Professional Documents

Culture Documents

STD - e - Hoist Aap-Cpp-Boiler - Tc50y9, U#5, Aph, 2023-24, PSD, 11.12.2023

STD - e - Hoist Aap-Cpp-Boiler - Tc50y9, U#5, Aph, 2023-24, PSD, 11.12.2023

Uploaded by

bboneyt1Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

STD - e - Hoist Aap-Cpp-Boiler - Tc50y9, U#5, Aph, 2023-24, PSD, 11.12.2023

STD - e - Hoist Aap-Cpp-Boiler - Tc50y9, U#5, Aph, 2023-24, PSD, 11.12.2023

Uploaded by

bboneyt1Copyright:

Available Formats

Jibanananda Sanabada, B.

Sc, BE, BOE

DHANUPALI, NEAR-GOVT GIRLS HIGH

SCHOOL, SAMBALPUR-768005

COMPETANT PERSON Under Section 2 (ca) of the Factories Act. 1948, CP (O) NO 173 (G) 8763692142, JIBANANANDAPSM@gmail.com

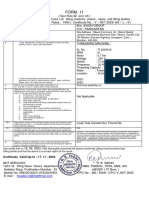

PSD/2021/ELECTRIC HOIST/AAP-CPP-BOILER/TC/ 50 Y9 11-Dec-2023

Report of periodic examination of lifting machines, chains, ropes and lifting tackles

[As Prescribed under Rule 55-C , Sub-section (2) of Section 29, Factory Rules, 1950]

1 Name of Occupier of Factory M/s ADITYA ALUMINIUM Ltd.,

2 Address of the factory: M/s ADITYA ALUMINIUM Ltd.,

Lapanga, Sambalpur, Odisha

3 Distinguishing number or mark, if any, and MONORAIL ELECTRIC HOIST

description sufficient to identify the lifting

ID/EQPT. No: B5/E-Hoist/APH/TWH-1

machine, chain, rope or the lifting tackle:

Installation level (Bottom of Monorail: EL. +16.500m Appx.

Travel Length 32.40m

Installed Cap: 1T

Rated Cap. 1T

Height of Lift: 15 mtr

Duty Class: II

Operation Mode: Pendant

Location: BOILER-5, AT AIR PRE

HEATER A & B

Drg. No: 2-99-400-40627,

Sheet 1 of 1, Rev 00

4 Date when the lifting machine, chain, rope or 26-11-2016

lifting tackle was first taken into use in the factory:

5 Date and number of certificate relating to any test First examination 26-11-2016

and examination made under Rules 55-A and 55-G complying to

together with the name and address of the person Rule 55-A done on

who issued the certificate:

6 Date of each periodical thorough examination Last examination done 11-12-2022

made under Rule 55-F and the name of examiner: by Parthasarathi Dalai

on

7 Date of annealing or other heat treatment of the New Hoist

chain and other lifting tackle made under Rule 55-

E and by whom it was carried out:

8 Particulars of any defects affecting the safe Nothing observed

working load found at any such thorough

examination or after annealing and of the steps

taken to remedy such defects:

E-HOIST CPP BOILER Y9, 2023

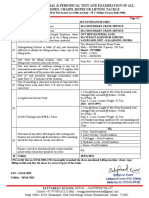

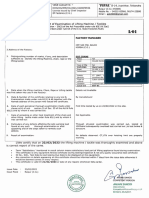

DETAILS OF THOROUGH EXAMINATIONS / TESTS CONDUCTED

VISUAL EXAMINATION

a. Overrunning devices Good condition

b Suspension ropes or chains and their attatchments Good condition

c Brakes Good condition

d Worm or spur gearing Internals not accessible, but no

unwanted sound was observed

e Other electrical equipment Good condition

f Other parts Good condition

LOAD TEST

a. Static tests 1.25 T lifted to a height of 100mm ground

clearance and held for about

20minutes. No slippage nor any

tendency of failure observed.

b Dynamic tests 1.0 T lifted to a height of 2000mm and

lowered. No abnormalities oobserved.

c Stability tests No instability observed during the Static

and Dynamic loading

Maximum Safe Working Capacity Below 1 T

Others Always lubricate the ropes and check

the operation of proper functioning of

limit switches at regular intervals

I certify that on 11-Dec-2023 the above ELECTRIC HOIST

was thoroughly cleaned to the extent possible and made accessible for through examination and for such

tests as were necessary to ascertain the health of the above ELECTRIC HOIST. I have thoroughly examined

this ELECTRIC HOIST and that the above is a correct report of the result.

