratings yet

- ITTC High Speed Marine Vehicles-Propulsion TestDocument6 pagesITTC High Speed Marine Vehicles-Propulsion TestGayatri LakkimsettiNo ratings yet

- CAUSTIC Naoh SOLVAY PDFDocument3 pagesCAUSTIC Naoh SOLVAY PDFlaquetengoNo ratings yet

- Spe 106346 MSDocument0 pagesSpe 106346 MSManthan MarvaniyaNo ratings yet

- Drilling Rig Selection Guidelines Only PDFDocument79 pagesDrilling Rig Selection Guidelines Only PDFRafael Charry AndradeNo ratings yet

- An Overview of Single Stage Autogenous and Semiautogenous Grinding MillsDocument12 pagesAn Overview of Single Stage Autogenous and Semiautogenous Grinding Millsjosesejo123No ratings yet

- International Society For Soil Mechanics and Geotechnical EngineeringDocument5 pagesInternational Society For Soil Mechanics and Geotechnical EngineeringYashwantNo ratings yet

- Geomechanics in A Depleted Carbonate Environment 1695742520Document10 pagesGeomechanics in A Depleted Carbonate Environment 1695742520Clau BustamanteNo ratings yet

- Slickline and Wireline Op. Course Summary in Mar-2024Document75 pagesSlickline and Wireline Op. Course Summary in Mar-2024Yovaraj KarunakaranNo ratings yet

- Underground Mining Equipment HandbookDocument223 pagesUnderground Mining Equipment Handbookjayman1980.11.10No ratings yet

- Advanced Technologies, Solutions Are Improving Wellbore ConstructionDocument5 pagesAdvanced Technologies, Solutions Are Improving Wellbore ConstructionArais Jr.No ratings yet

- Non Rotating BHAsDocument9 pagesNon Rotating BHAsLeandro NavarroNo ratings yet

- Economical Operation and Estimation of ODocument13 pagesEconomical Operation and Estimation of OMansi mishraNo ratings yet

- Sugiura2010 PDFDocument10 pagesSugiura2010 PDFMuhammad AndaruNo ratings yet

- Rigging TrainingDocument124 pagesRigging TrainingaamirdesireNo ratings yet

- 0.1 - Extreme Technical BulletinDocument5 pages0.1 - Extreme Technical BulletinDiego CorreaNo ratings yet

- OLGA 2014 New Functionalities For Well and DrillingDocument26 pagesOLGA 2014 New Functionalities For Well and DrillingAkin MuhammadNo ratings yet

- 1 Logging ProceduresDocument11 pages1 Logging ProceduresArdita S IrwanNo ratings yet

- Spe/Iadc 79915 Gyrostab Project: The Missing Link Azimuth and Inclination Mastered With New Principles For Standard Rotary BhasDocument11 pagesSpe/Iadc 79915 Gyrostab Project: The Missing Link Azimuth and Inclination Mastered With New Principles For Standard Rotary BhasJohnSmithNo ratings yet

- Narrow Vein Minimum Dilution Case StudyDocument6 pagesNarrow Vein Minimum Dilution Case StudyKudzie Maphy MasaireNo ratings yet

- XS-1755 Peak Performance DippersDocument52 pagesXS-1755 Peak Performance DippersromachNo ratings yet

- SPE-177898-MS Bending Rules With High Build Rate RSSDocument12 pagesSPE-177898-MS Bending Rules With High Build Rate RSScarloszapata1No ratings yet

- Kongsberg Marine Drilling Riser Analysis ProductsheetDocument2 pagesKongsberg Marine Drilling Riser Analysis ProductsheetStoyan StoyanovNo ratings yet

- Design Analysis of Parts of Francis Turbine: Provision of Features To Blend Some Reaction Into ImpulseDocument35 pagesDesign Analysis of Parts of Francis Turbine: Provision of Features To Blend Some Reaction Into ImpulseSyaiful AzharNo ratings yet

