Professional Documents

Culture Documents

TECHNICAL SPECIFICATION - POWER FRC CABLE-Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022

Uploaded by

nnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TECHNICAL SPECIFICATION - POWER FRC CABLE-Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022

Uploaded by

nnCopyright:

Available Formats

REQ No. : Ref. No.

: LSAG-22-PD2204020

User / Customer : Hyundai Engineering Page No. : 1 of 5

Title : WP-1 LINE Project

Manufacture : LSAG Cable Indonesia

Document Title :

Technical Specification for

Fire Resistance

Power Cable

Armoured

N2XRY-FRC 0.6/1(1.2)kV

(CU/MICA/XLPE/PVC/SWA/PVC-FR)

0 28 Jul 2022 Original Issue Reza S.M Teguh S W.Y Jung

Rev. No. Date Descriptions Prepared By Reviewed By Approved By

1. SCOPE

1.1. This specification covers fire resistance Power Cable with Rated Voltage 0.6/1(1.2) kV.

The standard or specification referred shall be the latest issue as of the date of award of

the purchase order

1.2. The types of power cable included in this specification :

Cable description Cable type

0.6/1(1.2) kV Fire Resistance Power

Cable

N2XRY-FRC 0.6/1(1.2) kV

Copper conductor, XLPE Insulation, Steel

(CU/MICA/XLPE/PVC/SWA//PVC-FR)

Wire armour, PVC over sheathed cables

Flame Retardant Cat. C

2. REFERENCE STANDARDS

IEC 60228 : Conductors of insulated cables

SNI IEC 60502-1 : Power cables with extruded insulation and their accessories for rated

voltages from 1 kV (Um = 1,2 kV) up to 30 kV (Um = 36 kV) - Part 1: Cables

for rated voltages from 1 kV (Um = 1,2 kV) up to 3 kV (Um = 3,6 kV)

IEC 60811 : Common test methods for insulating and sheathing materials of electric

cables

IEC 60332-3-24 : Test on electric and optical fibre cables under fire conditions (Cat.C)

IEC 60331-21 : Tests for electric cables under fire conditions - Circuit integrity - Part 21:

Procedures and requirements - Cables of rated voltage up to and including

0,6/1,0 kV

SNI 0225 : 2011 : Persyaratan Umum Instalasi Listrik 2011

3. CONSTRUCTION AND MATERIAL

3.1. Conductor

The conductor shall be the plain annealed copper conductor complying with IEC 60228

(Class 2). The shape of conductor shall be round stranded for size under 16 sqmm,

compacted circular stranded for size 16 sqmm and above.

3.2. Fire Proof Layer

The fireproof layer shall be consisted of mica/glass tape or mica laminated plastic film

tape. The layer shall be applied between the conductor and insulation.

3.3. Insulation

The insulation shall be extruded layer of cross-linked polyethylene (XLPE) compound

complying with SNI IEC 60502-1.

The minimum thickness at any point shall not fall below 90% of the nominal value by more

than 0.1 mm.

TECHNICAL SPECIFICATION_FIRE RESISTANCE LV POWER CABLE 2 of 6

3.4. Laying-up and fillers

The cores shall be laid up together and suitable direction. Where necessary, non

hygroscopic filler may be used to give the completed cable suitable circular cross-section.

The filler shall consist of an extruded layer of black flame retardant PVC compound and

PP Yarn in the layer filler.

3.5. Inner sheath / Separation Sheath

The inner sheath shall be an extruded layer of black PVC complying with SNI IEC 60502-

1.

The minimum thickness at any point shall not fall below the value given in the attached 1

till 5. by more than 20% + 0.2mm

3.6. Armoured

The armoured type of cable covered use galvanized steel round wire armour (SWA) for

multicore cable.

3.7. Outer sheath

The outer sheath shall be an extruded layer of Orange PVC Flame Retardant compound.

Complying with SNI IEC 60502-1 (Rated Voltage 0.6/1(1.2) kV).

The minimum thickness at any point shall not fall below the value given in the attached 1

till 5. by more than 20% + 0.1mm

4. CORE IDENTIFICATION

Each core of cable shall be identified by color :

- 3 cores : Brown – Black - Grey

5. TEST

The test shall be carried out in accordance with SNI IEC 60502-1 & IEC 60331-21. For detail

test will be info in Inspection Test Plan (ITP) document.

