Professional Documents

Culture Documents

Calc Report

Uploaded by

chandra BandaraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calc Report

Uploaded by

chandra BandaraCopyright:

Available Formats

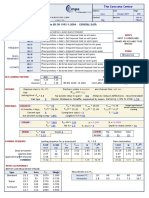

Design Calculations

CIRIA Report 108

Section 3.2

Pmax = 25x[ 1x(0.6)1/2 +0.3x0.77 x((6-1x(0.6)1/2)1/2]

C1 = 1

C2 = 0.3

h= 5m

K= 0.77

R= 0.6 m/hr

0

T= 25 C

3

D= 25 kN/m

0

T= 25 C

K= 0.77

2

Pmax = 49.526 kN/m

Dxh =150 is higher than the above Pmax value

Hydrostatice pressure region from top of

formwork = 49.526/25

1.981 m

= 1.981 m

=4.01m

49.526 kN/m2 PRESSURE ENVELOPE ON FORMWORK

Hence

Section modulus of the ply wood considering vertical lumber at 300 mm space

S= 0.075x0.152/6

= 28.125x104 cm3

Mall = FbS

Design conditions

2-1 Applied design codes, standards and references

a) BS5950 Part 1:2000 Structural use of steelwork in building

b) BS5268 Part 2:2002 Structural use of timber

Material property

Steel material property

Unit weight = 77.0 kN/m3 (BS5950 Part 1:2000)

8 2

Elastic modulus, E = 2.05 × 10 kN/m

Steel grade S275 (BS5950 Part 1:2000, Table 9)

Yield steel, py = 275 N/mm2 (t ≤ 16mm)

Yield steel, py = 265 N/mm2 (16 < t ≤ 40 mm)

Timber (D50)

Hard wood timber

Strength class = D50 (BS5268 Part 2:2002, Table 8)

Average density = 7.80 kN/m3

Elastic modulus, E = 15.0 x 106 kN/m2

Bending strength, Pb = 16.0 N/mm2

Shear strength, τ = 2.2 N/mm2

Plywood (t = 18mm)

Unit weight = 0.11 kN/m2

Elastic modulus, E = 11.8 x 106 kN/m2

Bending strength, Pb = 13.0 N/mm2

Shear strength, τ = 1.7 N/mm2

Analysis Model

Pmax= 49.5 kN/m

275

Structural Model of Plywood at Side Formwork

Member Capacity Check

Shear Capacity

Applied Shear Force, Fv = (Pmax x L) / 2 = (49.5 x 0.275)/2

= 6.8 kN

2

Design Shear Capacity

= 1.7 N/mm of timber,

Shear Capacity of timber, Pv =τxA

= 1.7 x 1000 x 18

= 30.6 kN > Fv = 6.8 kN

Hence OK

Moment Capacity

Applied Moment, Mx = Pmax x L2 / 8 = 49.5 x (0.275)2 / 8

= 0.47 kNm

= 13.0 N/mm2

Pb of timber,

Bending Stress

Moment capacity, Mc = Pb x Z

=13(1/6)x1000x182

= 0.48 kNm > Mx = 0.45 kNm Hence OK

Deflection check

Actual deflection,

δ = 5 x Pmax x L4 / (384 x EI)

= 5 x 49.5 x 0.2754 x 103/ (384 x11.8 x 106 x (1.0 x 0.0183/12))

= 0.64 mm

δ

Allowable Deflection, a = 0.003 x Span

= 0.003 x 275

= 0.825 mm > δ = 0.673 mm Hence OK

Timber at the Side (50 x 100) SC4

Consider the side formwork with the 50 x100 mm timber at the spacing of 275 mm. And continues

beam model is adopted for analysis.Considering 275 mm wide strip in concrete laid area.