- Spe SysdrillDocument18 pagesSpe SysdrillRicardo De LeonNo ratings yet

- Guideline For Hand Held Shear Vane Test: August 2001Document11 pagesGuideline For Hand Held Shear Vane Test: August 2001Rajeuv GovindanNo ratings yet

- 用定向井技术实现油藏目标 Reservoir Targets Reached With Directional DrillingDocument2 pages用定向井技术实现油藏目标 Reservoir Targets Reached With Directional Drilling叶芊No ratings yet

- Spe 79796Document16 pagesSpe 79796Leandro NavarroNo ratings yet

- IADC Directional DrillingDocument10 pagesIADC Directional DrillingomnoyNo ratings yet

- Crosby Manual 2Document10 pagesCrosby Manual 2Salih KaderNo ratings yet

- PDA Methodology Kohelia BridgeDocument10 pagesPDA Methodology Kohelia Bridgembp planningNo ratings yet

- BP Colombia Directional Drilling Handbook - Rev1 - 4214161 - 01Document23 pagesBP Colombia Directional Drilling Handbook - Rev1 - 4214161 - 01Gharib HashemNo ratings yet

- Bounding Volume: Exploring Spatial Representation in Computer VisionFrom EverandBounding Volume: Exploring Spatial Representation in Computer VisionNo ratings yet

- Excel Filter Integer TechniqueDocument7 pagesExcel Filter Integer TechniqueJosh SabimanNo ratings yet

- Understanding Runaway Markets - LunoDocument6 pagesUnderstanding Runaway Markets - LunoJosh SabimanNo ratings yet

- An Operational Comparison of Push-The-Bit Rotary Steerable ToolsDocument12 pagesAn Operational Comparison of Push-The-Bit Rotary Steerable ToolsJosh SabimanNo ratings yet

- Liner Hanger Journal TOPEJ-5-88Document9 pagesLiner Hanger Journal TOPEJ-5-88Josh SabimanNo ratings yet

- Drill Pipe Tool JointDocument1 pageDrill Pipe Tool JointJosh SabimanNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument3 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJosh SabimanNo ratings yet

- CMF in High-Integrity C&I Systems - 1329414280 - 2Document9 pagesCMF in High-Integrity C&I Systems - 1329414280 - 2Josh SabimanNo ratings yet

- Selection of Technical Risk Responses For Efficient Contingencies Edouard Kujawski, PH.DDocument26 pagesSelection of Technical Risk Responses For Efficient Contingencies Edouard Kujawski, PH.DJosh SabimanNo ratings yet

- Investment Appraisal Technique - Payback Method: Prepared by William Armah, ForDocument12 pagesInvestment Appraisal Technique - Payback Method: Prepared by William Armah, ForJosh SabimanNo ratings yet

- 02 WholeDocument128 pages02 WholeJosh SabimanNo ratings yet

- Freedom To Choose. Power To IntegrateDocument36 pagesFreedom To Choose. Power To IntegrateJosh SabimanNo ratings yet

- Kick-Off Techniques: Hassan AlemiDocument47 pagesKick-Off Techniques: Hassan AlemiJosh SabimanNo ratings yet

- 09 RTS RedundancyDocument36 pages09 RTS RedundancyJosh SabimanNo ratings yet

- Measurement: Life of A WellDocument50 pagesMeasurement: Life of A WellJosh SabimanNo ratings yet

- Lithology - Porosity ToolsDocument50 pagesLithology - Porosity ToolsJosh SabimanNo ratings yet

- Shaly Sand Evaluation: ShalesDocument24 pagesShaly Sand Evaluation: ShalesJosh SabimanNo ratings yet

- 5 ResistivityDocument45 pages5 ResistivityJosh SabimanNo ratings yet

- Saturation ComputationDocument22 pagesSaturation ComputationJosh SabimanNo ratings yet

