Professional Documents

Culture Documents

SOP 14-4069 - Handling and Deployment of Pipe in The Field

Uploaded by

pidipo3379Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SOP 14-4069 - Handling and Deployment of Pipe in The Field

Uploaded by

pidipo3379Copyright:

Available Formats

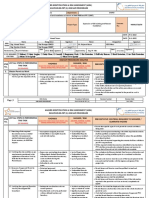

TEMPLATE #: 14-0002

Revision #: 1.0

Revision Date: April 9, 2015

FIELD OPERATIONS PAGE: 1 of 6

Standard Operating Procedure (SOP) - Work Instruction Template

Subject

Handling and Deployment of Flexpipe in the SOP #: 14-4069 SOP Revision #: 1.0

SOP Title:

Field SOP Related JHA/HAA #: 3002, 3006, 3023 SOP Revision Date: May 6, 2015

Job Title(s) to Perform Task: Field Technician, Contractors

First Created By: Kevin Johnson Title: Regional Operations Manager Signature: Kevin Johnson Date: May 6/15

Last Revised By: Title: Signature: Date:

SOP Type/Category (Inspection, Installation, Re-work, Maintenance, Rentals) Location (Solution Center/Installation Site)

(Select applicable from options above) (Add Department/Area if applicable)

Installation, Re-work Installation Site - Canada/ USA/ International

Approvals

Last HSE Approved By: Title: Signature: Date:

Last Ops Approved By: Title: Signature: Date:

Last Ops Approved By: Title: Signature: Date:

Requirements to Perform Task (To insert symbols use file path I:\HSE Communication\Icons)

Tools / Equipment / Materials / Personal Protective Equipment (PPE)

Other

Training Description(s) Symbol(s)

Rated Slings/Rigging, Taglines, Fire Resistant & Reflective Personal Gas

Adequate Sized Lifting Equipment Coveralls, Hardhat, Leather Monitor

(Trackhoe/Picker), Flexpipe Installation Gloves, Safety Eyewear, Safety

Guide, A-Frame, Deployment Trailer, Footwear, Hearing Protection,

Chop Saw, Sawzall, End Caps Personal Monitor, Face Shield

UNCONTROLLED DOCUMENT IF PRINTED OR NOT VIEWED FROM IFS

TEMPLATE #: 14-0002

Revision #: 1.0

Revision Date: April 9, 2015

FIELD OPERATIONS PAGE: 2 of 6

Standard Operating Procedure (SOP) - Work Instruction Template

Hazard Awareness (To insert symbols use file path I:\HSE Communication\Icons)

Description(s) Symbol(s)

Slips, Trips, Falls, Pinch Points, Overhead Loads, Reel movement, High Pressure Hydraulics, Heavy

Lifting, Stored Energy - Pipe Memory, Moving Equipment, Sharp Tools, Hot Work, Flying Debris

Purpose

To assist the worker in the safe and efficient deployment of Flexpipe Spoolable Products in the field and to avoid damage to equipment, pipe or

people.

UNCONTROLLED DOCUMENT IF PRINTED OR NOT VIEWED FROM IFS

TEMPLATE #: 14-0002

Revision #: 1.0

Revision Date: April 9, 2015

FIELD OPERATIONS PAGE: 3 of 6

Standard Operating Procedure (SOP) - Work Instruction Template

Procedure

Step # Description Picture

UNLOADING REELS

Find a suitable spot to park the trailer prior to unloading the reels. Ensure that it is a flat

level surface, out of the way of other traffic.

Block reels prior to removing the straps to prevent them from rolling.

Attach Tagline to reel that is to be lifted, and after inspecting, attach adequately rated

lifting device (slings/chains/shackles etc) to reel at appropriate lift points. ***REFER to

1 Flexpipe Installation Guide Section 2.2 Unloading Reels for more details***

Remove straps/chains only from reel that is to be lifted.

Using hand signals direct picker/hoe operator and lift reel slowly off the trailer.