Next due date for examination by Competent Person subject to following SOP and SMP 11-Dec-2024

Signature:

Qualification: B.Sc, BE, BOE

Competant Person Regn no: CP(O)NO 173(G)

Address: Dhanupali, Near- Govt. Girls high School,

Date: Sambalpur-768005

11-Dec-2023

E-HOIST CPP BOILER Y9, 2023

You might also like

- 2005 Chevrolet Tahoe/Suburban Owner ManualDocument530 pages2005 Chevrolet Tahoe/Suburban Owner ManualClaudio Hernández PobleteNo ratings yet

- Form, Test TardjoenDocument30 pagesForm, Test TardjoenDangolNo ratings yet

- Jsa. Cable Laying and TerminationDocument10 pagesJsa. Cable Laying and TerminationMon Trang NguyễnNo ratings yet

- Ready For Telecom Installation (Rfti) Inspection Checklist: Participants Name Position Contact No. CompanyDocument15 pagesReady For Telecom Installation (Rfti) Inspection Checklist: Participants Name Position Contact No. Companyjohn helyNo ratings yet

- LT 2021-6847 (Equipment Inspection Report - Crane & Lifting Devices)Document4 pagesLT 2021-6847 (Equipment Inspection Report - Crane & Lifting Devices)michaelNo ratings yet

- 18 - Fork Lift Defect - OptDocument4 pages18 - Fork Lift Defect - OptMoataz NazeemNo ratings yet

- Site Test Report: Under Ground Cables Precommissioning Test SheetDocument1 pageSite Test Report: Under Ground Cables Precommissioning Test SheetNaser Mahamid100% (1)

- Foreword: Quick Reference IndexDocument3 pagesForeword: Quick Reference Indexjrrodrigueza2No ratings yet

- Spare Parts Catalogue: 200 DukeDocument61 pagesSpare Parts Catalogue: 200 DukePankaj GuptaNo ratings yet

- Result of Inspection Report Overhead Traveling Crane Single GirderDocument3 pagesResult of Inspection Report Overhead Traveling Crane Single GirderRusdi BaccoNo ratings yet

- Switch Gears 134-149Document16 pagesSwitch Gears 134-149Vijaya KumarNo ratings yet

- Jeepney ResearchDocument70 pagesJeepney ResearchHannah Faye ValdezNo ratings yet

- CT Testing LTDocument25 pagesCT Testing LTVijaya Kumar100% (2)

- Davit & Socket Gondola System - Visual Inspection Checklist: Sonria CondominlumDocument3 pagesDavit & Socket Gondola System - Visual Inspection Checklist: Sonria CondominlumAmbo Ganzon100% (1)

- 1.high Voltage Discharge Rod PDFDocument1 page1.high Voltage Discharge Rod PDFsaptarshi Das100% (1)

- A Study On Marketing Strategy of Honda Two WheelersDocument27 pagesA Study On Marketing Strategy of Honda Two WheelersAnzel Mannuu100% (1)

- P-G-R-T / P-G-R-S Truck: Preventative Maintenance GuideDocument2 pagesP-G-R-T / P-G-R-S Truck: Preventative Maintenance GuideKANG PRIYONo ratings yet

- Final ReportDocument13 pagesFinal Reportستار الزيديNo ratings yet

- Crawler TPI J-15540Document1 pageCrawler TPI J-15540RajuNo ratings yet

- BBC Tech Associates: E-MailDocument1 pageBBC Tech Associates: E-MailRajuNo ratings yet

- Tpi of Bobcut PDFDocument1 pageTpi of Bobcut PDFSanu RajNo ratings yet

- Crane 100T-00022 KECDocument1 pageCrane 100T-00022 KECRajuNo ratings yet

- ST-6293-02 Mobile Crane 50.5 TonDocument14 pagesST-6293-02 Mobile Crane 50.5 TonMohammed HamzaNo ratings yet

- Zoomlion 80 Ton - 011Document2 pagesZoomlion 80 Ton - 011Susil Kumar SahooNo ratings yet

- Isolat orDocument2 pagesIsolat orchin46No ratings yet

- TC 000104 - VSL MadhavaramDocument1 pageTC 000104 - VSL MadhavaramMK BALANo ratings yet

- BBC Tech Associates: E-MailDocument5 pagesBBC Tech Associates: E-MailRajuNo ratings yet

- Level TransmitterDocument3 pagesLevel TransmitterMohd A IshakNo ratings yet

- Form - 11 E450AJ Boom Lift - 300092303Document1 pageForm - 11 E450AJ Boom Lift - 300092303Arif KhanNo ratings yet