Effective action on vertical timber SC4 Timber

= 49.5x0.275

=13.61 kN/m

Shear at support

= 13.61x0.9/2

Fv =6.12 kN

Maximum Bending moment on SC 4 Timber (vertical)

= 13.61x0.92/8

Mc =1.37 kNm

Moment Capacity

= 16.0 N/mm2

Pb of timber,

Bending Stress

Moment capacity, Mc = Pb x Z

= 16.0 x (1/6) x 50 x1002x 10-6

= 1.38 kNm > Mx = 1.37 kNm Hence OK

Shear Capacity

Design Shear N/mm2of timber,

Capacity

= 2.2

Shear Capacity of timber, Pv =τx A

= 2.2 x 50 x 100 x 10-3

= 11 kN > Fv = 6.17 kN Hence OK

Deflection check

Allowable Deflection, δa = 0.003 x Span

=0.003x900

= 0.37 mm > δ = 0.00023 mm Hence OK

4

Actual deflection,

δ = 5 x Pmax x L / (384 x EI)

= 5 x 49.5x0.275x x 0.94 x 103/ (384 x11.8 x 106 x (0.05 x 0.103/12))

= 0.048 mm

Allowable Deflection, δa =0.37mm>0.048mm Hence OK

You might also like

- Design Calculation of Falsework For Construction of 1800mm Thick Slab - r3Document14 pagesDesign Calculation of Falsework For Construction of 1800mm Thick Slab - r3Chan Kin Cheung100% (1)

- Stair CaseDocument12 pagesStair Casevenkatesh19701No ratings yet

- ASASDocument18 pagesASASmohamadNo ratings yet

- Level 2 BeamDocument5 pagesLevel 2 BeamNadir Khattak Jr.No ratings yet

- New SlabDocument1 pageNew SlabParthiban ArivazhaganNo ratings yet

- 8b.design of Control Room BuildingDocument49 pages8b.design of Control Room BuildingNuru TwahaNo ratings yet

- Design Calculations For Primary Beam Connections As Moment ConnectionDocument3 pagesDesign Calculations For Primary Beam Connections As Moment ConnectionRajesh PoreNo ratings yet

- 4.5 - Design of DRS - Simply SupportedDocument18 pages4.5 - Design of DRS - Simply Supportedron thombareNo ratings yet

- Staging and Scaffolding of Bridge Deck SlabDocument3 pagesStaging and Scaffolding of Bridge Deck SlabPhanindra Nath100% (1)

- New Beam FileDocument5 pagesNew Beam FileNadir Khattak Jr.No ratings yet

- 2.2 Simply Supported Beam V.2Document7 pages2.2 Simply Supported Beam V.2Hafiz95 ReactsNo ratings yet

- Rafters British Standards 06-02-2023 0931Document4 pagesRafters British Standards 06-02-2023 0931João SidônioNo ratings yet

- 05.08.2009 - Cable Trench SectionsDocument22 pages05.08.2009 - Cable Trench SectionsandyhrNo ratings yet

- Crack Width Check (CoP Concrete 2013) CPRDocument4 pagesCrack Width Check (CoP Concrete 2013) CPRAndrew WtchengNo ratings yet

- Design of Elastomeric Pad Bearing To Support A Tee Beam Girder of A Bridge Pertaing To Following DataDocument3 pagesDesign of Elastomeric Pad Bearing To Support A Tee Beam Girder of A Bridge Pertaing To Following DataMadhav Singla100% (3)

- Referenc e Calculation RemarksDocument13 pagesReferenc e Calculation RemarksJin ChuanNo ratings yet

- Lifting FrameDocument10 pagesLifting Framethienthanh81100% (1)

- Chequered DesignDocument2 pagesChequered DesignSaravana N100% (1)

- Design of Cantilever Slab As Per Is 456 2000Document2 pagesDesign of Cantilever Slab As Per Is 456 2000dhanasekaran33% (3)

- Grid Slab WITH BBSDocument11 pagesGrid Slab WITH BBSJyoti PatilNo ratings yet

- Cantilever Walkway Design WS1Document2 pagesCantilever Walkway Design WS1Raju SainiNo ratings yet

- Steel Manbasket DesignDocument9 pagesSteel Manbasket DesignvpjagannaathNo ratings yet