Clear area of uneccessary personnel.

Ensure all personnel in the area are aware of the overhead loads and stay clear until reel

is set down.

Ensure that reel is properly blocked to keep it from rolling/sinking once on the ground.

UNCONTROLLED DOCUMENT IF PRINTED OR NOT VIEWED FROM IFS

TEMPLATE #: 14-0002

Revision #: 1.0

Revision Date: April 9, 2015

FIELD OPERATIONS PAGE: 4 of 6

Standard Operating Procedure (SOP) - Work Instruction Template

Step # Description Picture

LOADING REELS INTO A-FRAME

Remove the racheting load binders that secure the support shaft to the Aframe.

Lift the shaft from A-frame using picker/hoe. Slide the appropriate size spacer onto the

shaft and insert shaft into the reel using the picker/hoe to support the weight of it. Slide the

other spacer onto the shaft on the other side of the reel.

Attach lifting device (slings/chains/shackles etc) to appropriate lift points on the reel.

Attach tagline and lift reel slowly keeping it as close to the ground as possible.

Guide reel into the Aframe using taglines and make sure that it is centered in the saddles

prior to setting it down.

Secure with racheting load binders.

2

LOADING REELS ONTO DEPLOYMENT TRAILER

Remove support shaft from trailer and insert into reel as mentioned above. Ensure

spacers are in place and secured with safety pins.

Hook trailer up to suitable tow vehicle (sideboom/One Ton etc). Ensure hitch is locked

using safety pin and attach safety chains. Remove Jack and place in transport position on

the hitch.

Using a landguide back the trailer into position with the lifting arms in the lowered position.

Once lifting arms are centered under the support bar, raise the lifting arms using the

hydraulics until they come in contact with the support shaft. Lift high enough that the shaft

locks in place and secure with chains. Insert the pins to secure for transport.

** Refer to Deployment Trailer Operators Manual for further information**

UNCONTROLLED DOCUMENT IF PRINTED OR NOT VIEWED FROM IFS

TEMPLATE #: 14-0002

Revision #: 1.0

Revision Date: April 9, 2015

FIELD OPERATIONS PAGE: 5 of 6

Standard Operating Procedure (SOP) - Work Instruction Template

Step # Description Picture

PIPE DEPLOYMENT from stationary A-Frame/Trailer

Secure the end of the pipe to equipment using sling or other approved method as

described in the Flexpipe Installation manual Section 5.4 Stinging Methods.

When unspooling ensure someone is watching for issues at the pull point whenever

possible so that pipe doesn’t pull free.

Ensure good communication with operator while unspooling and unspool pipe by pulling at

slow, steady pace with no sudden stops or starts.

Stay clear of reel while deploying and watch for any issues at the reel (ie slack, damage

etc). Stop and inspect if anything abnormal is noticed as it may be difficult to find later.

Be aware when you are getting close to the end of the reel and restrain the end if

necessary to avoid it coming dislodged from the reel.

3

PIPE DEPLOYMENT from moving A-Frame/Trailer

Secure the pipe end to stationary object using sling or other approved method as

described in Flexpipe Installation manual Section 5.4 Stringing Methods.

Drive away slowly to ensure that pipe is anchored securely. Continue unspooling at a

slow, steady pace until desired length or the end of the reel is reached.

NOTE: Avoid moving trailer across side slopes or steep inclines/declines. Spot the trailer

and pull across these sections if possible.

CUTTING OF PIPE

Cut pipe using either Sawzall or Chop Saw and restrain the pipe to keep it from springing

when cut is completely through.

**Refer to manufacturers Operators Manual for instructions on operating saws**

4 Nite cap the end following Flexpipe Nite Capping procedure as described in the Flexpipe

Installation Guide Section 2.4 Storage of Reels

If reel still has pipe left on it secure the end to the reel using rope or polyken tape.