6. MARKING

6.1. Cable Marking

The following legend shall be printed on the surface of over sheath throughout the length

of cable (e.g) :

Ref. standard no. : e.g. SNI IEC 60502-1

Brand name : e.g. LSAG

Cable type : e.g. CU/MICA/XLPE/PVC/SWA/PVC-FR

Fire resistance grade : e.g. FRC 750

Common Indonesian cable type : e.g. (N2XRY-FRC)

Nos. of core & Conductor size : e.g. 3 x 16 mm2

Rated voltage : e.g. 0.6/1(1.2) kV

Year of manufacture

Length marking per meter

ex) SNI IEC 60502-1 LSAG CU/MICA/XLPE/PVC/SWA/PVC FR FRC 750 (N2XRY-FRC) 3 x 16 mm2

0.6/1(1.2) kV 2022 0001M

TECHNICAL SPECIFICATION_FIRE RESISTANCE LV POWER CABLE 3 of 6

6.2. Drum Marking

The Following information shall be marked.

Rated voltage and cable type

Nos. of core and conductor size

Cable length

Net weight

Gross weight

Direction of rotation

End position of cable

Manufacturer’s name

Year of manufacture

Drum Number

7. PACKING

The completed cables shall be supplied a non-returnable wooden drum to prevent from

damage during the transportations.

The end of cable shall be sealed to prevent the ingress of moisture.

The diameter of wooden drum shall be complied manufacturer’s standard.

TECHNICAL SPECIFICATION_FIRE RESISTANCE LV POWER CABLE 4 of 6

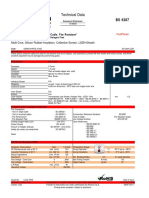

Attached 1 : Technical Data and Drawing Armoured Fire Resistance Power Cable

N2XRY-FRC (CU/MICA/XLPE/PVC/SWAPVC-FR) 0.6/1(1.2) kV Two Core

Current-Carrying

Conductor Thickness DC Short

Thickness Weight Capacity

Nominal of Overal Resistance circuit

Cross- of of

Outside Over Diameter at current

sectional No. of Insulation Cable in air in

Diamete Sheath 20oC at 1 sec

Area Wire at ground

r 300C at 200C

(min) Approx. (nom.) (nom.) Approx. Approx. Max. Max. Max. Max.

2

mm - mm mm mm mm kg/km (W/km) (A) (A) (kA)

4 7 2.5 0.7 1.8 19.0 655 4.61 45 43 0.57

6 7 3.0 0.7 1.8 20.0 752 3.08 58 53 0.86

10 7 4.0 0.7 1.8 22.0 924 1.83 69 80 1.43

16 6 5.0 0.7 1.8 24.0 1230 1.15 91 107 2.29

25 6 6.0 0.9 1.8 27.5 1619 0.727 119 138 3.58

35 6 7.0 0.9 1.8 30.0 1933 0.524 148 171 5.01

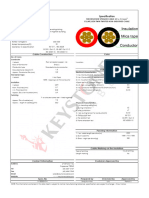

N2XRY-FRC (CU/MICA/XLPE/PVC/SWAPVC-FR) 0.6/1(1.2) kV Three Core

Current-Carrying

Conductor Thickness DC Short

Thickness Weight Capacity

Nominal of Overal Resistance circuit

Cross- of of

Outside Over Diameter at current

sectional No. of Insulation Cable in air in

Diamete Sheath 20oC at 1 sec

Area Wire at ground

r 300C at 200C

(min) Approx. (nom.) (nom.) Approx. Approx. Max. Max. Max. Max.