- Calculation of Slab ReinforcementDocument2 pagesCalculation of Slab ReinforcementwaquarstrNo ratings yet

- PROJECT5Document6 pagesPROJECT5nkjm rtdtNo ratings yet

- Perhitungan Tulangan Plat Atap: β (0,85 f' / f) (ε E / (ε E + f) )Document2 pagesPerhitungan Tulangan Plat Atap: β (0,85 f' / f) (ε E / (ε E + f) )Dewi RagilNo ratings yet

- Floor Details: Tatprofiled SteelDocument14 pagesFloor Details: Tatprofiled SteelshaimenneNo ratings yet

- Floor Details: Tatprofiled SteelDocument14 pagesFloor Details: Tatprofiled SteelshaimenneNo ratings yet

- Slab DesignDocument25 pagesSlab DesignSabin Leroy HmgnNo ratings yet

- Purlin Design Astino ProjectDocument1 pagePurlin Design Astino ProjectSalvatore ShwNo ratings yet

- Plate Loads CalculationDocument2 pagesPlate Loads CalculationarabindaNo ratings yet

- FFB2Document8 pagesFFB2prajjwal patidarNo ratings yet

- Ug Tank PreviewDocument2 pagesUg Tank Previewaaditya chopadeNo ratings yet

- Design of Rectangular Underground Water Tank: S S M C+ SSTDocument6 pagesDesign of Rectangular Underground Water Tank: S S M C+ SSTRatul PalodhiNo ratings yet

- Larsen & Toubro Limited: 1. Sectional PropertiesDocument8 pagesLarsen & Toubro Limited: 1. Sectional Propertiesprajjwal patidarNo ratings yet

- FFB4Document8 pagesFFB4prajjwal patidarNo ratings yet

- Design of BearingsDocument24 pagesDesign of BearingsFarrukh RizwanNo ratings yet

- FloorDocument4 pagesFloorNadir Khattak Jr.No ratings yet

- Pad Foundation DesignDocument4 pagesPad Foundation Designg4goharNo ratings yet

- Example 6.1 - Slab-Simply Supported (One-Way) PDFDocument5 pagesExample 6.1 - Slab-Simply Supported (One-Way) PDFnur100% (1)

- Perhitungan Tulangan Plat Lantai: β (0,85 f' / f) (ε E / (ε E + f) )Document2 pagesPerhitungan Tulangan Plat Lantai: β (0,85 f' / f) (ε E / (ε E + f) )Dewi RagilNo ratings yet

- Design of Double Pilecap: Design For Axial Load and MomentDocument16 pagesDesign of Double Pilecap: Design For Axial Load and MomentMidhun BabuNo ratings yet

- Design of RCC Staircase For Lachen - R0Document4 pagesDesign of RCC Staircase For Lachen - R0KRKA Engineers100% (1)

- Pad Foundation DesignDocument4 pagesPad Foundation DesignNaison StanleyNo ratings yet

- Sheet Pile Design: Fspiii S275 Hot RolledDocument1 pageSheet Pile Design: Fspiii S275 Hot Rolledhessian123No ratings yet

- Design of Culvert.Document4 pagesDesign of Culvert.Mariappan .PNo ratings yet

- Transverse-Design771 TriDocument17 pagesTransverse-Design771 TriBasava SowmyaNo ratings yet

- Design of Square FootingDocument8 pagesDesign of Square FootingvishalNo ratings yet

- Example 3.3 - Simply Supported One Way Slab PDFDocument6 pagesExample 3.3 - Simply Supported One Way Slab PDFFarhana HussinNo ratings yet

- Maxspan Slab WordDocument3 pagesMaxspan Slab WordJames Aswa100% (1)

- EAS356 RC Design II W4 Student Version2 SSZDocument18 pagesEAS356 RC Design II W4 Student Version2 SSZSteven KuaNo ratings yet

