Professional Documents

Culture Documents

Techneau Storage Handling and Installation

Uploaded by

mohdmmedniyaz786Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Techneau Storage Handling and Installation

Uploaded by

mohdmmedniyaz786Copyright:

Available Formats

Techneau, ZA la Chevalerie, 50570 Marigny,France Tel : 0033. 2.33.56.62.08 info@techneau.

com

Polyester & Steel Horizontal Devices

To be read upon receipt of the device

Handling :

- Before any handling, important to check that there is no water inside each compartments.

- Handling of the device must be carried out using a suitable lifting device.

- When available use lifting hooks provided with the device

- If no lifting hooks follow lifting instructions shown below. Only use textile cables (steel cables are PROHIBITED)

- Once lifted, the device must be guided using ropes.

Delivery and storage :

- Check by visual inspection that the external structure of the device has not been damaged during transportation.

- In the event of any identified defect, please mention it on the documentation provided by the carrier.

- Store the device in a safe place, away from any risk of shock. Prevent rainwater from entering into the device (the device must

be absolutely empty during handling operations).

Important Precautions:

- Never fill up a device that has not been correctly supported and secured. In the event of a leak test, only proceed with filling

after having carried out step 5 of the installation procedure or by following the above-ground installation procedure below. Then

observe the evolution of the filling during a period of 12 hours.

- It is strongly advised to install the device in an area which is not subject to constant applied loads. Important to proceed to

installation considering a reduced and optimized depth so then maintenance operations will be facilitated.

- Do not use a compacting machine to stabilize the backfill of the device. Use <15mm self-compacting gravel.

- Clearly define the working area in order to store the material and to prevent all vehicles to enter during installation.

- Please refer to technical data sheets or contact us in order to define the appropriate installation depth. If depth is beyond our

recommandation a protective structure (see #8 of the procedure) is mandatory. The device must rest on stable excavation edges

and its structural dimensioning must be defined by a Civil Engineering design office (The device cannot be subject to any

residual pressures exceeding static loads.

Ensure that no transferable loads from concrete are applied on the device (floating installation).

- In the event of exposure to additional static loads (deep foundations, embankments, loads from accumulation of various

materials, steep slopes, use of concrete extensions, etc.) or dynamic loads (rolling vehicles, etc.), a protective structure is

mandatory, whatever the considered depth. In the case of installation above roads, the plastic cover has to be removed (A

suitable cover to be provided).

- It is important to assess the level of groundwater (hydromorphic soil). The presence of water may be related to an

unexpected rise in the level of underground water. The low permeability of the surrounding soil can also cause issues,

preventing the good infiltration of rainfalls, which will lead to an accumulation in the excavation area around the tank (coef. of

permeability K<10-5 cm/s rocks, clays, silt, etc.). Please refer to any available ground report. The website

http://www.georisques.gouv.fr can also help in assessing the presence of groundwater.

- To find out the maximum level of immersion (N rating) please refer to the corresponding technical sheet or contact us. If any

doubt, do not install the device and contact us.

- Assess the need for tank weighting. A saturation (even partial) of the excavation by underground waters or by water runoff

may require the tank to be weighted (« Chassis Speed » or additional anchoring on a concrete slab, or weighting by upper slab).

The quantity of concrete must compensate Archimedes' thrust applied on an empty device.

- In addition to their low permeability (see above), clay soils can generate high pressure related to the action of

shrinkage/swelling of clays. In the event of medium to high exposure (see https://www.georisques.gouv.fr), add 200 kg of

cement per m3 of gravel when backfilling the tank.

- Maximum inside temperature: 50°C for Polyester and painted steel, 90°C for stainless steel.

- If any risk of freezing the tank has to be emptied.

- If any doubt refer to NF P16-442, NF 976-2 standards or contact TECHNEAU.

