Professional Documents

Culture Documents

EPSON WF-C20590 Service Manual Page451-500

Uploaded by

ion ionCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EPSON WF-C20590 Service Manual Page451-500

Uploaded by

ion ionCopyright:

Available Formats

EPSON WF-C20590 Revision A

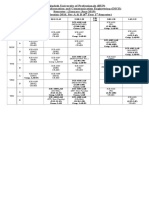

Table 7-1. Adjustment and Inspection List

Program For More

Program Name Purpose Time

No. Instructions

B. Counter Reset: MENU

Pick Up Roller, MP --- When a periodic replacement part has been replaced, resets the life counter that manages the life in 40 sec

the printer.

Pick Up Roller, C1 --- 40 sec

For the life, count method, and UI display for periodic replacement parts, see p.83.

Pick Up Roller, C2 --- 40 sec

Pick Up Roller, C3 --- 40 sec

Pick Up Roller, C4 --- 40 sec

Belt Drawer Unit/ Filters --- 40 sec p.1185

Belt Cleaner Unit --- 40 sec

Head --- 40 sec

Maintenance Unit --- 40 sec

Pick Up Roller, ADF --- 40 sec

Pick Up Roller, Hi-Capacity --- 40 sec

Repair work Adjustment and Inspection Work 451

Confidential

EPSON WF-C20590 Revision A

7.2.3 Adjustments Required before/after Repair

The following pages show work procedures, adjustments, and inspections

required when removing or replacing parts or components. When repairing

multiple parts or components, be sure to perform all the required work

procedures for all the parts or components. If multiple adjustments are required

and you perform them one by one individually, make sure to start from the one

listed uppermost in the table. The adjustments must be performed in order from

the top to the bottom.

To help you to easily find target parts or components in the tables on the

following pages, the tables are divided by category as shown below. Check the

table below first.

Category Page

Head, Ink System (IS), Paper Feed (PF) Table 7-2. (p.453)

ASF, Multi-Cassette ASF Table 7-3. (p.455)

MP, Paper Ejection (EJ), Electrical components, ADF/Scanner (ADF/

Table 7-4. (p.457)

SCN), Main Unit

Options Table 7-5. (p.459)

C H E C K See "7.2.4 Adjustment/Inspection Details" (p.460) for

P O IN T details of the procedures of operation/adjustment/inspection.

Repair work Adjustment and Inspection Work 452

Confidential

EPSON WF-C20590 Revision A

HEAD, INK SYSTEM (IS), PAPER FEED (PF) C H E C K Meaning of the marks used in the tables on the following

P O IN T pages are as follows.

“RP”: Required only when replacing

“RM”: Required when removing and/or replacing

Blank: No adjustment is required

Table 7-2. Required Adjustments for Head, Ink System (IS), Paper Feed (PF)

Category Head IS PF

Maintenance Unit

Belt Cleaner Unit

Wiper HP Sensor

Anti Static Brush

Belt Drawer Unit

Cap Motion Unit

HP Sensor, Head

Ink Supply Unit

Relay Ink Path

Wiper Assy

Head FFC

Cap Unit

Part/Component

Head

Assy

Adjustment Item Program No.

3. Before Repair Operation: MENU

Head (p.460) 31 RM

Ink Supply Path: MENU (p.466) 32

Ink Supply Unit (p.466) 321 RM

Relay Flow Path Assy (p.468) 322 RM

Ink Discharge Path (p.470) 33 RM RM RM

Belt Drawer Unit (p.471) 34 RM RM

Individual: MENU (p.472) 35

Antistatic Brush Assy (p.472) 351 RM

Wiper Assy (p.472) 352 RM RM

4. Adjustment - Main/ Option Unit: MENU

Head (p.473) 41 RM

Ink Supply Path: MENU (p.477) 42

Ink Supply Unit (p.477) 421 RM

Relay Flow Path Assy (p.479) 422 RM

Ink Discharge Path (p.481) 43 RM RM RM

Belt Drawer Unit (p.482) 44 RM

Individual Adjustment: MENU (p.488) 46

PG Adjustment: MENU (p.490) 4602

HP Sensor, Head (p.492) 46023 RM

Head FFC Noise Check (p.495) 4604 RM

Repair work Adjustment and Inspection Work 453

Confidential

EPSON WF-C20590 Revision A

Table 7-2. Required Adjustments for Head, Ink System (IS), Paper Feed (PF)

Category Head IS PF

Maintenance Unit

Wiper HP Sensor

Belt Cleaner Unit

Anti Static Brush

Belt Drawer Unit

HP Sensor, Head

Cap Motion Unit

Ink Supply Unit

Relay Ink Path

Wiper Assy

Head FFC

Cap Unit

Part/Component

Head

Assy

Adjustment Item Program No.

4. Adjustment - Main/ Option Unit: MENU (continued)

Individual Adjustment: MENU (continued)

Wiper Stroke Adjustment (p.495) 4605 RM RM

Side Registration Adjustment (p.496) 4606

Top Registration Adjustment (p.499) 4607

Paper Sensor, Post-Head Sensitivity Adjustment (p.499) 4609

PW Sensor Adjusted Value Writing (p.506) 4610

5. Adjustment - SCN/ADF: MENU

SCAN/ADF MENU Select ---

MENU(1/7) > SCN ADF Simple Mech Setup (p.522) ---

B. Counter Reset: MENU (p.1185)

Pick Up Roller, MP ---

Pick Up Roller, C1 ---

Pick Up Roller, C2 ---

Pick Up Roller, C3 ---

Pick Up Roller, C4 ---

Belt Drawer Unit/ Filters --- RP

Belt Cleaner Unit ---

Head --- RP

Maintenance Unit --- RP

Pick Up Roller, ADF/ Paper Guide Inner Cover ---

Pick Up Roller, Hi-Capacity ---

Repair work Adjustment and Inspection Work 454

Confidential

EPSON WF-C20590 Revision A

ASF, MULTI-CASSETTE ASF C H E C K Meaning of the marks used in the tables on the following

P O IN T pages are as follows.

“RP”: Required only when replacing

“RM”: Required when removing and/or replacing

Blank: No adjustment is required

Table 7-3. Adjustments Required for ASF, Multi-Cassette ASF

Category ASF Multi-Cassette ASF

Paper Feed Motor, C1

Paper Conveying Unit

Paper Feed Roller, C1

Cover Multi-Cassette

Multi-Cassette Paper

Multi-Cassette Paper

Paper Feed Unit, C1

Paper Width Sensor

Multi-Cassette Feed

Multi-Cassette Feed

Feed Motor, C2-C4

Pre-Printing Paper

Paper Guide Inner

Paper Feed Roller,

Paper Feed Motor

Feed Unit, C2-C4

Inner Cover C1

Cassette C2-C4

Register Roller

Register Unit

Paper Guide

Cassette C1

Cover Assy

Part/Component

Detector

C2-C4

Motor

Adjustment Item Program No.

3. Before Repair Operation: MENU

Head (p.460) 31

Ink Supply Path: MENU (p.466) 32

Ink Supply Unit (p.466) 321

Relay Flow Path Assy (p.468) 322

Ink Discharge Path (p.470) 33

Belt Drawer Unit (p.471) 34

Individual: MENU (p.472) 35

Antistatic Brush Assy (p.472) 351

Wiper Assy (p.472) 352

4. Adjustment - Main/ Option Unit: MENU

Head (p.473) 41

Ink Supply Path: MENU (p.477) 42

Ink Supply Unit (p.477) 421

Relay Flow Path Assy (p.479) 422

Ink Discharge Path (p.481) 43

Belt Drawer Unit (p.482) 44

Individual Adjustment: MENU (p.488) 46

PG Adjustment: MENU (p.490) 4602

HP Sensor, Head (p.492) 46023

Repair work Adjustment and Inspection Work 455

Confidential

EPSON WF-C20590 Revision A

Table 7-3. Adjustments Required for ASF, Multi-Cassette ASF

Category ASF Multi-Cassette ASF

Paper Feed Motor, C1

Paper Feed Roller, C1

Paper Conveying Unit

Cover Multi-Cassette

Multi-Cassette Paper

Multi-Cassette Paper

Paper Feed Unit, C1

Paper Width Sensor

Multi-Cassette Feed

Multi-Cassette Feed

Feed Motor, C2-C4

Pre-Printing Paper

Paper Guide Inner

Paper Feed Roller,

Paper Feed Motor

Feed Unit, C2-C4

Inner Cover C1

Cassette C2-C4

Register Roller

Register Unit

Paper Guide

Cassette C1

Cover Assy

Part/Component

Detector

C2-C4

Motor

Adjustment Item Program No.

