Professional Documents

Culture Documents

S Civ Drain - 00

Uploaded by

HARIOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S Civ Drain - 00

Uploaded by

HARICopyright:

Available Formats

TECHNICAL SPECIFICATIONS FOR ELECTRIC WORKS

CIVIL WORKS

DRAINAGE WORKS

Group: Civil Works

Subject: Drainage Works

0 JAN 2022 First Issue

Rev. Date Description/issued for

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: CIVIL WORKS DRAINAGE WORKS

DOCUMENT NO: S-CIV-DRAIN_00.DOCX Rev: 0-2022 Sheet: 1 of: 12

INDEX

TECHNICAL SPECIFICATIONS FOR ELECTRIC WORKS .................................................. 1

1 SCOPE.............................................................................................................................. 3

2 APPLICATION FIELD .................................................................................................. 3

3 REFERENCE DOCUMENTS ....................................................................................... 3

3.1 TAQA/ADDC/AADC specifications ................................................................................ 3

3.2 Reference standards........................................................................................................... 3

3.3 Regulation and law ............................................................................................................ 4

4 SERVICE CONDITIONS AND DESIGN..................................................................... 4

5 TECHNICAL DESCRIPTION ...................................................................................... 5

5.1 General .............................................................................................................................. 5

5.2 Materials ............................................................................................................................ 5

5.3 Execution ........................................................................................................................... 6

5.4 Tests and Properties........................................................................................................... 6

5.5 Braced and Sheeted Trenches (if applicable) .................................................................... 7

5.6 Drainage Work Requirements ........................................................................................... 7

5.7 Access Covers ................................................................................................................... 7

5.7.1 Heavy Duty Manhole Covers, Grade-A ............................................................................ 7

5.7.2 Medium Duty Manhole Covers, Grade-B ......................................................................... 7

5.7.3 Light Duty Manhole Covers, Grade-C .............................................................................. 8

5.7.4 Light Duty Small Covers ................................................................................................... 8

5.8 Floor Drain Covers ............................................................................................................ 8

5.9 Maintenance Access .......................................................................................................... 8

5.10 Earthing of Metal Parts...................................................................................................... 8

5.11 Description of Sanitary Sewer ........................................................................................... 8

5.12 Septic Tanks ...................................................................................................................... 8

5.13 Disposal of Storm Water ................................................................................................... 8

5.14 Inspection of Sewer Line ................................................................................................... 9

5.15 Testing ............................................................................................................................... 9

5.16 Standard Details .............................................................................................................. 10

6 QUALITY AND CERTIFICATION ........................................................................... 11

6.1 Documentation supplied during the tender...................................................................... 11

6.2 Document to be supplied after the order ......................................................................... 11

7 DELIVERY, HANDLING AND LOGISTIC ISSUES ............................................... 12

8 EXCEPTIONS ............................................................................................................... 12

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: CIVIL WORKS DRAINAGE WORKS

DOCUMENT NO: S-CIV-DRAIN_00.DOCX Rev: 0-2022 Sheet: 2 of: 12

1 SCOPE

The scope of this specification is to provide the technical requirements for the design,

manufacturing, inspection and construction for substation and building drainage works, to be used

in the distribution networks of TAQA/ADDC/AADC.

2 APPLICATION FIELD

This specification refers to design, manufacturing, inspection and construction for substation and

building drainage works.

3 REFERENCE DOCUMENTS

The list of the reference documents is indicated in the following paragraphs.

In case of discrepancy between these Specifications and any of the applicable Codes and

Standards, the following order of precedence shall apply:

1) TAQA/ADDC/AADC specifications

2) applicable reference standards

3) other documents.

The Supplier shall note that compliance with the provision of these specifications does not relieve

him from his responsibility to supply proper design, material and construction, suited to meet the

operating guarantees at the specified service conditions.

3.1 TAQA/ADDC/AADC specifications

Table 1- List of TAQA/ADDC/AADC specifications

S-GEN-SER S-GEN-ID

S-CIV-WORK S-CIV-GEN

S-GEN-COR S-CIV-CONCRETE

3.2 Reference standards

The last edition of following standards is applicable for the scope specified in the present

document. In case of deviation, the Supplier can propose equipment/material compliant to an

alternative standard, subject to TAQA/ADDC/AADC approval.

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: CIVIL WORKS DRAINAGE WORKS

DOCUMENT NO: S-CIV-DRAIN_00.DOCX Rev: 0-2022 Sheet: 3 of: 12

Table 2- List of Standards

Standard Description

ADIBC Abu Dhabi International Building Code

Abu Dhabi International

National Plumbing specifications

Plumbing Code

Abu Dhabi International National Plumbing specifications for private sewage systems

Private Sewage Disposal

Code

Standard Specification for Reinforced Concrete Culvert, Storm Drain, and

ASTM C 76

Sewer Pipe

Standard Test Methods for Concrete Pipe, Concrete Box Sections, Manhole

ASTM C 497-75

Sections, or Tile

ASTM F1144 Standard specifications for Manhole cover assembly

3.3 Regulation and law

All works shall be in accordance with the following Regulation and laws:

• Abu Dhabi International Building Code

• Abu Dhabi International Plumbing Code

• Abu Dhabi International Private Sewage Disposal Code

The prescription included in the Regulations and Law shall prevail on all other international

standards mentioned in paragraph 3.2

4 SERVICE CONDITIONS AND DESIGN

The service conditions are specified in S-GEN-SER. Design shall be in accordance with S-CIV-

GEN and prescriptions mentioned in the present specification.