- Ul 1283 Bulletin 2015Document8 pagesUl 1283 Bulletin 2015Mboriko MwashaNo ratings yet

- 0172 Motorized Gondola (GB2)Document2 pages0172 Motorized Gondola (GB2)polaris projectNo ratings yet

- Screenshot 2021-09-27 at 9.43.50 PMDocument3 pagesScreenshot 2021-09-27 at 9.43.50 PMhqc8pmcfsjNo ratings yet

- Certificate of Avion GroupDocument2 pagesCertificate of Avion GroupAmit BhattNo ratings yet

- 26-1 E.O.T CraneDocument3 pages26-1 E.O.T CraneAkhilNo ratings yet

- Pipelineman No.2876Document3 pagesPipelineman No.2876Hussein HishamNo ratings yet

- Ei Call TRDocument1 pageEi Call TRXyz AvmcNo ratings yet

- 02-Side Boom-Tec00548Document2 pages02-Side Boom-Tec00548Mujahid AyyubNo ratings yet

- 41-1220 S & Y Crane ServicesDocument1 page41-1220 S & Y Crane Servicessamisaeed300No ratings yet

- Box Up All Lighting CircuitDocument2 pagesBox Up All Lighting CircuitHafiz YunusNo ratings yet

- 001 - 250 Ton Crawler Crane ReportDocument1 page001 - 250 Ton Crawler Crane ReportA.K.M. Shabbir AhmmedNo ratings yet

- Adobe Scan 27-Jan-2024Document3 pagesAdobe Scan 27-Jan-2024kardinyendu100% (1)

- Auto Buff PM Check ListDocument1 pageAuto Buff PM Check ListPiyush VyasNo ratings yet

- Beam Clamp 25-05-2022Document21 pagesBeam Clamp 25-05-2022dele jimohNo ratings yet

- Denny Street Propeties LTD C/o David Wilson 1st Floor Lesley Studios 32-36 May Street Belfast County Antrim Northern Ireland Bt1 4NzDocument5 pagesDenny Street Propeties LTD C/o David Wilson 1st Floor Lesley Studios 32-36 May Street Belfast County Antrim Northern Ireland Bt1 4NztitsNo ratings yet

- Construction Check Sheet E-008A: Electrical LV Starters, Fuse Switch / Isolators & FeederDocument2 pagesConstruction Check Sheet E-008A: Electrical LV Starters, Fuse Switch / Isolators & FeederhrimklimNo ratings yet

- "Pipal B-14, Jivanvihar, Telibandha: Factory ManagerDocument2 pages"Pipal B-14, Jivanvihar, Telibandha: Factory ManagerNiranjan KumarNo ratings yet

- HT CableDocument3 pagesHT Cablejalaj bisenNo ratings yet

- Ns2-Dh01-P0zen-140008 - Itp For Communication & Security CCTV System - Rev.0Document6 pagesNs2-Dh01-P0zen-140008 - Itp For Communication & Security CCTV System - Rev.0Anh VàngNo ratings yet

- Level TransmitterDocument3 pagesLevel TransmitterMohd A IshakNo ratings yet

- Product Manual 4250Document8 pagesProduct Manual 4250Gopi Krishna RNo ratings yet

- 7CP Tensioner TestDocument5 pages7CP Tensioner Testatifali729No ratings yet

- Chainpully Block 3 Ton-GOOD WILL ENGGDocument1 pageChainpully Block 3 Ton-GOOD WILL ENGGLingam sasthaNo ratings yet

- 14.03.2024 MM Handler F-15Document1 page14.03.2024 MM Handler F-15Susil Kumar SahooNo ratings yet

- Farana 15 T PTCL DolviDocument2 pagesFarana 15 T PTCL DolviAmjad PathanNo ratings yet

- 150m Winch-Test ReportDocument20 pages150m Winch-Test Reportx yNo ratings yet

- Operation Patrol Checklist - CIP IIDocument5 pagesOperation Patrol Checklist - CIP IIJaime Hiquiana Jr.No ratings yet

- Spreader Beam-02Document1 pageSpreader Beam-02Moustafa AshrafNo ratings yet

- Ccr4 Bus Pt1Document2 pagesCcr4 Bus Pt1Neeraj SinghNo ratings yet

- Generic EICRDocument6 pagesGeneric EICRKuljinder VirdiNo ratings yet

- Ccr4 Bus Pt2Document2 pagesCcr4 Bus Pt2Neeraj SinghNo ratings yet

- Annexure To Start-Up & Commissioning of Fire Water PumpsDocument5 pagesAnnexure To Start-Up & Commissioning of Fire Water PumpsMina KhalilNo ratings yet

