Professional Documents

Culture Documents

Abs Jul 2005 Interior Article 1

Uploaded by

Richard Floyd0 ratings0% found this document useful (0 votes)

4 views2 pagesOriginal Title

abs-jul-2005-interior-article-1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views2 pagesAbs Jul 2005 Interior Article 1

Uploaded by

Richard FloydCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

INTERIORS

THE INSIDE STORY

BY DENNIS WOLTER

AIR MOD, CINCINNATI, OHIO

There is a lot more to a good interior than a pretty cover-up job. If doctors could do for your body what owners and technicians can do for an airplane, we’d be young

and beautiful forever.

he process of education is defi- were always the focal point of these glaring sun, endure a noise-polluted

T nitely a rewarding and, at times,

frustrating experience. As a kid, I

was always kind of a creative type.

My hobbies were all about building, fix-

ing or changing things. Fortunately, in

projects, that love at times became frus-

tration as I soon realized that the air-

planes I was flying, even new ones,

were an ergonomic disaster.

Let’s face it. You spend most of the

environment where the ventilation

could be better, and sit in a seat that is

right out of the last millennium (the first

half of it). And then, when our bodies

have really had enough, comes the hard-

the early '60s a mentor directed me to a time in your airplane relating to it est part: the approach and landing.

five-year industrial design program at the through its interior. From a human-fac- The point is, there is a lot more to a

University of Cincinnati. tors perspective, the flying experience is good interior than a pretty cover-up job.

As luck would have it, the space backwards, with the easy part usually Here’s a great opportunity to use mod-

race was on, and UC’s design depart- coming first. ern materials, good design concepts and

ment was deeply engaged in prelimi- You start out in the morning feeling skilled labor to make the space between

nary design projects with NASA. fresh after a good night’s sleep and a the firewall and aft bulkhead as safe and

Having had a pilot’s license since high nutritious breakfast. And we all know comfortable as possible, with the added

school, I loved this involvement with the takeoffs are easy. Then we climb to benefit of making it durable, easier to

aerospace design. Since human factors an oxygen-deprived altitude, sit in the maintain and aesthetically pleasing.

Page 9123 www.bonanza.org ABS July 2005

Walter Beech was an intuitive most expensive. There are good compa- Doing the interior

human-factors design guy before any- nies producing quality and value on many Full ergonomic study with customer in airplane

one else in the aviation business. I don’t levels, and it is my hope that this series of Pre-project check– radios, lights, door latches, etc.

think he saw the genius in what he was articles will help you find that value. Tear down & evaluation of interior components

doing when he did it. He quietly sur- My interior “inside story” will help Evaluation of aircraft wiring (remove unused)

veyed the pool of design engineers an owner distinguish between who is Customer conference

working at Beech and chose four whom pushing hype and who is providing sub- Build new ergonomic foam; sew & mount seats

he determined were of average size. stance. The reality is that an interior Modify, repair & upholster side panels

Then he sat them down in card table installer is like a dry-waller who can Install customer-requested enhancements &

chairs—two in front and two in back easily cover myriad electrical, plumbing modifications

(see where we’re going here?)—and and structural problems. On the walk- Component modification & repairs

said, “Gentlemen, I want you to design a thru, the place looks good, the lights Corrosion clean-up & prevention

retractable-gear, low-wing, semi-mono- come on and the plumbing seems to Remove floorboards, evaluate for repair

coque, all-aluminum airplane. It is to be work. So you write the contractor a Solvent-clean belly, landing gear transmission, etc.

powered by Continental's new 165-hp check only to find out later about the Insulation & soundproofing

engine and, most importantly, it will com- corners that were cut. Plastic repair & reinforcement

fortably house these four people and their This situation with airplanes is com- Interior painting & placarding

baggage.” The rest is history. pounded by the fact that we are disas- Glareshield & instrument panel

