Professional Documents

Culture Documents

FIR - TGPP - 1 - Turbine Casing Signed

Uploaded by

neiltaneo96Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FIR - TGPP - 1 - Turbine Casing Signed

Uploaded by

neiltaneo96Copyright:

Available Formats

CMG FIELD INSPECTION REPORT

POWER PLANT / UNIT TGPP / UNIT 1 FIR NO. TGPP-1-MAA-10-SD-001-032223-1,0

EQUIPMENT / SN TURBINE SYSTEM WORK ORDER NO. 5082823

COMPONENT TURBINE CASING DATE (M/D/YYYY) March 22, 2023

ACTIVITY INSPECTION OF TURBINE CASING

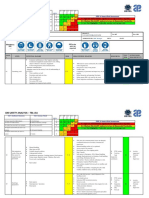

Nature of Findings (Please put X if applicable)

Phase 1 : X Field Need RCA X Yes No

Phase 2 : Laboratory Where?

Evidence Of Deviation:

Severe erosion, corrosion, material loss and thinning

Heavy accumulation of solid deposits

Clogged-up drains

Severity Of Deviation:

Light Moderate X Heavy

Extent Of Deviation:

Isolated Location >1 Location X Stage Involved

Location Of Deviation:

Lower and upper casing stay pipes

Turbine chest drain piping DE and NDE side

Chest drain DE side (clogged-up)

Lower and upper stage 1 & 2 casing webs

Possible Cause Of Deviation:

Poor steam quality (erosive and corrosive)

Steam solid particles carry-over

Presence of condensates on steam

Ineffective steam scrubber

Action Taken/s

Conduct NDT-UTG on lower and upper casing stay pipes

Replaced eroded stay pipes according to MHPS repair procedure and conduct NDT-PT on welded joints (Passed)

Replaced eroded chest drain piping by weld repair and conduct NDT-PT (Passed)

De-clogged chest drain, piping and valves

Cleaned and de-scaled lower and upper casing

Applied belzona composite on Stage 1 and 2 casing webs as temporary stop gap remedy

Recommendation/s:

Conduct visual and NDT (UTG) on stay pipes on next major PMS

Conduct visual inspection of chest drain and piping

Frequently monitor the turbine chest pressure

Maintain the required steam supply operating parameters and quality

Repair seal, non-seal and radial face by weld build-up and bore machining of lower and upper casing webs

Comment/s:

5/7 stay pipes at lower casing were replaced

3/7 stay pipes at upper casing were replaced

See below photos for the details

COPYRIGHT © ENERGY DEVELOPMENT CORPORATION. ALL RIGHTS RESERVED 2019.

AS-FOUND

STAY PIPE LOWER HALF

NDE

Right Left

Damaged

Damaged Damaged Damaged

Damaged

DE

STAY PIPE UPPER HALF

NDE

Right Left

Damaged

Damaged

DE Damaged

COPYRIGHT © ENERGY DEVELOPMENT CORPORATION. ALL RIGHTS RESERVED 2019.

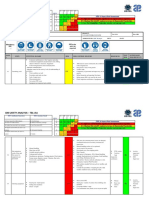

CHEST DRAIN

NDE SIDE DE SIDE

Clogged-up

Clogged-up

Clogged-up

CHEST DRAIN PIPING (LOWER CASING)

NDE SIDE DE SIDE

COPYRIGHT © ENERGY DEVELOPMENT CORPORATION. ALL RIGHTS RESERVED 2019.

CASING WEBS

Stage 1

DE Lower Half NDE DE Upper Half NDE

Stage 2

DE Lower Half NDE DE Upper Half NDE

COPYRIGHT © ENERGY DEVELOPMENT CORPORATION. ALL RIGHTS RESERVED 2019.

AS-LEFT

STAY PIPE LOWER HALF

NDE

Right Left

DE

COPYRIGHT © ENERGY DEVELOPMENT CORPORATION. ALL RIGHTS RESERVED 2019.

