Professional Documents

Culture Documents

Bael CHP Crane Report

Uploaded by

Yonten WangchukOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bael CHP Crane Report

Uploaded by

Yonten WangchukCopyright:

Available Formats

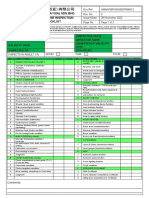

EOT Crane Inspection Customer:

Details Bhutan Automation &

Engineering Limited

Manufacture : USHA MARTIN Ltd, India

Crane Name/ Identification : Single Girder /Bhutan Automation & Engineering Limited

Safe Working Load : 3T=1.2T

Type of Crane : Single Girder

Capacity of Main Hoist : 200T

Voltage : 110 VAC, 415, 50 Hz

Phase :3ф

Test Date : 14.06.2023

Date for next inspection : 01.08.2022

Testing Analyst : Tika Devi Sharma and Karma Dorji

Description Good Defective Comments

Push Buttons

Stop Push Buttons √

No. of Stop Push Buttons 1 1 No.

No. of Push Buttons 8 8Nos.

Remote control √

Hoist Stop Limit Switches (Geared limit switches) √

Down Travel Limit Switches (Geared limit switches) √

Long Travel Limit Switches √

Cross Travel Limit Switches √

Anti-Collision Limit Switches/ Stoppers √

Hook Block

Load Hook √

Sheaves √

Sheaves Bearing √

Hook Bearing √

Safety Latches √

Hoist

Wire Rope √

Wire rope lubrication √

Type of speed Control 1 Speed

Type of Motor Control 3 Ф induction

Motor √

Motor Speed √ 1380 RPM

Brake System

Braking action of all Travel Motion √

Brake Oil Leakage No leakage

Drift in Brake √ No drift

Girder √ Single Girder

Span √ 14.5 Meters

Condition Based Mechanical Assessment (CBMA) Unit

Centre of Excellence for Condition Based Monitoring (CoECBM) Division

DRUK GREEN POWER CORPORATION LIMITED

Rinchentshe, Chhukha Dzongkhag, Web: www.drukgreen.bt

Table 1 Load Hook Block Inspections

Crane No. A2 Original Diameter (mm) H2 Original (mm) Remarks

H2 measurement is taken with reference

3T 52 60.5 position near safety base (Refer figure 1 (i))

Table 2 Wire Rope Inspection

Rope Dia. (3 Ton)

Crane No. Remarks

Actual (mm) Used (mm)

3T 10.1 10.1 (Refer figure no. 1 (ii))

H2

A2

(i) (ii)

Figure 1 Pictorial View of Load hook (i) and Wire Rope (ii) for 3T

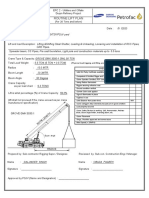

Load Test for 3T EOT Crane:

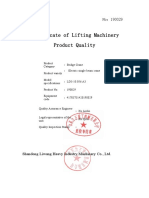

The entire Inspection of Electric Overhead Travelling Crane was carried out as per ISO

Standard for EOT Cranes, ISO – 3177:1 999.

Load Hook Block inspections were conducted as per ISO 9927-1 and ISO-4309 for wire

rope inspection. ( Refer Figure No.1 (i) & (ii))

Load tested = 3T= 1.2T (Refer Figure No.2)

Condition Based Mechanical Assessment (CBMA) Unit

Centre of Excellence for Condition Based Monitoring (CoECBM) Division

DRUK GREEN POWER CORPORATION LIMITED

Rinchentshe, Chhukha Dzongkhag, Web: www.drukgreen.bt

Result

The 3T crane was found satisfactory during the load test. The load test was carried out at

30% of its rated capacity (As per the O&M Coordination Meeting dated 06.06.2019 (Point

No.7.3)). Therefore, the crane is safe to lift the load up to the tested load. However, if the

hoists are required to handle more than the tested loads, the hoists will have to be tested

as per the required load to ascertain their capacities.

Deflection couldn’t be tested due to unavailability of rated capacity load at site.