- Pile Cap (2 Piles)Document4 pagesPile Cap (2 Piles)KH ChungNo ratings yet

- Structural Analysis For A Composite Parallel Beam Structures Using QSE 7 Staad Pro Software in Accordance To BS 5950 - 1 Advanced UK BeamsDocument6 pagesStructural Analysis For A Composite Parallel Beam Structures Using QSE 7 Staad Pro Software in Accordance To BS 5950 - 1 Advanced UK BeamsKhalid Abdel Naser Abdel RahimNo ratings yet

- Cantilever Slab DesignDocument2 pagesCantilever Slab Designsibu_bhusalNo ratings yet

- Manual Deisgn Shear WallDocument4 pagesManual Deisgn Shear WallQuality Design & ConstructionNo ratings yet

- Timber - Example Calculation - RoymechDocument4 pagesTimber - Example Calculation - RoymechDavid O'MearaNo ratings yet

- Larsen & Toubro Limited: 1. Sectional PropertiesDocument8 pagesLarsen & Toubro Limited: 1. Sectional Propertiesprajjwal patidarNo ratings yet

- Standard Isolated Footing f1Document11 pagesStandard Isolated Footing f1Saajan bhathalNo ratings yet

- FFB3Document8 pagesFFB3prajjwal patidarNo ratings yet

- 3.0 Butterfly Valve Chamber Precast Panel DesignDocument2 pages3.0 Butterfly Valve Chamber Precast Panel DesignGaurav BhabadNo ratings yet

- Printreg v1-1Document1 pagePrintreg v1-1chandra BandaraNo ratings yet

- LiquidRet IndianDocument13 pagesLiquidRet Indianchandra BandaraNo ratings yet

- TCC42 Post Tensioned Analysis & DesignDocument17 pagesTCC42 Post Tensioned Analysis & Designhala_azhariNo ratings yet

- Typical Beam 201Document7 pagesTypical Beam 201chandra BandaraNo ratings yet

- Beam DesignDocument50 pagesBeam Designchandra BandaraNo ratings yet

- සමුදය අත්ථංගම සහ උදය වැයDocument44 pagesසමුදය අත්ථංගම සහ උදය වැයchandra BandaraNo ratings yet

- The Institution of Engineers, Sri Lanka: Elections To The Council For Session 2022/2023 Instructions To The VotersDocument2 pagesThe Institution of Engineers, Sri Lanka: Elections To The Council For Session 2022/2023 Instructions To The Voterschandra BandaraNo ratings yet

- Guidance For Standard Form Contract - Sri Lanka PDFDocument301 pagesGuidance For Standard Form Contract - Sri Lanka PDFNuwantha UduwageNo ratings yet

- Publication Iqssl 2020 08 27 Uid661Document132 pagesPublication Iqssl 2020 08 27 Uid661chandra BandaraNo ratings yet

- COVID-19 Impacts On Current Construction and Engineering Projects - Opinion - Daily MirrorDocument7 pagesCOVID-19 Impacts On Current Construction and Engineering Projects - Opinion - Daily Mirrorchandra BandaraNo ratings yet

- Geometric Design of Roads and HighwaysDocument2 pagesGeometric Design of Roads and Highwayschandra BandaraNo ratings yet

- Modulus June 2022Document24 pagesModulus June 2022chandra BandaraNo ratings yet

- Paddy Statistics 2018-19mahaDocument33 pagesPaddy Statistics 2018-19mahachandra BandaraNo ratings yet

- Appendix 1 - Formwork BasicsDocument12 pagesAppendix 1 - Formwork Basicschandra BandaraNo ratings yet

- Dynamometers 161011144109Document28 pagesDynamometers 161011144109Mr.S UpenderNo ratings yet

- The Modelling and Design of Scale Inhibitor Squeeze Treatments PDFDocument14 pagesThe Modelling and Design of Scale Inhibitor Squeeze Treatments PDFLaura Natalia SalcedoNo ratings yet

- Master Course 2017 - Photonic Imaging in Neurobiology - C. LeterrierDocument56 pagesMaster Course 2017 - Photonic Imaging in Neurobiology - C. LeterrierlechristopheNo ratings yet