What a stroke of genius: Build the sembling a 30- to 50-year-old machine Door & window seals

machine to fit the mission of comfort- that has some substantial aging issues,

Door rigging & adjusting

ably carrying four adults seated in nor- easily covered up by someone who

Final installation & assembly

mal chairs. Until then, engineers would merely wants to get done and get paid.

figure frontal area, coefficient of drag, Think of it! This airplane is going Paperwork & FAA approvals

STCs, field approvals, etc.

horsepower, etcetera, and come up with to be stripped out to a point that will

Materials testing, approvals & documentation

an aerodynamic shape into which they expose its inner structure and systems in

Logbook entries

stuffed people. (Mooney pilots certainly a way that has not happened since it was

know a little about this.) built. Here’s your opportunity to go the Weight & balance & equipment list changes

Since the average person has extra mile to ensure that this machine Owner-performed maintenance entries for the

do-it-yourselfer

become taller over the past 50 years, by can safely remain in service for genera-

today’s standards early Bonanzas (late tions to come, and not die a slow and Interior maintenance

Damage prevention

ones, too) have their human-factors defi- unseen death because someone covered

Cleaning

ciencies. But the basic cabin dimensions up corrosion or structural defects with

Mechanical component maintenance

and geometry were remarkable for their new insulation and beautiful upholstery.

Materials preservation

day. This being said, with contemporary Since this is the intro article, details

techniques and good ergonomic design, will follow in later issues. Here is a very Even if you’re not planning to have

Bonanza-derivative airplanes can still set general outline of the focus of the an interior done in the near future, this

the standard for comfort and safety. upcoming installments on this subject: series will be valuable if you need to

In the coming months we will go make a repair, plan to install a modifi-

through every aspect of how to design, Common pre-project questions cation or upgrade, or choose to do only

fabricate, install and maintain the interi- Project sequencing part of an interior.

or of your dreams. Friends have cau- Doing it yourself – what you’ll need These articles will be written to

tioned me against giving away my Selecting a professional shop – questions to ask, give you an insight to many of the aging-

secrets. To that I say, it’s time to educate things to look for airplane issues. We will show you where

the consumer. Designing the interior to look for problems, how to fix them

If Beech owners are made aware of Pre-design checklist based on customer’s notes and how to avoid future degradation.

the potential of what can be done in Color coordination & aesthetic design Until next month!

their airplanes, as well as all that is Material choices

involved in this process, they will begin ABS member Dennis Wolter started Air Mod in1973

Types of foam to bring innovative design and high-quality renova-

to understand why cost and downtime Standard vs. later seat style tions to the general aviation market. Dennis, his wife

are what they are, and can better decide Taller seatbacks vs. headrests Cynthia and 10 dedicated employees complete

about 40 renovations each year at their facility on

what is the optimum interior for them in Ventilation, passenger restraints, lighting, sound- the east side of Cincinnati. Dennis has a degree in

both value and comfort. proofing, etc. industrial design from the University of Cincinnati.

The best solution is not always the Instrument panel modification & upgrades He is an A&P, IA and a 3,000-hour instrument pilot.

ABS July 2005 www.bonanza.org Page 9124

You might also like

- What A Great: Idea!Document4 pagesWhat A Great: Idea!Manuel HervasNo ratings yet

- Present Trends in Ejection Seat DesignDocument30 pagesPresent Trends in Ejection Seat DesignFlorin NiteNo ratings yet

- Offices at Work: Uncommon Workspace Strategies that Add Value and Improve PerformanceFrom EverandOffices at Work: Uncommon Workspace Strategies that Add Value and Improve PerformanceNo ratings yet

- Practical Design of Small AirplaneDocument4 pagesPractical Design of Small AirplaneSenja RiraNo ratings yet

- Design and Analysis of Fuselage StructurDocument9 pagesDesign and Analysis of Fuselage Structurjacob ellyNo ratings yet