Recommendation

Timely inspection of overall EOT Cranes should be carried out by the crane operator.

Timely check the gear and brake oil level/colour is necessary. Oil sampling/testing to be

carried out as per the requirement.

To maintain daily based record of total load lifted by EOT crane in hours/day to record the

safe working period (SWP).

To carry out Non- Destructive Testing on Load hook blocks

To arrange proper dead load for next inspection.

Test Conducted By: Witnessed By:

Tika Devi Sharma Ugyen Dorji

Analyst Sr. Foreman

CBMA, HRDC BEAL,CHP

Condition Based Mechanical Assessment (CBMA) Unit

Centre of Excellence for Condition Based Monitoring (CoECBM) Division

DRUK GREEN POWER CORPORATION LIMITED

Rinchentshe, Chhukha Dzongkhag, Web: www.drukgreen.bt

Figure 2 Load testing of 3T Crane

Condition Based Mechanical Assessment (CBMA) Unit

Centre of Excellence for Condition Based Monitoring (CoECBM) Division

DRUK GREEN POWER CORPORATION LIMITED

Rinchentshe, Chhukha Dzongkhag, Web: www.drukgreen.bt

You might also like

- 26-1 E.O.T CraneDocument3 pages26-1 E.O.T CraneAkhilNo ratings yet

- Manual AEGP018 DMADocument11 pagesManual AEGP018 DMAFelix MelendezNo ratings yet

- Croller CraneDocument28 pagesCroller Craneİlyas FeyziyevNo ratings yet

- Nencki Bogie Test Stand Evaluation DescriptionDocument22 pagesNencki Bogie Test Stand Evaluation DescriptionLalNabiNo ratings yet

- Torque Monitoring: Prüftechnik Condition Monitoring GMBH Seite 1Document17 pagesTorque Monitoring: Prüftechnik Condition Monitoring GMBH Seite 1SunnyNo ratings yet

- Manual GuindasteDocument23 pagesManual GuindasteRoberto SantosNo ratings yet

- Final Drawing: 2×1.0T Engine Room CraneDocument25 pagesFinal Drawing: 2×1.0T Engine Room CraneYuriiNo ratings yet

- Machine Inspection Form ExcavatorDocument27 pagesMachine Inspection Form ExcavatorAwanNo ratings yet

- 12 EPT20-15ET Training PPT - 20200303 - 102011Document83 pages12 EPT20-15ET Training PPT - 20200303 - 102011Lacatusu MirceaNo ratings yet

- Training For KOJA RTGDocument211 pagesTraining For KOJA RTGAntonio100% (1)

- 1 25MWDocument33 pages1 25MWmadivala nagarajaNo ratings yet

- Man Riding Car RopeDocument7 pagesMan Riding Car RopeRahul GNo ratings yet

- 12 ES10-10ES Training PPT - 20200303 - 140558Document83 pages12 ES10-10ES Training PPT - 20200303 - 140558Lacatusu MirceaNo ratings yet

- TA1 Visual Inspection Form Master - Track-Type Tractor (Hydrostatic)Document8 pagesTA1 Visual Inspection Form Master - Track-Type Tractor (Hydrostatic)CarlosNo ratings yet

- Qy70v533 Technical SpecificationDocument28 pagesQy70v533 Technical SpecificationMallikarjun DevarapalliNo ratings yet

- Winch Testing RequirementsDocument4 pagesWinch Testing Requirementsksangeeth2000No ratings yet

- Eco Smart Compression Testing Machine PDFDocument2 pagesEco Smart Compression Testing Machine PDFsyed sulemanNo ratings yet

- ZCT900V532.127YA-1 MSWord 1 ADocument15 pagesZCT900V532.127YA-1 MSWord 1 ASlamat BasukiNo ratings yet

- Mooring Winch Tests1Document7 pagesMooring Winch Tests1RachitNo ratings yet

- SGT - Le.014 Crane Inspection Type 1Document10 pagesSGT - Le.014 Crane Inspection Type 1ryangillespie100% (1)

