Professional Documents

Culture Documents

Welder (Electric) Pre Mob

Uploaded by

Guruh Suprayitno0 ratings0% found this document useful (0 votes)

5 views1 pageThis inspection report is for welding equipment including wire feeders, fusion machines, and plasma cutters. It lists 29 items to check such as appearance, manuals, decals, guards, electrical components, fans, transformers, rectifiers, hoses, controls, and attachments. For each item, the inspector notes the inspection code and indicates if the item is okay or needs corrective action by referencing the item number.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis inspection report is for welding equipment including wire feeders, fusion machines, and plasma cutters. It lists 29 items to check such as appearance, manuals, decals, guards, electrical components, fans, transformers, rectifiers, hoses, controls, and attachments. For each item, the inspector notes the inspection code and indicates if the item is okay or needs corrective action by referencing the item number.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views1 pageWelder (Electric) Pre Mob

Uploaded by

Guruh SuprayitnoThis inspection report is for welding equipment including wire feeders, fusion machines, and plasma cutters. It lists 29 items to check such as appearance, manuals, decals, guards, electrical components, fans, transformers, rectifiers, hoses, controls, and attachments. For each item, the inspector notes the inspection code and indicates if the item is okay or needs corrective action by referencing the item number.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 1

WELDING EQUIPMENT IN/OUT INSPECTION REPORT, ELECTRIC POWERED

PERTAINS TO MULTI-PAC, WIRE FEEDERS, FUSION, PLASMA CUTTERS AND ATTACHMENTS WELDING EQUIPMENT

EQUIPMENT NUMBER INSPECTED BY DATE

--------------------------------------------------------------------------------------------------------------------------------------------------------

MAKE MODEL SERIAL #

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

HOUR METER LOCATION

----------------------------------------------------------------------------------------------------------------

INSPECTION INITIAL

NO. ITEM TO CHECK CODE OK COMMENTS / CORRECTIVE ACTION - REFERENCE ITEM NUMBER

1MACHINE SAFE TO OPERATE/TEST YES

2A P P E A R A N C E 1

3OPERATORS MANUAL 4, 5

4PARTS & SERVICE MANUAL 4, 5

5DECALS & LABELS 2, 3

6AMECO LOGO & EQUIPMENT # 4

7SHEET METAL & GUARDS 2, 4

8SERVICE POWER CONNECTIONS 2, 3

9WELDING LEAD CONNECTIONS 2, 3, 4

10ELECTRICAL WIRING 2, 4, 7

11ELECTRICAL COMPONENTS 3, 4

1 2COOLING FAN & CONTROLS 4, 5, 6

13AUX. POWER CONNECTIONS 2, 3

1 4TRANSFORMERS 4, 5

1 5RECTIFIERS 4, 5

1 6REMOTE CONNECTIONS 2, 3, 4

17TORCH ASSEMBLY 2, 3, 5,8

18AIR/GAS CONNECTIONS 2, 3, 4,8

19AIR/GAS REGULATORS, GAUGE 1,2,3,4,7,9

2 0TORCH COOLING SYSTEM 8,9,10

2 1HOSES & LINES 2, 3, 4, 7, 8

22CONTROLS 2, 4, 5

23FUNCTION CHECK OUT 9

24

LIST ATTACHMENTS

25

26

27

28

29

DESCRIBE SPECIAL CONFIGURATION

INSPECTION REFERENCE CODES

1. PAINT, RUST, STAINS, CLEANLINESS 5. FLUID LEVEL 9. OPERATION

2, ADJUSTMENT 6. INSTALLATION 10. TORQUE PROPERLY

3. CONTAMINATION 7. LEAKS 11. SERVICE PER MANUFACTURER

4. CRACKED, BENT, BROKEN 8. LUBRICATION 12. WEAR, FRAYED, CUT

You might also like

- Weld Engine (Driven) Pre MobDocument1 pageWeld Engine (Driven) Pre MobGuruh SuprayitnoNo ratings yet