UNCONTROLLED DOCUMENT IF PRINTED OR NOT VIEWED FROM IFS

TEMPLATE #: 14-0002

Revision #: 1.0

Revision Date: April 9, 2015

FIELD OPERATIONS PAGE: 6 of 6

Standard Operating Procedure (SOP) - Work Instruction Template

LOWERING PIPE INTO TRENCH

Attach a set of cradles/sling to side boom/track hoe and around the pipe.

Clear the area of unnecessary personnel and equipment and check to make sure there is

no one working in the trench.

Proceed to lower pipe into trench using the side boom/track hoe.

5 Make sure that all personnel is on the work side of the ROW when lowering in to avoid

being struck/tripped by the pipe as it is being lowered in.

As slack is encountered, pull it out to the end in short sections or "snake" it in the trench.

Comments

Reference Flexpipe Systems Installation Guide

Revision Log

Revision # Revision Description Revised By Revision Date

UNCONTROLLED DOCUMENT IF PRINTED OR NOT VIEWED FROM IFS

You might also like

- Insert Facility/Institute Logo Here: TemplateDocument5 pagesInsert Facility/Institute Logo Here: TemplateJay Vee100% (1)

- Work at Height Procedure: Document Ref NoDocument16 pagesWork at Height Procedure: Document Ref NoDharmavir Singh100% (1)

- Work at Height ChecklistDocument3 pagesWork at Height ChecklistThillai8975No ratings yet

- OHS-07 Personal Protective EquipmentDocument15 pagesOHS-07 Personal Protective EquipmentAshok PatelNo ratings yet

- 04 - Tata Power Work at Height ProcedureDocument21 pages04 - Tata Power Work at Height Procedurehse bsjNo ratings yet

- ABB VFD CatalogesDocument25 pagesABB VFD CatalogesadehriyaNo ratings yet

- Lower GI BleedingDocument40 pagesLower GI BleedingMohammad Firdaus100% (2)

- Herbal Materia Medica 5th Ed. by Michael MooreDocument57 pagesHerbal Materia Medica 5th Ed. by Michael MooreIreneRains100% (3)

- Ohs-Pr-09-09-F31 (A) Leadership Safety Inspection & Walkthrough FormDocument6 pagesOhs-Pr-09-09-F31 (A) Leadership Safety Inspection & Walkthrough FormSiddiqui100% (1)

- JSP For SS 9013 No. JSP#05 Concrete Breaking Work Using EquipmentDocument10 pagesJSP For SS 9013 No. JSP#05 Concrete Breaking Work Using EquipmentAbdul Rasheed Mangrio50% (2)

- JSA LoadingDocument10 pagesJSA LoadingOcktri Bobet100% (3)

- A Guide To The Art of Adjusting Saxophone Reeds 2Document12 pagesA Guide To The Art of Adjusting Saxophone Reeds 2louish91758410% (1)

- Lift Elevator SafetyDocument17 pagesLift Elevator SafetyPraful E. PawarNo ratings yet

- Job/Task/Experimental Procedure Job Hazard Analysis (Jha) FormDocument4 pagesJob/Task/Experimental Procedure Job Hazard Analysis (Jha) FormMonzurNo ratings yet

- Scaffold Safety ProcedureDocument24 pagesScaffold Safety ProcedureAlif Rahmat Febrianto100% (1)

- Sri ChakrarchanaDocument25 pagesSri Chakrarchanarpasham67% (3)

- Lifting Equipment ManagementDocument12 pagesLifting Equipment ManagementAlaa Eldin Mohamed100% (1)

- Hse Audit Checklist SafetyDocument7 pagesHse Audit Checklist Safetysubhanmusadiq50% (2)

- 01 - Layered Process Audit Example B 2011Document7 pages01 - Layered Process Audit Example B 2011RN XaverNo ratings yet

- Serious Incident Prevention: How to Sustain Accident-Free Operations in Your Plant or CompanyFrom EverandSerious Incident Prevention: How to Sustain Accident-Free Operations in Your Plant or CompanyRating: 5 out of 5 stars5/5 (1)