4. Adjustment - Main/ Option Unit: MENU (continued)

Individual Adjustment: MENU (continued)

Head FFC Noise Check (p.495) 4604

Wiper Stroke Adjustment (p.495) 4605

Side Registration Adjustment (p.496) 4606 RP RP RP RP RP RP RP RP RP

Top Registration Adjustment (p.499) 4607 RP RP RP RP RP RP RP

Paper Sensor, Post-Head Sensitivity Adjustment 4609

(p.499)

PW Sensor Adjusted Value Writing (p.506) 4610 RP

5. Adjustment - SCN/ADF: MENU

SCAN/ADF MENU Select ---

MENU(1/7) > SCN ADF Simple Mech Setup (p.522) ---

B. Counter Reset: MENU (p.1185)

Pick Up Roller, MP ---

Pick Up Roller, C1 --- RP RP

Pick Up Roller, C2 --- RP RP

Pick Up Roller, C3 --- RP RP

Pick Up Roller, C4 --- RP RP

Belt Drawer Unit/ Filters ---

Belt Cleaner Unit ---

Head ---

Maintenance Unit ---

Pick Up Roller, ADF ---

Pick Up Roller, Hi-Capacity ---

Repair work Adjustment and Inspection Work 456

Confidential

EPSON WF-C20590 Revision A

MP, PAPER EJECTION (EJ), ELECTRICAL COMPONENTS, ADF/ C H E C K Meaning of the marks used in the tables on the following

SCANNER (ADF/SCN), MAIN UNIT P O IN T pages are as follows.

“RP”: Required only when replacing

“RM”: Required when removing and/or replacing

Blank: No adjustment is required

Table 7-4. Adjustments Required for MP, Paper Ejection (EJ), Electrical components, ADF/Scanner (ADF/SCN), Main Unit

Electrical Main Unit

Category MP EJ ADF/Scanner

Components (printer)

Pick Up Roller, ADF

SCN Document Mat

Head Drive Board

MP Pickup Roller

MP Hopper Assy

ADF/SCN Board

MP Tray Unit

ADF Unit

SCN Unit

EJ Unit

Part/Component

Filters

Adjustment Item Program No.

3. Before Repair Operation: MENU

Head (p.460) 31

Ink Supply Path: MENU (p.466) 32

Ink Supply Unit (p.466) 321

Relay Flow Path Assy (p.468) 322

Ink Discharge Path (p.470) 33

Belt Drawer Unit (p.471) 34

Individual: MENU (p.472) 35

Antistatic Brush Assy (p.472) 351

Wiper Assy (p.472) 352

4. Adjustment - Main/ Option Unit: MENU

Head (p.473) 41

Ink Supply Path: MENU (p.477) 42

Ink Supply Unit (p.477) 421

Relay Flow Path Assy (p.479) 422

Ink Discharge Path (p.481) 43

Belt Drawer Unit (p.482) 44

Individual Adjustment: MENU (p.488) 46

PG Adjustment: MENU (p.490) 4602

HP Sensor, Head (p.492) 46023

Repair work Adjustment and Inspection Work 457

Confidential

EPSON WF-C20590 Revision A

Table 7-4. Adjustments Required for MP, Paper Ejection (EJ), Electrical components, ADF/Scanner (ADF/SCN), Main Unit

Electrical Main Unit

Category MP EJ ADF/Scanner

Components (printer)

Pick Up Roller, ADF

SCN Document Mat

Head Drive Board

MP Pickup Roller

MP Hopper Assy

ADF/SCN Board

MP Tray Unit

ADF Unit

SCN Unit

Part/Component

EJ Unit

Filters

Adjustment Item Program No.

4. Adjustment - Main/ Option Unit: MENU (continued)

Individual Adjustment: MENU (continued)

Head FFC Noise Check (p.495) 4604 RM

Wiper Stroke Adjustment (p.495) 4605

Side Registration Adjustment (p.496) 4606 RP RP

Top Registration Adjustment (p.499) 4607

Paper Sensor, Post-Head Sensitivity Adjustment 4609 RP

(p.499)

PW Sensor Adjusted Value Writing (p.506) 4610

5. Adjustment - SCN/ADF: MENU

SCAN/ADF MENU Select ---

MENU(1/7) > SCN ADF Simple Mech Setup (p.522) --- RP RP RP RP

B. Counter Reset: MENU (p.1185)

Pick Up Roller, MP --- RP RP

Pick Up Roller, C1 ---

Pick Up Roller, C2 ---

Pick Up Roller, C3 ---

Pick Up Roller, C4 ---

Belt Drawer Unit/ Filters --- RP

Belt Cleaner Unit ---

Head ---

Maintenance Unit ---

Pick Up Roller, ADF --- RP RP

Pick Up Roller, Hi-Capacity ---

Repair work Adjustment and Inspection Work 458

Confidential

EPSON WF-C20590 Revision A

OPTIONS Table 7-5. Adjustments Required for Options

Finisher

Category High Capacity Unit

Table 7-5. Adjustments Required for Options Unit

Finisher Part/Component Paper

Category High Capacity Unit Paper Feed Separation

Unit TBD

Adjustment Item Program No. Feed Unit Roller Roller

Part/Component Paper Holder

Paper Feed Separation

TBD 5. Adjustment - SCN/ADF: MENU

Adjustment Item Program No. Feed Unit Roller Roller

Holder

SCAN/ADF MENU Select ---

3. Before Repair Operation: MENU

MENU(1/7) > SCN ADF Simple ---

Head (p.460) 31 Mech Setup (p.522)

Ink Supply Path: MENU (p.466) 32 B. Counter Reset: MENU (p.1185)

Ink Supply Unit (p.466) 321 Pick Up Roller, MP ---

Relay Flow Path Assy (p.468) 322 Pick Up Roller, C1 ---

Ink Discharge Path (p.470) 33 Pick Up Roller, C2 ---

Belt Drawer Unit (p.471) 34 Pick Up Roller, C3 ---

Individual: MENU (p.472) 35 Pick Up Roller, C4 ---

Antistatic Brush Assy (p.472) 351 Belt Drawer Unit/ Filters ---

Wiper Assy (p.472) 352 Belt Cleaner Unit ---

4. Adjustment - Main/ Option Unit: MENU Head ---

Head (p.473) 41 Maintenance Unit ---

Ink Supply Path: MENU (p.477) 42 Pick Up Roller, ADF ---

Ink Supply Unit (p.477) 421 Pick Up Roller, Hi-Capacity --- RP RP RP

Relay Flow Path Assy (p.479) 422

Ink Discharge Path (p.481) 43

C H E C K Meaning of the marks used in the tables on the following

Belt Drawer Unit (p.482) 44 P O IN T pages are as follows.

Individual Adjustment: MENU (p.488) 46

“RP”: Required only when replacing

PG Adjustment: MENU (p.490) 4602 “RM”: Required when removing and/or replacing

HP Sensor, Head (p.492) 46023 Blank: No adjustment is required

Head FFC Noise Check (p.495) 4604

Wiper Stroke Adjustment (p.495) 4605

Side Registration Adjustment (p.496) 4606 RP

Top Registration Adjustment (p.499) 4607

Paper Sensor, Post-Head Sensitivity 4609

Adjustment (p.499)

PW Sensor Adjusted Value Writing 4610

(p.506)

Repair work Adjustment and Inspection Work 459

Confidential

EPSON WF-C20590 Revision A

7.2.4 Adjustment/Inspection Details 7.2.4.3.1 [31 Head]

Overview

7.2.4.1 [1. Maintenance: MENU]

Before replacing the head, perform the necessary sequence of work. Also,

For details on this menu, see 8.4 Periodic Replacement Parts (p1185). when discharging ink, supplemental work is required, so perform the following

procedures.

7.2.4.2 [2. Individual Action Check: MENU]

Execution timing

For details on this menu, see 6.6 Individual Action Check (p355).

Before Replacing Head

Workflow

7.2.4.3 [3. Before Repair Operation: MENU]

START

During the preparation before repair, be careful not to [46031 Head Data Transfer: Before

Replacing Head]

mistouch the control panel to avoid unintended cancellation

or to avoid unintended re-execution.

Perform Supplemental Work (1)

(p 532) [621 Special Discharge Sequence 1]

C H E C K To execute this menu, "7.2.4.11 Supplemental Work" (p.532)

Perform part of Supplemental Work

P O IN T is required. Refer to the workflow before executing each (2) (p 532)

up to the step before using the Tube Clip.* Perform the rest of Supplemental

menu to check whether or not there is supplemental work. Work (2) (p 532)

Invalid the Interlock Switch, Duplex.

[621 Special Discharge Sequence 2]

Turn power on

(Service mode startup (p 183))

Head Fixing Cam Release &

Cap Motion Unit Descent

Execute [31 Head]

Ink ejection complete screen

Supplemental Work (1) (p 532)

completion check

FINISH

*Perform the Supplemental Work (2) and disassemble the printer until the Head can be seen. However, do not

clamp the ink tubes with the tube clips (x2) or remove the Head Joint, ink.

Figure 7-34. Workflow

Repair work Adjustment and Inspection Work 460

Confidential

EPSON WF-C20590 Revision A

Preparation Work Procedure

Prepare a jig for holding the Interlock Switch, Duplex as follows. 1. Perform Supplemental Work (1) (p 532)

1. Remove the Housing Rear, Left. (p.822)

2. Clamp the ink supply tubes in the Ink Supply Unit with the two tube

Jig dimensions clips to stop the supply. (p.796)

Width: approx. 12 mm

Length: approx. 50 mm

Thickness: approx. 5 mm

Figure 7-35. Jig for holding the switch

1. Prepare A5 size paper.

It is OK to make 148 mm x 210 mm paper by cutting A4 size paper in half.

2. Fold paper into fourth and then turn it at 90 degrees and fold it in fourth

again, and then fold it into thirds once and lastly fold it in half as shown

below.