IN501B Installation- Polyester & Steel Horizontal Devices 08/09/2022

Techneau, ZA la Chevalerie, 50570 Marigny,France Tel : 0033. 2.33.56.62.08 info@techneau.com

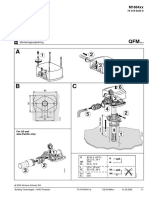

Underground installation procedure:

1– The lowest part of the excavation has to be stabilized. Important to ensure that this bottom part is perfectly horizontal.

If any needs of anchoring the device (see § "precautions"), build an additional concrete slab on the bottom of the excavation and

include anchoring irons. The quantity of concrete has to be calculated considering Archimedes thrust applied on an empty device.

2– Provide a layer of sand or 100mm thickness of gravel on the stabilized excavation bottom.

3– Position the device on the sand layer after having removed transport cradles and all protections.

4– Adjust straps / belts or anchor tensioners (optional) without pre-stressing the tank. If no anchoring, fill the device with clear

water (20% of the total capacity) in order to stabilize the structure.

5– Backfill the lower part of the device with sand and/or 10-14 cat.

gravel. Please proceed progressively/by step considering 300mm

thickness layers.

- ensure the stability of the backfill between each layer (mechanical

compacting is excluded)

A special care to be given to the lowest part of closed spaces in

order to ensure a perfect stability of the device.

- Keep proceeding until 50% of the tank has been filled

6–Connect the inlet and the outlet, (as well as any ventilation and

sheath). Nozzles are designed for PVC piping

7– Backfill with sand or 10-14 gravel until the tank being

completely buried.

8– If necessary (see § “important precautions”), install the

additional protective structure.

9– Install extensions/shafts if any and adjust them according ground

level.

10– Backfill using natural ground.

Standard installation Deep installation / below concrete slab

Above-ground device installation procedure:

1- The ground must be stable, horizontal, free of stones and bumps.

Pour a clean concrete slab if necessary

2- Position the device on corresponding metal cradles (optional).

Refer to the corresponding technical datasheet in order to

position cradles.

If no specific cradles, proceed as indicated below:

1- The ground must be stable, horizontal, free of stones and bumps.

Pour a clean concrete slab if necessary

2- Build a closed area whose dimensions accommodate the access to

the tank structure while maintaining a free space of 30cm all around in

order to allow the backfilling. This closed area will allow the device to

be backfilled over at least 1/3 of its height

Provide a draining system so that this closed area will not retain

runoff water.

3- Install a 10cm sand layer.

4- Position the tank on the sand layer (after removing transport

cradles)

5- Fill the tank at 20% of its total capacity in order to stabilize the structure.

6- Backfill the base of the tank with 10-14 gravel or sand, taking care of closed spaces in the lowest part. If using sand for

backfilling, compact it by adding water.

7- The backfilled height must reach at least 50% of the device diameter

IN501B Installation- Polyester & Steel Horizontal Devices 08/09/2022

You might also like

- Construction Method Statement For The Installation of The Proposed Treatment Plant at Zip World, BethesdaDocument12 pagesConstruction Method Statement For The Installation of The Proposed Treatment Plant at Zip World, BethesdaazrulNo ratings yet

- Annex 6. Working Procedures and InstructionsDocument11 pagesAnnex 6. Working Procedures and InstructionsNjiaNo ratings yet

- Box Culvert, VUP & Minor BridgeDocument22 pagesBox Culvert, VUP & Minor BridgeĐărsĥąna RanasingheNo ratings yet

- Frameless Glass InstallationDocument4 pagesFrameless Glass InstallationNita Jamnu60% (5)

- Pole Installation MethodologyDocument10 pagesPole Installation MethodologyHitesh Garg43% (14)

- Pond Liner Installation GuideDocument2 pagesPond Liner Installation GuidedsethiaimtnNo ratings yet

- Lifting Lug CalculationDocument4 pagesLifting Lug CalculationHassan SleemNo ratings yet

- Important: Installation InstructionsDocument8 pagesImportant: Installation InstructionsChris KhouriNo ratings yet

- Method Statement For ConstructionDocument8 pagesMethod Statement For ConstructionTin DanNo ratings yet