- Trailer Pre MobDocument1 pageTrailer Pre MobGuruh SuprayitnoNo ratings yet

- Hydraulic Crane Pre MobDocument1 pageHydraulic Crane Pre MobGuruh SuprayitnoNo ratings yet

- Rayburn 400K PF InstalDocument28 pagesRayburn 400K PF InstalJordan Wolfgang RobineauNo ratings yet

- GE Power Management: Bus Bar Protection Bus Bar Protection Bus Bar Protection Bus Bar ProtectionDocument129 pagesGE Power Management: Bus Bar Protection Bus Bar Protection Bus Bar Protection Bus Bar Protectionprashant jindalNo ratings yet

- Cuu4 IsidgidDocument60 pagesCuu4 Isidgidadielev2No ratings yet

- Compresor Sullair ES-8-15-30HP-02250117-368Document86 pagesCompresor Sullair ES-8-15-30HP-02250117-368pabloNo ratings yet

- Re 2100Document186 pagesRe 2100Lucas BarriosNo ratings yet

- Em 474 N 09 02 Cincinnati CL 7a Laser System With PC Control Operation Safety and Maintenance ManualDocument149 pagesEm 474 N 09 02 Cincinnati CL 7a Laser System With PC Control Operation Safety and Maintenance ManualManolo MedranoNo ratings yet

- Electrical System PDFDocument95 pagesElectrical System PDFmohamed eissaNo ratings yet

- Dokumen - Tips - Sullair Supervisor Controller Manual 02250146 049Document32 pagesDokumen - Tips - Sullair Supervisor Controller Manual 02250146 049zernnNo ratings yet

- ls10 30,40 PDFDocument105 pagesls10 30,40 PDFJohnny Martinez100% (1)

- Air Compressor Industrial: Preliminary Copy 2006Document80 pagesAir Compressor Industrial: Preliminary Copy 2006taufik100% (1)

- ls10 25hpDocument90 pagesls10 25hpasperfudNo ratings yet

- SUZUKI - DF25 - DF250 - Small RiggingDocument110 pagesSUZUKI - DF25 - DF250 - Small RiggingJohn PatistasNo ratings yet

- OM Manual As Built PDFDocument379 pagesOM Manual As Built PDFBar AvaitNo ratings yet

- Lambda Emi: Instruction Manual ForDocument66 pagesLambda Emi: Instruction Manual ForAntonio Carlos CardosoNo ratings yet

- RAS Multibend 9000 Folding Machine Safety & Operation InstructionsDocument263 pagesRAS Multibend 9000 Folding Machine Safety & Operation InstructionscasperksnNo ratings yet

- Au5 Online Operating ManualDocument303 pagesAu5 Online Operating ManualAjesh Babu100% (1)

- DCR Pc10eDocument181 pagesDCR Pc10ekupivipNo ratings yet

- Rotary Screw Air Compressor Es-11Document98 pagesRotary Screw Air Compressor Es-11luisedonossa100% (1)

- Mec 2 Microprocesador ThomsonDocument90 pagesMec 2 Microprocesador ThomsonNubia ArizaNo ratings yet

- Construction Check Sheet E-008A: Electrical LV Starters, Fuse Switch / Isolators & FeederDocument2 pagesConstruction Check Sheet E-008A: Electrical LV Starters, Fuse Switch / Isolators & FeederhrimklimNo ratings yet

- Sullair Industrial Air Compressor TS-20 V200TSDocument64 pagesSullair Industrial Air Compressor TS-20 V200TScolinatorNo ratings yet

- Laz 5000 ElacDocument75 pagesLaz 5000 ElacMorseNo ratings yet

- Site Acceptance Test (SAT) Protocol: Project No. 2205 100 GPM Amine Sweetening Unit PlantDocument28 pagesSite Acceptance Test (SAT) Protocol: Project No. 2205 100 GPM Amine Sweetening Unit PlantIsaias de la CruzNo ratings yet