- Introduction To Log InterpretationDocument65 pagesIntroduction To Log InterpretationJosh SabimanNo ratings yet

- The Best RANK Function Use in ExcelDocument9 pagesThe Best RANK Function Use in ExcelJosh SabimanNo ratings yet

- Ee04 801 - Jun11Document1 pageEe04 801 - Jun11Angamuthu AnanthNo ratings yet

- ImplementationsDocument14 pagesImplementationsanuNo ratings yet

- City of Atlanta Demolition Permit and ProceduresDocument2 pagesCity of Atlanta Demolition Permit and ProceduresgragsdaleNo ratings yet

- HSDPA Link Budget Presentation v1.09Document25 pagesHSDPA Link Budget Presentation v1.09Nguyen LeNo ratings yet

- Axial Capacity of Piles in Soil As Per Irc78-2014Document1 pageAxial Capacity of Piles in Soil As Per Irc78-2014Sushant MallickNo ratings yet

- IMO Performance Standards For Heading Control SystemsDocument2 pagesIMO Performance Standards For Heading Control Systemsatinder13No ratings yet

- Velocity TrianglesDocument17 pagesVelocity TrianglesRavi Kiran JanaNo ratings yet

- Sopep EquipmentDocument1 pageSopep EquipmentmvladysemaNo ratings yet

- Claas Kgaa MBHDocument3 pagesClaas Kgaa MBHRasoolKhadibiNo ratings yet

- Plate Load TestDocument3 pagesPlate Load TestniteshNo ratings yet

- Standard Practice For Preparation and Use of Ice Point Bath E563.Bsrx8065Document4 pagesStandard Practice For Preparation and Use of Ice Point Bath E563.Bsrx8065Adrian ZamoraNo ratings yet

- Perbedaan Hill Climbing Dan P&ODocument13 pagesPerbedaan Hill Climbing Dan P&Obaymax love spideyNo ratings yet

- Inventory Management at Apollo Hospitals, BhubaneswarDocument9 pagesInventory Management at Apollo Hospitals, BhubaneswarArjun VaranasiNo ratings yet

- Low Gas Pressure Regulator: Product HandbookDocument31 pagesLow Gas Pressure Regulator: Product HandbookmanishaliveNo ratings yet

- Conservado SP: Water-Repellent For Facades With A High Protective PowerDocument2 pagesConservado SP: Water-Repellent For Facades With A High Protective PoweracarisimovicNo ratings yet

- Understanding Single Sign-On (SSO) Between IBM WebSphere Portal and IBM Lotus DominoDocument26 pagesUnderstanding Single Sign-On (SSO) Between IBM WebSphere Portal and IBM Lotus DominoAshish Daga100% (9)

- SCIC Newsletter 2018Document20 pagesSCIC Newsletter 2018eaang55No ratings yet

- Datesheet For Diploma HSBTE Exam Jan 2024 - 22.12.23Document494 pagesDatesheet For Diploma HSBTE Exam Jan 2024 - 22.12.23ls8612869No ratings yet

- T 5 Open MethodsDocument58 pagesT 5 Open Methodsvarunsingh214761No ratings yet

- MultiView 6.1 EN 201204Document12 pagesMultiView 6.1 EN 201204bian_barker100% (2)

- StormsaverDocument6 pagesStormsaverKanu LiNo ratings yet

- Transfer CharacteristicsDocument17 pagesTransfer Characteristicsgirishkumardarisi254No ratings yet

- Hydraulic Grab Carrier: Bauer GB 46Document8 pagesHydraulic Grab Carrier: Bauer GB 46RizkiNo ratings yet

- LED Color Temperature in KelvinDocument6 pagesLED Color Temperature in KelvinAndreson LNo ratings yet

- Discussion Bernoullis Theorem DemonstrationDocument3 pagesDiscussion Bernoullis Theorem DemonstrationAuzaNo ratings yet