- Attachment - I: Pre Start-Up Safety Review Checklist - 1Document15 pagesAttachment - I: Pre Start-Up Safety Review Checklist - 1HamzaNoumanNo ratings yet

- 01 JSA CLEANING BOILER Rev 05 013 BIDocument9 pages01 JSA CLEANING BOILER Rev 05 013 BIMohd KhaidirNo ratings yet

- Subject: Work at Height: Unit: Maihar Cement WorksDocument3 pagesSubject: Work at Height: Unit: Maihar Cement Workskaka100% (1)

- Cement Process OverviewDocument162 pagesCement Process OverviewRamachandra Rao Maddali50% (2)

- Lifting Work PermitDocument1 pageLifting Work PermitRadha BuildtechNo ratings yet

- Diagnostic Communication with Road-Vehicles and Non-Road Mobile MachineryFrom EverandDiagnostic Communication with Road-Vehicles and Non-Road Mobile MachineryRating: 1 out of 5 stars1/5 (1)

- Lesson 4 Cook Jams, Jellies, Marmalades and PreservesDocument35 pagesLesson 4 Cook Jams, Jellies, Marmalades and PreservesIan Venson F. BautistaNo ratings yet

- Periodic Inspection SOPDocument36 pagesPeriodic Inspection SOProberto santamariaNo ratings yet

- Checklist For Work at Height 13.02.01 HSE OCP-04 F-01 R-1Document1 pageChecklist For Work at Height 13.02.01 HSE OCP-04 F-01 R-1Sabari StunnerNo ratings yet

- Pump Inspection ChecklistDocument1 pagePump Inspection ChecklistSefaNo ratings yet

- Test 1Document6 pagesTest 1bekNo ratings yet

- Engine Driver Inspection ChecklistDocument1 pageEngine Driver Inspection ChecklistSefaNo ratings yet

- REC 12 - Hydrant - PIV - Deluge Station InstallationDocument1 pageREC 12 - Hydrant - PIV - Deluge Station InstallationAmir ChipNo ratings yet

- SF - 43 Ergonomics ChecklistDocument4 pagesSF - 43 Ergonomics ChecklistmphatuseniNo ratings yet

- PT ALSTOM GRID Operating Instruction Sit PDFDocument8 pagesPT ALSTOM GRID Operating Instruction Sit PDFAhmed AminNo ratings yet

- 3 CON 8749 REC 02 - Equipment Installation RecordDocument1 page3 CON 8749 REC 02 - Equipment Installation RecordmiorNo ratings yet

- 40 F032 120E Crane (Crawler) Inspection Daily RevBDocument1 page40 F032 120E Crane (Crawler) Inspection Daily RevBrashid7930% (1)

- MECH REC12 - Hydrant PIV Deluge Station InstallationDocument1 pageMECH REC12 - Hydrant PIV Deluge Station InstallationtinzarmoeNo ratings yet

- 40 F035 120E Crane (Gantry) Inspection Daily RevADocument1 page40 F035 120E Crane (Gantry) Inspection Daily RevArashid793No ratings yet

- PED-FRM-01-035 Worksite Inspection Form Rev 2Document6 pagesPED-FRM-01-035 Worksite Inspection Form Rev 2Almerindo DOS SANTOSNo ratings yet

- Report Documentation Page: Please Do Not Return Your Form To The Above AddressDocument39 pagesReport Documentation Page: Please Do Not Return Your Form To The Above Addresswhorne24No ratings yet

- Format No. 13.01.05 F-03 Visual Felt Leadership - HSE Checklist R1 15.06.2020Document2 pagesFormat No. 13.01.05 F-03 Visual Felt Leadership - HSE Checklist R1 15.06.2020Aarti100% (1)

- Permit To Work Checklist 11 - Isolation Permit - WATER INGRESS SENSOR CH 6Document2 pagesPermit To Work Checklist 11 - Isolation Permit - WATER INGRESS SENSOR CH 6Reg GulfoNo ratings yet

