Professional Documents

Culture Documents

SOP L

Uploaded by

nirmal krisnaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SOP L

Uploaded by

nirmal krisnaCopyright:

Available Formats

Rev. No.

Document Reference

0 SBPL/M/EM/SOP-03

ENVIRONMENTAL MANAGEMENT SYSTEM

SENTINI BIOPRODUCTS (P) LTD Standard Operating Procedure(Maintenance)

GANDEPALLI

As per the requirements of ISO 14001:2015,

Issue. No. Date Page

1 01-08-19

SOP FOR THE DISPOSAL OF METALIC SCRAP

SCOPE : Procedure to dispose the metallic scrap.

Responsibility : D.G.M (Mech.)

Engineer (Mech.)

1.Collect the scrap material and welding electrodes end pieces generated during regular

fabrication / maintenance works.

2.Inspect the material,If any material can be used separate the material for re use.

3.Collect the scrap and send to the scrap yard.

4. Seperate SS / MS / Aluminium scrap for easy disposal.

5.Intimate stores dept. for the disposal.

PREPARED BY APPROVED BY

Sr.MANAGER(PROJ.& MECH.) Sr.V.P(OP.)

Rev. No. Document Reference

0 SBPL/M/EM/SOP-02

ENVIRONMENTAL MANAGEMENT SYSTEM

SENTINI BIOPRODUCTS (P) LTD Standard Operating Procedure(Maintenance)

GANDEPALLI

As per the requirements of ISO 14001:2004,

Issue. No. Date Page

1 03-04-09

SOP FOR THE DISPOSAL OF NON METALIC SCRAP

SCOPE : Procedure to dispose the metallic scrap.

Responsibility : Sr.Manager (Proj & Mech.)

Engineer (Mech.)

1.Collect the non metallic scrap like rubber,plastic etc during maint. works.

2.Collect the non metallic scrap in separate bins.

3.Intimate to stores dept. for disposal after a period of two months.

PREPARED BY APPROVED BY

Sr.MANAGER(PROJ.& MECH.) Sr.V.P(OP.)

.

Rev. No. Document Reference

0 SBPL/M/EM/SOP-01

ENVIRONMENTAL MANAGEMENT SYSTEM

SENTINI BIOPRODUCTS (P) LTD Standard Operating Procedure(Maintenance)

GANDEPALLI

As per the requirements of ISO 14001:2004,

Issue. No. Date Page

1 03-04-09

SOP FOR THE DISPOSAL OF USED LUBRICANTS

SCOPE : Procedure to dispose the used lubricants

Responsibility : Sr.Manager (Proj & Mech.)

Engineer (Mech.)

1.Collect all used lubricants from the work place.

2.Never throw the waste oil on the shop floor or outside.

3.Keep waster oil drums separately with cover to store the waste oil.

4.Keep the oil drums far away from flammable materials.

5.Avoid spillage of oil at the time of collecting and storing of oil. In the case of spillage

immediately clean the place and cover the area with sand/ saw dust.

6.Intimate the stores dept. to dispose the waste oil with in three months through standard form 3.

PREPARED BY APPROVED BY

Sr.MANAGER(PROJ.& MECH.) Sr.V.P(OP.)

Rev. No. Document Reference

0 SBPL/M/EM/SOP-04

ENVIRONMENTAL MANAGEMENT SYSTEM

SENTINI BIOPRODUCTS (P) LTD Standard Operating Procedure(Maintenance)

GANDEPALLI

As per the requirements of ISO 14001:2004,

Issue. No. Date Page

1 03-04-09

SOP FOR THE USAGE OF LPG GAS

SCOPE : Procedure to use LPG at the time of gas cutting

Responsibility : Sr. Manager (Proj & Mech.)

Engineer (Mech.)

1. Keep the cylinder always in vertical position.

2. Never roll the cylinder.

3. Check for leakages from the cylinder.

4.Fix the regulator and set the pressure as required.

5. Check for tube leakages. If any leakages are found replace the tube.

6. Remove all flammable materials in the surroundings.

7. Keep always fire extinguisher and water at the place of gas cutting.

8. Send a stores issue slip at the time of taking the cylinder from stores.

9. Handover the empty cylinder to stores to take new one.

PREPARED BY APPROVED BY

Sr.MANAGER(PROJ.& MECH.) Sr.V.P(OP.)

Rev. No. Document Reference

0 SBPL/M/EM/SOP-05

ENVIRONMENTAL MANAGEMENT SYSTEM

SENTINI BIOPRODUCTS (P) LTD Standard Operating Procedure(Maintenance)

GANDEPALLI

As per the requirements of ISO 14001:2004,

Issue. No. Date Page

1 03-04-09

SOP - PROCEDURE TO FOLLOW AT THE TIME OF FAILURE OF EQUIPMENT

SCOPE : Procedure to to follow at the time of failure of the equipment.