STAY PIPE UPPER HALF

NDE

Right Left

DE

COPYRIGHT © ENERGY DEVELOPMENT CORPORATION. ALL RIGHTS RESERVED 2019.

CHEST DRAIN

NDE SIDE DE SIDE

CHEST DRAIN PIPING (LOWER CASING)

COPYRIGHT © ENERGY DEVELOPMENT CORPORATION. ALL RIGHTS RESERVED 2019.

CASING WEBS

Cleaned and cup brushed casing surface webs

Applied Belzona composite (Metal based) as temporary stop gap solution

Recommended for major repair on next major shutdown

COPYRIGHT © ENERGY DEVELOPMENT CORPORATION. ALL RIGHTS RESERVED 2019.

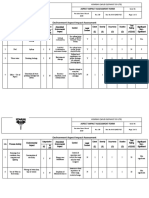

Reference Dimensions

Stage 1

Stage 2

Eroded Areas

Prepared by: Reviewed by: Approved by:

ARNULFO N. ASTRONOMO JC LAHAY-LAHAY / AB VERANO ALDRIN D. GASGA

CMG –FS MECHANICAL CMG – FS MECHANICAL AREA LEAD/ CO-LEAD CMG – HEAD FS MECHANICAL

COPYRIGHT © ENERGY DEVELOPMENT CORPORATION. ALL RIGHTS RESERVED 2019.

You might also like

- FIR - TGPP - 1 - Turbine Casing SignedDocument9 pagesFIR - TGPP - 1 - Turbine Casing Signedneiltaneo96No ratings yet

- Fulton ModSync Wiring DiagramDocument3 pagesFulton ModSync Wiring DiagramjrodNo ratings yet

- Grand Summary - p1Document3 pagesGrand Summary - p1Jojee Catap YabutNo ratings yet

- One Point LessonDocument1 pageOne Point LessonMohamad Adli AbdullahNo ratings yet

- Form 1B Pre Work Risk AssessmentDocument2 pagesForm 1B Pre Work Risk AssessmentXudong LiuNo ratings yet

- Advanced EM Winter Seminar: Training CurriculumDocument78 pagesAdvanced EM Winter Seminar: Training CurriculumDiana Urrutia MonroyNo ratings yet

- 3006-500a-Dm116701, Mechanical, Specification For Piping Layout (Addendum)Document40 pages3006-500a-Dm116701, Mechanical, Specification For Piping Layout (Addendum)Jonathan MartinezNo ratings yet

- To Start & Run Fire Water Pump, Welding Machines and Air Compressors Including Topping Up of Diesel Fuel. PlatformDocument2 pagesTo Start & Run Fire Water Pump, Welding Machines and Air Compressors Including Topping Up of Diesel Fuel. PlatformMohamad Hakim Kamal ArifinNo ratings yet

- Smi - Hse Firf02Document11 pagesSmi - Hse Firf02Talal AlrwyanNo ratings yet

- Ground Floor Plan For Ceiling: Abra District Engineering OfficeDocument1 pageGround Floor Plan For Ceiling: Abra District Engineering OfficeJun Michael Artates VelascoNo ratings yet

- Anchoring PDFDocument2 pagesAnchoring PDFengineer63No ratings yet

- Hazards To Responders IMO 3Document38 pagesHazards To Responders IMO 3carlosrodriguezscelzaNo ratings yet

- Comm Modity in Donesia N Steam Coal:: Sep RA/GEN/12/ Tter of Int Ptember 20 /9/00026 Tent 12Document1 pageComm Modity in Donesia N Steam Coal:: Sep RA/GEN/12/ Tter of Int Ptember 20 /9/00026 Tent 12Ali Sofwan HadiNo ratings yet

- 11 VLF TD WeaverDocument20 pages11 VLF TD WeaverMiguel ZuñigaNo ratings yet

- Defect Report Sat C AntennaDocument2 pagesDefect Report Sat C AntennaRose AriantiNo ratings yet