A5 size paper or Tube Clips

148 mm x 210 mm

paper Figure 7-37. Work before head replacement (1)

Figure 7-36. Jig for holding the switch

Repair work Adjustment and Inspection Work 461

Confidential

EPSON WF-C20590 Revision A

2. Perform part of Supplemental Work (2) (p 532). 3. Invalid the Interlock Switch, Duplex by inserting the jig into the hole on

Disassemble the unit as shown in Figure 7-38. However, do not clamp the the Stacker Sub Cover fully.

ink tubes with the tube clips (x2) or remove the Head Joint, ink.

1. Remove the SCN Rear Cover. (p.674)

2. Remove the NFC Cover. (p.674)

3. Remove the SCN Housing Cap. (p.675)

4. Open the ADF/SCN. (p.675)

5. Remove the Front Tray Guide. (p.677)

6. Remove the Rear Tray Guide. (p.678)

7. Remove the Cable Cover. (p.678)

8. Remove the Reverse Guide Plate. (p.679)

Hole on the Stacker Sub Cover

Jig for holding the switch

Figure 7-38. Work before head replacement (2)

Figure 7-39. Work before head replacement (3)

4. Start the service support mode.

(Refer to 5.1.1 Service mode startup (p183))

Repair work Adjustment and Inspection Work 462

Confidential

EPSON WF-C20590 Revision A

5. From the service support mode top menu, select [3.Before Repair 6. Since the operation message of Collateral operation 1 is displayed, confirm

Operation: MENU] > [31. Head] in that order. the Ink Supply Tube of the Ink Supply Unit is clamped with the two tube

clips.

[]LEFT____________________________[]UP_______________________________RIGHT[]

Service Support Mode Top After pressing OK, when the start confirmation screen appears press OK

1. Maintenance : MENU again.

2. Individual Action Check: MENU

3. Before Repair Operation: MENU

4. Adjustment ‐ Main/ Option Unit: MENU

5. Adjustment ‐ SCN/ADF: MENU __________________________________________________________________________

6. Ink Charge/ Discharge: MENU 31 Head

7. Installation: MENU

8. User Log Get Mode

9. USBMemory FWUpdate Please operate as follows.

A. Swap Mech Unit: MENU Collateral operation 1

B. Counter Reset

Details :

Close the ink supply tube of the ink supply unit with two tube clips.

Operation finish . Push OK.

[]BACK__________________________[]DOWN______________________________RUN[]

[]LEFT____________________________[]UP_______________________________RIGHT[] _______________________________________________________________________OK[]

3. Before Repair Operation: MENU

31 Head

32 Ink Supply Path: MENU

33 Ink Discharge Path

34 Belt Drawer Unit __________________________________________________________________________

35 Individual :MENU 31 Head

Start?

[]BACK__________________________[]DOWN______________________________RUN[]

Figure 7-40. Work before head replacement (4)

_______________________________________________________________________OK[]

Figure 7-41. Work before head replacement (5)

Repair work Adjustment and Inspection Work 463

Confidential

EPSON WF-C20590 Revision A

7. After the initializing screen appears, the Ink Discharge Sequence 1 screen

__________________________________________________________________________

is displayed. 621 Special Ink Discharge Sequence 1

Please operate as follows.

Collateral operation 2

__________________________________________________________________________ Details :

621 Special Ink Discharge Sequence 1 Remove the Head ink joint from the Head unit.

Processing Operation finish . Push OK

_______________________________________________________________________OK[]

Figure 7-44. Work before head replacement (8)

9. After the Ink Discharge Sequence 2 screen appears, completion screen is

Figure 7-42. Work before head replacement (6) displayed if the ink discharge is complete normally.

8. When the screen shown in Figure 7-44 appears, perform the rest of the

Supplemental Work (2) (p 532) and press OK. __________________________________________________________________________

622 Special Ink Discharge Sequence 2

1. Remove the Head Joint, Air. (p.679) Processing

2. Clamp the ink tubes with the tube clips (x2) and then remove the Head

__________________________________________________________________________

Joint, ink. (p.680) 31 Head

Finish.

Several drops of ink may drip from the Head Joint, ink so Please Power off.

Push [Power] Botton

prevent ink getting on other places by attaching the Head

Joint Cap or wiping with non-woven fabric or the like.

Ink Tubes

Head Joint Cap

Figure 7-45. Work before head replacement (9)

If the jig for holding the switch is removed, the mechanism

initialization starts and then the cam locks the printhead.

Therefore, do not remove the jig after turning the power off.

Tube Clips 10. Turn off the printer and replace the Head Unit.

Figure 7-43. Work before head replacement (7)

Repair work Adjustment and Inspection Work 464

Confidential

EPSON WF-C20590 Revision A

[31 HEAD] REFERENCE INFORMATION OF ERROR DURING If Head Data Transmission Error occurs during Ink Discharge Sequence 1

HEAD REPLACEMENT

__________________________________________________________________________

31 Head

If the Interlock Switch, Duplex is not invalid during the Supplemental Head Data Transfer is failed.

Work (2) (p 532) after Ink Discharge Sequence or “DupCover Open Err” Processing

is displayed Please take notes of the following Print Head Unit Count.

And return it with a failure head unit.

If the switch is not invalid or an error is displayed, ink may not be discharged Print Head Unit Count : 123

normally even if the Ink Discharge Sequence 2 is run. Please skip this menu.

In such a case, turn the printer off once and perform the steps of Ink Discharge

Sequence 2 one by one as follows. During this process, keep clamping the ink

tubes as instructed in Supplemental Work (1) (p 532) and Supplemental Work _______________________________________________________________________OK[]

(2) (p 532). Figure 7-46. Head data transmission error screen

Select service support mode top menu > [6. Ink Charge/ Discharge: MENU] > Before the Ink Discharge Sequence 1 is run, the data for analysis after

[62 Ink Discharge: MENU] > [622 Special Discharge Sequence2] to run the collecting the replaced head is written from the printer to the Head Unit in the

sequence. background. This message is indicated when the error occur then.

In such a case, write down the counter of “Print Head Unit Count” on the

screen.

Print the service status sheet after replacing the Head Unit, write the counter

value to the sheet, and include it with the Head Unit when returning it.

Pressing the OK button skips the head data transmission and the ink discharge

continues.

Repair work Adjustment and Inspection Work 465

Confidential

EPSON WF-C20590 Revision A

7.2.4.3.2 [32 Ink Supply Path: MENU] Work Procedure

Overview 1. Perform Supplemental Work (1) (p 532)

Before replacing the ink supply path component parts, perform the necessary

C H E C K Do not remove the tube clips of the ink supply unit in the

sequence of work. Also, supplemental work is required so give consideration to

P O IN T following work.

the following procedures.

[321 INK SUPPLY UNIT]

Overview If the supplemental work was not performed, ink discharging

Start the printer in the mechanical state required to replace the Ink Supply Unit will not complete normally. Perform this procedure again.

and then discharge the ink in the Ink Supply Unit.

However, it is not possible to discharge all ink in the path in

the case of only the Ink Supply Unit. During the work, do not 2. Start the service support mode.

remove the tube clips clamped to the tubes to stop the supply (Refer to 5.1.1 Service mode startup (p183))

until the relay joint cap has been attached. 3. Select [3. Before Repair Operation: MENU] from the service support mode top

menu.

Execution timing

Before replacing ink supply unit

Workflow

START

Perform Supplemental Work (1) Execute [321 Ink Supply Unit]

(p 532)

Turn power on [621 Special Discharge Sequence 1]

(Service mode startup (p 183)) Figure 7-48. [3. Before Repair Operation: MENU] Screen

Turn power off

FINISH

Figure 7-47. Workflow

Repair work Adjustment and Inspection Work 466

Confidential

EPSON WF-C20590 Revision A

4. Select [32. Ink Supply Path: MENU] from the Before Repair Operation screen. 5. Select [321. Ink Supply Unit] from the Ink Supply Path screen.

Then, sequentially perform the required work. Follow the instructions on the

screen.

Figure 7-49. [32. Ink Supply Path: MENU] Screen

Figure 7-50. [321. Ink Supply Unit] Screen (1)

Repair work Adjustment and Inspection Work 467

Confidential

EPSON WF-C20590 Revision A

6. Turn off the power as described on the screen. [322 RELAY INK PATH ASSY]

Overview

Start the printer in the mechanical state required to replace the Relay Ink Path

Assy and then discharge the ink inside the Relay Ink Path Assy.

Execution timing

Before replacing Relay Ink Path Assy

Workflow

START

Figure 7-51. [321. Ink Supply Unit] Screen (2)

7. Then, perform disassembly and assembly.

Perform Supplemental Work (1)

(p 532) Execute [322 Relay Ink Path Assy]

Turn power on

(Service mode startup (p 183)) [621 Special Discharge Sequence 1]

Perform Supplemental Work (3)

(p 533)

[623 Special Discharge Sequence 3]

Turn power off

FINISH

Figure 7-52. Workflow

Repair work Adjustment and Inspection Work 468

Confidential

EPSON WF-C20590 Revision A

Work Procedure

1. Perform Supplemental Work (1) (p 532)

C H E C K Do not remove the tube clips of the ink supply unit in the

P O IN T following work.