Responsibility : Sr. Manager (Proj & Mech.)

Engineer (Mech.)

1.Immediately go to the work area where the failure occurred.

2. Evaluate the type of failure and plan accordingly for the manpower, tools and tackles, spares.

3.Immediately engage the manpower.

4.Rectify the problem and hand over the equipment.

5.Clean the work area thoroughly before leaving the work place.

6.Clean the oil, grease etc.

7.Collect the waste oil separately and store in the specified drum.

8.Collect the metallic and non metallic scrap and store in the specified bins.

9. Take the failed equipment from the work place to the workshop for repairing.

10. Rectify the equipment and keep the equipment separately with proper cover to keep the

equipment clean.

11. Hand over the scrap / used lubricants to stores.

12. Analyze the problem and try to prevent the problem in future.

PREPARED BY APPROVED BY

Sr.MANAGER(PROJ.& MECH.) Sr.V.P(OP.)

You might also like

- Biosafety CabinetDocument8 pagesBiosafety CabinetkinzaNo ratings yet

- 8001-WI-01-05-07 (Handling Schedule Waste)Document7 pages8001-WI-01-05-07 (Handling Schedule Waste)Agung Tri SugihartoNo ratings yet

- TOTL-SP02 Factilities and Environmental Conditions ProcedureDocument9 pagesTOTL-SP02 Factilities and Environmental Conditions ProcedureahmedNo ratings yet

- Leave Form (2017)Document1 pageLeave Form (2017)Muhd Nazrin Ab RasidNo ratings yet

- House Keeping (Shazoo)Document3 pagesHouse Keeping (Shazoo)usman javaid100% (1)

- MB 27 03Document18 pagesMB 27 03Ana Milena Diaz RuedaNo ratings yet

- Sop of Production DepartmentDocument185 pagesSop of Production Department0921py88% (50)

- OCP 123 Noise ProcedureDocument7 pagesOCP 123 Noise Procedurematam natarajNo ratings yet

- Sop For Cleaning & HousekeepingDocument4 pagesSop For Cleaning & HousekeepingvinodsnNo ratings yet

- Field Training ReportDocument39 pagesField Training ReportShamsul Azhar Mohd100% (9)

- US Environmental Protection Agency Office of Pesticide ProgramsDocument18 pagesUS Environmental Protection Agency Office of Pesticide Programsskype2121No ratings yet

- Qhse-Integrated Management System Process Engineering Procedure ManualDocument5 pagesQhse-Integrated Management System Process Engineering Procedure Manualshanku_bietNo ratings yet

- 5-Operation & Cleaning of Ropp Sealing MachineDocument3 pages5-Operation & Cleaning of Ropp Sealing MachineananthNo ratings yet

- Neptune Orthopaedics Standard Operating Procedure-ProductionDocument2 pagesNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurNo ratings yet

- Techno-Commercial Offer 100 KLD STP, Betul Based On MBBR HybridDocument9 pagesTechno-Commercial Offer 100 KLD STP, Betul Based On MBBR HybridTech MongerNo ratings yet

- Sop OPOP Eng 007 - Operating Diesel Bowsers and TanksDocument8 pagesSop OPOP Eng 007 - Operating Diesel Bowsers and Tankscontrax8100% (1)

- Environmetal Management PlanDocument4 pagesEnvironmetal Management PlanNev DelgadoNo ratings yet

- B MercaptoethanolDocument6 pagesB MercaptoethanolEllieNo ratings yet

- Main TextDocument23 pagesMain Textfatimah100% (1)

- Test Methods For The Examination of Composting and Comost TMECC - Thompson Et Al USCC 2002 Excerpt RespirometryDocument24 pagesTest Methods For The Examination of Composting and Comost TMECC - Thompson Et Al USCC 2002 Excerpt RespirometryGerad ValdezNo ratings yet

- 630-Lubrication of CSR#3Document7 pages630-Lubrication of CSR#3Buddy HartNo ratings yet

- US Environmental Protection Agency Office of Pesticide ProgramsDocument17 pagesUS Environmental Protection Agency Office of Pesticide ProgramsAngeles SuarezNo ratings yet

- Iso 14001 General Information and Action DirectivesDocument47 pagesIso 14001 General Information and Action DirectivesJohan KaufmannNo ratings yet

- List of SOP's: Dhaka, BangladeshDocument1 pageList of SOP's: Dhaka, BangladeshPharmacistNo ratings yet