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: CIVIL WORKS DRAINAGE WORKS

DOCUMENT NO: S-CIV-DRAIN_00.DOCX Rev: 0-2022 Sheet: 4 of: 12

5 TECHNICAL DESCRIPTION

5.1 General

The work to be carried out under this Article comprises various kinds of drainage culverts, pipes,

and the like, including all accessories such as inspection shafts, etc., if not otherwise specified.

Upon architectural design the Supplier shall prepare a schematic diagram of the drainage system

to be executed. The diagram shall show material and dimensions of pipes to be used and the

proportion of slope, as well as, the invert level at all connection points. The flow diagram and

proposed installation and materials are subject to approval, both of TAQA/ADDC/AADC and the

relevant local authorities.

5.2 Materials

Materials and components, which the Supplier shall supply, and install shall be in accordance with

the local regulations (Abu Dhabi International Plumbing Code) and standards acceptable to

TAQA/ADDC/AADC. They shall be standardized and adequate for the purpose required.

Culverts, frames, gullies, manhole covers, sand, grease and petrol traps, shall be out of ductile iron

and shall be coated with a protective coating of tar-based composition.

The minimum quality requirements of the drainage pipes shall be as follows:

• Above ground drainage pipes shall be UPVC complying to ASTM D1785 (Standard Specification

for Poly (Vinyl Chloride) (PVC) Plastic Pipe, Schedules 40, 80, and 120) or equivalent with solvent

welded joints / push fit rubber ring joints.

• Waste branch pipes shall be UPVC/ABS/MUPVC complying to ASTM D1785 (Standard

Specification for Poly(Vinyl Chloride) (PVC) Plastic Pipe, Schedules 40, 80, and 120) or

Polypropylene complying to ASTM F409 – (Standard specification for Thermoplastic Accessible

and replaceable plastic tube and tubular fittings) or equivalent with solvent welded joints/push fit

rubber ring joints.

• Underground drainage pipes shall be UPVC complying to ASTM D1785 (Standard Specification for

Poly (Vinyl Chloride) (PVC) Plastic Pipe, Schedules 40, 80, and 120) or equivalent with solvent

welded joints / push fit rubber ring joints.

• Underground drainage pipes between Manholes shall be UPVC Class-16 with solvent welded joints

/ push fit rubber ring joints.

• Above ground rainwater pipes shall be UPVC complying to ASTM D1785 (Standard Specification

for Poly (Vinyl Chloride) (PVC) Plastic Pipe, Schedules 40, 80, and 120) or equivalent with solvent

welded joints / push fit rubber ring joints. The exposed rainwater pipes shall be painted, matching the

surrounding finish, subject to TAQA/ADDC/AADC’s approval. However, underground rainwater

pipes shall be same as underground drainage pipes specified above.

• Pre-cast concrete pipes, if applicable, shall comply with ASTM C 76 (Standard Specification for

Reinforced Concrete Culvert, Storm Drain, and Sewer Pipe).

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: CIVIL WORKS DRAINAGE WORKS

DOCUMENT NO: S-CIV-DRAIN_00.DOCX Rev: 0-2022 Sheet: 5 of: 12

5.3 Execution

Special care shall be taken to avoid any damage during transport, loading and off-loading, storage,

etc. Storing of pipes alongside trenches shall be done only for the shortest time possible before

placing into the trench. All pipes shall be checked for defects and damages prior to placing.

Manual and mechanical tools and hoist for lifting and lowering of pipes shall allow for smooth

and continuous moving.

During excavation, minimum depth for laying the pipes down should be considered, depending on

the locations/areas. The covering layers should be as follows:

• 400mm of ground covering in the yards

• 700mm of ground covering in the roads

During connection of pipe sections, the contact surfaces carrying sealing compounds shall be kept

clean; all open ends for later connections shall be closed to avoid entering of soil or other

contamination into the bores.

After placing, each pipe section shall be thoroughly checked as to alignment, level and slope. Pipe

supports shall be constructed to guarantee the uniform transmission of loads. Neither line nor point

bearing of loads will be allowed.

The bearing section for supported circular profiles shall cover at least an arc of 60° if not otherwise

specified.

The trench bottom shall not be loosened by any means. If, however, loosening occurs, the loosened

soil shall be excavated and replaced by non-cohesive soil, which shall then be compacted, all at

the expense of the Supplier.

Supports in sand or coarse sand shall be executed by forming the bed according to the shape of the

pipe to be laid to allow each pipe section support along its full length.

Soil not usable for direct pipe laying shall be excavated on the trench bottom to place a supporting

layer of sand, coarse sand or concrete, thoroughly compacted. The minimum thickness of such

layer shall be 10 cm plus 1/10th of the pipe outer diameter.

For concrete supports, a cement-mortar layer shall be applied before placing the pipes, to guarantee

a uniform transmission of forces.

Connections of through-pipes to inspection chambers or other structures shall be of flexible

construction.

For all earthwork in connection with drainage work item "Earth and Rockwork" applies.

Any concrete work required for the execution of the drainage work shall be made in accordance

with the Specification, S-CIV-CONCRETE

5.4 Tests and Properties

The minimum number of tests to be performed shall be as follows:

• One water tightness test for each diameter of non-reinforced concrete pipe

• One cracking and crushing test for each diameter of non-reinforced concrete pipe absorption and

hydraulic test as per ASTM C 497-75

• All drainage lines, joints and fittings must be tested before covering up with sand or approved soil by

water and or by smoke

• Test at site shall be carried out in the presence of TAQA/ADDC/AADC by an approved laboratory.