2. Start the service support mode.

(Refer to 5.1.1 Service mode startup (p183))

3. Select [3. Before Repair Operation: MENU] from the service support mode top

menu.

4. Select [32. Ink Supply Path: MENU] from the Before Repair Operation screen.

5. Select [322. Relay Ink Path Assy] from the Ink Supply Unit screen.

Then, sequentially perform the required work. Follow the instructions on the

screen.

6. Perform Supplemental Work (3) (p 533)

7. Turn off the power as described on the screen.

8. Then, perform disassembly and assembly.

Repair work Adjustment and Inspection Work 469

Confidential

EPSON WF-C20590 Revision A

7.2.4.3.3 [33 Ink Discharge Path] Work Procedure

Overview 1. Perform Supplemental Work (1) (p 532)

Before replacing the ink discharge path component parts, perform the

C H E C K Do not remove the tube clips of the ink supply unit in the

necessary sequence of work. Also, supplemental work is required so give

consideration to the following procedures.

P O IN T following work.

Execution timing

Before replacing the Maintenance Unit

2. Start the service support mode.

Before replacing the Cap Motion Unit (Refer to 5.1.1 Service mode startup (p183))

Before replacing the Ink Discharge Path related parts

3. Select [3. Before Repair Operation: MENU] from the service support mode top

Workflow menu.

4. Select [33. Ink Discharge Path] from the Before Repair Operation screen.

START Then, sequentially perform the required work. Follow the instructions on the

screen.

5. Turn off the power as described on the screen.

Perform Supplemental Work (1)

(p 532) 6. Then, perform disassembly and assembly.

Turn power on

(Service mode startup (p 183))

Execute [33 Ink Discharge Path]

[624 Special Discharge Sequence 4]

Turn power off

FINISH

Figure 7-53. Workflow

Repair work Adjustment and Inspection Work 470

Confidential

EPSON WF-C20590 Revision A

7.2.4.3.4 [34 Belt Drawer Unit] Work Procedure

Overview 1. Start the service support mode.

Before replacing the Belt Drawer Unit, perform the necessary sequence of (Refer to 5.1.1 Service mode startup (p183))

work. 2. Select [3. Before Repair Operation: MENU] from the service support mode top

menu.

Execution timing 3. Select [34 Belt Drawer Unit] from the Before Repair Operation screen. A

Before replacing/cleaning Belt Drawer Unit confirmation screen appears. Press the OK button. (To cancel the procedure, press

the Cancel button.)

Workflow Then, sequentially perform the required work. Follow the instructions on the

screen.

START 4. Turn off the power as described on the screen.

5. Then, perform disassembly and assembly or cleaning.

C H E C K The mechanical state becomes the normal state if you turn

Turn power on

(Service mode startup (p 183))

P O IN T the power on normally.

Execute [34 Belt Drawer Unit]

[351 Release Belt Tension & Head

Capping]

Turn power off

FINISH

Figure 7-54. Workflow

Repair work Adjustment and Inspection Work 471

Confidential

EPSON WF-C20590 Revision A

7.2.4.3.5 [35 Individual: MENU] [352 WIPER POSITION SHIFT]

[351 RELEASE BELT TENSION & HEAD CAPPING] Overview

Overview Move the wiper position and switch to the mechanical state to enable

removing/replacing the wiper unit.

To prevent creep of the Belt Drawer Unit (belt material), the tension is released

for turning the power off. If you perform the removal and replacement work Execution timing

with this tension in the released state, the belt and main unit frame may Before replacing/removing the wiper unit

interfere with each other, and if you perform the replacement work of the Anti

Work Procedure

Static Brush in the head capped state, the front head guide and Anti Static

Brush may interfere with each other. Therefore, execute this function to switch 1. Start the service support mode.

to the mechanical state which allows the Belt Drawer Unit and Anti Static (Refer to 5.1.1 Service mode startup (p183))

Brush to be removed. 2. Select [3. Before Repair Operation: MENU] from the service support mode top

menu.

Execution timing

3. Select [35 Individual :MENU] from the Before Repair Operation screen.

Before replacing/cleaning Belt Drawer Unit

4. Select [352 Wiper Assy] from the Individual Adjustment menu screen.

Before replacing/cleaning Paper Dust Cleaner PET Blade,

5. A confirmation screen appears. Press the OK button. If you wish to cancel the

Before replacing Anti Static Brush procedure, press the Cancel button.

Work Procedure 6. A screen instructing you to turn off the main power appears after the operation

completes. Press the power button to turn off the power.

1. Start the service support mode.

(Refer to 5.1.1 Service mode startup (p183))

C H E C K When the main unit starts normally after the replacement

2. Select [3. Before Repair Operation: MENU] from the service support mode top P O IN T work, the state automatically returns to the normal state.

menu.

3. Select [35 Individual :MENU] from the Before Repair Operation screen.

4. Select [351 Antistatic Brush Assy] from the Individual Adjustment menu screen.

5. A confirmation screen appears. Press the OK button. If you wish to cancel the

procedure, press the Cancel button.

6. A screen instructing you to turn off the main power appears after the operation

completes. Press the power button to turn off the power.

C H E C K When the main unit starts normally after the replacement

P O IN T work, the state automatically returns to the normal state.

Repair work Adjustment and Inspection Work 472

Confidential

EPSON WF-C20590 Revision A

[353 HP SENSOR] 7.2.4.4 [4. Adjustment - Main/ Option Unit: MENU]

7.2.4.4.1 [41 Head]

Overview

Overview

Reset the height adjustment value of the head before replacing the HP Sensor, This adjustment menu is for performing all the adjustments required after Head Unit

Head. If you perform PG adjustment after replacing the HP Sensor, Head replacement at one time in accordance with the sequence flow. This menu includes the

without having reset the adjustment value with this menu, the head height following adjustment items.

adjustment value cannot be reflected properly and PG adjustment cannot be Perform the replacement work using this menu after normal Head Unit replacement.

performed in a normal state. When performing adjustments individually as necessary, refer to the following table

and flow diagram.

Execution timing Details

Program

Before replacing HP Sensor, Head Adjustment menu name

No.

reference

page

Work Procedure

Head FFC Noise Check 4604 p.495

1. Start the service support mode. Head Data Transfer: After Replacing Head 46032 p.494

(Refer to 5.1.1 Service mode startup (p183)) PG Adjustment: Head 46021 p.490

2. Select [3. Before Repair Operation: MENU] from the service support mode top Ink Charge: Head 61 p.527

menu.

Head Angular Adjustment 4608 p.502

3. Select [35 Individual :MENU] from the Before Repair Operation screen.

Check Pattern Print 14 ---

4. Select [353 HP Sensor] from the Individual Adjustment menu screen.

5. A confirmation screen appears. Press the OK button. If you wish to cancel the Execution timing

procedure, press the Cancel button. After replacing the Head Unit

6. A screen instructing you to turn off the main power appears after the operation

completes. Press the power button to turn off the power.

Repair work Adjustment and Inspection Work 473

Confidential

EPSON WF-C20590 Revision A

Workflow Work Procedure

1. Start the service support mode.

START (Refer to 5.1.1 Service mode startup (p183))

2. Select [4.Adjustment - Main/Option Unit: MENU] from the service support mode

Turn power on

top menu.

(Service mode startup (p 183))

Execute [41 Head]

[4604 Head FFC Noise Check]

[46032 Head Data Transfer: After

Replacing Head]

[611 Ink Charge Head]

Figure 7-56. [4.Adjustment - Main/Option Unit: MENU] Screen

Print nozzle check pattern Head Cleaning

Check nozzle check pattern

NG

OK

[46081 Adjustment Pattern Print]

[46082 Input Adjusted Value]

Print final check pattern

FINISH

Figure 7-55. Workflow

Repair work Adjustment and Inspection Work 474

Confidential

EPSON WF-C20590 Revision A

3. Select [41 Head] from the Adjustment - Main/Option Unit menu. Then, 4. Execute the Head FFC noise check.

sequentially perform the required work. Follow the instructions on the screen. Press the OK button to execute. The Head state and Head FFC connection state are

checked automatically. If “NG” is selected, adjustment is canceled.

If there was a connection failure at this time, the Failure Determination Code 06

screen appears. If that happens, cancel adjustment, turn off the power of the unit,

and then check the Head connection state again.

Figure 7-57. [41 Head] Screen

Figure 7-58. Head FFC Noise Check Screen

Repair work Adjustment and Inspection Work 475

Confidential

EPSON WF-C20590 Revision A

5. Execute the head data transfer. This writes the information in the head to the main 8. Check the printed nozzle check pattern.

unit. Furthermore, the print adjustment reference information and other If you can see missing nozzles, select “NG” to execute head cleaning. (Go to the

information of the main unit are written to the internal memory of the head. Nozzle Check Pattern Print screen again after execution.)

Execute writing by selecting “Do”, or skip the head data transfer and go to nozzle If printing is normal, select “OK”. Go to the next adjustment page.

check pattern printing by selecting “Skip”.