- Sop Inert GasDocument5 pagesSop Inert GasvinodsnNo ratings yet

- SMP For Calibration of Gauges & TransmittersDocument3 pagesSMP For Calibration of Gauges & Transmitterspradeep1987coolNo ratings yet

- H2so4 SpillDocument4 pagesH2so4 SpilludayNo ratings yet

- 13 SOP Classification of Clean RoomsDocument5 pages13 SOP Classification of Clean RoomsNoor Javed100% (1)

- Microbiologist Validation Protocol Protocol No: DNIL - AV.P.021.00 Page 1 of 7Document7 pagesMicrobiologist Validation Protocol Protocol No: DNIL - AV.P.021.00 Page 1 of 7HBNNo ratings yet

- 01 - 04.00 Sop For Cleaning CorridorsDocument3 pages01 - 04.00 Sop For Cleaning CorridorsYashNo ratings yet

- Standard Operating Procedure Handling, Storage and Disposal: Punyam Manufacturing INCDocument4 pagesStandard Operating Procedure Handling, Storage and Disposal: Punyam Manufacturing INCJaijeev PaliNo ratings yet

- Sop For Om For Ball MillDocument7 pagesSop For Om For Ball MillvinodsnNo ratings yet

- Process Document: Health Safety & Environment Management (Version 1.0)Document8 pagesProcess Document: Health Safety & Environment Management (Version 1.0)Tonmay MajumderNo ratings yet

- Orientation On: Environmental Aspect-Impact Assessment (EAIA)Document69 pagesOrientation On: Environmental Aspect-Impact Assessment (EAIA)Von Eric PerezNo ratings yet

- 1602041044-MD-04-MT-RSANA-PD-076 Rev.00 Maintenance Procedure For TOC-COD Analyzer PDFDocument20 pages1602041044-MD-04-MT-RSANA-PD-076 Rev.00 Maintenance Procedure For TOC-COD Analyzer PDFKy Nguyen TrongNo ratings yet

- SOP Orbital ShakerDocument7 pagesSOP Orbital ShakerAmrul HanifahNo ratings yet

- AOAC Use Dilution Method For Testing Disinfectants MB-05Document19 pagesAOAC Use Dilution Method For Testing Disinfectants MB-05Romildo da SilvaNo ratings yet

- Sop OPOP - 050 - Breath Analyser, Alcohol and DrugsDocument5 pagesSop OPOP - 050 - Breath Analyser, Alcohol and Drugscontrax8100% (1)

- Blackline Corrosion Test ReportDocument8 pagesBlackline Corrosion Test ReportAs Ad Ali MutakinNo ratings yet

- Solid and Liquid Waste Procedure - ENGDocument9 pagesSolid and Liquid Waste Procedure - ENGErlan Gus HermawanNo ratings yet

- ROG-HSE-PRO-003, Rev 00 - Waste Management ProcedureDocument15 pagesROG-HSE-PRO-003, Rev 00 - Waste Management ProcedurevladNo ratings yet

- AuditReportAarti TarapurDocument12 pagesAuditReportAarti TarapurVijay KotwalNo ratings yet

- 621-CC#09 Idler and Frame ChangingDocument4 pages621-CC#09 Idler and Frame ChangingBuddy Hart100% (1)

- Material Safety Data Sheet: Omyacarb 1T / 2T / 3T / 4T - SJDocument3 pagesMaterial Safety Data Sheet: Omyacarb 1T / 2T / 3T / 4T - SJHeri SetiyantoNo ratings yet

- Lab 002 PDFDocument11 pagesLab 002 PDFMohsin ALiNo ratings yet

- Ai Controller (内置可充电锂离子电池包组件inr2404p15a 25. 9v 4000mah 103.6wh) Tjtest Ghs Sds Report t220113015e 英文版Document9 pagesAi Controller (内置可充电锂离子电池包组件inr2404p15a 25. 9v 4000mah 103.6wh) Tjtest Ghs Sds Report t220113015e 英文版PaddyNo ratings yet

- Implementation of - Iso 14001 - 2015Document24 pagesImplementation of - Iso 14001 - 2015S SeetharamanNo ratings yet

- 6404 MONOLEC Oil MSDS (2012-04)Document9 pages6404 MONOLEC Oil MSDS (2012-04)Jonathan RiveraNo ratings yet

- MSDS For All NR Grades (MCL)Document5 pagesMSDS For All NR Grades (MCL)Andy OktavianoNo ratings yet