- HPCJUL06Document4 pagesHPCJUL06GON MTONo ratings yet

- Boat Strength IBEXDocument46 pagesBoat Strength IBEXrakesh reghuNo ratings yet

- The-Sportplane-Builder 5be57cd7097c4788468b47d1Document5 pagesThe-Sportplane-Builder 5be57cd7097c4788468b47d1jacob ellyNo ratings yet

- Selecting A Homebuilt Design 01Document3 pagesSelecting A Homebuilt Design 01YvessNo ratings yet

- Zero Thrust Glide TestingDocument8 pagesZero Thrust Glide TestingLysterNo ratings yet

- Laboratorio #3: ABSTRACT: Trough A Document About TheDocument7 pagesLaboratorio #3: ABSTRACT: Trough A Document About TheDavid UlloaNo ratings yet

- FalcoDocument9 pagesFalcoPredrag PavlovićNo ratings yet

- The-Sportplane-Builder 5bae8279097c47df248b45b1Document11 pagesThe-Sportplane-Builder 5bae8279097c47df248b45b1jacob ellyNo ratings yet

- Builda Plane FinalDocument9 pagesBuilda Plane Finaljacob ellyNo ratings yet

- 'Aeronautical 'Trade Project' by LewishDocument36 pages'Aeronautical 'Trade Project' by LewishLewishNo ratings yet

- Poka-Yoke Designs Make Assemblies Mistakeproof: Cad/CamDocument4 pagesPoka-Yoke Designs Make Assemblies Mistakeproof: Cad/CamvikaspalNo ratings yet

- Poka-Yoke Designs Make Assemblies Mistakeproof: Cad/CamDocument4 pagesPoka-Yoke Designs Make Assemblies Mistakeproof: Cad/CamamondacaNo ratings yet

- Phoenix Model Classic EP Trainer - ReviewDocument3 pagesPhoenix Model Classic EP Trainer - Reviewyfm660No ratings yet

- Cons Raln: Knowing How Much Is Enough-And How Much-Is A Key To Successful Design. James SkakoonDocument5 pagesCons Raln: Knowing How Much Is Enough-And How Much-Is A Key To Successful Design. James Skakoonzk7No ratings yet

- NASA: 190040main Sep21colorDocument8 pagesNASA: 190040main Sep21colorNASAdocumentsNo ratings yet

- High Speed Journal and Thrust Bearing Design: B. S. HerbageDocument6 pagesHigh Speed Journal and Thrust Bearing Design: B. S. Herbagemanjunath k sNo ratings yet

- ScriptDocument11 pagesScriptMykhailo ShaidaNo ratings yet

- 2005 Article AMilestoneForCompositesInAviatDocument3 pages2005 Article AMilestoneForCompositesInAviatDan GriffithsNo ratings yet

- Why Airplanes Look Like They DoDocument41 pagesWhy Airplanes Look Like They DoMo HoNo ratings yet

- MSC Aerospace DissertationDocument76 pagesMSC Aerospace Dissertationanirudh666100% (3)

- Aerolite 103: Reviewing Engines at AV 2014 Getting Started in Powered ParachutesDocument8 pagesAerolite 103: Reviewing Engines at AV 2014 Getting Started in Powered ParachutesNofriagara Davit Harnawan40% (5)

- 198302-1983 Beech Duke B60Document8 pages198302-1983 Beech Duke B60RODRIGO SEBASTIÁN CICUTTO AGOSTINELLO100% (2)

- Chapter 8Document4 pagesChapter 8Michael HarveyNo ratings yet

- Research Paper On Ejection SeatDocument4 pagesResearch Paper On Ejection Seatnqdpuhxgf100% (1)

- Lofting PDFDocument1 pageLofting PDFVikrant YadavNo ratings yet

- AIAA-2002-2931 Aerodynamic Optimization of Subsonic Flying Wing ConfigurationsDocument7 pagesAIAA-2002-2931 Aerodynamic Optimization of Subsonic Flying Wing ConfigurationsSanteBrucoliNo ratings yet