All tests shall be recorded and countersigned by TAQA/ADDC/AADC if successful.

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: CIVIL WORKS DRAINAGE WORKS

DOCUMENT NO: S-CIV-DRAIN_00.DOCX Rev: 0-2022 Sheet: 6 of: 12

5.5 Braced and Sheeted Trenches (if applicable)

Open-cut trenches shall be braced and sheeted as may be necessary to protect persons, property,

traffic or the work or to prevent caving and harmful sinking.

The Supplier shall be responsible for any damage done to roads, mains, cables, pipes, sewers, etc.,

by the execution of the work. When close sheeting is required, it shall be so driven as to prevent

adjacent soil from entering the trench either below or through such sheeting. Where sheeting and

bracing are used, the trench width shall be increased accordingly.

TAQA/ADDC/AADC reserves the right to order the sheeting to be driven to the full depth of the

trench or to such additional depths as may be required for the protection of the works. Where the

soil in the lower limits of a trench has the necessary stability, TAQA/ADDC/AADC, at his

discretion, may permit the Supplier to stop the driving of sheeting at some designated elevation

above the trench bottom. The granting of permission by TAQA/ADDC/AADC, however, shall not

relieve the Supplier in any degree from his full responsibility under the Contract.

Trench basing must be removed when the backfilling has reached the respective levels of such

bracing. Sheeting must be removed after the backfilling has been completed or has been brought

up to such an elevation as to permit its safe removal.

The cost of furnishing, placing and removing, the sheeting and bracing shall be included in the

price bid for the work.

5.6 Drainage Work Requirements

The work to be carried out under this Article comprises various kinds of drainage culverts, pipes

and the like, including all accessories such as inspection shafts, etc. if not otherwise specified.

The work also includes supply, transportation, unloading and storage at site and placing according

to drawings and specifications of all materials and components connected therewith.

All earthwork and concrete works in connection with the work specified hereunder shall be carried

out as described under the Specifications S-CIV-WORK and S-CIV-CONCRETE.

5.7 Access Covers

Ductile iron access covers and frames shall be according ASTM F1144 (Standard specifications

for Manhole cover assembly), except that the bituminous based protective coating shall not flow

or chip when exposed to temperature in the range of 0 C to 76 C. Covers shall provide a clear

opening of at least 600 mm.

5.7.1 Heavy Duty Manhole Covers, Grade-A

The access cover shall be suitable for heavy duty, fast moving wheeled traffic. The cover shall be

double triangular/square or circular.

Heavy duty covers shall be used for main road.

5.7.2 Medium Duty Manhole Covers, Grade-B

The access cover shall be suitable where heavy commercial vehicle would be exceptional. The

cover shall be circular or rectangular. Medium duty covers shall be used for road and parking areas

within the building compound.

Medium duty covers shall be double sealed type or sealed with GRP sealing plate, if used within

5.0 Meters from the Sub-station Building.

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: CIVIL WORKS DRAINAGE WORKS

DOCUMENT NO: S-CIV-DRAIN_00.DOCX Rev: 0-2022 Sheet: 7 of: 12

5.7.3 Light Duty Manhole Covers, Grade-C

The access cover shall be suitable for pedestrian traffic only. The cover shall be rectangular.

Light duty covers shall be double sealed type or sealed with GRP sealing plate and shall be used

for paved areas inside the building compound.

5.7.4 Light Duty Small Covers

Access covers for Gully Traps, Valve Chambers, Inspection Chambers, Ventilating Chambers etc.

shall be rectangular 300 x 300 mm.

5.8 Floor Drain Covers

Floor drain covers shall be 150x150 mm or 200x200 mm, 0.60 mm thick, PVC, stainless steel or

made from brass, chromium plated with strainer and cover.

5.9 Maintenance Access

Vertical drainage pipes at each floor shall be provided with cleaning eyes to each pipe and

removable access covers/panels to pipe shaft. The finish of access covers/panels shall be according

to TAQA/ADDC/AADC’s approval.

5.10 Earthing of Metal Parts

The Supplier shall ensure electrical continuity of all metal parts installed by him.

5.11 Description of Sanitary Sewer

Sanitary sewage from the buildings shall be collected in septic tank. The cleaned water shall then

be disposed of in soakage pits. The whole sanitary sewer drainage system operates in gravity flow.

Note:

• In case a public sewer is existing, only the respective connection must be provided.

• Private sewage disposal systems shall conform to the Abu Dhabi International Private Sewage

Disposal Code.

5.12 Septic Tanks

For the treatment of sanitary sewage, adequately sized septic tanks shall be constructed of cast in

place concrete. They shall have approximately 3 chambers. Two manholes with cover and

ventilation shall be provided above the end chambers for cleaning with mobile pump. Before the

outlet in the last chambers, a screen board shall be provided to prevent the passage of floating

matter into the discharge pipe.

The size of septic tanks shall be based on a number of 10 people permanently working at each

station.

5.13 Disposal of Storm Water

In Basement/Cable cellars, all sumps shall be equipped with electrical pumps (one working + one

standby) and float switch with pipe connection outside the wall.

In case a public storm water system exits, rainwater pipes shall be connected; if not, rain water

pipes shall be drained by gravel filled away soak pits.