- "Project Formulation Survey" Under The Governmental Commission On The Projects For ODA Overseas Economic Cooperation in FY 2013Document11 pages"Project Formulation Survey" Under The Governmental Commission On The Projects For ODA Overseas Economic Cooperation in FY 2013altis1376No ratings yet

- Content: Standard Operating Procedure (SOP) Use and Maintenance of An InspissatorDocument6 pagesContent: Standard Operating Procedure (SOP) Use and Maintenance of An InspissatornazmiNo ratings yet

- Vibration ProcedureDocument6 pagesVibration Procedurematam natarajNo ratings yet

- Techno-Commercial Offer 100 KLD TM Shiv Shakti Developers, Betul SiteDocument9 pagesTechno-Commercial Offer 100 KLD TM Shiv Shakti Developers, Betul SiteTech MongerNo ratings yet

- APNC - Tack Coat Curing AgentDocument22 pagesAPNC - Tack Coat Curing Agentshiela fernandoNo ratings yet

- Environmental - Management - M&SDocument15 pagesEnvironmental - Management - M&SSusantha SampathNo ratings yet

- Cegelec Environmental Management PlanDocument10 pagesCegelec Environmental Management PlanREHOBOTH YAMBO KAHILUNo ratings yet

- Neptune Orthopaedics Standard Operating Procedure-ProductionDocument4 pagesNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurNo ratings yet

- Instr Procedure - 1y - PM - 28-K - 3112Document33 pagesInstr Procedure - 1y - PM - 28-K - 3112ofon OML102No ratings yet

- Reference Material Certificate I S O 1 7 0 3 4Document2 pagesReference Material Certificate I S O 1 7 0 3 4ROBINNo ratings yet

- Recent Trends and Innovations in Sustainable Treatment Technologies for Heavy Metals, Dyes and Other XenobioticsFrom EverandRecent Trends and Innovations in Sustainable Treatment Technologies for Heavy Metals, Dyes and Other XenobioticsNo ratings yet

- Indented Materil 2020Document29 pagesIndented Materil 2020nirmal krisnaNo ratings yet

- Derivatives RulesDocument31 pagesDerivatives Rulesjenilyn200No ratings yet

- Weeklyy Check List 1 T 5, 9Document7 pagesWeeklyy Check List 1 T 5, 9nirmal krisnaNo ratings yet

- Karthik - Resume (3) MECHANICAL ENGINEERDocument2 pagesKarthik - Resume (3) MECHANICAL ENGINEERnirmal krisnaNo ratings yet

- List of Candidates Who Qualified or Not Qualified Aissee 2024 Exam Held On 28012024 For Admission To Class Ix For The Academic Year 24 25Document795 pagesList of Candidates Who Qualified or Not Qualified Aissee 2024 Exam Held On 28012024 For Admission To Class Ix For The Academic Year 24 25nirmal krisnaNo ratings yet

- Class-8 Science Extra QuestionsDocument11 pagesClass-8 Science Extra Questionsnirmal krisnaNo ratings yet

- List of Weekly Check ListDocument1 pageList of Weekly Check Listnirmal krisnaNo ratings yet

- Aisse 2016 Class 9Document10 pagesAisse 2016 Class 9shyamNo ratings yet

- Phe M10Document2 pagesPhe M10sumit11235No ratings yet

- Sample Paper at 2324 Class V p1 At+pcbmDocument23 pagesSample Paper at 2324 Class V p1 At+pcbmSandhya KatiyarNo ratings yet

- File 1428726090 PDFDocument8 pagesFile 1428726090 PDFsimbamikeNo ratings yet

- N-21007-2-CGA2001 R0 (T-2013 AB) - ModelDocument1 pageN-21007-2-CGA2001 R0 (T-2013 AB) - Modelnirmal krisnaNo ratings yet

- Sample Paper-At-2324-Class-Ix-P1-At+pcbmDocument21 pagesSample Paper-At-2324-Class-Ix-P1-At+pcbmCodeItNowNo ratings yet

- Sample Paper-At-2324-Class-Vii-P1-At+pcbmDocument23 pagesSample Paper-At-2324-Class-Vii-P1-At+pcbmnirmal krisnaNo ratings yet

- N-21007-2-CGA2001 R0 (T-2013 AB) - ModelDocument1 pageN-21007-2-CGA2001 R0 (T-2013 AB) - Modelnirmal krisnaNo ratings yet

- Gear Boxes ListDocument4 pagesGear Boxes Listnirmal krisnaNo ratings yet

- SMF&W 851-01-07 Manual Arc Welding 220319Document9 pagesSMF&W 851-01-07 Manual Arc Welding 220319Shahid RazaNo ratings yet