2

mm - mm mm mm mm kg/km (W/km) (A) (A) (kA)

10 7 4.0 0.7 1.8 22.5 995 1.83 71 58 1.43

16 6 5.0 0.7 1.8 24.0 1,330 1.15 96 75 2.29

25 6 6.0 0.9 1.8 27.5 1,769 0.727 119 96 3.58

35 6 7.0 0.9 1.8 30.0 2,171 0.524 147 115 5.01

TECHNICAL SPECIFICATION_FIRE RESISTANCE LV POWER CABLE 5 of 6

VOLTAGE 0.6/1(1.2)kV NO. OF CORE 2 - 3 Cores CONDUCTOR SIZE 10-35 sqmm

ITEM DESCRIPTION DETAILS

1 Conductor Annealed copper stranded conductor

2 Conductor Wrapping Mica Tape

3 Insulation Extruded XLPE compound

4 Inner Sheath Extruded Black PVC FR Cat. C compound

5 Armour Galvanized steel round wire

*6 Binder Non metallic tape

7 Over Sheath Extruded Black PVC FR Cat. C compound

REMARK : * - Suitable non metallic tape may be applied on armour as a binder

TECHNICAL SPECIFICATION_FIRE RESISTANCE LV POWER CABLE 6 of 6

You might also like

- Technical Specification - LV Control Cable - WP4Document10 pagesTechnical Specification - LV Control Cable - WP4nnNo ratings yet

- TECHNICAL SPECIFICATION - LV CONTROL CABLE - Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022Document9 pagesTECHNICAL SPECIFICATION - LV CONTROL CABLE - Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022nnNo ratings yet

- Technical Specification - Special Screen Cable - WP4Document7 pagesTechnical Specification - Special Screen Cable - WP4nnNo ratings yet

- Technical Specification - Power Cable - WP4Document15 pagesTechnical Specification - Power Cable - WP4nnNo ratings yet

- TECHNICAL SPECIFICATION - INSTRUMENT & CONTROL CABLE-Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022Document9 pagesTECHNICAL SPECIFICATION - INSTRUMENT & CONTROL CABLE-Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022nnNo ratings yet

- TECHNICAL SPECIFICATION - LV POWER CABLE - Hyundai Engineering - WP-1 LINE Project - LSAG - 20Mar2023.Rev.5Document36 pagesTECHNICAL SPECIFICATION - LV POWER CABLE - Hyundai Engineering - WP-1 LINE Project - LSAG - 20Mar2023.Rev.5nnNo ratings yet

- TECHNICAL SPECIFICATION - LV POWER CABLE - Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022Document30 pagesTECHNICAL SPECIFICATION - LV POWER CABLE - Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022nnNo ratings yet

- Technical Specification - Instrument Cable - WP4Document7 pagesTechnical Specification - Instrument Cable - WP4nnNo ratings yet

- Technical Specification - Grounding - WP4Document6 pagesTechnical Specification - Grounding - WP4nnNo ratings yet

- BCC.23120008Document2 pagesBCC.23120008abdulkawi alasharyNo ratings yet

- TECHNICAL SPECIFICATION - INSTRUMENT & CONTROL FRC CABLE-Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022Document13 pagesTECHNICAL SPECIFICATION - INSTRUMENT & CONTROL FRC CABLE-Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022nnNo ratings yet

- Specification Instrument Cable With ArmouredDocument6 pagesSpecification Instrument Cable With ArmourednnNo ratings yet

- CablesDocument9 pagesCablesMoch ArfiandiNo ratings yet

- Iteco-010901-B (0.6 - 1KV TFR-CV Spec)Document9 pagesIteco-010901-B (0.6 - 1KV TFR-CV Spec)Kyaw ThihaNo ratings yet

- Technology Department Technical Data Sheet Low Voltage Power CableDocument2 pagesTechnology Department Technical Data Sheet Low Voltage Power CableMuhammad ShahidNo ratings yet

- ZTTSC MV Power Cables XJ10078 SPECDocument5 pagesZTTSC MV Power Cables XJ10078 SPECMarco VillalobosNo ratings yet

- Cable 3 X50Document2 pagesCable 3 X50Jalal AlbadriNo ratings yet

- BCC.12164210Document1 pageBCC.12164210abdulkawi alasharyNo ratings yet

- Technical Specification-33KV 1X500 SQ - MM XLPE CableDocument5 pagesTechnical Specification-33KV 1X500 SQ - MM XLPE Cableনাঈমুর রহমানNo ratings yet