- Excavation and Embankment. (REV 10-31-0212-18-02) (FA 1-14-03) (7-03)Document1 pageExcavation and Embankment. (REV 10-31-0212-18-02) (FA 1-14-03) (7-03)Pawan KumarNo ratings yet

- Pole Installation MethodologyDocument10 pagesPole Installation Methodologyrajaguru20003No ratings yet

- CaissonDocument10 pagesCaissonozgurdogerNo ratings yet

- Method of StatementDocument8 pagesMethod of StatementHisham BerrasaliNo ratings yet

- Back Filling - ReportDocument15 pagesBack Filling - ReportEmmanuel AzuelaNo ratings yet

- Upgrading of Approximately 104Km of Road D104/D791 Chipata To Mfuwe in Eastern Province Surfacing PlanDocument8 pagesUpgrading of Approximately 104Km of Road D104/D791 Chipata To Mfuwe in Eastern Province Surfacing PlanSidney MusondaNo ratings yet

- Clearing, Grubbing and ExcavationDocument11 pagesClearing, Grubbing and ExcavationArah Louise ApostolNo ratings yet

- Eone W Series Grinder Pump Installation InstructionsDocument20 pagesEone W Series Grinder Pump Installation InstructionsB100% (1)

- Bentofix® Geosynthetic Clay LinersDocument5 pagesBentofix® Geosynthetic Clay LinersHussein Amir MohsenNo ratings yet

- Foundation Safety ProceduresDocument22 pagesFoundation Safety ProceduresArul ManiNo ratings yet

- Septic Tank Installation ManualDocument12 pagesSeptic Tank Installation Manualingeni0sNo ratings yet

- Work Method Statement For Cable Excavation TrenchesDocument5 pagesWork Method Statement For Cable Excavation TrenchessamsungloverNo ratings yet

- Application Guide: Installation Guidelines For Landfill LiningDocument6 pagesApplication Guide: Installation Guidelines For Landfill LiningLuis Rolando AguilarNo ratings yet

- Pipeline InstallationDocument6 pagesPipeline InstallationSurya Kiran KNo ratings yet

- Wisconsin Construction Specification 3. Earthfill: 3-1 USDA-NRCS-Wisconsin Section IV, Technical Guide 5/12Document3 pagesWisconsin Construction Specification 3. Earthfill: 3-1 USDA-NRCS-Wisconsin Section IV, Technical Guide 5/12魏雨辰No ratings yet

- Sewer Install GuideDocument54 pagesSewer Install GuideSurieduth BuskalowaNo ratings yet

- Written Work Instruction (Sheet Piles Installation)Document14 pagesWritten Work Instruction (Sheet Piles Installation)cynthia100% (1)

- Grating Removal & InstallationDocument39 pagesGrating Removal & InstallationSreejith SureshNo ratings yet

- Work Tips 41Document2 pagesWork Tips 41Timothy MalinziNo ratings yet

- Construction Management Plan For Bund WallDocument14 pagesConstruction Management Plan For Bund WallNoNa Mohammed0% (1)

- Pipe Road Crossing MSDocument7 pagesPipe Road Crossing MSJeffrey WeyNo ratings yet

- FCT One Installation Guidelines PDFDocument1 pageFCT One Installation Guidelines PDFAndrei-Marian GradinaruNo ratings yet

- Section 02000: Milling, Hot Mix Asphalt and Patching Procedures: A. MillingDocument12 pagesSection 02000: Milling, Hot Mix Asphalt and Patching Procedures: A. MillingJojo DejucosNo ratings yet

- Inst Instructions 10 000 v1.0Document9 pagesInst Instructions 10 000 v1.0gangrukaNo ratings yet

- How To Backfill Foundations and Trenches Backfill Is The Key To A Solid and Stable Grading Share Flip Pin EmailDocument4 pagesHow To Backfill Foundations and Trenches Backfill Is The Key To A Solid and Stable Grading Share Flip Pin Emailram_babu_59No ratings yet