- 410 CTDocument2 pages410 CTSARAVANAN ANo ratings yet

- Plugs and Socket-Outlets For Household and Similar Purposes of Rated Voltage Upto and Including 250 V and Rated Current Upto and Including 16 ADocument12 pagesPlugs and Socket-Outlets For Household and Similar Purposes of Rated Voltage Upto and Including 250 V and Rated Current Upto and Including 16 AManav SinghalNo ratings yet

- TPI Certificate - RGB ExteriorsDocument1 pageTPI Certificate - RGB ExteriorsMohammad ArifNo ratings yet

- Safety DoccumentsDocument3 pagesSafety Doccumentsbboneyt1No ratings yet

- MFT NotesDocument4 pagesMFT Notesbboneyt1No ratings yet

- Sridhar BeheraDocument4 pagesSridhar Beherabboneyt1No ratings yet

- HcjcifiggiDocument27 pagesHcjcifiggibboneyt1No ratings yet

- Citizen Housing MapDocument2 pagesCitizen Housing MapSaqib HussainNo ratings yet

- Saturation Flow and Delay Study - ManualDocument5 pagesSaturation Flow and Delay Study - ManualDR LuotanNo ratings yet

- MyCESMM2 Class R - Roads & PavingsDocument8 pagesMyCESMM2 Class R - Roads & Pavings01 liewNo ratings yet

- Versión 09-08-2023Document20 pagesVersión 09-08-2023John Robinson Carvajal AcuñaNo ratings yet

- Capital Markets Day Presentation July 2022Document180 pagesCapital Markets Day Presentation July 2022cabralherreraNo ratings yet

- The New Actros 4x2 Tractor Head Range.: Everyone Talks, One DeliversDocument8 pagesThe New Actros 4x2 Tractor Head Range.: Everyone Talks, One DeliversЕвгений БережнойNo ratings yet

- 2022 VIN GuideDocument2 pages2022 VIN GuidemakoyNo ratings yet

- The-Tiguan-Product-Guide-october-2015Document12 pagesThe-Tiguan-Product-Guide-october-2015apostucristianNo ratings yet

- Clutch RepairDocument14 pagesClutch RepairKyaw MinAungNo ratings yet

- Introducing Electric Vehicles To Southern Africa A Systemic Innovation ApproachDocument20 pagesIntroducing Electric Vehicles To Southern Africa A Systemic Innovation Approachsiyabonga dlaminiNo ratings yet

- SWL 3210Document98 pagesSWL 3210Леонід Процик100% (1)

- A320 Checklist - TAMDocument1 pageA320 Checklist - TAMMacielNo ratings yet

- BFGoodrich Advantage Control Tires For All-SeasonDocument1 pageBFGoodrich Advantage Control Tires For All-SeasonMayra RodriguezNo ratings yet

- K40:8 ConfigDocument3 pagesK40:8 ConfigbokimendemNo ratings yet

- TransmissionDocument5,587 pagesTransmissionFabien LegayNo ratings yet

- Atmospheric Environment: Rahul Goel, Sarath K. GuttikundaDocument13 pagesAtmospheric Environment: Rahul Goel, Sarath K. GuttikundaBandish PatelNo ratings yet

- 3AR-3 Dela-Torre Renzz-Irvin Q. Research ReportDocument149 pages3AR-3 Dela-Torre Renzz-Irvin Q. Research ReportRDT 17No ratings yet

- Commander 750 875 1200 ManualDocument80 pagesCommander 750 875 1200 ManualCoco BangoNo ratings yet

- Manila - Cavite Toll Expressway Project (Cavitex) : VAT Inclusive Toll FeesDocument6 pagesManila - Cavite Toll Expressway Project (Cavitex) : VAT Inclusive Toll FeesChoy De VillaNo ratings yet

- Lubchart 2013Document1 pageLubchart 2013JUANNo ratings yet

- TOWN PLANNING TerminologiesDocument34 pagesTOWN PLANNING TerminologiesRiya Mehta0% (1)

- Buddh International Circuit Thesis ReportDocument44 pagesBuddh International Circuit Thesis Reportzakaria MohamedNo ratings yet

- Triplex (Triple Full Free Panoramic) Mast (5M15D To 5M35D) : Structure and FunctionDocument2 pagesTriplex (Triple Full Free Panoramic) Mast (5M15D To 5M35D) : Structure and FunctionMaz Ariez EkaNo ratings yet

- Cycling Safety ReportDocument44 pagesCycling Safety ReportoeskaerNo ratings yet