- ISGEC Heavy Engineering Limited: Construction Division Aspect and Impact RegisterDocument10 pagesISGEC Heavy Engineering Limited: Construction Division Aspect and Impact RegisterHSE ENNKAYNo ratings yet

- Form bbs2563Document3 pagesForm bbs2563Julián Tiburcio GonzálezNo ratings yet

- Industrial Gas Turbine Control Torsten StrandDocument66 pagesIndustrial Gas Turbine Control Torsten StrandmaherNo ratings yet

- Daily Dredging ReportDocument1 pageDaily Dredging Reportuygarkoprucu100% (1)

- Job Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentDocument5 pagesJob Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentMoaatazz NouisriNo ratings yet

- Data Sheet For Wind Energy Generation System: Internal NormalizationDocument13 pagesData Sheet For Wind Energy Generation System: Internal Normalizationkais rguiguiNo ratings yet

- Job Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentDocument4 pagesJob Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentMoaatazz NouisriNo ratings yet

- Earthr MeshDocument1 pageEarthr MeshwashieNo ratings yet

- 22-RA FORM OP-20-01 Camp Engine RepalcmetnDocument1 page22-RA FORM OP-20-01 Camp Engine Repalcmetnelnaas1993No ratings yet

- 0314 - 119T8901 - GT Package Connection Pipe TableDocument40 pages0314 - 119T8901 - GT Package Connection Pipe TablefaisalnadimNo ratings yet

- Consequence Development and Safeguards Exercise.02Document8 pagesConsequence Development and Safeguards Exercise.02samNo ratings yet

- Job Hazard Analysis Site InspectionDocument12 pagesJob Hazard Analysis Site InspectionNonsoufo eze100% (1)

- JHEA Loading and Offloading FENCEDocument13 pagesJHEA Loading and Offloading FENCEStansilous Tatenda NyagomoNo ratings yet

- 005-JSA X-Ray & Gamma Ray RadiographyDocument7 pages005-JSA X-Ray & Gamma Ray RadiographyMoaatazz NouisriNo ratings yet

- Infographic Offshore Asset RetirementDocument6 pagesInfographic Offshore Asset RetirementMarios DiasNo ratings yet

- MaritimeReporter 2019 05Document100 pagesMaritimeReporter 2019 05RokhmatuSivaNo ratings yet

- Form U-Dr-1 User, S Design Requirement For Single Chamber Pressure VesselsDocument4 pagesForm U-Dr-1 User, S Design Requirement For Single Chamber Pressure VesselsAmit SharmaNo ratings yet

- Valid SOP: Standard Operating ProceduresDocument10 pagesValid SOP: Standard Operating ProceduresShahid Raza100% (2)

- 004-JSA Manual WeldingDocument6 pages004-JSA Manual WeldingMoaatazz NouisriNo ratings yet

- Terminal Teluk Lamong Indonesias First Green Container Terminal - Agung Kresno SarwonoDocument19 pagesTerminal Teluk Lamong Indonesias First Green Container Terminal - Agung Kresno SarwonoZaidan AlkatiriNo ratings yet

- Recommended Procedures For Laying Up BoilerDocument11 pagesRecommended Procedures For Laying Up BoilerRamy OmarNo ratings yet

- Front Endsheet (Table of Contents)Document1 pageFront Endsheet (Table of Contents)MATTHEW BLUMBERGNo ratings yet

- Job Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentDocument6 pagesJob Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentMoaatazz Nouisri100% (1)

- RISK/IMPACT ASSESSMENT (To Be Used Both Occupation Health, Safety & Environment)Document1 pageRISK/IMPACT ASSESSMENT (To Be Used Both Occupation Health, Safety & Environment)Sijo Rajan100% (1)

- 002-JSA RoW Opening and Marking FinalDocument6 pages002-JSA RoW Opening and Marking FinalMoaatazz NouisriNo ratings yet

- Deep Water Exploration & Development in IndonesiaDocument21 pagesDeep Water Exploration & Development in IndonesiaScriptlance 2012No ratings yet