- Method Statement Asphalt PavingDocument3 pagesMethod Statement Asphalt PavingHussam WaleedNo ratings yet

- Technical SpecificationDocument7 pagesTechnical SpecificationRaisa AviannyNo ratings yet

- Scaffolding ProcedureDocument3 pagesScaffolding Proceduremd ruman100% (2)

- Pile Load Test MethodologyDocument4 pagesPile Load Test MethodologyAkhilesh Dwivedi100% (1)

- Conbextra EP65 SDSDocument4 pagesConbextra EP65 SDSEdwin HarrisNo ratings yet

- Installation Guidelines: 1. Preparing The SubgradeDocument3 pagesInstallation Guidelines: 1. Preparing The SubgradeElard QANo ratings yet

- Method Statement PVD (Wick Drain)Document9 pagesMethod Statement PVD (Wick Drain)Arq Mario Josue Lopez BasañezNo ratings yet

- Main Switchboard Maintenance PDFDocument17 pagesMain Switchboard Maintenance PDFAzman HanafiahNo ratings yet

- Method Statement: Conbextra GP2Document5 pagesMethod Statement: Conbextra GP2diwakar1978No ratings yet

- Glass Fibre Grids MethodologyDocument4 pagesGlass Fibre Grids MethodologyRaghavNo ratings yet

- Volclay Voltex Bentonite Geotextile Waterproofing System Specification GuidelinesDocument4 pagesVolclay Voltex Bentonite Geotextile Waterproofing System Specification GuidelinesjbonvierNo ratings yet

- Aluminium Dome Roof InstallationDocument7 pagesAluminium Dome Roof Installationmuhammad.younisNo ratings yet

- Box Culvert Handling and Jointing Instructions 2020 PDFDocument3 pagesBox Culvert Handling and Jointing Instructions 2020 PDFHpeso EmohseNo ratings yet

- Installation ManualDocument28 pagesInstallation ManualLuisa Fernanda Alvarez VillaNo ratings yet

- Methodology For Subgrade Construction - Highway GuideDocument4 pagesMethodology For Subgrade Construction - Highway GuidesvsrnbNo ratings yet

- Mehtod Statement Road Work - ROBDocument22 pagesMehtod Statement Road Work - ROBCivil FundaNo ratings yet

- Mehtod Statement Road Work - ROBDocument22 pagesMehtod Statement Road Work - ROBCivil FundaNo ratings yet

- Installation Guidance For Cable Troughs and Service Ducts PD84Document7 pagesInstallation Guidance For Cable Troughs and Service Ducts PD84sosi2020No ratings yet

- Installation Guidance For Cable Troughs and Service Ducts PD84Document7 pagesInstallation Guidance For Cable Troughs and Service Ducts PD84sosi2020No ratings yet

- Installation Guidance For Cable Troughs and Service Ducts PD84Document7 pagesInstallation Guidance For Cable Troughs and Service Ducts PD84sosi2020No ratings yet

- Risk Assessment & Method Statement: Pioneer Water TanksDocument5 pagesRisk Assessment & Method Statement: Pioneer Water TankswasiullNo ratings yet

- Slope ProtectionDocument3 pagesSlope Protectionshima2727No ratings yet

- Installation Vertical Flat Bottom TankDocument2 pagesInstallation Vertical Flat Bottom TankBudi MaryantoNo ratings yet

- Clearing, Grubbing and ExcavationDocument25 pagesClearing, Grubbing and ExcavationArah Louise ApostolNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Workshop Processes and MaterialsDocument3 pagesWorkshop Processes and MaterialsHaruna AbassNo ratings yet

- Sheet Processes and Technology Route: by DR - Saad Kariem ShatherDocument12 pagesSheet Processes and Technology Route: by DR - Saad Kariem ShatherSkipp BdjNo ratings yet

- 84.B 7 Types of AbnormalitiesDocument7 pages84.B 7 Types of AbnormalitiesVũ QuangNo ratings yet