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: CIVIL WORKS DRAINAGE WORKS

DOCUMENT NO: S-CIV-DRAIN_00.DOCX Rev: 0-2022 Sheet: 8 of: 12

5.14 Inspection of Sewer Line

All pipelines must be inspected and approved by TAQA/ADDC/AADC before backfilling.

The pipeline, which is the straight part connecting between manholes, shall be tested after making

the joints for bearing the pressure of a water head of 1.5 m in respect of pipes, as follows:

• The lower end of the pipe to be tested shall be closed with a solid plug, sealed by mortar or shall be

closed by a rubber plug and the upper part of the pipe shall be fitted with a plug having an opening

fitted with a funneled-top vertical pipe and then the pipeline shall be filled with water.

• TAQA/ADDC/AADC will have the authority to make visual inspection of all lines and joints to

ensure that there is no leakage. If, in the opinion of TAQA/ADDC/AADC, after test, pipes show any

unreasonable sign of moisture, then TAQA/ADDC/AADC shall have the authority to reject or to

instruct any measures deemed necessary to rectify such work at the Supplier’s expense.

• Any pipes, which show cracks, holes, or any other defect which TAQA/ADDC/AADC deems to be

in excess of a slight nature, TAQA/ADDC/AADC shall have the authority to reject and instruct the

Supplier to remove and replace in a satisfactory manner. The Supplier shall to exercise extreme care

in fitting the necessary rubber rings and/or making the cement mortar joint, including connections to

manholes and gullies and other appurtenances, in a manner to ensure that no leakage whatsoever

occurs from the joints. Should such leakage occur, then the Supplier shall remove and refit in a

manner to the satisfaction of TAQA/ADDC/AADC. The complete expenses of all tests, replacements

and/or reparative work, etc., shall be borne by the Supplier.

• In the event that after installation the pipe fails to meet the line test or other requirements, the Supplier

shall remove the defective pipe, except as noted below:

o At the request of the Supplier and subject to approval of TAQA/ADDC/AADC, the Supplier may

encase the defective portion of the pipe with a minimum of 15 cm of Class C 20 concrete,

however no additional payment shall be made for this work.

5.15 Testing

All testing of pipes and fittings shall be done at the cost of the Supplier. The Supplier shall also

bear the cost of the sampling and of any certificate, which may be required. The number of samples

as well as the testing procedure to be determined by TAQA/ADDC/AADC. Pipes of different

diameters shall be tested according to the requirements, or if not defined, according to the

applicable ASTM Standards.

The Supplier shall test all drainage pipelines, joints, fittings before carrying out haunching or

surrounding of pipes or backfilling trenches. The tests shall be carried out for all the drainage pipes

and pipes between each two manholes or less in the presence and with the approval of

TAQA/ADDC/AADC, considering the following:

• Drainage pipelines and concrete works shall be clean and dry and the joints not covered with earth

• The underground water level shall be at the lowest possible level

• Air, smoke or water may be used for testing drainage pipe- lines and TAQA/ADDC/AADC reserves

the right to carry out the tests by any of the three methods, and the Supplier shall comply with such

opinion, without claiming any compensation or addition. All plugs should be fixed prior to the testing

operation

• Drainage pipelines shall be tested at 0.15 bar for 6 hours.

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: CIVIL WORKS DRAINAGE WORKS

DOCUMENT NO: S-CIV-DRAIN_00.DOCX Rev: 0-2022 Sheet: 9 of: 12

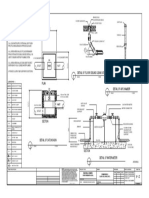

5.16 Standard Details

For following standard details reference shall be made to the below listed drawing, which are

provided in the Drawings Section:

• DWG AAA CIV 09 01 : Drainage Details (Sheet 1 of 8)

• DWG AAA CIV 09 02 : Drainage Details (Sheet 2 of 8)

• DWG AAA CIV 09 03 : Drainage Details (Sheet 3 of 8)

• DWG AAA CIV 09 04 : Drainage Details (Sheet 4 of 8)

• DWG AAA CIV 09 05 : Drainage Details (Sheet 5 of 8)

• DWG AAA CIV 09 06 : Drainage Details (Sheet 6 of 8)

• DWG AAA CIV 09 07 : Drainage Details (Sheet 7 of 8)

• DWG AAA CIV 09 08 : Drainage Details (Sheet 8 of 8)

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: CIVIL WORKS DRAINAGE WORKS

DOCUMENT NO: S-CIV-DRAIN_00.DOCX Rev: 0-2022 Sheet: 10 of: 12

6 QUALITY AND CERTIFICATION

6.1 Documentation supplied during the tender

The documentation supplied by the Supplier during tendering stage shall contain the following

minim elements:

• List of all types of piping materials and fittings to be supplied, in accordance with relevant standards

and specifications as described in this document.

• Certificates of all workshop tests performed.

• The quality assurance/control procedures

6.2 Document to be supplied after the order

The documentation supplied by the manufacturer after the order shall contain the following

elements:

• List of materials and components that are for temporary use during construction and are not to be

incorporated in the work may be used or new at the Contractors option if not otherwise prescribed in

the Specifications.

• List of materials and components that the Contractor shall supply and install and which therefore will

be incorporated in the work or structure shall be new and unused.

• Technical specification and datasheets of material

• Drawings

• Workshop tests certificates

• Packaging and shipping procedures

• Installation procedures

• Site tests and tolerances

• Cleaning and maintenance procedures

All materials shall comply with the regulations regarding quality and dimensions and shall be

adequate for the required work and shall comply with the specifications and standards accepted by

the Company.