- Deep Water Exploration & Development in IndonesiaDocument21 pagesDeep Water Exploration & Development in IndonesiaJanaMaulanaSupriatnaNo ratings yet

- P246101-E-BE-00-000-EL-EDS-005 (Diesel Generator)Document10 pagesP246101-E-BE-00-000-EL-EDS-005 (Diesel Generator)hafid CJSPNo ratings yet

- TK-103-FGL-26-matt Inspection Prior To Tissue ApplicationDocument1 pageTK-103-FGL-26-matt Inspection Prior To Tissue ApplicationjoseNo ratings yet

- Lifting Plan Top Rev 1Document3 pagesLifting Plan Top Rev 1Mohammad SyahirNo ratings yet

- Masen Noor IVDocument277 pagesMasen Noor IVVeintidós MarzoNo ratings yet

- Main Building: Borehole OWT Underground Fuel Storage TanksDocument1 pageMain Building: Borehole OWT Underground Fuel Storage TankspastorgeeNo ratings yet

- Kaizen Sheet: 8/11/2018 JD 619 Conveyor Bag Filter Vent Fan Bottom Casing Moc ModicationDocument1 pageKaizen Sheet: 8/11/2018 JD 619 Conveyor Bag Filter Vent Fan Bottom Casing Moc Modicationgullipalli srinivasa raoNo ratings yet

- Agcc & DBB (JV) Painting Inspection Report: Verified By: Verified byDocument6 pagesAgcc & DBB (JV) Painting Inspection Report: Verified By: Verified byJoseph DarwinNo ratings yet

- Daily Report 27 - 04 Januari 2022 - 22.1.5Document1 pageDaily Report 27 - 04 Januari 2022 - 22.1.5muis supriyadiNo ratings yet

- Rohan Builders (I) PVT - LTD.:: Mercedes BenzDocument3 pagesRohan Builders (I) PVT - LTD.:: Mercedes BenzPa imanNo ratings yet

- Inspection 150$Document23 pagesInspection 150$Дмитрий ТимофеевNo ratings yet

- P246101-E-BE-00-000-EL-EDS-005 (Diesel Generator)Document11 pagesP246101-E-BE-00-000-EL-EDS-005 (Diesel Generator)hafid CJSPNo ratings yet

- Globe Kangha - HW ID EVALDocument1 pageGlobe Kangha - HW ID EVALZhu Chen ChuanNo ratings yet

- Baby Shark: Ukulele Tablature, Lyrics, Chords, and Assessments!Document10 pagesBaby Shark: Ukulele Tablature, Lyrics, Chords, and Assessments!baltuslzNo ratings yet

- Form - 2023-09-29T102716.025Document2 pagesForm - 2023-09-29T102716.025yoa7539No ratings yet

- ANX 05 QHSE F16 EMS Aspect & Impact Assessment LatestDocument2 pagesANX 05 QHSE F16 EMS Aspect & Impact Assessment LatestVipin ThomasNo ratings yet

- The EdgeDocument37 pagesThe EdgeabdulNo ratings yet

- Competitor Comparation - 1270Document2 pagesCompetitor Comparation - 1270cribytritNo ratings yet

- Thermal Physics TemperatureDocument36 pagesThermal Physics TemperatureJames SarkerNo ratings yet

- An Advanced Protection Scheme For Enabling An LVDC Last Mile Distribution NetworkDocument8 pagesAn Advanced Protection Scheme For Enabling An LVDC Last Mile Distribution Networkmusharraf saeedNo ratings yet

- CXP 125 - 145 - 165 11-03-11Document8 pagesCXP 125 - 145 - 165 11-03-11pham duongNo ratings yet

- Measurement of Insulation Resistance (IR) - Part 2 - EEP PDFDocument16 pagesMeasurement of Insulation Resistance (IR) - Part 2 - EEP PDFHeri SulaimanNo ratings yet