Figure 7-61. Nozzle Check Screen

Figure 7-59. Head Data Transfer Screen

9. Execute head angular adjustment.

6. If execution of the head data transfer ends normally, the head is charged with ink.

Select “OK” in the Head Joint Adjust Print screen to print a head angular

7. Press “OK” to print the nozzle check pattern. adjustment pattern.

Figure 7-60. Nozzle Check Pattern Print Screen Figure 7-62. Head Angular Adjustment Pattern Print screen

Repair work Adjustment and Inspection Work 476

Confidential

EPSON WF-C20590 Revision A

10. Check the head angular adjustment pattern and input the adjustment value. 7.2.4.4.2 [42 Ink Supply Path: Menu]

(Refer to [4608 Head Angular Adjustment] (p502))

[421 INK SUPPLY UNIT]

Overview

This menu is for performing adjustment and ink charging after replacing/removing the

Ink Supply Unit. When this menu is executed, ink charging, adjustment, and inspection

are performed automatically. Do not turn the power off/on or open/close each cover

during menu execution.

Execution timing

After replacing/removing Ink Supply Unit

Workflow

Figure 7-63. Head Angular Adjustment Value Input Screen

START

11. Print and check the final check pattern for checking the adjustment results, and

then end adjustment.

Turn power on

(Service mode startup (p 183))

Execute [421 Ink Supply Unit]

Ink Charge[612 Ink Supply Path]

FINISH

Figure 7-64. Workflow

Repair work Adjustment and Inspection Work 477

Confidential

EPSON WF-C20590 Revision A

Work Procedure 4. Select [421 Ink Supply Unit] from the Ink Supply Path menu screen.

1. Start the service support mode.

(Refer to 5.1.1 Service mode startup (p183))

2. Select [4.Adjustment - Main/Option Unit: MENU] from the service support mode

top menu.

Figure 7-65. [4.Adjustment - Main/Option Unit: MENU] Screen

3. Select [42 Ink Supply Unit: MENU] from the Adjustment - Main/Option Unit

menu.

Figure 7-67. [421. Ink Supply Unit] Screen

5. The finished screen appears and the work finishes.

If the ink runs out or the maintenance cartridge becomes full during processing,

the processing is canceled.

Figure 7-66. [42 Ink Supply Unit: MENU] Screen

Repair work Adjustment and Inspection Work 478

Confidential

EPSON WF-C20590 Revision A

[422 RELAY INK PATH ASSY] Work Procedure

Overview 1. Start the service support mode.

(Refer to 5.1.1 Service mode startup (p183))

This menu is for performing adjustment and ink charging after replacing/removing the

2. Select [4.Adjustment - Main/Option Unit: MENU] from the service support mode

Relay Ink Path Assy. When this menu is executed, ink charging, adjustment, and

top menu.

inspection are performed automatically. Do not turn the power off/on or open/close

each cover during menu execution.

Execution timing

After replacing Relay Ink Path Assy

Workflow

START

Turn power on Figure 7-69. [4.Adjustment - Main/Option Unit: MENU] Screen

(Service mode startup (p 183))

3. Select [42 Ink Supply Unit: MENU] from the Adjustment - Main/Option Unit

menu.

Execute [422 Relay Ink Path Assy]

Ink Charge[612 Ink Supply Path]

FINISH

Figure 7-70. [42 Ink Supply Unit: MENU] Screen

Figure 7-68. Workflow

Repair work Adjustment and Inspection Work 479

Confidential

EPSON WF-C20590 Revision A

4. Select [422 Relay Ink Path Assy] from the Ink Supply Path menu screen.

Figure 7-71. [422 Relay Ink Path Assy] Screen (1)

5. The finished screen appears and the work finishes.

If the ink runs out or the maintenance cartridge becomes full during processing,

the processing is canceled.

Figure 7-72. [422 Relay Ink Path Assy] Screen (2)

Repair work Adjustment and Inspection Work 480

Confidential

EPSON WF-C20590 Revision A

7.2.4.4.3 [43 Ink Discharge Path] Work Procedure

Overview 1. Start the service support mode.

Perform the ink leak and ink path inspections and the adjustments required (Refer to 5.1.1 Service mode startup (p183))

after replacing the Ink Discharge Path component parts. 2. Select [4.Adjustment - Main/Option Unit: MENU] from the service support mode

top menu.

Execution timing 3. Select [43 Ink Discharge Path] from the Adjustment - Main/Option Unit menu.

After replacing the Maintenance Unit 4. The finished screen appears and the work finishes.

After replacing the Cap Motion Unit If a problem is detected in the ink path during menu execution, you are notified of

After replacing the Ink Discharge Path related parts an error.

Workflow

START

Turn power on

(Service mode startup (p 183))

Execute [43 Ink Discharge Path]

Ink Charge[112 CL1]

FINISH

Figure 7-73. Workflow

Repair work Adjustment and Inspection Work 481

Confidential

EPSON WF-C20590 Revision A

7.2.4.4.4 [44 Belt Drawer Unit] Workflow

Overview

START

This adjustment menu is for performing all the adjustments in the sequence

required after Belt Drawer Unit replacement. This menu includes the following

adjustment items.

Remove the Belt Cover and

check the correction value.

Details

Program

Adjustment menu name reference

No.

page

Turn power on

Eccentricity / Circumference Correction 4601 p.488 (Service mode startup (p 183))

Print registration adjustment pattern

Belt Drawer Unit 46022 p.491

Top Registration Adjustment 4607 p.499

Execute [44 Belt Drawer Unit]

Execution timing

Execute top registration adjustment

After replacing Belt Drawer Unit

[4601 Eccentricity / Circumference

Correction]

Check adjustment results

NG

Enter correction values Ka, Kb, and Kc OK

Print final check pattern

Execute PG Adjustment - Belt Drawer

Unit

FINISH

Enter correction value PG mea_V

Figure 7-74. Workflow

Repair work Adjustment and Inspection Work 482

Confidential

EPSON WF-C20590 Revision A

Work Procedure 4. Select [4. Adjustment - Main/ Option Unit: MENU] from the service support mode

top menu.

1. Remove the Belt Cover. (p.738)

5. Select [44 Belt Drawer Unit] from the Before Repair Operation screen.

2. Check the correction value label affixed to the Belt Drawer Unit. Then, sequentially perform the required work. Follow the instructions on the

screen.

Correction value label 6. Enter the eccentricity/circumferential correction values.

_______________________________________________________________Input Value[]

4601 Eccentricity / Circumference Correction

Please set parameter

Ka( 0 to 1016 ) ‐‐‐

Kb( 0 to 5760 ) ‐‐‐

Kc( 0 to 696 ) ‐‐‐

[]Cancel_______________________________________________________________OK[]

Figure 7-76. Eccentricity/Circumferential Correction Value Input

7. Enter the Paper Feed Belt PG adjustment value.

_______________________________________________________________Input Value[]

4601 Eccentricity / Circumference Correction

Please set parameter

mea_V (‐5000 to 5000 ) ‐‐‐

Correction value label

Belt Drawer Unit

[]Cancel_______________________________________________________________OK[]

Figure 7-77. Paper Feed Belt PG Adjustment Value Input

Figure 7-75. Correction value label

3. Start the service support mode.

(Refer to 5.1.1 Service mode startup (p183))

Repair work Adjustment and Inspection Work 483

Confidential

EPSON WF-C20590 Revision A

8. Print the top registration adjustment pattern. 10. Check the adjustment results, and then select YES[] to perform the top registration

adjustment again and []NO to not perform the adjustment again.

__________________________________________________________________________

44 Belt Drawer Unit

Resist Check Pattern Print __________________________________________________________________________

44 Belt Drawer Unit

Repeat Top Registration adjustment?

[]NG___________________________________________________________________OK[]

Figure 7-78. Top Registration Adjustment Pattern Print []NO__________________________________________________________________YES[]

9. Execute top registration adjustment. (p.499) 11. Print and check the final check pattern and then end the adjustment for after Paper

Feed Belt replacement.

________________________________[]UP___________________________Input Value[]

4607 Top Resistration Adjustment

Please set parameter

Type: Plain Paper

Value: 0

(‐50 to 50 / 0.1mm)

[]Cancel_________________________[]DOWN________________________________OK[]

Repair work Adjustment and Inspection Work 484

Confidential

EPSON WF-C20590 Revision A

7.2.4.4.5 [45 Diagnostics Pattern Print: Menu] Work Procedure

Overview 1. Start the service support mode.

(Refer to 5.1.1 Service mode startup (p183))

Use this menu to check the reproducibility of print/image related trouble and to

2. Select [4. Adjustment - Main/ Option Unit: MENU] from the service support mode

perform adjustments. top menu.

All of these diagnostics patterns can be output from [14 Check Pattern Print]. 3. Select [45 Diagnostics Pattern Print: MENU] from Before Repair Operation

screen.