- Next Generation Thermal AirshipDocument17 pagesNext Generation Thermal AirshipRalph BolzonaroNo ratings yet

- Homebuilt Kit Aircraft Construction Details & Article LibraryDocument4 pagesHomebuilt Kit Aircraft Construction Details & Article LibraryChukkaNo ratings yet

- There Is Plenty of Room at The TopDocument9 pagesThere Is Plenty of Room at The TopGuido MoviaNo ratings yet

- Aerospace Group Design Structures CAD deDocument29 pagesAerospace Group Design Structures CAD dejacob ellyNo ratings yet

- History of Human Factors in US Navy Aircraft Cockpit Design - 1969-2019Document5 pagesHistory of Human Factors in US Navy Aircraft Cockpit Design - 1969-2019Diego BaghinoNo ratings yet

- Class 4: Describing Technical Functions and ApplicationsDocument5 pagesClass 4: Describing Technical Functions and ApplicationsDavid JaramilloNo ratings yet

- Article Understanding and Preventing Turbine OverspeedDocument14 pagesArticle Understanding and Preventing Turbine OverspeedTan Nguyen HuuNo ratings yet

- Monocoque ThesisDocument5 pagesMonocoque Thesisaflpaftaofqtoa100% (2)

- LEAP Engine Design FlawsDocument7 pagesLEAP Engine Design FlawsaliNo ratings yet

- Butler - The Surface Effect ShipDocument54 pagesButler - The Surface Effect ShipJovic IlicNo ratings yet

- Exploration Connection: It's A Drag: MovingDocument3 pagesExploration Connection: It's A Drag: MovingDaoud KhanNo ratings yet

- Computer AnalysisDesign of Large Mat Foundations 1Document2 pagesComputer AnalysisDesign of Large Mat Foundations 1juan carlos molano toroNo ratings yet

- ADP ReportDocument56 pagesADP ReportsanjayNo ratings yet

- Canopy MoldingDocument4 pagesCanopy MoldingBerniSomex Somexemos100% (2)

- Structural Analysis of Aircraft Wing J Nose Panel Using Mono and Multi Core Composite MaterialsDocument6 pagesStructural Analysis of Aircraft Wing J Nose Panel Using Mono and Multi Core Composite MaterialsstaedtlerpNo ratings yet

- 1600 - Design Optimization - Fabrication - and - Testing of A 3D Printed Aircraft Structure Using FDMDocument16 pages1600 - Design Optimization - Fabrication - and - Testing of A 3D Printed Aircraft Structure Using FDMOKA FATRANo ratings yet

- Sae 0508Document2 pagesSae 0508cemdesignNo ratings yet

- Nasa Tech Brief: Ames Research CenterDocument2 pagesNasa Tech Brief: Ames Research Centerzzxc zzxcNo ratings yet

- Lancair Legacy KitplaneDocument14 pagesLancair Legacy Kitplaneanon-234564100% (5)

- Development of An Optimization Framework For Landing Gear DesignDocument91 pagesDevelopment of An Optimization Framework For Landing Gear DesignRaniero Falzon100% (1)

- Lockheed Martin - en FDM Case StudyDocument4 pagesLockheed Martin - en FDM Case StudyShabi HadashNo ratings yet

- Getting On The StepDocument4 pagesGetting On The StepGeorge W AndersonNo ratings yet

- Hartford Stadium Collapse: Why Software Should Never Be More Than A Tool To Be Used WiselyDocument3 pagesHartford Stadium Collapse: Why Software Should Never Be More Than A Tool To Be Used WiselynevinkoshyNo ratings yet

- Semi-Structured Decision Processes MITDocument201 pagesSemi-Structured Decision Processes MITÑøwty ÜshãñNo ratings yet

- Development of A Generic Inflatable De-Orbit Device For CubesatsDocument381 pagesDevelopment of A Generic Inflatable De-Orbit Device For CubesatsFernando Jesús Medina RodríguezNo ratings yet