- Description: Packag eDocument4 pagesDescription: Packag eVicenteAlvarezNo ratings yet

- Case Summary - Apple Inc: Syndicate 5Document2 pagesCase Summary - Apple Inc: Syndicate 5Diasty Widar HapsariNo ratings yet

- Class 12 Mathematics Project PDFDocument13 pagesClass 12 Mathematics Project PDFsonukum1289No ratings yet

- DIALux Module InformationDocument51 pagesDIALux Module Informationraja kumarNo ratings yet

- Bharat Petroleum: Star PEB India Private LimitedDocument10 pagesBharat Petroleum: Star PEB India Private LimitedParvinder Kaur100% (1)

- Canada CC TopupDocument22 pagesCanada CC TopupFree RobuxNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3314B Simotics SD - 315L - Im B3 - 4 PDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 7CV3314B Simotics SD - 315L - Im B3 - 4 PHEMANT RAMJINo ratings yet

- Code Source Du Script Shell C99Document3 pagesCode Source Du Script Shell C99Mora SOWNo ratings yet

- NEOM-NPR-GFR-Management Manual Rev 01Document24 pagesNEOM-NPR-GFR-Management Manual Rev 01MOHD ZEESHAN100% (3)

- Package ExampleDocument3 pagesPackage ExampleSunil SuryawanshiNo ratings yet

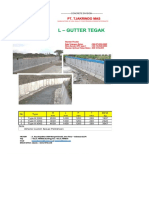

- Brosur L-Gutter TJMDocument4 pagesBrosur L-Gutter TJMPandu HarisurawanNo ratings yet

- MFL71143102 - ManualOwner - (EN+SP) - LW1019IVSM - Rev 02 - 111919 - (P12816-18202123)Document60 pagesMFL71143102 - ManualOwner - (EN+SP) - LW1019IVSM - Rev 02 - 111919 - (P12816-18202123)julio ariasNo ratings yet

- Bayesian Optimization With GradientsDocument17 pagesBayesian Optimization With Gradients刘明浩No ratings yet

- GlossaryDocument24 pagesGlossaryallNo ratings yet

- Eq List IEC 60335-2-14 (6.0) 2016-20170814Document3 pagesEq List IEC 60335-2-14 (6.0) 2016-20170814le duc huynhNo ratings yet

- CPJ 200 J1 j1-04 Basic Operationmod r2 (SMD) - 1Document20 pagesCPJ 200 J1 j1-04 Basic Operationmod r2 (SMD) - 1ngocbienk56No ratings yet

- Chapter 1 - Introduction To System AdministrationDocument27 pagesChapter 1 - Introduction To System AdministrationAbdul KilaaNo ratings yet

- Dadex Efast Price List 1ST August 2020Document1 pageDadex Efast Price List 1ST August 2020Jugno ShahNo ratings yet

- APlus Catalog - A675H-676H-678HDocument1 pageAPlus Catalog - A675H-676H-678HNgọc TrầnNo ratings yet

- SET General Aptitude SampleDocument11 pagesSET General Aptitude SampleFast FeneNo ratings yet

- Compal Confidential: Dali & Astro BKA40/BKA50/BKD40/BKD50 MB Schematic Document LA-D822PDocument46 pagesCompal Confidential: Dali & Astro BKA40/BKA50/BKD40/BKD50 MB Schematic Document LA-D822PPhạm CườngNo ratings yet

- Document From Sfere Electric23 AbcDocument29 pagesDocument From Sfere Electric23 AbcMuhammad SaleemNo ratings yet

- Quantus Fluorometer Operating Manual TM396Document17 pagesQuantus Fluorometer Operating Manual TM396Anggi ManurungNo ratings yet

- The Perfect Integrated Solution For All Your Reverse Engineering ProjectsDocument1 pageThe Perfect Integrated Solution For All Your Reverse Engineering ProjectsflibflurbNo ratings yet

- Bharatiya Vidya Bhavan (Dept. of Film, TV & Animation Studies)Document5 pagesBharatiya Vidya Bhavan (Dept. of Film, TV & Animation Studies)AshmanNo ratings yet

- Operating System (17CS64)Document3 pagesOperating System (17CS64)Pranove ABNo ratings yet

- Instant Neural Graphics Primitives With A Multiresolution Hash EncodingDocument13 pagesInstant Neural Graphics Primitives With A Multiresolution Hash EncodingHieu BuiNo ratings yet

- Math 149 ProjectDocument15 pagesMath 149 ProjectJeff CruzNo ratings yet

- Vix112 Vmrun Command PDFDocument20 pagesVix112 Vmrun Command PDFtrix337No ratings yet