Professional Documents

Culture Documents

000 MDR 0001

Uploaded by

Andreas NugrahaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

000 MDR 0001

Uploaded by

Andreas NugrahaCopyright:

Available Formats

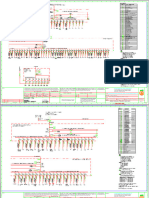

6000

500 1250 1250 1250 1250

12 Fix supports Sliding supports Sliding supports Sliding supports Sliding supports

N2

152

9

13

152

13

152

13

13

152

11

9

152

N2

3

1 10 1 2

300 X

N3

DETAIL - X

1:1

12

DRAFT

150

4

(124)

MR

GENERAL NOTES

1. Spare parts: for each flange mounted on the unit following materials are to be

8 supplied as spare parts: N° 2 gaskets and 10% of bolts with a min. of 2 pieces.

5 2. All nozzles shall be protected with wood plates before shipping.

Rev.: Date.: Description: Des.: Che.: Appr.: Rel.:

3. The dimensions are referred to outer surfaces unless otherwise stated.

DESIGNER

4. The external supports are specified by Manufacturer.

5. The maximum loads on nozzles as presented are estimated preliminary loads

exerted from connected piping. These are To Be Confirmed (TBC) later.

6. Lifting/transportation possibilites shall be determined by Manufacturer.

This drawing is the property of MANNVIT Ltd.and all rights of use and reproduction are reserved.

Design code ASME B31.1 Power Piping

6 7 N3 Two-phase flow rate kg/s 2 RADIOGRAPHY / OTHER N.D.T. accot.satndard

Minimum temperature °C 0 NDT testing group accot.satndard

DESIGN: TH/VHA DRAWN: VHA RELEASED:

Mech. design temperature °C 250 Corrosion allowance mm 2 CHECKED: APPROVED: DATE: 23.07.2020

Operating temperature °C 225 Empty weight kg 70

Minimum pressure bar(g) 0 Operating weight kg N/A * Diameter of the hole on tantalum injection quill shall be determined on site.

Design pressure bar(g) 35 Full water weight kg 150

13 4 Long radius return ASME B16.9 Gr. WPB ASTM A234 NPS 2" / Sch. 40

Operating pressure bar(g) 24,7 Grossvoulme L N/A

12 4 Seamless pipe ASME B36.10M Gr. B ASTM A106 NPS 2" / Sch. 40

Hydrostatic test pressure (PT) bar(g) 52,5 STEAM/BRINE

Contained fluid 11 8 Stud bolt with nuts ASME B18.2.1 / ASME B1.1 Gr. B8 / 8 ASTM A193 / A194 5/8" x 110mm

Joint efficiency 1 CONDENSATE

10 1 Spiral wound gasket ASME B16.20 PTFE / Hastelloy C NPS 2" / Class 300

Description Unit Value Description Unit Value

Z 9 2 Weld neck flange ASME B16.5 ASTM A105 NPS 2" / Class 300

DESIGN DATA MZ 8 4 Stud bolt with nuts ASME B18.2.1 / ASME B1.1 Gr. B8 / 8 ASTM A193 / A194 1/2" x 90mm

Y DRAWING TITLE

FZ 7 1 Spiral wound gasket ASME B16.20 PTFE / 316L NPS 1/2" / Class 300

FY 6 2* TanatulmniejcoitnQS

-ulihanghaJa

ingxM

i eatslCo. NPS 1/4" x 150mm / Sch. 40 Pilot Plant Design and Testing – Dieng

N3 1 1/2" WN 300# R.F.40S ACID INJECTION - - - - - - MX MY 5 1 Weld neck flange ASME B16.5 Gr. F53 ASTM A182 NPS 1/2" / Class 300 Acid injection and mixing

N2 1 2" WN 300# R.F.40S STEAM OUTLET - - - - - -

FX X 4 1 Seamless pipe ASME B36.19M Gr. S32750 ASTM A790 NPS 1/2" / Sch. 40S Mixing spool

N1 1 2" WN 300# R.F.40S STEAM INLET - - - - - -

3 1 Long radius return ASME B16.9 Gr. S32750 ASTM A182 NPS 2" / Sch. 40S

Mark N° NPS Type Rating Face Sch. Service FX FY FZ MX MY MZ PROJECT NO. SCALE SIZE

2 2 Seamless pipe ASME B36.19M Gr. S32750 ASTM A790 NPS 2" / Sch. 40S 5.692.127 1:10 A1

FORCE [kN] MOMENT [kNm]

1 2 Weld neck flange ASME B16.5 Gr. F53 ASTM A182 NPS 2" / Class 300 DRAWING NO. REV. NO.