- Ieee Paper Id 2589Document19 pagesIeee Paper Id 2589Sinan KeiyinciNo ratings yet

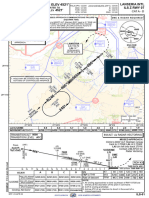

- Fact - Geten 1a Rwy 01 - Arr-02Document1 pageFact - Geten 1a Rwy 01 - Arr-02mrchinabeanNo ratings yet

- Fact - Ils Rwy 01 - Ils-01 10may2007Document1 pageFact - Ils Rwy 01 - Ils-01 10may2007Richard FloydNo ratings yet

- INV2Document1 pageINV2Richard FloydNo ratings yet

- Fala - Ils Rwy 07 - Ils-01Document1 pageFala - Ils Rwy 07 - Ils-01Richard FloydNo ratings yet

- Fact - Geten 1B Rwy 19 - Arr-07Document1 pageFact - Geten 1B Rwy 19 - Arr-07Richard FloydNo ratings yet

- Fact - Erdas 1B Rwy 19 - Arr-06Document1 pageFact - Erdas 1B Rwy 19 - Arr-06Richard FloydNo ratings yet

- INV3Document1 pageINV3Richard FloydNo ratings yet

- Inv 69311Document1 pageInv 69311Richard FloydNo ratings yet

- Inv 69311Document1 pageInv 69311Richard FloydNo ratings yet

- Sample: Aero Vodochody L-29 Delfin Approved Aircraft Inspection Program For: 591378Document62 pagesSample: Aero Vodochody L-29 Delfin Approved Aircraft Inspection Program For: 591378Richard FloydNo ratings yet

- Bajaj Qute 2016 DatasheetDocument2 pagesBajaj Qute 2016 DatasheetRichard FloydNo ratings yet

- Weekly Trends 2021-06-21 TO 2021-06-28Document2 pagesWeekly Trends 2021-06-21 TO 2021-06-28Richard FloydNo ratings yet

- AHS Uncertainty - FinalDocument1 pageAHS Uncertainty - FinalRichard FloydNo ratings yet

- Yetti K1Document1 pageYetti K1Richard FloydNo ratings yet

- FAPE - AERODROME CHART - AD-01 - 08 NOV 2018.cdrDocument1 pageFAPE - AERODROME CHART - AD-01 - 08 NOV 2018.cdrRichard FloydNo ratings yet

- CS Ne 20210617Document701 pagesCS Ne 20210617Richard FloydNo ratings yet

- CS NC 20210617Document529 pagesCS NC 20210617Richard FloydNo ratings yet

- CS Ec 20210422Document531 pagesCS Ec 20210422Richard FloydNo ratings yet

- CS Ak 20210422Document541 pagesCS Ak 20210422Richard FloydNo ratings yet

- CS NW 20210617Document375 pagesCS NW 20210617Richard FloydNo ratings yet

- Ergonomics Risk Assessment PDFDocument2 pagesErgonomics Risk Assessment PDFVictoriaNo ratings yet

- Success and Failure: Human As Hero Human As Hazard: Carl SandomDocument9 pagesSuccess and Failure: Human As Hero Human As Hazard: Carl SandomRola Mesrani SimbolonNo ratings yet

- 3.CE130 Lecture 3Document22 pages3.CE130 Lecture 3Jon JimmyNo ratings yet

- HPC 327 Week 9Document16 pagesHPC 327 Week 9Ian MorfeNo ratings yet

- Arch 324 Course GuideDocument4 pagesArch 324 Course GuidearkioskNo ratings yet

- "Ergonomic Design at Automotive Industry": QuestionnaireDocument6 pages"Ergonomic Design at Automotive Industry": QuestionnaireIda TomeyNo ratings yet

- ANTHROPOMETRICSDocument25 pagesANTHROPOMETRICSlrac_adazolNo ratings yet

- Human Factors: in Aviation OperationsDocument34 pagesHuman Factors: in Aviation OperationsPratiek RaulNo ratings yet