- KAVR Series - Manual PDFDocument214 pagesKAVR Series - Manual PDFtunghtdNo ratings yet

- KebDocument96 pagesKebEdis TursunovicNo ratings yet

- Es Au5t 1a348 Aa - 071030Document29 pagesEs Au5t 1a348 Aa - 071030chaivatNo ratings yet

- Installation Instruction & Maintenance Service Manual: Full Automatic Blood Cell CounterDocument78 pagesInstallation Instruction & Maintenance Service Manual: Full Automatic Blood Cell CounterevgenyNo ratings yet

- 58 TocDocument9 pages58 TocHuyNo ratings yet

- Air Assist CompressorDocument58 pagesAir Assist CompressorfoamtrailerNo ratings yet

- LS20S 02250115-257Document102 pagesLS20S 02250115-257sledhead47No ratings yet

- Avon UTC 1535c12Document31 pagesAvon UTC 1535c12juanaNo ratings yet

- Pid00a - 10 5715-616 UkDocument44 pagesPid00a - 10 5715-616 Uksmni00957No ratings yet

- Sx-Ca5xx Om 1999 PDFDocument327 pagesSx-Ca5xx Om 1999 PDFTNo ratings yet

- 019 HSC ManualDocument29 pages019 HSC ManualMarvin DuarteNo ratings yet

- Rapidtorc User Manual A5Document16 pagesRapidtorc User Manual A5Manish MohananNo ratings yet

- Instruction Manual: Bar Feeding SystemsDocument118 pagesInstruction Manual: Bar Feeding SystemsOmarAlirioSuarezCañareteNo ratings yet

- LX Wbvl65 DSPDocument61 pagesLX Wbvl65 DSPAlejandro DelgadoNo ratings yet

- Bur 87634755NA - J.C.M. 1150K Tier 3 (ENG) PDFDocument64 pagesBur 87634755NA - J.C.M. 1150K Tier 3 (ENG) PDFRicardo BilbaoNo ratings yet

- Salamandra de Pellet: Manual de Utilizador E de InstaladorDocument56 pagesSalamandra de Pellet: Manual de Utilizador E de InstaladorBeatriz Galharda de LavosNo ratings yet

- C and R PanelDocument91 pagesC and R PanelMere Thakur JiNo ratings yet

- Manual-Sullair LS-25SDocument104 pagesManual-Sullair LS-25Switsanu trachaiNo ratings yet

- Dokumen - Tips 45811151 Manual de Mantenimiento Sullair 185Document132 pagesDokumen - Tips 45811151 Manual de Mantenimiento Sullair 185guerrero1587No ratings yet

- Kxtda 600 BXDocument133 pagesKxtda 600 BXNguyen Thanh NamNo ratings yet

- ls12 PDFDocument112 pagesls12 PDFKhedr HamoudNo ratings yet

- Perkin-Elmer M83-Series. Model 8-32 Processor. Customer Installation Manual (29-526R02) May 1978Document26 pagesPerkin-Elmer M83-Series. Model 8-32 Processor. Customer Installation Manual (29-526R02) May 1978Lenina Viktoriya TeknyetovaNo ratings yet

- ICA 006 30 Revision 4 PDFDocument71 pagesICA 006 30 Revision 4 PDFtoraj mirahmadiNo ratings yet

- Manual Compresor Sullair PDFDocument68 pagesManual Compresor Sullair PDFKevin J. Peña CabarcasNo ratings yet

- Transfer Switch Controller: Software Version 1.7Document52 pagesTransfer Switch Controller: Software Version 1.7powermanagerNo ratings yet

- LS-20S - SullairDocument102 pagesLS-20S - SullairWalter CarmonaNo ratings yet

- 3.5 110318 R11-833 Rev 2Document102 pages3.5 110318 R11-833 Rev 2JSF315No ratings yet