- Mobile Crane Maintenance ChecklistDocument2 pagesMobile Crane Maintenance ChecklistAbdul Halim100% (1)

- O Kolkf D Ijh (K.K Fjiksvz Izfke CSP Lak ( K/: Ekg/: Eicher 551 TractorDocument11 pagesO Kolkf D Ijh (K.K Fjiksvz Izfke CSP Lak ( K/: Ekg/: Eicher 551 TractorMassey FergusonNo ratings yet

- Eot Crane Monthly ChecksheetDocument4 pagesEot Crane Monthly ChecksheetAmit ThakurNo ratings yet

- Condition Monitoring Ensures Against Mechanical Failure 020912Document8 pagesCondition Monitoring Ensures Against Mechanical Failure 020912satya krishna chagantiNo ratings yet

- Screenshot 2021-09-27 at 9.43.50 PMDocument3 pagesScreenshot 2021-09-27 at 9.43.50 PMhqc8pmcfsjNo ratings yet

- Machine Inspection Form Volvo EC700BLCDocument2 pagesMachine Inspection Form Volvo EC700BLCAwan100% (1)

- 012 Mobile Crane InspectionDocument2 pages012 Mobile Crane Inspectionhaslinda Abdul SahakNo ratings yet

- Calculation of Loads - Basic Bearing KnowledgeDocument17 pagesCalculation of Loads - Basic Bearing KnowledgekaustavNo ratings yet

- Fa HM400-2R Gen00081-00Document19 pagesFa HM400-2R Gen00081-00Apele PaceNo ratings yet

- Fdab 268402 e 3 DC 5 C 83075 F 334Document9 pagesFdab 268402 e 3 DC 5 C 83075 F 334Ivan SánchezNo ratings yet

- Zyc120bs GB1Document32 pagesZyc120bs GB1Mel ErphandNo ratings yet

- Contro Arm 20.03.2024 - SDocument58 pagesContro Arm 20.03.2024 - SUmesh PrajapatiNo ratings yet

- PM ClinicDocument2 pagesPM CliniccristianNo ratings yet

- General MaintenanceDocument2 pagesGeneral MaintenanceEdson CRNo ratings yet

- Analisis AmefDocument1 pageAnalisis AmefCarlos MatallanaNo ratings yet

- PM Clinic Excavator PDFDocument3 pagesPM Clinic Excavator PDFjheison valencia100% (1)

- Result of Inspection Report Overhead Traveling Crane Single GirderDocument3 pagesResult of Inspection Report Overhead Traveling Crane Single GirderRusdi BaccoNo ratings yet

- CircuitBreakerCatalogue2021 V01 EU EN LRDocument20 pagesCircuitBreakerCatalogue2021 V01 EU EN LRtedNo ratings yet

- English Translate 1 - 质量证明书Document12 pagesEnglish Translate 1 - 质量证明书Kiki Kiko KikoNo ratings yet

- Sany Scc1500e 150 Ton Crawler CranesDocument56 pagesSany Scc1500e 150 Ton Crawler CranesJSP Sudipta SekhNo ratings yet

- Daily Crane Inspection Report Laporan Pemeriksaan Crane HarianDocument1 pageDaily Crane Inspection Report Laporan Pemeriksaan Crane HarianIan Mardiansyah100% (1)

- Zd320使用说明书(en)Document116 pagesZd320使用说明书(en)मुकेश कुमार झा100% (1)

- 3520 TCD2012L06 3520P TCD2012L06 W enDocument2 pages3520 TCD2012L06 3520P TCD2012L06 W enMDK MAKİNENo ratings yet

- Fact Sheet Til 1292Document2 pagesFact Sheet Til 1292PervimNo ratings yet

- 41-1220 S & Y Crane ServicesDocument1 page41-1220 S & Y Crane Servicessamisaeed300No ratings yet

- Elevator Five Year Safety Test Report: WWW - Lni.Wa - Gov/Tradeslicensing/ElevatorsDocument2 pagesElevator Five Year Safety Test Report: WWW - Lni.Wa - Gov/Tradeslicensing/ElevatorsjhoniNo ratings yet