- Tech DataDocument24 pagesTech DataJai Sam DanielNo ratings yet

- Specification: 0.6/1kV XLPE CableDocument4 pagesSpecification: 0.6/1kV XLPE CableChrysthyan HitachiNo ratings yet

- Power and Control Cable IEC 60502-1: Flame Retardant, Sunlight Resistant 90 °C / U /U 0,6/1 KVDocument3 pagesPower and Control Cable IEC 60502-1: Flame Retardant, Sunlight Resistant 90 °C / U /U 0,6/1 KVShashank SaxenaNo ratings yet

- Nexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHDocument2 pagesNexans 10px 0.75mm2 MGT Xlpe Isos LSZH Swa LSZHRijo RajanNo ratings yet

- High Voltage 2xs FL 2y A2xs FL 2y 123kv Power CableDocument3 pagesHigh Voltage 2xs FL 2y A2xs FL 2y 123kv Power CableShailendra Kumar VermaNo ratings yet

- Mgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedDocument2 pagesMgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedJason Secret100% (1)

- SC - Low Voltage Catalogue - Copper - 2020Document46 pagesSC - Low Voltage Catalogue - Copper - 2020May OngNo ratings yet

- Material Datasheets for Fire Resistant CablesDocument74 pagesMaterial Datasheets for Fire Resistant Cablesabdowais0% (1)

- SDOC 0401409 GG 01 1590 G03 CA 15 003 - Rev0 BeaconDocument1 pageSDOC 0401409 GG 01 1590 G03 CA 15 003 - Rev0 Beaconchandrahai hrangkhawlNo ratings yet

- 7A784BDocument7 pages7A784BHelar Armejo VasquezNo ratings yet

- Opgw-12b1-48 (62.7 12.7)Document9 pagesOpgw-12b1-48 (62.7 12.7)Palle YulianNo ratings yet

- ZTT OPGW 18-96689-56 Hilos Con 2 Capas - Ver.CDocument9 pagesZTT OPGW 18-96689-56 Hilos Con 2 Capas - Ver.CGiancarlos OliveraNo ratings yet

- Summary Results of North Arm Bridge Cable Model AnalysisDocument7 pagesSummary Results of North Arm Bridge Cable Model Analysisbcdavid100% (1)

- OPGWDocument18 pagesOPGWGuilhermeNo ratings yet

- Power and Control Cable IEC 60502-1: Flame Retardant, Sunlight Resistant 90 °C / U /U 0,6/1 KVDocument2 pagesPower and Control Cable IEC 60502-1: Flame Retardant, Sunlight Resistant 90 °C / U /U 0,6/1 KVShashank SaxenaNo ratings yet

- Li# 1 - 3c X 70 + 35mm2 Swa Fr-3 BahraDocument2 pagesLi# 1 - 3c X 70 + 35mm2 Swa Fr-3 BahraMuhammad ShahidNo ratings yet

- Cable Cross LayoutDocument4 pagesCable Cross LayoutWong Chung MengNo ratings yet

- 2.3 Cable de Guardia - OPGW SPEC (15-53931)Document9 pages2.3 Cable de Guardia - OPGW SPEC (15-53931)xcazor morayNo ratings yet

- 3-Low Voltage Aerial Bundle Cables (6001000V)Document11 pages3-Low Voltage Aerial Bundle Cables (6001000V)apranaguptaNo ratings yet

- T 190152Document27 pagesT 190152Mohd Izham IdrisNo ratings yet

- Technical Submittal For MV - Cable Data SheetsDocument4 pagesTechnical Submittal For MV - Cable Data SheetskhaledelgamalNo ratings yet

- Bahra Cables-Technical SheetsDocument33 pagesBahra Cables-Technical Sheetsmir sadat aliNo ratings yet

- Sc. Cl. - 001 - SAR0214HFESL-F3 (IE) CDocument1 pageSc. Cl. - 001 - SAR0214HFESL-F3 (IE) CSudarshika SumathipalaNo ratings yet

- Tech Spec For DC String CablesDocument6 pagesTech Spec For DC String CablesPaari BNo ratings yet

- 0.6 - 1 KV XLPE - LSHF (4 CORES)Document1 page0.6 - 1 KV XLPE - LSHF (4 CORES)suttichaiteamNo ratings yet