- Inspection Unisco (PF) Hse-09Document4 pagesInspection Unisco (PF) Hse-09Benasher IbrahimNo ratings yet

- SOP TowingDocument6 pagesSOP TowingbasdNo ratings yet

- Pre-Mobilize Vehicle-Equipment Inspection ChecklistDocument1 pagePre-Mobilize Vehicle-Equipment Inspection ChecklistUsama HanifNo ratings yet

- Lifting Operations AZDP Directive 008 - Edition 4.0: U:TobeusedasisDocument7 pagesLifting Operations AZDP Directive 008 - Edition 4.0: U:TobeusedasisSiddharth AsthanaNo ratings yet

- VAL-SV-E0163-P PCBA Depanelization Router Elite Machine Validation Plan - Edy-29 Nov (CK)Document8 pagesVAL-SV-E0163-P PCBA Depanelization Router Elite Machine Validation Plan - Edy-29 Nov (CK)arumNo ratings yet

- JHA Concrete Rectification - Epoxy InjectionDocument4 pagesJHA Concrete Rectification - Epoxy Injectionarnold arayataNo ratings yet

- MMH Dan StoringDocument13 pagesMMH Dan Storingfilza100% (1)

- Attachment H Installation Requirements DateDocument5 pagesAttachment H Installation Requirements DatemarcipomoyfanNo ratings yet

- EMOC 216 - N2 Line For Instrument AirDocument16 pagesEMOC 216 - N2 Line For Instrument Airtejcd1234No ratings yet

- Forflift ProcedureDocument15 pagesForflift ProcedurerichardNo ratings yet

- SYN-WI-001 Fall Prevention and ProtectionDocument24 pagesSYN-WI-001 Fall Prevention and ProtectionfaiqahNo ratings yet

- IMS 138-DSTI Checklist Rev05Document2 pagesIMS 138-DSTI Checklist Rev05victor100% (2)

- ER-201581 Final ReportDocument157 pagesER-201581 Final ReportRenatoNo ratings yet

- Work Method Statement: Location of Work: Submitted By: Site Name: Maintenance ActivityDocument6 pagesWork Method Statement: Location of Work: Submitted By: Site Name: Maintenance ActivityVishal RathodNo ratings yet

- Hse Audit Checklist Safety CompressDocument7 pagesHse Audit Checklist Safety CompressnaeemNo ratings yet

- B Report # EFI-MF-9-NP-2020Document3 pagesB Report # EFI-MF-9-NP-2020ghulamrasool726No ratings yet

- Technical Specification: Document Revision, Review, & Approval HistoryDocument10 pagesTechnical Specification: Document Revision, Review, & Approval HistorylisetteNo ratings yet

- Form 01 Crane Carry in InspectionDocument3 pagesForm 01 Crane Carry in InspectionDenny Syafwalufi0% (1)

- 9) SWP-09 Lifting Equipment, Appliances & GearsDocument5 pages9) SWP-09 Lifting Equipment, Appliances & GearsRachel NoraNo ratings yet

- Installation Method StatementDocument11 pagesInstallation Method StatementAnonymousNo ratings yet

- Sapura Subsea Services SDN BHD: ControlledDocument1 pageSapura Subsea Services SDN BHD: ControlledAnson Chew Wai YinNo ratings yet

- I-OPE-RA-003 - Rope Access Operating - Rev.7 (Em Revisao)Document36 pagesI-OPE-RA-003 - Rope Access Operating - Rev.7 (Em Revisao)Rael Zorzo MichelsNo ratings yet

- JSP For SS 9013 No. JSP#03 Excavation Using Electrical Jack HammerDocument11 pagesJSP For SS 9013 No. JSP#03 Excavation Using Electrical Jack HammerAbdul Rasheed MangrioNo ratings yet

- Sop 001 Fibre CT Site Set UpDocument8 pagesSop 001 Fibre CT Site Set UpjoseltnNo ratings yet