NOZZLES DATA MAXIMUM LOAD ON NOZZLES No. N° Description Material Size

C:\Mannvit\5\692\5.692.127\05\5692127-000-MDR-0001.dwg 5692127-000-MDR-0001 01

You might also like

- DC01 (STAT Table) DA01 (Reagent Refrigerator) GA01: Heat ExchangerDocument2 pagesDC01 (STAT Table) DA01 (Reagent Refrigerator) GA01: Heat ExchangerQuốc CườngNo ratings yet

- Amparito RocaDocument2 pagesAmparito RocaFERRAN VIVAS FIERREZNo ratings yet

- 2 at Grade Roof Level Lighting Layout Sheet 3: LLLLJ IDocument1 page2 at Grade Roof Level Lighting Layout Sheet 3: LLLLJ IbalabhaviniNo ratings yet

- Js200w Гидросхема с ДавлениямиDocument1 pageJs200w Гидросхема с ДавлениямиNikolay KuznetsovNo ratings yet

- Heavy Fuel Oil System (Boiler Area)Document1 pageHeavy Fuel Oil System (Boiler Area)sambhuNo ratings yet

- Anchor Bolt Detail 1Document1 pageAnchor Bolt Detail 1Julius MuhimboNo ratings yet

- 2 Carcassi Etude 2 Notes PDFDocument1 page2 Carcassi Etude 2 Notes PDFAndrew StainberhNo ratings yet

- AR02-10 - TOWER 6&7 FLOOR PLANS 5th FloorDocument1 pageAR02-10 - TOWER 6&7 FLOOR PLANS 5th FloorJay Berlin EsguerraNo ratings yet

- AR02-10 - TOWER 6&7 FLOOR PLANS 6th-18thDocument1 pageAR02-10 - TOWER 6&7 FLOOR PLANS 6th-18thJay Berlin EsguerraNo ratings yet

- Cortes Ascensor y Escalera 1Document1 pageCortes Ascensor y Escalera 1jeryNo ratings yet

- Amplificadorshamsonic-Amc-8000 221102 193809Document1 pageAmplificadorshamsonic-Amc-8000 221102 193809Claudean SoaresNo ratings yet

- Hartland: LegendDocument1 pageHartland: LegendrajatNo ratings yet

- Pos. Descripción / DescriptionDocument4 pagesPos. Descripción / DescriptionomarNo ratings yet

- Secondary Reheater CoilDocument1 pageSecondary Reheater CoilHardik MehraNo ratings yet

- Component Placing Layout Xperia Z3+ Plus E6553, E6553 PDFDocument2 pagesComponent Placing Layout Xperia Z3+ Plus E6553, E6553 PDFCelublack CkNo ratings yet

- Conn 4 Conn 34: MTR BatDocument1 pageConn 4 Conn 34: MTR BatKevinCollenNo ratings yet

- Short Score String Quartet No. 8 MVT 2 ShostakovichDocument9 pagesShort Score String Quartet No. 8 MVT 2 ShostakovichMacKenzie KNo ratings yet

- RED DE AGUA-Title BlockDocument1 pageRED DE AGUA-Title BlockAngel Luis Paredes PierolaNo ratings yet

- Chalana Chitra Nirmaata TeluguDocument12 pagesChalana Chitra Nirmaata TeluguMurali GurajalaNo ratings yet

- Lighting and Irrigation Plan - 22.04.2019Document1 pageLighting and Irrigation Plan - 22.04.2019muskanNo ratings yet

- Gre Eec D 99 Co P 10036 03 057Document9 pagesGre Eec D 99 Co P 10036 03 057Carlos GamarraNo ratings yet

- Electrical System 320 and 323 Excavator: Volume 3 of 4: CGC Volume 2 of 4: Cab Volume 1 of 4: ChassisDocument5 pagesElectrical System 320 and 323 Excavator: Volume 3 of 4: CGC Volume 2 of 4: Cab Volume 1 of 4: ChassisfalahNo ratings yet

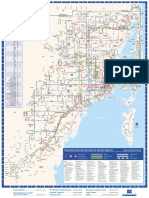

- Miami-Dade County Transit System: LegendDocument2 pagesMiami-Dade County Transit System: LegendMarcos BerlingieriNo ratings yet

- Pilar H.A.:P1 Pilar H.A.:P2: A B C D E FDocument1 pagePilar H.A.:P1 Pilar H.A.:P2: A B C D E FclaudioNo ratings yet

- Moraine State Park MapDocument1 pageMoraine State Park Mapinvading_jam7582No ratings yet

- Away From The Rain: Rubato ( 120)Document7 pagesAway From The Rain: Rubato ( 120)AlFisherGaiusCoronadoNo ratings yet

- 232B E.E.Document1 page232B E.E.Paulo FeitozaNo ratings yet

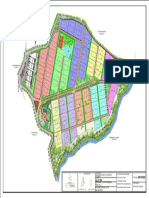

- NAINA DP Under Sec 26 A141 - 11inch - 25Document1 pageNAINA DP Under Sec 26 A141 - 11inch - 25Shailesh Thakur0% (1)