- Cur Soar Condicion A Do AutoDocument37 pagesCur Soar Condicion A Do AutoFabio Adriana FláviaNo ratings yet

- Routine Lift Plan For All Crane-Grove GMK 50 TonDocument1 pageRoutine Lift Plan For All Crane-Grove GMK 50 TonKannan Murugesan100% (1)

- Container Crane PresentationDocument62 pagesContainer Crane PresentationOussama radikiNo ratings yet

- Legal Requirements, - OEM Maintenance, - Tower Crane Specs - Acd - Wire RopesDocument36 pagesLegal Requirements, - OEM Maintenance, - Tower Crane Specs - Acd - Wire Ropesmaharshi mNo ratings yet

- HST-YAW2000DH Computer Control Compression Testing MachineDocument6 pagesHST-YAW2000DH Computer Control Compression Testing MachineRiezky HerdiantoNo ratings yet

- Especificaciones Tecnicas Ecd35Document3 pagesEspecificaciones Tecnicas Ecd35Jorge Eduardo Muñoz MadridNo ratings yet

- Daily Report Juillet 2020Document165 pagesDaily Report Juillet 2020Salim82 LKNo ratings yet

- PM Clinic WA500-3LEDocument3 pagesPM Clinic WA500-3LEJheison ValenciaNo ratings yet

- Manual 160928Document18 pagesManual 160928JUANKMUGNONo ratings yet

- zoomlion-truck-QY100 HDocument16 pageszoomlion-truck-QY100 Hالبديري بهاءNo ratings yet

- CRT InquiryDocument2 pagesCRT Inquirysalman buttNo ratings yet

- Wheelchair Lifts Inclined Wheelchair Lifts and Stairway Chairlifts A18.1 Annual Maintenance and Testing ChecklistDocument2 pagesWheelchair Lifts Inclined Wheelchair Lifts and Stairway Chairlifts A18.1 Annual Maintenance and Testing ChecklistUmmi HuraizahNo ratings yet

- Crane Maintenance ManualDocument32 pagesCrane Maintenance ManualjuanetnaNo ratings yet

- Tutorial 2 - Settlement of Shallow FoundationsDocument4 pagesTutorial 2 - Settlement of Shallow FoundationsNametso MoatsheNo ratings yet

- District CoolingDocument8 pagesDistrict Coolingmsn20091No ratings yet

- FM Global Property Loss Prevention Data Sheets: List of FiguresDocument25 pagesFM Global Property Loss Prevention Data Sheets: List of FiguresTienda JoselenaNo ratings yet

- PF5700 00 1.8TS Master US Dec 06Document1,654 pagesPF5700 00 1.8TS Master US Dec 06mohammedNo ratings yet

- Measurement of Payment (Insulation Work)Document4 pagesMeasurement of Payment (Insulation Work)Steven JosephNo ratings yet

- Brochure-Ras - Refractory AnchorsDocument2 pagesBrochure-Ras - Refractory AnchorsMohamed EwaisNo ratings yet

- 5.0 Design Methodology 5.1 Pipeline Wall Thickness: FET S PD TDocument14 pages5.0 Design Methodology 5.1 Pipeline Wall Thickness: FET S PD TTeck Tiong HuanNo ratings yet

- UDocument1 pageUmohd as shahiddin jafriNo ratings yet

- What Is Versitank® Versitank Is A Heavy Duty Plastic Tank ThatDocument10 pagesWhat Is Versitank® Versitank Is A Heavy Duty Plastic Tank ThatsreekanthchemiNo ratings yet

- Philippine Overseas & Domestic Construction Board: Executive Director, PODCBDocument37 pagesPhilippine Overseas & Domestic Construction Board: Executive Director, PODCBZamhyrreNo ratings yet

- Cas-White Chemical Resistant and Anti SlipDocument28 pagesCas-White Chemical Resistant and Anti SlipAnonymous llBSa7No ratings yet