- Waste Management Plan-1Document16 pagesWaste Management Plan-1usama basionyNo ratings yet

- Augmentin Paed Susp MF gdsv26 Ipiv14 Dated 13 June 2019 24022021Document15 pagesAugmentin Paed Susp MF gdsv26 Ipiv14 Dated 13 June 2019 24022021Phisit PanasophonkulNo ratings yet

- An Introduction To Vibration Control in BuildingsDocument45 pagesAn Introduction To Vibration Control in Buildingsosama alabsiNo ratings yet

- ATV320 Getting Started EN NVE21763 02Document4 pagesATV320 Getting Started EN NVE21763 02Berkah Jaya PanelNo ratings yet

- Philips FR 970 Service ManualDocument116 pagesPhilips FR 970 Service ManualJohn WalesNo ratings yet

- ICS501 RevQDocument9 pagesICS501 RevQreteversiliaNo ratings yet

- Circular Motion ReviewDocument4 pagesCircular Motion ReviewrasajatiNo ratings yet

- Essay Topics For FrankensteinDocument8 pagesEssay Topics For Frankensteinafabilalf100% (2)

- VOIDING TRANSACTIONS in ALLSCRIPTSDocument1 pageVOIDING TRANSACTIONS in ALLSCRIPTSluzmercNo ratings yet

- Firms and The Financial MarketDocument57 pagesFirms and The Financial MarketSakinahNo ratings yet

- Medical Research With Music and The BrainDocument4 pagesMedical Research With Music and The BrainEngerber MarquezNo ratings yet

- Bayam Kadar Air Meningkat, SNI, Kadar AbuDocument14 pagesBayam Kadar Air Meningkat, SNI, Kadar AbuRirin WidiastutiNo ratings yet

- Defects in Metal Additive Manufacturing ProcessesDocument11 pagesDefects in Metal Additive Manufacturing ProcessesNiraj 93No ratings yet

- Technical Reference - Lightning Protection To Nfpa and Ul StandardsDocument1 pageTechnical Reference - Lightning Protection To Nfpa and Ul StandardsMarcons Jon Maturan CasabaNo ratings yet

- Carrot Cake Cupcakes - Sugar Spun RunDocument2 pagesCarrot Cake Cupcakes - Sugar Spun RunSean BermejoNo ratings yet

- E. Development of Nanocomposite Based Antimicrobial Cotton FabricsDocument11 pagesE. Development of Nanocomposite Based Antimicrobial Cotton FabricsAbreham BekeleNo ratings yet

- Generic Name: Phytonadione Brand Name:: Mechanism of ActionDocument3 pagesGeneric Name: Phytonadione Brand Name:: Mechanism of ActionJay VillasotoNo ratings yet

- MN-SVI FF Digital Positioner-IOM-GEA31031F-English-ReducedDocument264 pagesMN-SVI FF Digital Positioner-IOM-GEA31031F-English-Reducedravichandran0506No ratings yet

- Multi Purpose Floor Coating - Nippon PaintDocument2 pagesMulti Purpose Floor Coating - Nippon PaintNippon Paint Total Coating and Construction SolutionsNo ratings yet

- NASA Facts International Space Station Environmental Control and Life Support System 2008Document4 pagesNASA Facts International Space Station Environmental Control and Life Support System 2008Bob AndrepontNo ratings yet

- RM AOSASw GBHWK7 RW 7 MP 99 QDocument38 pagesRM AOSASw GBHWK7 RW 7 MP 99 QfernanroldanNo ratings yet

- ICT - Css 9 Getting To Know Your Computer: Quarter 1Document21 pagesICT - Css 9 Getting To Know Your Computer: Quarter 1Carlota GarciaNo ratings yet

- Landslide Hazard and Risk AssessmentDocument10 pagesLandslide Hazard and Risk AssessmentSiencia No Enjinaria DitNo ratings yet