- RelayDocument4 pagesRelayharrypotter 05No ratings yet

- Tugas 1 Structure IDocument2 pagesTugas 1 Structure Idesound Phinisi PointNo ratings yet

- Loop Test For Location of Faults in Underground CablesDocument21 pagesLoop Test For Location of Faults in Underground CablesCathryn FriasNo ratings yet

- Intarder3 - MBB NM - 03-2021 - PrintDocument12 pagesIntarder3 - MBB NM - 03-2021 - PrintLuis LeyvaNo ratings yet

- Design and Fabrication of Wick Type Solar StillDocument59 pagesDesign and Fabrication of Wick Type Solar StillmktutyNo ratings yet

- Selecting Filter Media For Your Cartridge-Style Dust CollectorDocument4 pagesSelecting Filter Media For Your Cartridge-Style Dust CollectorbeemasundarNo ratings yet

- Man C 0186Document2 pagesMan C 0186Ravindar aNo ratings yet

- Paper Presentation: Alternative Fuels (Hho Gas)Document13 pagesPaper Presentation: Alternative Fuels (Hho Gas)Yemmina MadhusudhanNo ratings yet

- K20 Engine Control Module X1 (LTG) Document ID# 4699507Document3 pagesK20 Engine Control Module X1 (LTG) Document ID# 4699507Data TécnicaNo ratings yet

- Energy ManagementDocument50 pagesEnergy ManagementPavithra AcharyaNo ratings yet

- PCE Lecture 3 2 HeatTransfer TemperatureProfilesDocument16 pagesPCE Lecture 3 2 HeatTransfer TemperatureProfilesDaniel MarkNo ratings yet

- Alkenes Detection From Drill Bit Metamorphism and Real-Time Geochemical Elemental Analysis On Drill Cuttings Aids Drilling Optimization and GeosteerDocument6 pagesAlkenes Detection From Drill Bit Metamorphism and Real-Time Geochemical Elemental Analysis On Drill Cuttings Aids Drilling Optimization and GeosteerRadwan AliNo ratings yet

- Fs 4018 Rev-3 Boost Charging SystemDocument11 pagesFs 4018 Rev-3 Boost Charging SystemDinesh RajNo ratings yet

- Nissan Almera n15 Series Service ManualDocument1,712 pagesNissan Almera n15 Series Service ManualFieru CorsuNo ratings yet

- Membrane-Cryogenic Post-Combustion Carbon CaptureDocument11 pagesMembrane-Cryogenic Post-Combustion Carbon CaptureJohn Jairo RamosNo ratings yet

- Primary-Feeder Voltage LevelDocument31 pagesPrimary-Feeder Voltage LevelRauda Nano AntolNo ratings yet

- 2.7. Kiln and Raw MillDocument2 pages2.7. Kiln and Raw MillOrane DrakeNo ratings yet

- Power Plants Layout MWM 07 2022 enDocument343 pagesPower Plants Layout MWM 07 2022 enM AbdalilarkiNo ratings yet

- Diagrama Electrico AsfaltadoraDocument25 pagesDiagrama Electrico AsfaltadoraSebastian SucerquiaNo ratings yet

- Lecture 10 - Particles in 3D Box and Hydrogen AtomDocument28 pagesLecture 10 - Particles in 3D Box and Hydrogen AtomArc ZeroNo ratings yet

- Kolpin Powersports 180cc Service ManualDocument87 pagesKolpin Powersports 180cc Service ManualBerk Alper SarıkayaNo ratings yet

- XC975 EV 英语译文Document2 pagesXC975 EV 英语译文abangNo ratings yet

- VDL Workshop ManualDocument260 pagesVDL Workshop Manual吳坤益No ratings yet

- ME 211 Plate Exercises 2Document3 pagesME 211 Plate Exercises 2Francis Jhon EDEROSASNo ratings yet

- Spec ST1800 ST2200 25-30 LA 60HZDocument1 pageSpec ST1800 ST2200 25-30 LA 60HZAlexis Winston MejiaNo ratings yet