- 805AA Flexor 5 SAE 100 R5: Wire BraidDocument1 page805AA Flexor 5 SAE 100 R5: Wire BraidRodrigo Pessoa VespaNo ratings yet

- Level-V On-Site Building Construction ManagementDocument77 pagesLevel-V On-Site Building Construction ManagementFenta Dejene91% (22)

- Tablas CM y CV - Asce 7-10Document9 pagesTablas CM y CV - Asce 7-10Josep R HerreraNo ratings yet

- Kooltherm K7 Pitched Roof BoardDocument9 pagesKooltherm K7 Pitched Roof BoardMarkNo ratings yet

- Chemical Composition: Si Fe Cu MN MG Ni ZN SN Ti PB CRDocument2 pagesChemical Composition: Si Fe Cu MN MG Ni ZN SN Ti PB CRQuality teamNo ratings yet

- PL O Tfqdu - Ot : L"Dcoej, Q ) S?: Po P./JDocument14 pagesPL O Tfqdu - Ot : L"Dcoej, Q ) S?: Po P./JSswahyudiNo ratings yet

- Cable Tray BS 4678 Part 1 BS 50085 Part 1 2Document2 pagesCable Tray BS 4678 Part 1 BS 50085 Part 1 2Deepak SwainNo ratings yet

- Mech PropertiesDocument1 pageMech PropertiesLLNo ratings yet

- SOM-BMT Lab Manual FinalDocument48 pagesSOM-BMT Lab Manual FinalHarish T S Gowda100% (1)

- CIVIL - MSC (Eng) 22-23 - CivE Syllabus - Nov 2021Document13 pagesCIVIL - MSC (Eng) 22-23 - CivE Syllabus - Nov 2021tot730158No ratings yet

- Construction &demolition Waste RecyclingDocument20 pagesConstruction &demolition Waste Recyclingvinothpandi50% (2)

- OberoiDocument8 pagesOberoiNardev KumarNo ratings yet

- Omega Factor DiscussionDocument2 pagesOmega Factor Discussionardi_xyz100% (1)

- Final Selection Criteria Tunnel Cons TraDocument32 pagesFinal Selection Criteria Tunnel Cons TraMd Mobshshir NayeemNo ratings yet

- Design TrafficDocument29 pagesDesign TrafficSeanam DM80% (5)

- Shielding Properties of Common Building MaterialsDocument1 pageShielding Properties of Common Building MaterialsJameel AhmedNo ratings yet

- Formwork and Shoring Solutions: A.H. Harris & Sons, IncDocument8 pagesFormwork and Shoring Solutions: A.H. Harris & Sons, IncFrancisco GonzalezNo ratings yet

- Copy (1) My SWEP Report 2010Document30 pagesCopy (1) My SWEP Report 2010Fayemi Slim Oluwasola80% (5)

- 496 Mount Auburn ST, Watertown, MA 02472 - MLS# 71685553 - RedfinDocument9 pages496 Mount Auburn ST, Watertown, MA 02472 - MLS# 71685553 - Redfinashes_xNo ratings yet

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsFrom EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsRating: 4 out of 5 stars4/5 (4)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Biostratigraphic and Geological Significance of Planktonic ForaminiferaFrom EverandBiostratigraphic and Geological Significance of Planktonic ForaminiferaRating: 4 out of 5 stars4/5 (5)

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesFrom EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesRating: 5 out of 5 stars5/5 (5)

- Gas and Oil Reliability Engineering: Modeling and AnalysisFrom EverandGas and Oil Reliability Engineering: Modeling and AnalysisRating: 4.5 out of 5 stars4.5/5 (6)

- Mooring System Engineering for Offshore StructuresFrom EverandMooring System Engineering for Offshore StructuresRating: 5 out of 5 stars5/5 (1)

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityFrom EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityRating: 3 out of 5 stars3/5 (2)

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Petroleum Production Engineering, A Computer-Assisted ApproachFrom EverandPetroleum Production Engineering, A Computer-Assisted ApproachRating: 4.5 out of 5 stars4.5/5 (11)