- Fire Alarm-Fir (Shield) : 2 Core (Cu/Mica Tape/PVC-FR/CAM+ATC Drain wire/PVC-FRLS)Document1 pageFire Alarm-Fir (Shield) : 2 Core (Cu/Mica Tape/PVC-FR/CAM+ATC Drain wire/PVC-FRLS)Cost RootsNo ratings yet

- Specs ZTT OPGW 24 Fibers PDFDocument9 pagesSpecs ZTT OPGW 24 Fibers PDFVictor DoyoganNo ratings yet

- Cable Specification 400kV 1200SQDocument4 pagesCable Specification 400kV 1200SQluis lopezNo ratings yet

- BCC.12103150Document1 pageBCC.12103150sashtiNo ratings yet

- SC - Low Voltage Catalogue - Aluminium - 2020Document18 pagesSC - Low Voltage Catalogue - Aluminium - 2020ooi.impacNo ratings yet

- ZTT Et Expressway Tacsr'Aw TW Conductor 22 - Xj10296Document5 pagesZTT Et Expressway Tacsr'Aw TW Conductor 22 - Xj10296Benjamin SalinasNo ratings yet

- 2 - 7714-U0gy8-HaDocument1 page2 - 7714-U0gy8-HaMohd Sami UddinNo ratings yet

- 33kv Techni8cal Specification Edited FormatDocument16 pages33kv Techni8cal Specification Edited Formatvikas kumarNo ratings yet

- 0.6 - 1 KV MICA-XLPE-LSHF CAT A MC Rev.02Document19 pages0.6 - 1 KV MICA-XLPE-LSHF CAT A MC Rev.02Supakanit LimsowanNo ratings yet

- NYCWYDocument1 pageNYCWYacarisimovicNo ratings yet

- Cable Specification 400kV AL-800SQDocument4 pagesCable Specification 400kV AL-800SQluis lopezNo ratings yet

- Keystone Fire Alarm Cables (Twisted Pair Non Sheathed)Document3 pagesKeystone Fire Alarm Cables (Twisted Pair Non Sheathed)Edwin LoquinaNo ratings yet

- 0.6/1 KV Xlpe Insulated Single Core Cables With Copper ConductorDocument1 page0.6/1 KV Xlpe Insulated Single Core Cables With Copper Conductorgari_monsantoNo ratings yet

- Bmz1Kas 1,8/3 KV - Medium Voltage Power Cable: DescriptionDocument3 pagesBmz1Kas 1,8/3 KV - Medium Voltage Power Cable: DescriptionMauricio AgudeloNo ratings yet

- 132kV XLPE Power Cable Technical SpecificationDocument6 pages132kV XLPE Power Cable Technical SpecificationA. HassanNo ratings yet

- Line WP1Document1 pageLine WP1nnNo ratings yet

- Specification Instrument Cable With ArmouredDocument6 pagesSpecification Instrument Cable With ArmourednnNo ratings yet

- Specification Instrument Cable With ArmouredDocument6 pagesSpecification Instrument Cable With ArmourednnNo ratings yet

- TECHNICAL SPECIFICATION - LV POWER CABLE - Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022Document30 pagesTECHNICAL SPECIFICATION - LV POWER CABLE - Hyundai Engineering - WP-1 LINE Project - LSAG 25NOV2022nnNo ratings yet

- Technical Specification - Instrument Cable - WP4Document7 pagesTechnical Specification - Instrument Cable - WP4nnNo ratings yet

- TECHNICAL SPECIFICATION - LV POWER CABLE - Hyundai Engineering - WP-1 LINE Project - LSAG - 20Mar2023.Rev.5Document36 pagesTECHNICAL SPECIFICATION - LV POWER CABLE - Hyundai Engineering - WP-1 LINE Project - LSAG - 20Mar2023.Rev.5nnNo ratings yet

- Technical Specification - Grounding - WP4Document6 pagesTechnical Specification - Grounding - WP4nnNo ratings yet

- Technical Specification - Instrument Cable - WP4Document7 pagesTechnical Specification - Instrument Cable - WP4nnNo ratings yet