- Simple Machines: Principle of MomentsDocument3 pagesSimple Machines: Principle of Momentsearl pannilaNo ratings yet

- Student Manual of Spiral Spring ApparatusDocument3 pagesStudent Manual of Spiral Spring ApparatusaqibNo ratings yet

- Parts Manual: Part Number IndexDocument172 pagesParts Manual: Part Number Indexzakaria talbiNo ratings yet

- Fan Static Pressure CalculationsDocument2 pagesFan Static Pressure Calculationsscribd9919086% (7)

- KT EVO Data Sheet EDocument1 pageKT EVO Data Sheet EAndy Kong KingNo ratings yet

- Conception Analysis and Design of A 3d Steel BuildingDocument87 pagesConception Analysis and Design of A 3d Steel BuildingMyunSu GooNo ratings yet

- Hand Written Notes Class 10 ANSWERS ELECTRICITYDocument19 pagesHand Written Notes Class 10 ANSWERS ELECTRICITYANTIMA SINGHNo ratings yet

- Valvula Reductora de PresionDocument2 pagesValvula Reductora de Presionsergio blandon lNo ratings yet

- Mathematics Schemes and Question For Jss 2: Week 1Document14 pagesMathematics Schemes and Question For Jss 2: Week 1Omagbemi WilliamNo ratings yet

- BCH (Bhartia Cutler Hammer) Pricelist 23.01Document42 pagesBCH (Bhartia Cutler Hammer) Pricelist 23.01Narendra Kumar100% (1)

- Potentiometer Calibration of Low Range VoltageDocument7 pagesPotentiometer Calibration of Low Range Voltagetreesakdevasia3No ratings yet

- Dwyer A Young Franklin Actuators Frm6UG09Document22 pagesDwyer A Young Franklin Actuators Frm6UG09JavierNo ratings yet

- Supplier Cost Floor Drain Roof DrainDocument6 pagesSupplier Cost Floor Drain Roof DrainSupawat RangsiwongNo ratings yet

- HV04-07 Parts Manual IssEDocument96 pagesHV04-07 Parts Manual IssEJonathan Mercier100% (1)

- Dynamic Spine Calculator Rev 5-12 2007Document8,037 pagesDynamic Spine Calculator Rev 5-12 2007Ngatijo AlyasinNo ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 159Document1 pageNissan Almera n16 2001 Electronic Repair Manual 159netifig352No ratings yet

- Dead Stock 2015Document56 pagesDead Stock 2015humam mzuhriNo ratings yet

- Duct Sensor For Rel. Humidity - Temperature QFM.. - DaDocument1 pageDuct Sensor For Rel. Humidity - Temperature QFM.. - DaGiang BùiNo ratings yet

- SHORTSTOPP® Welding Fittings - TDWDocument3 pagesSHORTSTOPP® Welding Fittings - TDWsheikbba100% (1)

- PT2606 Eng 03 303855078Document2 pagesPT2606 Eng 03 303855078Shane LinNo ratings yet

- Cushman Catalog Rev1Document36 pagesCushman Catalog Rev1CaryNo ratings yet

- AJR Breif ProfileDocument13 pagesAJR Breif ProfilesajalNo ratings yet

- Grinding Lab ManualDocument4 pagesGrinding Lab ManualArun kumar rouniyar100% (1)

- Casing ThreadsDocument7 pagesCasing ThreadsNaser KhanNo ratings yet

- Variable Displacement Motors: Series 51-1: 60 CC, 80 CC, and 110 CCDocument68 pagesVariable Displacement Motors: Series 51-1: 60 CC, 80 CC, and 110 CCRodrigues de OliveiraNo ratings yet

- Directional Drilling - Manual E - SchlumbergerDocument44 pagesDirectional Drilling - Manual E - SchlumbergerAli Azmat Khan100% (1)

- Drafting SystemDocument11 pagesDrafting SystemRatul HasanNo ratings yet