The Contractor shall be solely responsible for securing all the materials required for the project

regarding quantity, type and quality. Any delay in the supply and for the delivery thereof shall not

entitle the Contractor to make a claim for the extension of the contract period nor for any additional

expenses on account of such delay.

The work is subject to inspection and examination by TAQA/ADDC/AADC personnel and/or an

independent third party at the Project Site, for full compliance with all requirements of this

Specification, the Contract and Supplier’s design drawings.

Gravity sewer sections shall be tested by filling with water the catch basins/manholes relevant to

the portion to be tested after blocking all openings and manhole inlets and allowing water to stand

for one hour with no change in water level.

On completion, flushing or the use of mechanical equipment as necessary to remove foreign

material from pipes shall clean all piping.

Manufacturers’ details of all materials used shall be submitted for the Company approval.

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: CIVIL WORKS DRAINAGE WORKS

DOCUMENT NO: S-CIV-DRAIN_00.DOCX Rev: 0-2022 Sheet: 11 of: 12

7 DELIVERY, HANDLING AND LOGISTIC ISSUES

The Supplier is responsible for all the delivery procedures and provisions for storage of materials

and components.

8 EXCEPTIONS

Possible exceptions to the present prescriptions, concerning the adoption of technical and/or

manufacturing aspects different from the ones prescribed in the present document, can be

evaluated by TAQA/ADDC/AADC.

In such a case, TAQA/ADDC/AADC will take into account the opportunity to require additional

tests with regard to the technical/manufacturing proposed solutions. Such exceptions can be

approved by TAQA/ADDC/AADC.

Client: ADDC/ AADC

STANDARD TECHNICAL SPECIFICATIONS FOR ELECTRICITY DISTRIBUTION WORKS

Title: CIVIL WORKS DRAINAGE WORKS

DOCUMENT NO: S-CIV-DRAIN_00.DOCX Rev: 0-2022 Sheet: 12 of: 12

You might also like

- S Civ Cab - 00Document19 pagesS Civ Cab - 00HARINo ratings yet

- S Civ Ohl - 00Document26 pagesS Civ Ohl - 00HARINo ratings yet

- Practical Hydraulic Systems: Operation and Troubleshooting for Engineers and TechniciansFrom EverandPractical Hydraulic Systems: Operation and Troubleshooting for Engineers and TechniciansRating: 4 out of 5 stars4/5 (8)

- S Civ Light - 00Document17 pagesS Civ Light - 00HARINo ratings yet

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- S Civ Mas - 00Document10 pagesS Civ Mas - 00HARINo ratings yet

- S Civ Surf - 00Document10 pagesS Civ Surf - 00HARINo ratings yet

- Practical Grounding, Bonding, Shielding and Surge ProtectionFrom EverandPractical Grounding, Bonding, Shielding and Surge ProtectionRating: 4 out of 5 stars4/5 (15)

- S Civ Concrete - 00Document28 pagesS Civ Concrete - 00HARINo ratings yet

- S Civ Site - 00Document8 pagesS Civ Site - 00HARINo ratings yet

- Practical Industrial Data Communications: Best Practice TechniquesFrom EverandPractical Industrial Data Communications: Best Practice TechniquesRating: 5 out of 5 stars5/5 (2)

- 16 Samss 512Document40 pages16 Samss 512siddiq alviNo ratings yet

- S Met CT - 00Document8 pagesS Met CT - 00HARINo ratings yet

- Deploying QoS for Cisco IP and Next Generation Networks: The Definitive GuideFrom EverandDeploying QoS for Cisco IP and Next Generation Networks: The Definitive GuideRating: 5 out of 5 stars5/5 (2)

- SEWA-E-D-004 11kV Cable AccessoriesDocument44 pagesSEWA-E-D-004 11kV Cable Accessorieszaheer2931100% (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- QPED-9742R1 Pipe Line ConstructionDocument26 pagesQPED-9742R1 Pipe Line ConstructionPiping_Specialist100% (3)

- S Gen Lightning 00Document15 pagesS Gen Lightning 00raviaggrawalla8727No ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNo ratings yet

- Piping Design Criteria Gd-006 - 000pgd006 0 20040909Document28 pagesPiping Design Criteria Gd-006 - 000pgd006 0 20040909Felipe Eduardo Guzmán SilvaNo ratings yet

- S Met Test - 00Document10 pagesS Met Test - 00HARINo ratings yet

- S LV SWG Pub - 00Document31 pagesS LV SWG Pub - 00afsar.erNo ratings yet

- PanelboardsDocument15 pagesPanelboardsMohamed FaragNo ratings yet

- Sagana Kutus 132kv Transmission Line and SubstationDocument324 pagesSagana Kutus 132kv Transmission Line and Substationshivvaram-1100% (1)

- KM Epm D CBL Acc 22 Heat Joints - F05Document21 pagesKM Epm D CBL Acc 22 Heat Joints - F05Rajeeb MohammedNo ratings yet

- Low-Voltage Elec Power Conductors and CablesDocument12 pagesLow-Voltage Elec Power Conductors and Cableswamiq wasiNo ratings yet

- SEC cable joints and accessories specificationDocument25 pagesSEC cable joints and accessories specificationSukant BhattacharyaNo ratings yet

- 06.12 Road LightingDocument37 pages06.12 Road LightingMustaqeem KhanNo ratings yet