- Physics ProjectDocument16 pagesPhysics ProjectAll about GamingNo ratings yet

- Ps10ex Pressure Switch PresostatoDocument1 pagePs10ex Pressure Switch PresostatoJULIO AREVALONo ratings yet

- Check Proportional Valve and Swash-plate Sensors MOPDocument2 pagesCheck Proportional Valve and Swash-plate Sensors MOPŞansal DikmenerNo ratings yet

- TestBlock - ETB-14Document8 pagesTestBlock - ETB-14rudyplNo ratings yet

- Panel BOQDocument3 pagesPanel BOQBavakar ScribdNo ratings yet

- O&m Part 01Document256 pagesO&m Part 01mohammadNo ratings yet

- ELECTRONIC COMPONENTS HandoutDocument22 pagesELECTRONIC COMPONENTS HandoutVineeth WilsonNo ratings yet

- Cerberr31 Manual EngDocument8 pagesCerberr31 Manual EngAdlenNo ratings yet

- Form turning - The tool is ground to shape workpieceDocument10 pagesForm turning - The tool is ground to shape workpieceJohn Paul DomingoNo ratings yet

- Hälge DriveDocument8 pagesHälge DrivesupermonzrNo ratings yet

- Test Units and Accessories: Sinteso™Document22 pagesTest Units and Accessories: Sinteso™Imad QsnNo ratings yet

- TeB1 TEB2Document4 pagesTeB1 TEB2Luiz AlmeidaNo ratings yet

- 3300 XL 11mm Proximity Transducer System Datasheet - 146256Document25 pages3300 XL 11mm Proximity Transducer System Datasheet - 146256fitasmounirNo ratings yet

- ION SA5600 Quick InstallDocument4 pagesION SA5600 Quick InstallJaeson VelascoNo ratings yet

- Worksheet - Converging LensesDocument13 pagesWorksheet - Converging LensesmwagweNo ratings yet

- Moen MotionSense FaucetDocument7 pagesMoen MotionSense FaucetTomNo ratings yet

- Cable-And Connection List, Kongsberg Maritime AS, Merchant MarineDocument6 pagesCable-And Connection List, Kongsberg Maritime AS, Merchant MarineSerhiiNo ratings yet

- PT Burden Calculations 01 PDFDocument4 pagesPT Burden Calculations 01 PDFArunava Basak100% (2)

- Linear Luminaire Fluorescent Lamp Series EXLUX 6001Document9 pagesLinear Luminaire Fluorescent Lamp Series EXLUX 6001sclim4435No ratings yet

- Pemrograman NCDocument3 pagesPemrograman NCPurwadyaziNo ratings yet

- New DV-E BrochureDocument1 pageNew DV-E BrochureKapil SharmaNo ratings yet

- Waukesha Gas Engines: GE Power Distributed PowerDocument4 pagesWaukesha Gas Engines: GE Power Distributed PowerdfmolinaNo ratings yet

- FirearmsDocument82 pagesFirearmsJuli ReyNo ratings yet

- Ericsson Minilink TN R4Document15 pagesEricsson Minilink TN R4Ebenezer AnnanNo ratings yet

- Z20 Disturbance Sensor Calculator V3.0Document1 pageZ20 Disturbance Sensor Calculator V3.0bsdygswdywNo ratings yet

- MK8 SVMOD 0002 - PeripheralsDocument48 pagesMK8 SVMOD 0002 - Peripheralswillian eduardo santiago cardenasNo ratings yet

- Samyo MPR 714Document79 pagesSamyo MPR 714Anonymous D8ay3BMJ5No ratings yet

- Diagrama Ligação Controlador de Carga C/ Função LOAD em InversorDocument3 pagesDiagrama Ligação Controlador de Carga C/ Função LOAD em InversorNikolas AugustoNo ratings yet

- METHOD FOR GROUNDING RESISTANCE TESTDocument8 pagesMETHOD FOR GROUNDING RESISTANCE TESTHân TiênNo ratings yet

- 160-170precision Machining TechnologyDocument11 pages160-170precision Machining TechnologyCarlos Junior Alexander Ruiz SánchezNo ratings yet