- HSE Ergonomic Considerations ForDocument12 pagesHSE Ergonomic Considerations ForMaurice LamarcheNo ratings yet

- Business PlanDocument55 pagesBusiness PlanCherelyn Maglasang100% (1)

- Wiha 30Document200 pagesWiha 30Alfredo RiberaNo ratings yet

- P 7Document8 pagesP 7Marko BrkicNo ratings yet

- Job Analisis 1Document12 pagesJob Analisis 1Masrun FatanahNo ratings yet

- Manual Handling Guidance Note L23-1992Document95 pagesManual Handling Guidance Note L23-1992khatija_No ratings yet

- Human FactorDocument14 pagesHuman FactorJoseph Nathan MarquezNo ratings yet

- Ppce Unit-1Document118 pagesPpce Unit-1Jackson ..No ratings yet

- Sesi 1. Konsep & Prinsip Dasar K3Document15 pagesSesi 1. Konsep & Prinsip Dasar K3Tio SebastianNo ratings yet

- AntrophometryDocument11 pagesAntrophometryCrystal Gaile Padrigao100% (1)

- M.Tech ME ISE 2015Document30 pagesM.Tech ME ISE 2015Tŕəñdinğ TəjNo ratings yet

- Design 3 College of Architecture Pontifical and Royal University of Santo Tomas The Catholic University of The PhilippinesDocument25 pagesDesign 3 College of Architecture Pontifical and Royal University of Santo Tomas The Catholic University of The PhilippinesDanielle RoblesNo ratings yet

- HCIqDocument78 pagesHCIqOanh NguyenNo ratings yet

- Ergonomic Risk Identification and Assessment - Identification and Assessment ToolDocument54 pagesErgonomic Risk Identification and Assessment - Identification and Assessment Toolhitm357No ratings yet

- Solutions Manual For Canadian Human Resource Management Canadian 11th Edition by Hermann F 190329034249Document45 pagesSolutions Manual For Canadian Human Resource Management Canadian 11th Edition by Hermann F 190329034249Rohan DwivediNo ratings yet

- Review and Analysis of HCIDocument13 pagesReview and Analysis of HCInnoumanNo ratings yet

- Casting An Ergonomic Eye On University Libraries: Nicole Ferrer and Vilma VillaroucoDocument7 pagesCasting An Ergonomic Eye On University Libraries: Nicole Ferrer and Vilma VillaroucoCarlos JúniorNo ratings yet

- Fundamentals of Engineering (FE) INDUSTRIAL AND SYSTEMS CBT Exam SpecificationsDocument3 pagesFundamentals of Engineering (FE) INDUSTRIAL AND SYSTEMS CBT Exam SpecificationsSalma AbdullahNo ratings yet

- Chapter 3Document36 pagesChapter 3AbhishekNo ratings yet

- Stairway Falls PSJan 2009Document6 pagesStairway Falls PSJan 2009Himad Beg, P.E.No ratings yet

- The Human-Centred Approach - Best Practice in Ship and Equipment DesignDocument32 pagesThe Human-Centred Approach - Best Practice in Ship and Equipment Designyoler478No ratings yet

- Incident Reporting ProcedureDocument24 pagesIncident Reporting ProcedureAnonymous qRbPsLpuNNo ratings yet

- Clean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeFrom EverandClean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeRating: 5 out of 5 stars5/5 (2)

- How to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingFrom EverandHow to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingRating: 4.5 out of 5 stars4.5/5 (844)

- Survival Mom: How to Prepare Your Family for Everyday Disasters and Worst-Case ScenariosFrom EverandSurvival Mom: How to Prepare Your Family for Everyday Disasters and Worst-Case ScenariosRating: 3.5 out of 5 stars3.5/5 (8)

- Kintsugi Wellness: The Japanese Art of Nourishing Mind, Body, and SpiritFrom EverandKintsugi Wellness: The Japanese Art of Nourishing Mind, Body, and SpiritRating: 4.5 out of 5 stars4.5/5 (3)