- 10045D-000-PI-SP-005 - Rev 0 - 07sep10Document21 pages10045D-000-PI-SP-005 - Rev 0 - 07sep10RVELEZNo ratings yet

- (No. 90) - 11 - SDMS-04 - R0 - FinalDocument20 pages(No. 90) - 11 - SDMS-04 - R0 - Finalpmurali_10490025467% (3)

- Section 32150 - Bonded Epoxy LiningDocument11 pagesSection 32150 - Bonded Epoxy LininghelalsolimanNo ratings yet

- Specification of 24V DC MotorsDocument9 pagesSpecification of 24V DC Motorswaleed.liaquat.kkNo ratings yet

- Specification For Motor Actuators For ValvesDocument13 pagesSpecification For Motor Actuators For ValvesDanish MohammedNo ratings yet

- QCS 2010 Part 12 Road LightingDocument37 pagesQCS 2010 Part 12 Road LightingRotsapNayrb75% (4)

- S Met CTVT - 00Document10 pagesS Met CTVT - 00HARINo ratings yet

- Specification For Electrical Installations: Rev. Date Description/issued For Prepared Authorised Client: Project: TitleDocument55 pagesSpecification For Electrical Installations: Rev. Date Description/issued For Prepared Authorised Client: Project: TitleNael SwedanNo ratings yet

- 12 SDMS 01rev3Document16 pages12 SDMS 01rev3Dipak VaghelaNo ratings yet

- 12-SDMS-01 (CABLE JOINTS, TERMINATIONS, AND ACCESSORIES UP TO 36 KV) Rev03 PDFDocument16 pages12-SDMS-01 (CABLE JOINTS, TERMINATIONS, AND ACCESSORIES UP TO 36 KV) Rev03 PDFHaytham BafoNo ratings yet

- Rev. NO. Date BY Checked MEI Lead MEI Approval Conoco Revision AA 09/13/00 EJL TD DJ KM MWJ Issued For BidDocument14 pagesRev. NO. Date BY Checked MEI Lead MEI Approval Conoco Revision AA 09/13/00 EJL TD DJ KM MWJ Issued For BidThinh NguyenNo ratings yet

- SEWA-E-C-001 Fiber Optic CableDocument34 pagesSEWA-E-C-001 Fiber Optic Cablezaheer2931100% (1)

- Potable Water PumpsDocument17 pagesPotable Water PumpsNijasNo ratings yet

- Specification For Hdpe (3lpe) Coating of Carbon Steel PipesDocument21 pagesSpecification For Hdpe (3lpe) Coating of Carbon Steel PipesDanish MohammedNo ratings yet

- Civil Design Criteria: Sociedad Minera Cerro Verde S.A.A. Project No. A6CvDocument27 pagesCivil Design Criteria: Sociedad Minera Cerro Verde S.A.A. Project No. A6CvJohnny vargas suclupeNo ratings yet

- ELECTRICAL SYSTEM FOR BARC DESALINATION FACILITYDocument63 pagesELECTRICAL SYSTEM FOR BARC DESALINATION FACILITY9044nksNo ratings yet

- 17 Samss 017Document14 pages17 Samss 017Eagle SpiritNo ratings yet

- Concrete Reservoir SpecificationDocument25 pagesConcrete Reservoir SpecificationAdrianto HermawanNo ratings yet

- Saep-324 2018 PDFDocument23 pagesSaep-324 2018 PDFAdnan Rafiq100% (1)

- 34 Samss 846Document37 pages34 Samss 846Artur UzeevNo ratings yet

- Piping Standard and SpecificationDocument22 pagesPiping Standard and SpecificationMuhamad Firdaus Bin Azizan100% (5)

- 11-Division 2-Section 02300 Sewage Works-Version 2.0Document24 pages11-Division 2-Section 02300 Sewage Works-Version 2.0Avaan Ivaan50% (2)

- Saline Water Conversion Corporation Kingdom of Saudi Arabia Projects Engineering DepartmentDocument23 pagesSaline Water Conversion Corporation Kingdom of Saudi Arabia Projects Engineering DepartmentBhavanishankar ShettyNo ratings yet

- Check ListsDocument84 pagesCheck ListsMuhammad Wazim AkramNo ratings yet

- 16 Samss 518Document10 pages16 Samss 518adnanmppNo ratings yet

- S Met Stem DC 1P 1C - 00Document18 pagesS Met Stem DC 1P 1C - 00HARINo ratings yet

- E 713Document30 pagesE 713KibarNo ratings yet

- E 720Document50 pagesE 720Shama100% (2)

- 2 08P28 PDFDocument20 pages2 08P28 PDFMike2322No ratings yet

- S Gen PS - 00Document9 pagesS Gen PS - 00HARINo ratings yet

- 3 12CH12Document4 pages3 12CH12HARINo ratings yet

- S Met Stem DC 1P 1C - 00Document18 pagesS Met Stem DC 1P 1C - 00HARINo ratings yet

- S Met Stem CT 3p 1c 00Document19 pagesS Met Stem CT 3p 1c 00HARINo ratings yet

- S Met Stem CT 3p 1c 00Document19 pagesS Met Stem CT 3p 1c 00HARINo ratings yet

- S Met Stem DC 1P 1C - 00Document18 pagesS Met Stem DC 1P 1C - 00HARINo ratings yet