4. Execute each menu from the Diagnostics Pattern Print menu screen.

Diagnostics Pattern List

Pattern Image

Program No. Pattern Name Specification (the arrow shows the paper feed Associated Print Quality Problem

direction)

Black and green lines are printed evenly spaced apart, and a

black box surrounding the lines is also printed. The lines

are for checking if the printer can print straight lines

Ruled lines are not straight

precisely, and the box is for checking the print start

Characters are deformed

451 Ruled Line Pattern position at sides and top of paper.

Color shift

Compensation for clogged nozzles: Yes

Incorrect margins

Pattern size: A4, Letter

Print mode: plain paper standard (23ips)

Total number of pages: 1

White or dark lines

White or dark smudges

Color banding

Smeared printout 1 (paper is rubbed

A solid 25% grayscale box is printed.

against head or rollers)

Compensation for clogged nozzles: Yes

Cockling

452 Gradation pattern Pattern size: A4, Letter

Wrinkling of paper

Print mode: plain paper_standard (23ips)

Blank pages print

Total number of pages: 3

Entirely too dark printout

Ripple pattern

Strike-through

Faint printout

Repair work Adjustment and Inspection Work 485

Confidential

EPSON WF-C20590 Revision A

Pattern Image

Program No. Pattern Name Specification (the arrow shows the paper feed Associated Print Quality Problem

direction)

Four shades each of four colors are printed. Starting from

the darkest one, the shade becomes lighter in the paper feed

direction. Diagonal unevenness

453 Black 25% Pattern Compensation for clogged nozzles: Yes Failure in fixing ink

Pattern size: A4, Letter White or dark banding

Print mode: plain paper_standard (23ips)

Total number of pages: 1

Prints No.2 gradation pattern on one side, then ejects paper

without printing on the other side.

Compensation for clogged nozzles: Yes Ruled lines are not straight

454 Adsorption Check Pattern ---

Pattern size: A4, Letter Color shift

Print mode: plain paper_standard (23ips)

Total number of pages: 1

Continuously feeds 10 sheets of paper in the simples

Smeared printout 2 (the belt is smeared)

printing path and ejects them without printing.

Feeding&Ejecting 10 sheets Smeared printout 3

455 Pattern size: A4, Letter

without printing (simplex path) (roller mark smudges made by serrated

Print mode: plain paper_standard (23ips)

roller and paper feed roller)

Total number of pages: 10

Blank 10 pages

Smeared printout 2 (the belt is smeared)

Feeds 1 sheet of paper in the simples printing path and

Smeared printout 3

ejects it without printing.

Feeding&Ejecting 1 sheets (roller mark smudges made by serrated

456 Pattern size: A4, Letter

without printing (simplex path) roller and paper feed roller)

Print mode: plain paper_standard (23ips)

Abnormal printing

Total number of pages: 1

Damage of paper

Blank 1 page

Repair work Adjustment and Inspection Work 486

Confidential

EPSON WF-C20590 Revision A

Pattern Image

Program No. Pattern Name Specification (the arrow shows the paper feed Associated Print Quality Problem

direction)

Continuously feeds 10 sheets of paper in the duplex

printing path and ejects them without printing. Smeared printout 3(roller mark smudges

Feeding&Ejecting 10 sheet

457 Pattern size: A4, Letter made by serrated roller and paper feed

without printing (duplex path)

Print mode: plain paper_standard (23ips) roller)

Total number of pages: 10

Blank 10 pages

Feeds 1 sheet of paper in the duplex printing path and

ejects it without printing. Smeared printout 3 (roller mark smudges

Feeding&Ejecting 1 sheet

458 Pattern size: A4, Letter made by serrated roller and paper feed

without printing (duplex path)

Print mode: plain paper_standard (23ips) roller)

Total number of pages: 1

Blank 1 page

Repair work Adjustment and Inspection Work 487

Confidential

EPSON WF-C20590 Revision A

7.2.4.4.6 [46 Individual Adjustment: MENU] Workflow

[4601 ECCENTRICITY / CIRCUMFERENCE CORRECTION]

Overview

START

Slight variations are generated in each Belt Drawer Unit at the time of

manufacture. Therefore, the variations of each Belt Drawer Unit are measured

at the time of shipping the units. To reduce ink impact position offset to obtain

Remove the Belt Cover and

the optimal print quality, you need to reflect the measurement values in the check the correction value.

main unit to execute the correction process.

Eccentricity / Circumference Correction is an adjustment item to input

correction values after replacing the Belt Drawer Unit. Turn power on

(Service mode startup (p 183))

Execution timing

After replacing Belt Drawer Unit

Execute [4601 Eccentricity /

Circumference Correction]

Enter Ka, Kb, and KC correction

values

Press OK after correction value input

Attach the Belt Cover

FINISH

Figure 7-79. Workflow

Repair work Adjustment and Inspection Work 488

Confidential

EPSON WF-C20590 Revision A

Work Procedure 3. Start the service support mode.

(Refer to 5.1.1 Service mode startup (p183))

1. Remove the Belt Cover. (p.738)

4. Select [4. Adjustment - Main/ Option Unit: MENU] from the service support mode

2. Check the correction value label affixed to the Belt Drawer Unit. top menu.

5. Select [46 Individual Adjustment: MENU] from the Adjustment - Main/Option

Correction value label Unit menu screen.

6. Select [4601 Eccentricity/Circumference Correction] from the Individual

Adjustment menu screen.

7. Enter the Ka, Kb, and Kc correction values you confirmed in step 1.

8. Recheck the entered correction values and then press OK[] to reflect the setting

values. (Return to the Individual Adjustment menu after reflecting the values.)

_______________________________________________________________Input Value[] Input screen switching button

4601 Eccentricity / Circumference Correction

Please set parameter

Ka( 0 to 1016 ) ‐‐‐

Kb( 0 to 5760 ) ‐‐‐

Kc( 0 to 696 ) ‐‐‐

Software Keyboard

If you enter a value that is outside of

[]Cancel_______________________________________________________________OK[] the range, the entered value is cleared.

After entering a value, press OK to return

to the adjustment value input screen.

Button for Applying the Setting

Figure 7-81. Correction Value Input

9. Attach the Belt Cover.

Belt Drawer Unit

Figure 7-80. Correction value label

Repair work Adjustment and Inspection Work 489

Confidential

EPSON WF-C20590 Revision A

[4602 PG ADJUSTMENT: MENU] Work Procedure

1. Start the service support mode.

[46021 Head]

(Refer to 5.1.1 Service mode startup (p183))

Overview 2. Select [4. Adjustment - Main/ Option Unit: MENU] from the service support mode

top menu.

Read the individual differences generated at the time of manufacturing the

3. Select [46 Individual Adjustment: MENU] from the Adjustment - Main/Option

head from the head internal memory and then reflect them in the main unit PG Unit menu screen.

adjustment values to match the head individual differences. Furthermore, HP 4. Select [4602 PG Adjustment: MENU] from the Individual Adjustment menu

Sensor, Head position measurement values to match the individual differences screen.

are saved at the same time. 5. Execute [46021 Head] from the PG Adjustment menu.

Execution timing

After replacing the Head Unit

Workflow

START

Turn power on

(Service mode startup (p 183))

Execute [46021 Head]

FINISH

Figure 7-82. Workflow

Repair work Adjustment and Inspection Work 490

Confidential

EPSON WF-C20590 Revision A

[46022 Belt Drawer Unit] Work Procedure

Overview 1. Remove the Belt Cover. (p.738)

Enter the measurement value obtained at the time of manufacturing the belt 2. Check the correction value label affixed to the Belt Drawer Unit.

from the panel to reflect it in the main unit PG adjustment values to match the

belt individual differences.

Execution timing

After replacing Belt Drawer Unit

Workflow

START

Remove the Belt Cover

and check the correction value.

Turn power on

(Service mode startup (p 183))

Execute [46022 Belt Drawer Unit]

Belt Drawer Unit

Correction value label

Enter correction value PG mea_V

(-5000 to 5000)

Confirm correction input value

Figure 7-84. Correction value label

Attach the Belt Cover

FINISH

Figure 7-83. Workflow

Repair work Adjustment and Inspection Work 491

Confidential

EPSON WF-C20590 Revision A

3. Start the service support mode. [46023 HP Sensor, Head]

(Refer to 5.1.1 Service mode startup (p183))

Overview

4. Select [4. Adjustment - Main/ Option Unit: MENU] from the service support mode

top menu. Detect and measure any small offset of the HP Sensor, Head installation position

5. Select [46 Individual Adjustment: MENU] from the Adjustment - Main/Option when the HP Sensor, Head is reattached after being replaced or removed, and then

Unit menu screen. reflect the value in the PG adjustment values and execute correction.

6. Select [4602 PG Adjustment: MENU] from the Individual Adjustment menu

screen. Execution timing

7. Execute [46022 Belt Drawer Unit] from the PG Adjustment menu. After replacing HP Sensor, Head

8. Enter the PG_mea_V correction value you confirmed in step 1. When HP Sensor, Head is reattached after it has been removed

9. Recheck the entered correction value and then press OK[] to reflect the setting Workflow

value. (Return to the Individual Adjustment menu after reflecting the values.)

_______________________________________________________________Input Value[] Input screen switching button START

4601 Eccentricity / Circumference Correction

Please set parameter

mea_V (‐5000 to 5000 ) ‐‐‐

Turn power on

(Service mode startup (p 183))

Software Keyboard

Execute [46023 HP Sensor, Head]

If you enter a value that is outside of

[]Cancel_______________________________________________________________OK[] the range, the entered value is cleared.

After entering a value, press OK to return

to the adjustment value input screen.

Button for Applying the Setting

FINISH

Figure 7-85. Correction Value Input

Figure 7-86. Workflow

10. Attach the Belt Cover.

Work Procedure

1. Start the service support mode.

(Refer to 5.1.1 Service mode startup (p183))

2. Select [4. Adjustment - Main/ Option Unit: MENU] from the service support mode

top menu.