- Installation Instruction & Maintenance Service Manual: Full Automatic Blood Cell CounterDocument80 pagesInstallation Instruction & Maintenance Service Manual: Full Automatic Blood Cell CounterassiaNo ratings yet

- 85 EA E 78035 - 00 Control RoomDocument31 pages85 EA E 78035 - 00 Control RoomAdetunji TaiwoNo ratings yet

- 1200531-01 PROFINET PxE 900 Rev.02 Manual enDocument92 pages1200531-01 PROFINET PxE 900 Rev.02 Manual enGustavo CarvalhoNo ratings yet

- Terrameter SAS 1000Document148 pagesTerrameter SAS 1000canahicordovasalazarNo ratings yet

- Communications: Navigation Echosounder LAZ 5100Document79 pagesCommunications: Navigation Echosounder LAZ 5100Parul MehtaNo ratings yet

- Token Ring Technology ReportFrom EverandToken Ring Technology ReportNo ratings yet

- TF Roof Access PermitDocument1 pageTF Roof Access PermitGuruh SuprayitnoNo ratings yet

- TF - Use of Suspended ManbasketsDocument9 pagesTF - Use of Suspended ManbasketsGuruh SuprayitnoNo ratings yet

- 0107 DART MIER ReportDocument2 pages0107 DART MIER ReportGuruh SuprayitnoNo ratings yet

- Excavating Fibrous MaterialsDocument7 pagesExcavating Fibrous MaterialsGuruh SuprayitnoNo ratings yet

- TF Scaffolding ProcedureDocument11 pagesTF Scaffolding ProcedureGuruh SuprayitnoNo ratings yet

- Vision Screening ProcessDocument1 pageVision Screening ProcessGuruh SuprayitnoNo ratings yet

- High Pressure Water Cleaning (HPWC) Procedure Typical HPWC Lancing ArrangementDocument1 pageHigh Pressure Water Cleaning (HPWC) Procedure Typical HPWC Lancing ArrangementGuruh SuprayitnoNo ratings yet

- JLG 800a 800aj PM 2011 1Document454 pagesJLG 800a 800aj PM 2011 1Guruh SuprayitnoNo ratings yet

- Part & Consumable ReportDocument6 pagesPart & Consumable ReportGuruh SuprayitnoNo ratings yet

- Service PERIODE JUL-AUG PT. FreeportDocument2 pagesService PERIODE JUL-AUG PT. FreeportGuruh SuprayitnoNo ratings yet

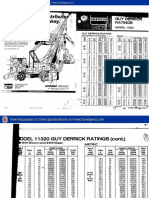

- American 11320 With MastDocument4 pagesAmerican 11320 With MastGuruh SuprayitnoNo ratings yet

- Scope of Work MechanicDocument4 pagesScope of Work MechanicGuruh SuprayitnoNo ratings yet

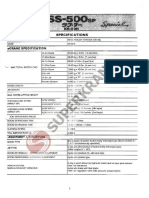

- Kato 50T SS500SP (50t)Document7 pagesKato 50T SS500SP (50t)Guruh SuprayitnoNo ratings yet

- Scissorlift Skyjack8mSJ3226Document2 pagesScissorlift Skyjack8mSJ3226Guruh SuprayitnoNo ratings yet

- Installation Manual: Generator SetDocument86 pagesInstallation Manual: Generator SetAdrián Darío Nieves LeyvaNo ratings yet

- VFD-B - Manual de Variador de Frecuencia Extactor de Gases PDFDocument239 pagesVFD-B - Manual de Variador de Frecuencia Extactor de Gases PDFAlejandro Jose Arguedas JaramilloNo ratings yet

- Seating Plan For PH.D Students During Mid Semester (Odd) Exam 2018-19Document6 pagesSeating Plan For PH.D Students During Mid Semester (Odd) Exam 2018-19Aakash PathakNo ratings yet