- Primer PisoDocument1 pagePrimer PisoDiegoErickNo ratings yet

- Lay Out CDocument1 pageLay Out CMuhammad FauzanNo ratings yet

- BLANCO Y AZUL Juan FaluDocument2 pagesBLANCO Y AZUL Juan FalujotaoNo ratings yet

- 10E-3 Windscreen Wiper, Washer XLRTEH4300G033850Document1 page10E-3 Windscreen Wiper, Washer XLRTEH4300G033850Miller Andres ArocaNo ratings yet

- Diamond City Lights (LazuLight) UpdatedDocument6 pagesDiamond City Lights (LazuLight) UpdatedAda AdaNo ratings yet

- Polar 37CTV3160 54CTV3160 U21AXTDocument1 pagePolar 37CTV3160 54CTV3160 U21AXTalexmaster073No ratings yet

- Always With Me Guitar ScoreDocument2 pagesAlways With Me Guitar ScoreAlisa OngNo ratings yet

- Section - 9: Bangladesh, Matarbari 2 X 600MW Coal Fired Power Plant ProjectDocument15 pagesSection - 9: Bangladesh, Matarbari 2 X 600MW Coal Fired Power Plant Projectruhul01No ratings yet

- 005-Oow Dubai 2019 - SponsorDocument1 page005-Oow Dubai 2019 - SponsorAjinkya ShindeNo ratings yet

- Fig 1. 331/47239 - Issue 1: V2 C2 CC/rev CC/revDocument1 pageFig 1. 331/47239 - Issue 1: V2 C2 CC/rev CC/revNikNo ratings yet

- PressedDocument6 pagesPressedVijay KumarNo ratings yet

- L4 CaDocument1 pageL4 CaSuryaNo ratings yet

- CNG Tanke Base: Boundarywall BoundarywallDocument2 pagesCNG Tanke Base: Boundarywall Boundarywallwalid kawsarNo ratings yet

- Miami-Dade County Metrobus Routes & Metrorail Alignment: Biscayne BayDocument1 pageMiami-Dade County Metrobus Routes & Metrorail Alignment: Biscayne BayBrettMatthewsNo ratings yet

- 10083a 1X M6 Ab 00002 02Document1 page10083a 1X M6 Ab 00002 02wael zakariaNo ratings yet

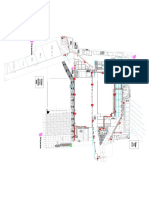

- Uncontrolled If Printed: KeyplanDocument2 pagesUncontrolled If Printed: KeyplansayedNo ratings yet

- HD3600 MK4Document3 pagesHD3600 MK4Dheeraj kumar YadavNo ratings yet

- Machine Room: Tape & Ingest ServicesDocument1 pageMachine Room: Tape & Ingest ServicesIgor SkakofNo ratings yet

- St150030 Aru Elc 06 z15 DRG Le 0006 s3 x01 Redline UpdatedDocument1 pageSt150030 Aru Elc 06 z15 DRG Le 0006 s3 x01 Redline UpdatedJamie CannellNo ratings yet

- Presentación Monterra Hoy 22 de Enero 2022Document1 pagePresentación Monterra Hoy 22 de Enero 2022Willian Alberto Nuñez GonzalezNo ratings yet

- Fire Safety Control PlanDocument1 pageFire Safety Control PlanALPHA OMEGANo ratings yet

- Set Out Plan (BCM) : Produced by An Autodesk Student VersionDocument1 pageSet Out Plan (BCM) : Produced by An Autodesk Student Versiontanu kukrejaNo ratings yet

- HVSC Layout OuterDocument1 pageHVSC Layout OuterRasika WankhadeNo ratings yet

- Vals in e Min Bartolome CalatayudDocument1 pageVals in e Min Bartolome CalatayudFranc MullerNo ratings yet

- Samsung Gt-p6800 Service SchematicsDocument12 pagesSamsung Gt-p6800 Service SchematicsC. Lennin MendozaNo ratings yet

- F. Durante 12 Partimenti Diminuiti With RealizationsDocument21 pagesF. Durante 12 Partimenti Diminuiti With RealizationsValeria BisioNo ratings yet

- 25 Top - Rock ClassicsDocument308 pages25 Top - Rock ClassicsAtiloNo ratings yet

- Alçadoesquerdo: BlocosDocument1 pageAlçadoesquerdo: BlocossantosdeabrantesNo ratings yet

- 2Nd Floor Plan: DN UPDocument1 page2Nd Floor Plan: DN UPgood boyNo ratings yet

- 8-1. Schematic Diagram (Main)Document2 pages8-1. Schematic Diagram (Main)CADiLONo ratings yet