3. Select [46 Individual Adjustment: MENU] from the Adjustment - Main/Option

Unit menu screen.

4. Select [4602 PG Adjustment: MENU] from the Individual Adjustment menu

screen.

5. Execute [46023 HP Sensor, Head] from the PG Adjustment menu.

Repair work Adjustment and Inspection Work 492

Confidential

EPSON WF-C20590 Revision A

[4603 HEAD DATA TRANSFER: MENU] Work Procedure

[46031 Head Data Transfer: Before Replacing Head] 1. Start the service support mode.

(Refer to 5.1.1 Service mode startup (p183))

Overview 2. Select [4. Adjustment - Main/ Option Unit: MENU] from the service support mode

Write the printer information to the internal memory of the old head before top menu.

replacing it in order to correct the variations of individual heads and analyze 3. Select [46 Individual Adjustment: MENU] from the Adjustment - Main/Option

and reuse the old head after replacing the head unit. Unit menu screen.

Write Direction Head Data Transfer Write Items

4. Select [4603 Head Data Transfer: MENU] from the Individual Adjustment menu

screen.

Information that is written

5. Execute [46031 Head Data Transfer: Before Replacing Head] from the Head Data

Total number of sheets printed Transfer menu.

Main Unit Replacement date and time

(printer) Head-related fatal errors (last five)

↓ Total number of jams

Old Head Total number of jobs

Main unit serial number

Head FFC noise check result

Execution timing

Before replacing the Head Unit

Workflow

START

Turn power on

(Service mode startup (p 183))

Execute [46031 Head Data Transfer:

Before Replacing Head]

FINISH

Figure 7-87. Workflow

Repair work Adjustment and Inspection Work 493

Confidential

EPSON WF-C20590 Revision A

[46032 Head Data Transfer: After Replacing Head] Work Procedure

Overview 1. Start the service support mode.

(Refer to 5.1.1 Service mode startup (p183))

Write the printer information to the internal memory of the new head after

replacing the head in order to correct the variations of individual heads and 2. Select [4. Adjustment - Main/ Option Unit: MENU] from the service support mode

top menu.

analyze and reuse the old head after replacing the head unit.

3. Select [46 Individual Adjustment: MENU] from the Adjustment - Main/Option

Write Direction Head Data Transfer Write Items Unit menu screen.

New Head Head ID 4. Select [4603 Head Data Transfer: MENU] from the Individual Adjustment menu

↓

screen.

Correction values

Main Unit 5. Execute [46032 Head Data Transfer: After Replacing Head] from the Head Data

(printer) Head FFC noise information Transfer menu.

Main Unit Total number of sheets printed

(printer) Total number of jams

↓ Total number of jobs

New Head Installation date and time

Execution timing

After replacing the Head Unit

Workflow

START

Turn power on

(Service mode startup (p 183))

Execute [46032 Head Data Transfer:

After Replacing Head]

FINISH

Figure 7-88. Workflow

Repair work Adjustment and Inspection Work 494

Confidential

EPSON WF-C20590 Revision A

[4604 HEAD FFC NOISE CHECK] [4605 WIPER STROKE ADJUSTMENT]

Overview Overview

Check whether or not there is noise due to a poor FFC connection or dirty Measure individual differences of the wiper drive screw axis to optimize the

terminals after disconnecting and connecting the Head FFC. wiper position.

Execution timing Execution timing

After replacing the Head Unit After replacing the Wiper Unit

Workflow Workflow

START START

Turn power on Turn power on

(Service mode startup (p 183)) (Service mode startup (p 183))

Execute [4604 Head FFC Noise Execute [4605 Wiper Stroke

Check] Adjustment]

FINISH FINISH

Figure 7-89. Workflow Figure 7-90. Workflow

Work Procedure Work Procedure

1. Start the service support mode. 1. Start the service support mode.

(Refer to 5.1.1 Service mode startup (p183)) (Refer to 5.1.1 Service mode startup (p183))

2. Select [4. Adjustment - Main/ Option Unit: MENU] from the service support mode 2. Select [4. Adjustment - Main/ Option Unit: MENU] from the service support mode

top menu. top menu.

3. Select [46 Individual Adjustment: MENU] from the Adjustment - Main/Option 3. Select [46 Individual Adjustment: MENU] from the Adjustment - Main/Option

Unit menu screen. Unit menu screen.

4. Select [4604 Head FFC Noise Check] from the Individual Adjustment menu 4. Select [4605 Wiper Stroke Adjustment] from the Individual Adjustment menu

screen. screen.

Repair work Adjustment and Inspection Work 495

Confidential

EPSON WF-C20590 Revision A

[4606 SIDE REGISTRATION ADJUSTMENT] Workflow

Overview

Perform adjustment to align the actual paper feed center position of paper

START

individually for each paper feed tray/cassette with respect to the head center

position so that output images are output positioned exactly central. Measure

the side registration from the side and top registration adjustment pattern Turn power on

(Service mode startup (p 183))

printout of the diagnostics patterns, enter that offset amount in the panel, and

perform adjustment.

Adjustable range: ±5 mm Print [451 Ruled Line Pattern]

Execution timing

When print the side and top registration adjustment pattern and there is

Measure offset amount

a side registration offset

Execute [4604 Side Registration

Adjustment]

C H E C K Please use this menu when unable to adjust the side

P O IN T registration by hard side registration adjustment.

*Please use it when adjust the second page of the duplex Enter adjustment value

print.

Have to input “0” to adjustment value by [4604 Side

Print [451 Ruled Line Pattern]

Registration Adjustment] before perform this menu.

The past adjustment value is reset when input “0” and is

changed to the initial value.

Unable to adjust it correctly when do not input “0”. Measure offset amount NG

OK

FINISH

Figure 7-91. Workflow

Repair work Adjustment and Inspection Work 496

Confidential

EPSON WF-C20590 Revision A

Work Procedure 7. Select [45 Diagnostics Pattern Print: MENU] from the Adjustment - Main/Option

Unit menu screen.

1. Start the service support mode. 8. Select [451 Ruled Line Pattern] from the Diagnostics Pattern Print menu screen.

(Refer to 5.1.1 Service mode startup (p183))

9. Print the ruled line offset/side and top registration adjustment pattern from the

2. Select [4. Adjustment - Main/ Option Unit: MENU] from the service support mode paper feed tray/cassette for which adjustment is to be performed.

top menu.

3. Return to [46 individual Adjustment: MENU] and then select [4606 Side

Registration Adjustment]. []LEFT______________________________[]UP_____________________Change Setting[]

Print Settings Change Button

451 Ruled Line Pattern

4. With Tray/Size selected, press Input Value[] and select the paper feed tray/cassette Current Setting

Feed Tray: MP Tray Print Settings

you wish to adjust. Output tray: Face down

Paper Size: A4(Vertical) Feed Tray Paper feed tray

5. With Value selected, press Input Value[] and then enter the adjustment value you Output Tray Paper output tray

calculated in step 6.

Paper Size Paper size

6. Check the input and then press OK[] to reflect the adjustment value

________________________________[]UP_______________________________________

4606 Side Resistration Adjustment

Select set Tray/Size and Value

[]BACK_____________________________[]DOWN___________________________Print[] Print Start Button

Tray/Size: C3 Large size

Figure 7-93. Printing Ruled Line Offset/Top and Side Registration Adjustment Pattern

C H E C K The past adjustment value is reset when input “0” and is

P O IN T changed to the initial value.

[]Cancel_________________________[]DOWN________________________________OK[]

________________________________[]UP___________________________Input Value[]

4606 Side Resistration Adjustment

Please set parameter

Tray/Size: C1 Large size

Value: 0

(‐50 to 50 / 0.1mm)

Software Keyboard

If you enter a value that is outside of

[]Cancel_________________________[]DOWN________________________________OK[]

the range, the entered value is cleared.

After entering a value, press OK to return

to the adjustment value input screen.

Setting fixed button

Figure 7-92. Method to input value

Repair work Adjustment and Inspection Work 497

Confidential

EPSON WF-C20590 Revision A

10. Measure the offset amount from the adjustment pattern and calculate the input 11. Return to [46 individual Adjustment: MENU] and then select [4606 Side

value. Registration Adjustment].

12. With Tray/Size selected, press Input Value[] and select the paper feed tray/cassette

you wish to adjust.

(1) Offset amount X = (a-b) / 2 13. With Value selected, press Input Value[] and then enter the adjustment value you

(2) Adjustment value Y = Offset value X x 10 calculated in step 10.

Offset 14. Check the input and then press OK[] to reflect the adjustment value.

value

X ________________________________[]UP_______________________________________

4606 Side Resistration Adjustment

▲

Select set Tray/Size and Value

Tray/Size: C3 Large size

Paper feed direction

Paper center line []Cancel_________________________[]DOWN________________________________OK[]

Image center line

________________________________[]UP___________________________Input Value[]

4606 Side Resistration Adjustment

Please set parameter

Margin on Margin on

front side b rear side a Tray/Size:

Value:

C1 Large size

0

Calculation of input value (adjustment value) (‐50 to 50 / 0.1mm)

1. Calculate the offset amount

Measure margins a and b between the paper edge and ruled line

vertical line edge with a ruler, insert the values in calculation

formula (1), and calculate offset amount X. Software Keyboard

2. Calculate the adjustment value If you enter a value that is outside of

Move the decimal point of the calculated offset amount X up []Cancel_________________________[]DOWN________________________________OK[] the range, the entered value is cleared.