- 3 14GDocument4 pages3 14GHARINo ratings yet

- AREMADocument8 pagesAREMALuis FernandoNo ratings yet

- 4 Aar FrontDocument2 pages4 Aar FrontSarisha HarrychundNo ratings yet

- 4 Aar P4Document4 pages4 Aar P4HARINo ratings yet

- 4 Aar P3Document4 pages4 Aar P3HARINo ratings yet

- 4 Aar CoverDocument2 pages4 Aar CoverSarisha HarrychundNo ratings yet

- S Met CTVT - 00Document10 pagesS Met CTVT - 00HARINo ratings yet

- E864x4 Ed3Document21 pagesE864x4 Ed3HARINo ratings yet

- D Met Test Cal - 00Document5 pagesD Met Test Cal - 00HARINo ratings yet

- D Civ Fire DSS - 00Document7 pagesD Civ Fire DSS - 00HARINo ratings yet

- S Civ Concrete - 00Document28 pagesS Civ Concrete - 00HARINo ratings yet

- D Civ Fire Prim - 00Document22 pagesD Civ Fire Prim - 00HARINo ratings yet

- E864x7 Ed3Document4 pagesE864x7 Ed3HARINo ratings yet

- Specification For Architectural WorksDocument82 pagesSpecification For Architectural WorksVJ QatarNo ratings yet

- Track Construction - 2015 - : Section/Article DescriptionDocument6 pagesTrack Construction - 2015 - : Section/Article DescriptionHARINo ratings yet

- Arema Mre 2013 Toc-Vol1 Ch5Document3 pagesArema Mre 2013 Toc-Vol1 Ch5Ndoro Bei0% (3)

- Utility Gate Valve Data SheetsDocument9 pagesUtility Gate Valve Data SheetsArunkumarNo ratings yet

- Design Calculation of Plumbing Systems for Temporary Construction FacilitiesDocument13 pagesDesign Calculation of Plumbing Systems for Temporary Construction FacilitiesBhavanishankar shetty100% (2)

- Installation Instructions: Decorative Bottle TrapDocument2 pagesInstallation Instructions: Decorative Bottle TrapAfzal FasehudeenNo ratings yet

- Storm Water Pipe Size CalculatorDocument4 pagesStorm Water Pipe Size CalculatorKrish ChennaiNo ratings yet

- PSVDocument13 pagesPSVUMESH GORE100% (1)

- Grohe Retail Price List 2022Document24 pagesGrohe Retail Price List 2022bathsopkNo ratings yet

- 441 Terra Alegria Automated - BrochureDocument7 pages441 Terra Alegria Automated - BrochureLaboratoire D'Analyses MédicalesNo ratings yet

- LS25S Parts List-88290007-837Document79 pagesLS25S Parts List-88290007-837Isidro OnezNo ratings yet

- BLDGDESIGN Lesson 5 - Plumbing DesignDocument18 pagesBLDGDESIGN Lesson 5 - Plumbing DesignDough NutNo ratings yet

- 900 Series: Split Case Fire PumpDocument24 pages900 Series: Split Case Fire Pumpcarlos eduardo gutierrez gomezNo ratings yet

- 2 Showers 2Document17 pages2 Showers 2jdwood66No ratings yet

- V65 Alarm Check ValveDocument2 pagesV65 Alarm Check ValveChinith012No ratings yet

- Afr200 Series Air Fuel Ratio Controller: CanbusDocument20 pagesAfr200 Series Air Fuel Ratio Controller: CanbusHernan RiveraNo ratings yet

- Calculo de Dimension Cajon OverDocument7 pagesCalculo de Dimension Cajon OverJonathan Romero AlfaroNo ratings yet

- Aqualisa Quartz CaseDocument6 pagesAqualisa Quartz CaseSrinivas Kannan100% (2)

- Essco CatalogueDocument80 pagesEssco CatalogueDarjeelingNo ratings yet

- ANSI Gate Valves Specifications and DimensionsDocument80 pagesANSI Gate Valves Specifications and DimensionsMOHAMEDNo ratings yet

- Pipe Friction Loss AnalysisDocument2 pagesPipe Friction Loss Analysissunii19847908No ratings yet

- Detail of Floor/ Ceiling Clean Out: Plumbing NotesDocument1 pageDetail of Floor/ Ceiling Clean Out: Plumbing NotesHana YeppeodaNo ratings yet

- Hose Reel Calculation (Malaysia)Document5 pagesHose Reel Calculation (Malaysia)Kazehaya Ali88% (8)

- Pipe Wall Thickness Calculation SheetDocument88 pagesPipe Wall Thickness Calculation SheetSunday Paul100% (2)

- Flange Coupling ReportDocument11 pagesFlange Coupling ReportOm DixitNo ratings yet

- Hd605-7e0 S - N 10732-Up - Lubrication Piping, Rear (2 - 2) (#10732-)Document2 pagesHd605-7e0 S - N 10732-Up - Lubrication Piping, Rear (2 - 2) (#10732-)Maria Elena MessemakerNo ratings yet

- AISC2005 V (r1.025) - LRFDDocument17 pagesAISC2005 V (r1.025) - LRFDJuan Gutier CcNo ratings yet

- Kohler-Booklet CatlogeDocument201 pagesKohler-Booklet CatlogeRishitha NaveenkumarNo ratings yet

- Abribiaturas PipingDocument15 pagesAbribiaturas Pipingmarceloankzy100% (1)

- Construction Specification Building8.0Document12 pagesConstruction Specification Building8.0GaurangNo ratings yet