- Restriction OrificeDocument4 pagesRestriction OrificeRaghulal SethumadhavanNo ratings yet

- Solutions - Revision Book Chemistry PDFDocument89 pagesSolutions - Revision Book Chemistry PDFJatin GoyalNo ratings yet

- Temkin 100 YearsDocument30 pagesTemkin 100 YearsMarina ShestakovaNo ratings yet

- 53 TOP Structural Analysis - Civil Engineering Multiple Choice Questions and Answers PDF - MCQs Preparation For Engineering Competitive ExamsDocument7 pages53 TOP Structural Analysis - Civil Engineering Multiple Choice Questions and Answers PDF - MCQs Preparation For Engineering Competitive Examseid ibrahimNo ratings yet

- Sheet 1 PED 232 2nd Year 2017Document2 pagesSheet 1 PED 232 2nd Year 2017MhmdKordyNo ratings yet

- 303-05 Accessory Drive - Diagnosis and Testing - Accessory DriveDocument7 pages303-05 Accessory Drive - Diagnosis and Testing - Accessory DriveCARLOS LIMADANo ratings yet

- Justification Document For The Chilled Water Piping InstallationDocument7 pagesJustification Document For The Chilled Water Piping InstallationFrancis Mayowa EzekielNo ratings yet

- Work Power Energy QuestionsDocument17 pagesWork Power Energy QuestionsAnupam MNo ratings yet

- Design of Reinforced Concrete Structures BEG451CIDocument3 pagesDesign of Reinforced Concrete Structures BEG451CIAnil MarsaniNo ratings yet

- Plano Electrico PC130-8Document9 pagesPlano Electrico PC130-8jon fredyNo ratings yet

- Q200680 - Ledeen Technical DescriptionDocument7 pagesQ200680 - Ledeen Technical Descriptioncoyana9652No ratings yet

- Light-Reflection and RefractionDocument41 pagesLight-Reflection and Refractionapi-268345960No ratings yet

- Equilibrium BWDocument54 pagesEquilibrium BWFranca OkechukwuNo ratings yet

- High Performance Computing in Science and Engineering 16Document665 pagesHigh Performance Computing in Science and Engineering 16Kamchatka TacalaskaNo ratings yet

- CTVPRC 007 enDocument56 pagesCTVPRC 007 enrommel duranNo ratings yet

- Kinetics 3.2. Surfaces and InterfacesDocument43 pagesKinetics 3.2. Surfaces and InterfacesCường Nguyễn ĐứcNo ratings yet

- Factors Affecting Weather 10Document24 pagesFactors Affecting Weather 10Jaypee CarlNo ratings yet

- Physics Homework Questions #2Document2 pagesPhysics Homework Questions #2Phoenix SuohNo ratings yet

- Atomic Emission SpectrometryDocument21 pagesAtomic Emission SpectrometryArslan Muhammad EjazNo ratings yet

- Compressible Gas Flow in PipelinesDocument3 pagesCompressible Gas Flow in PipelinesRahul ChandrawarNo ratings yet

- Narayana... Iit Jee PaperDocument26 pagesNarayana... Iit Jee PaperAbhishek KumarNo ratings yet

- Blowing AgentDocument12 pagesBlowing AgentHimanshu PainulyNo ratings yet

- A Study On The Peculiar Problems of Cold Formed Steel DesignDocument3 pagesA Study On The Peculiar Problems of Cold Formed Steel DesignarjunNo ratings yet

- Ps2 GeoDocument9 pagesPs2 GeoRio Fae BautistaNo ratings yet

- Module 1 Quiz AaDocument8 pagesModule 1 Quiz AaGUILLER BELENNo ratings yet

- Riprap Revetment Ahn Polvi TrabantDocument10 pagesRiprap Revetment Ahn Polvi TrabantdihsadhisahdaNo ratings yet

- Activity WorksheetsDocument9 pagesActivity WorksheetsJessa Eraldin OriginesNo ratings yet