- MODEL NO.: M185B1-P01: TFT LCD Approval SpecificationDocument25 pagesMODEL NO.: M185B1-P01: TFT LCD Approval Specificationcesar calderonNo ratings yet

- ZJ Audio Systems 8F - 1Document16 pagesZJ Audio Systems 8F - 1Dalton WiseNo ratings yet

- Part1 Chapter2 FAB and Photolithography EE3165 EE3425 EE4051Document52 pagesPart1 Chapter2 FAB and Photolithography EE3165 EE3425 EE4051Minh Phan QuangNo ratings yet

- 3.1. OmniStudio Work With Child FlexCardsDocument18 pages3.1. OmniStudio Work With Child FlexCardsAmol ManeNo ratings yet

- NMPED License New Guide EditedDocument10 pagesNMPED License New Guide EditedVashnadze EDNo ratings yet

- Introduction To Iso 55000 Asset ManagementDocument25 pagesIntroduction To Iso 55000 Asset ManagementAndreja Zelenković100% (4)

- 01 Ngx-Manual en PDFDocument5 pages01 Ngx-Manual en PDFzhyhhNo ratings yet

- Smart Home Energy Management System Using GSMDocument5 pagesSmart Home Energy Management System Using GSMDat NguyenNo ratings yet

- CountersDocument10 pagesCountersS KaranNo ratings yet

- Cost Reduction Through Industrialization, Standardization and SimplificationDocument16 pagesCost Reduction Through Industrialization, Standardization and SimplificationRoo FaNo ratings yet

- Output LogDocument14 pagesOutput LogAndy VictorNo ratings yet

- Empowerment TechnologyDocument14 pagesEmpowerment TechnologyRIZA SAMPAGANo ratings yet

- Epoca: User ManualDocument18 pagesEpoca: User ManualAntonio FavuzziNo ratings yet

- General Specifications - YTA110 Temperature Transmitter HART Communication PDFDocument2 pagesGeneral Specifications - YTA110 Temperature Transmitter HART Communication PDFcbaliveNo ratings yet

- COBIT An IT Governance Tool For The CIO and CEODocument4 pagesCOBIT An IT Governance Tool For The CIO and CEOmtal232No ratings yet

- Lesson 14:: "The Software As An Educational Resource" ExperienceDocument6 pagesLesson 14:: "The Software As An Educational Resource" ExperienceJackie DumaguitNo ratings yet

- BCAROY271221Document2 pagesBCAROY271221roy kristianto100% (1)

- ERF EC8 EC 8.28 (6X4/8X4) : Normal ModerateDocument4 pagesERF EC8 EC 8.28 (6X4/8X4) : Normal Moderateعبدالغني القباطيNo ratings yet

- Electrical Machine Drives: Dr. Arsalan ArifDocument10 pagesElectrical Machine Drives: Dr. Arsalan ArifFaraz AhmadNo ratings yet

- SOP - MassEdit For NIOS 6.8.6Document12 pagesSOP - MassEdit For NIOS 6.8.6Fahmi YasserNo ratings yet

- Windows Server 2012: Active Directory Domain ServicesDocument42 pagesWindows Server 2012: Active Directory Domain ServicesAbdul KasimNo ratings yet

- ND PBT 1028 1155 1158Document38 pagesND PBT 1028 1155 1158wannur amirahNo ratings yet

- Windows Server 2012 R2 Server Virtualization White PaperDocument116 pagesWindows Server 2012 R2 Server Virtualization White PapergubdaNo ratings yet

- Geh 6777Document94 pagesGeh 6777Lyman ConnorNo ratings yet

- Working With COBOL SourceDocument3 pagesWorking With COBOL Sourceramakantshankar4869No ratings yet

- Happy VPN SymbianizersDocument5 pagesHappy VPN SymbianizersjamesoverosNo ratings yet