- EC480D - Main Control Valve TroubleshootingDocument3 pagesEC480D - Main Control Valve TroubleshootingPreett Rajin MenabungNo ratings yet

- Il DS 174 PDFDocument1 pageIl DS 174 PDFSatgas Yekda DN BCM BatamNo ratings yet

- PS 15 69 Round Duct STD FlangeDocument3 pagesPS 15 69 Round Duct STD Flangeazdhim ghazaliNo ratings yet

- ChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessFrom EverandChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessNo ratings yet

- Learn Power BI: A beginner's guide to developing interactive business intelligence solutions using Microsoft Power BIFrom EverandLearn Power BI: A beginner's guide to developing interactive business intelligence solutions using Microsoft Power BIRating: 5 out of 5 stars5/5 (1)

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveFrom EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveNo ratings yet

- Excel for Beginners 2023: A Step-by-Step and Quick Reference Guide to Master the Fundamentals, Formulas, Functions, & Charts in Excel with Practical Examples | A Complete Excel Shortcuts Cheat SheetFrom EverandExcel for Beginners 2023: A Step-by-Step and Quick Reference Guide to Master the Fundamentals, Formulas, Functions, & Charts in Excel with Practical Examples | A Complete Excel Shortcuts Cheat SheetNo ratings yet

- Computer Science Beginners Crash Course: Coding Data, Python, Algorithms & HackingFrom EverandComputer Science Beginners Crash Course: Coding Data, Python, Algorithms & HackingRating: 3.5 out of 5 stars3.5/5 (12)

- Design and Build Modern Datacentres, A to Z practical guideFrom EverandDesign and Build Modern Datacentres, A to Z practical guideRating: 3 out of 5 stars3/5 (2)

- Designing Data-Intensive Applications: The Big Ideas Behind Reliable, Scalable, and Maintainable SystemsFrom EverandDesigning Data-Intensive Applications: The Big Ideas Behind Reliable, Scalable, and Maintainable SystemsRating: 5 out of 5 stars5/5 (6)

- Agile Project Management: A Complete Beginner's Guide to Agile Project Management, Learn the Basic Concept and ToolsFrom EverandAgile Project Management: A Complete Beginner's Guide to Agile Project Management, Learn the Basic Concept and ToolsRating: 4.5 out of 5 stars4.5/5 (9)

- Change Management for Beginners: Understanding Change Processes and Actively Shaping ThemFrom EverandChange Management for Beginners: Understanding Change Processes and Actively Shaping ThemRating: 4.5 out of 5 stars4.5/5 (3)

- Excel 2023: A Comprehensive Quick Reference Guide to Master All You Need to Know about Excel Fundamentals, Formulas, Functions, & Charts with Real-World ExamplesFrom EverandExcel 2023: A Comprehensive Quick Reference Guide to Master All You Need to Know about Excel Fundamentals, Formulas, Functions, & Charts with Real-World ExamplesNo ratings yet

- Fundamentals of Data Engineering: Plan and Build Robust Data SystemsFrom EverandFundamentals of Data Engineering: Plan and Build Robust Data SystemsRating: 5 out of 5 stars5/5 (1)

- Balanced Scorecards and Operational Dashboards with Microsoft ExcelFrom EverandBalanced Scorecards and Operational Dashboards with Microsoft ExcelRating: 2 out of 5 stars2/5 (1)

- Agile Metrics in Action: How to measure and improve team performanceFrom EverandAgile Metrics in Action: How to measure and improve team performanceNo ratings yet

- A Modern Enterprise Architecture Approach: Enterprise ArchitectureFrom EverandA Modern Enterprise Architecture Approach: Enterprise ArchitectureRating: 4 out of 5 stars4/5 (3)

- Mastering Microsoft Excel 2016: How to Master Microsoft Excel 2016 in 30 daysFrom EverandMastering Microsoft Excel 2016: How to Master Microsoft Excel 2016 in 30 daysRating: 5 out of 5 stars5/5 (1)

- Python for Beginners: A Crash Course Guide to Learn Python in 1 WeekFrom EverandPython for Beginners: A Crash Course Guide to Learn Python in 1 WeekRating: 4.5 out of 5 stars4.5/5 (7)

- Creating Online Courses with ChatGPT | A Step-by-Step Guide with Prompt TemplatesFrom EverandCreating Online Courses with ChatGPT | A Step-by-Step Guide with Prompt TemplatesRating: 4 out of 5 stars4/5 (4)

- Product Operations: How successful companies build better products at scaleFrom EverandProduct Operations: How successful companies build better products at scaleNo ratings yet

- Lean Startup: How to Work Smarter and Not Harder While Innovating Faster and Satisfying CustomersFrom EverandLean Startup: How to Work Smarter and Not Harder While Innovating Faster and Satisfying CustomersRating: 5 out of 5 stars5/5 (2)

- Managing Humans: Biting and Humorous Tales of a Software Engineering ManagerFrom EverandManaging Humans: Biting and Humorous Tales of a Software Engineering ManagerRating: 4 out of 5 stars4/5 (90)

- Engineering Document Control, Correspondence and Information Management (Includes Software Selection Guide) for AllFrom EverandEngineering Document Control, Correspondence and Information Management (Includes Software Selection Guide) for AllNo ratings yet

- Modeling Enterprise Architecture with TOGAF: A Practical Guide Using UML and BPMNFrom EverandModeling Enterprise Architecture with TOGAF: A Practical Guide Using UML and BPMNRating: 4.5 out of 5 stars4.5/5 (8)