- The Martha Manual: How to Do (Almost) EverythingFrom EverandThe Martha Manual: How to Do (Almost) EverythingRating: 4 out of 5 stars4/5 (11)

- The Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyFrom EverandThe Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyRating: 4 out of 5 stars4/5 (277)

- Success at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.From EverandSuccess at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.Rating: 4 out of 5 stars4/5 (17)

- The Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterFrom EverandThe Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterRating: 4 out of 5 stars4/5 (467)

- Nobody Wants Your Sh*t: The Art of Decluttering Before You DieFrom EverandNobody Wants Your Sh*t: The Art of Decluttering Before You DieRating: 4.5 out of 5 stars4.5/5 (21)

- Martha Stewart's Organizing: The Manual for Bringing Order to Your Life, Home & RoutinesFrom EverandMartha Stewart's Organizing: The Manual for Bringing Order to Your Life, Home & RoutinesRating: 4 out of 5 stars4/5 (11)

- The Buy Nothing, Get Everything Plan: Discover the Joy of Spending Less, Sharing More, and Living GenerouslyFrom EverandThe Buy Nothing, Get Everything Plan: Discover the Joy of Spending Less, Sharing More, and Living GenerouslyRating: 4 out of 5 stars4/5 (40)

- The Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and OrganizingFrom EverandThe Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and OrganizingRating: 4 out of 5 stars4/5 (2995)

- Summary of Goodbye, Things: The New Japanese Minimalism by Fumio SasakiFrom EverandSummary of Goodbye, Things: The New Japanese Minimalism by Fumio SasakiRating: 4.5 out of 5 stars4.5/5 (5)

- How to Manage Your Home Without Losing Your Mind: Dealing with Your House's Dirty Little SecretsFrom EverandHow to Manage Your Home Without Losing Your Mind: Dealing with Your House's Dirty Little SecretsRating: 5 out of 5 stars5/5 (339)

- Declutter Like a Mother: A Guilt-Free, No-Stress Way to Transform Your Home and Your LifeFrom EverandDeclutter Like a Mother: A Guilt-Free, No-Stress Way to Transform Your Home and Your LifeRating: 4.5 out of 5 stars4.5/5 (164)

- Martha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeFrom EverandMartha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeNo ratings yet

- At Home with Madame Chic: Becoming a Connoisseur of Daily LifeFrom EverandAt Home with Madame Chic: Becoming a Connoisseur of Daily LifeRating: 4 out of 5 stars4/5 (58)

- Dwelling: Simple Ways to Nourish Your Home, Body, and SoulFrom EverandDwelling: Simple Ways to Nourish Your Home, Body, and SoulRating: 4.5 out of 5 stars4.5/5 (9)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseFrom EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseRating: 5 out of 5 stars5/5 (3)

- Ultimate Guide: Plumbing, Updated 5th EditionFrom EverandUltimate Guide: Plumbing, Updated 5th EditionRating: 4 out of 5 stars4/5 (3)

- 52 Prepper Projects: A Project a Week to Help You Prepare for the UnpredictableFrom Everand52 Prepper Projects: A Project a Week to Help You Prepare for the UnpredictableRating: 5 out of 5 stars5/5 (1)

- Decluttering at the Speed of Life: Winning Your Never-Ending Battle with StuffFrom EverandDecluttering at the Speed of Life: Winning Your Never-Ending Battle with StuffRating: 4.5 out of 5 stars4.5/5 (578)

- The Declutter Challenge: A Guided Journal for Getting your Home Organized in 30 Quick Steps (Guided Journal for Cleaning & Decorating, for Fans of Cluttered Mess)From EverandThe Declutter Challenge: A Guided Journal for Getting your Home Organized in 30 Quick Steps (Guided Journal for Cleaning & Decorating, for Fans of Cluttered Mess)Rating: 3.5 out of 5 stars3.5/5 (7)