After entering a value, press OK to return

(calculation formula (2)) and then round down to the first decimal to the adjustment value input screen.

place. This value is the adjustment value to be entered in [4606 Button for Applying the Setting

Side Registration Adjustment].

Figure 7-95. Adjustment Value Input

Example: When a = 2.5 mm and b = 3.5 mm

15. Select [451 Ruled Line Pattern] from the Diagnostics Pattern Print menu screen.

Offset amount X= (2.5 - 3.5) / 2 = -0.5

(0.5 mm offset for main unit rear (a side)) 16. Print the Printing Ruled Line Offset/Top and Side Registration Adjustment Pattern

Adjustment value Y = -0.5 x 10 = 5 (Round down to first decimal from the adjusted tray/cassette and then check that the offset is within a

place) permissible range. If there is still offset, return to Procedure 3 and perform the

adjustment again.

Figure 7-94. Calculation of Offset Amount

Repair work Adjustment and Inspection Work 498

Confidential

EPSON WF-C20590 Revision A

[4607 TOP REGISTRATION ADJUSTMENT] Workflow

Overview

Adjust the timing from the leading edge until start of printing. Furthermore,

START

adjust the image start position to match the paper type. Determine the top

registration offset from the side and top registration adjustment pattern printout

of the diagnostics patterns, enter the adjustment value in the panel in Turn power on

(Service mode startup (p 183))

accordance with that offset amount, and perform adjustment.

Adjustable range: ±5 mm

Print [451 Ruled Line Pattern]

Execution timing

When print the side and top registration adjustment pattern and there is

a top registration offset

Measure offset amount

After replacing Belt Drawer Unit

Execute [4605 Top Registration

Adjustment]

Have to input “0” to adjustment value by [4605 Top

Registration Adjustment] before perform this menu.

The past adjustment value is reset when input “0” and is Enter adjustment value

changed to the initial value.

Unable to adjust it correctly when do not input “0”.

Print [451 Ruled Line Pattern]

Measure offset amount

NG

OK

FINISH

Figure 7-96. Workflow

Repair work Adjustment and Inspection Work 499

Confidential

EPSON WF-C20590 Revision A

Work Procedure

Print Settings Change Button

1. Start the service support mode. []LEFT______________________________[]UP_____________________Change Setting[]

451 Ruled Line Pattern

(Refer to 5.1.1 Service mode startup (p183)) Current Setting

Feed Tray: MP Tray Print Settings

Output tray: Face down

2. Select [4. Adjustment - Main/ Option Unit: MENU] from the service support mode Paper Size: A4(Vertical) Feed Tray Paper feed tray

top menu. Output Tray Paper output tray

3. Return to [46 individual Adjustment: MENU] and then select [4607 Top Paper Size Paper size

Registration Adjustment].

4. With Tray/Size selected, press Input Value[] and select the paper feed tray/cassette

you wish to adjust.

5. With Value selected, press Input Value[] and then enter the adjustment value you

Print Start Button

calculated in step 6. []BACK_____________________________[]DOWN___________________________Print[]

6. Check the input and then press OK[] to reflect the adjustment value

Figure 7-98. Printing Ruled Line Offset/Top and Side Registration Adjustment Pattern

________________________________[]UP___________________________Input Value[]

4606 Top Resistration Adjustment

Please set parameter

C H E C K The past adjustment value is reset when input “0” and is

Type:

Value: 0

Plain Paper P O IN T changed to the initial value.

(‐50 to 50 / 0.1mm)

Software Keyboard

If you enter a value that is outside of

[]Cancel_________________________[]DOWN________________________________OK[]

the range, the entered value is cleared.

After entering a value, press OK to return

to the adjustment value input screen.

Setting fixed button

Figure 7-97. Method to input value

7. Select [45 Diagnostics Pattern Print: MENU] from the Adjustment - Main/Option

Unit menu screen.

8. Select [451 Ruled Line Pattern] from the Diagnostics Pattern Print menu screen.

9. Print the ruled line offset/Side and top registration adjustment pattern from the

paper feed tray/cassette for which adjustment is to be performed.

Repair work Adjustment and Inspection Work 500

Confidential

You might also like

- Ivity (1 - Februari - 2020)Document1 pageIvity (1 - Februari - 2020)Aditya JabarNo ratings yet

- P. 300 CM X L. 120 CM X T. 140 CM: Kabel Pompa BackwashDocument1 pageP. 300 CM X L. 120 CM X T. 140 CM: Kabel Pompa BackwashOis HarefaNo ratings yet

- New 001 2014 HYDocument4 pagesNew 001 2014 HYРома БлошенкоNo ratings yet

- CK 800-EU Pump StationDocument30 pagesCK 800-EU Pump Stationtiago calderNo ratings yet

- Basic Operation AL-840Document31 pagesBasic Operation AL-840Environ PrintersNo ratings yet

- Ipendant Operator Manual FRJP (B-81464EN) (Color)Document18 pagesIpendant Operator Manual FRJP (B-81464EN) (Color)tickets.fabriceNo ratings yet

- Error 1622Document16 pagesError 1622Andante Agung BramastaNo ratings yet

- B300 B300C MX05 Environmentall Systems 04APR16Document88 pagesB300 B300C MX05 Environmentall Systems 04APR16Edison RestrepoNo ratings yet

- QuickSelection AppliedProductsDocument60 pagesQuickSelection AppliedProductsBlend BrifkanyNo ratings yet

- Bomaksan Air Tower ALVER CatalogueDocument7 pagesBomaksan Air Tower ALVER CatalogueErinc CelikNo ratings yet

- Dầu bôi trơn máy phay MORISEIKI-MAINTENANCE-CLASS PDFDocument410 pagesDầu bôi trơn máy phay MORISEIKI-MAINTENANCE-CLASS PDFPhạm Hoài AnhNo ratings yet

- Epson WF C5790 WF C5790A WF C5710 ET 8700 WF C5210 WF C5290 WF C5290A Service Manuals 451 500Document50 pagesEpson WF C5790 WF C5790A WF C5710 ET 8700 WF C5210 WF C5290 WF C5290A Service Manuals 451 500조장현100% (2)

- Electronics Experimenters Handbook 1996 OctDocument116 pagesElectronics Experimenters Handbook 1996 OctBenjamin Dover100% (2)

- Standard Operating Procedure (Sop) Maintenance of Dynamic Pass BoxDocument4 pagesStandard Operating Procedure (Sop) Maintenance of Dynamic Pass BoxJakaria ShawonNo ratings yet

- APPENDIX I: UF Operation Timing Chart: Description Tag No. Type of Valve Filtration (Normal)Document3 pagesAPPENDIX I: UF Operation Timing Chart: Description Tag No. Type of Valve Filtration (Normal)Gloria HamiltonNo ratings yet

- Warning: Do Not Reset C/B's Within 2 Min of Aircraft Power Up. (Self Test of FMGC)Document3 pagesWarning: Do Not Reset C/B's Within 2 Min of Aircraft Power Up. (Self Test of FMGC)anarko arsipelNo ratings yet

- Final Control System Final Control System Final Control System Final Control System Final Control System Selection Guide Selection Guide Selection Guide Selection Guide Selection GuideDocument16 pagesFinal Control System Final Control System Final Control System Final Control System Final Control System Selection Guide Selection Guide Selection Guide Selection Guide Selection GuideDatt NguyenNo ratings yet

- 5-12-04 Inspection Phase 4Document2 pages5-12-04 Inspection Phase 4Lady Laura Sierra RuizNo ratings yet

- Belmont MANUAL OP ClestaIICM HolderType-EnDocument24 pagesBelmont MANUAL OP ClestaIICM HolderType-EnAzzamNo ratings yet

- RIONOTE Datasheet With Wireless Function 1405-8Document4 pagesRIONOTE Datasheet With Wireless Function 1405-8SamirNo ratings yet

- 2007 Room Air Conditioners: Factory Location I Located As First Digit in Serial NumberDocument61 pages2007 Room Air Conditioners: Factory Location I Located As First Digit in Serial NumberEnmanuel J AriasNo ratings yet

- Instrument Panel: SectionDocument14 pagesInstrument Panel: Sectionfearimus1No ratings yet

- Epson WF C5790 WF C5790A WF C5710 ET 8700 WF C5210 WF C5290 WF C5290A Service Manuals 401 450Document50 pagesEpson WF C5790 WF C5790A WF C5710 ET 8700 WF C5210 WF C5290 WF C5290A Service Manuals 401 450조장현No ratings yet

- Numbers Sheet Name Numbers Table NameDocument50 pagesNumbers Sheet Name Numbers Table NameMehul ShuklaNo ratings yet

- Service Manual: Video Cassette RecorderDocument50 pagesService Manual: Video Cassette RecordersugedaNo ratings yet

- Case - AptiTune - Cascade-Loops Tuning of Cascade Loop (Master-Slave) in Single ShotDocument4 pagesCase - AptiTune - Cascade-Loops Tuning of Cascade Loop (Master-Slave) in Single Shot賴明宏No ratings yet