- CONCERTO BWV 1056, 2ème MVT: Jean-Sébastien BACHDocument3 pagesCONCERTO BWV 1056, 2ème MVT: Jean-Sébastien BACHEduardo Dutra RompaNo ratings yet

- Analisis de Reacto Con ChemcadDocument42 pagesAnalisis de Reacto Con ChemcadIgnacio Alvarez MendozaNo ratings yet

- EEE Lesson Planning - CYJDocument2 pagesEEE Lesson Planning - CYJvalatejas007No ratings yet

- S 125 Op ManDocument41 pagesS 125 Op ManzholdasspeedyNo ratings yet

- Full Report Hysys Cumene CPE603Document28 pagesFull Report Hysys Cumene CPE603Amni Saufian100% (2)

- Environmental Scinece (MCQS)Document36 pagesEnvironmental Scinece (MCQS)Fahad Areeb67% (6)

- 36-775 Control of Plant Construction Repair and Maintenance Welding Activities (Rev 1)Document22 pages36-775 Control of Plant Construction Repair and Maintenance Welding Activities (Rev 1)Vinoth Rajendra100% (1)

- Piping Engineering Technical Interview QuestionDocument22 pagesPiping Engineering Technical Interview Questionmohamed faragNo ratings yet

- Climatology - QUESTION BANK (NTU)Document8 pagesClimatology - QUESTION BANK (NTU)Vinoth KumarNo ratings yet

- Module-1 Introduction To Cement and Concrete-1 (Lec 2) PDFDocument30 pagesModule-1 Introduction To Cement and Concrete-1 (Lec 2) PDFSaniaNo ratings yet

- AP Preliminary Prospectus 04.19.17 - For Website - 2 PDFDocument557 pagesAP Preliminary Prospectus 04.19.17 - For Website - 2 PDF3 stacksNo ratings yet

- Biomass Student HandbookDocument21 pagesBiomass Student HandbookPillai AkhilNo ratings yet

- WORKING DOC EV Extrication UPDATED 140822Document29 pagesWORKING DOC EV Extrication UPDATED 140822Syahrir ShahNo ratings yet

- p3 1 3 3 3 4 Energy Work and PowerDocument5 pagesp3 1 3 3 3 4 Energy Work and PowerAhmed Jomaa SalemNo ratings yet

- Emsland Germany Ka26 CCPP Project DatasheetDocument6 pagesEmsland Germany Ka26 CCPP Project DatasheetNihed KilaniNo ratings yet

- Lecture 1 DR Shery PDFDocument21 pagesLecture 1 DR Shery PDFhskakNo ratings yet

- Solid Waste Management in India 2018Document28 pagesSolid Waste Management in India 2018tsrinivasan5083No ratings yet

- Borri Ups b9000 Ups Service Manual - CompressDocument180 pagesBorri Ups b9000 Ups Service Manual - CompressArun SNo ratings yet

- Detail Calculation 13.04.12Document247 pagesDetail Calculation 13.04.12sitehabNo ratings yet

- Xq2fod Switching Power SupplyDocument9 pagesXq2fod Switching Power Supplydp500No ratings yet

- Resume Aditya Agarwal IndiaDocument1 pageResume Aditya Agarwal IndiaAditya AgarwalNo ratings yet

- DEPA Air Pump Service ManualDocument52 pagesDEPA Air Pump Service ManualCalNo ratings yet

- Dragflow-Datasheet El12.5ss eDocument1 pageDragflow-Datasheet El12.5ss eEme Eme LorcaNo ratings yet

- Bich411 Enzyme Catalysis PDFDocument7 pagesBich411 Enzyme Catalysis PDFAn TranNo ratings yet

- Spun Concrete PilesDocument38 pagesSpun Concrete PilesYatendra TyagiNo ratings yet

- AAS or ICP-OES-Are They Competing TechniquesDocument8 pagesAAS or ICP-OES-Are They Competing TechniquesKim HiềnNo ratings yet

- Rising Middle Class Essay (Geography)Document3 pagesRising Middle Class Essay (Geography)KikeNo ratings yet

- Lecture 5 - Absorption and StrippingDocument15 pagesLecture 5 - Absorption and StrippingNihad S ZainNo ratings yet

- 2018 Dmax 4JJ1Document6 pages2018 Dmax 4JJ1Matias MartinezNo ratings yet

- Catalyst Loading by Dense Method Multi Bed Reactor Inert AtmosphereDocument7 pagesCatalyst Loading by Dense Method Multi Bed Reactor Inert Atmospherevishal bailurNo ratings yet

- IEEE 485 Lead Acid Batteries For Stationary ApplicationsDocument3 pagesIEEE 485 Lead Acid Batteries For Stationary Applicationsdineshkrish67% (3)