Professional Documents

Culture Documents

PFI ES-24-2015 Pipe Bending Methods, Tolerances, Process and Material Requirements

PFI ES-24-2015 Pipe Bending Methods, Tolerances, Process and Material Requirements

Uploaded by

smlvl01Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PFI ES-24-2015 Pipe Bending Methods, Tolerances, Process and Material Requirements

PFI ES-24-2015 Pipe Bending Methods, Tolerances, Process and Material Requirements

Uploaded by

smlvl01Copyright:

Available Formats

PFI Standard ES-24

|Denotes Revision (Revised December 2015)

PIPE BENDING METHODS,

TOLERANCES,

--```,`,,`,,``,,``,``,,```,,,`,`-`-`,,`,,`,`,,`---

PROCESS AND MATERIAL

REQUIREMENTS

Prepared by

Pipe Fabrication Institute Engineering Committee

All PFI Standards are advisory only. There is no

agreement to adhere to any PFI Standard and their

use by anyone is entirely voluntary.

Copyright by

PIPE FABRICATION INSTITUTE

Dedicated to Technical Advancements and Standardization in

the Pipe Fabrication Industry

Since 1913

USA CANADA

511 Avenue of America’s, # 601 655, 32nd Avenue, # 201

New York, NY 10011 Lachine, QC H8T 3G6

WEB SITE

www.pfi-institute.org

Copyright Pipe Fabrication Institute

Provided by IHS Markit under license with PFI Licensee=BHP Billiton Nickel West - Perth, Kalgoolie, Kamb/8115459001, User=Pree

No reproduction or networking permitted without license from IHS Not for Resale, 12/04/2018 21:10:43 MST

PFI Standard ES-24

|Denotes Revision (Revised December 2015)

Pipe Bending Methods, Tolerances,

Process and Material Requirement

METRIC CONVERSIONS

The conversion of quantities between systems of units involves a determination of the number of significant digits to be retained. All

conversions depend upon the intended precision of the original quantity and are rounded to the appropriate accuracy.

Pipe sizes together with applicable wall thicknesses are not shown with metric equivalents.

The SI (metric) values where included with the customary U.S. values in this Standard are the rounded equivalents of the U.S.

values and are for reference only.

Metric units were derived utilizing the following conversion factor:

Conversion Factor Conversion Factor

Inches to 25.4 Deg. Fahr. to 5/9 (Deg. F.– 32)

Mitlimeters Deg. Cent.

Lb/in2 to 0.0703

Kg/cm2

1. Scope Dn = Nominal outside diameter of pipe.

tn = Nominal wall thickness of pipes.

1.1 This standard covers methods, process tm = Minimum calculated wall thickness

requirements, tolerances and acceptance criteria for required by the applicable code.

shop fabricated pipe bends. T = Pipe wall thickness (measured or

--```,`,,`,,``,,``,``,,```,,,`,`-`-`,,`,,`,`,,`---

minimum, in accordance with purchase

1.2 The bending methods described in this standard are specification).

a partial representation of commonly used R = Center line radius of bend.

processes and do not preclude the use of other

methods.

3. Bending Methods

2. Terminology 3.1 This standard covers bends formed by both hot and

cold bending methods. For this standard, a

2.1 The symbols and terms defined below are used temperature 100 degrees F below the lower critical

throughout this standard: temperature of the material is defined as being the

boundary between hot and cold bending.

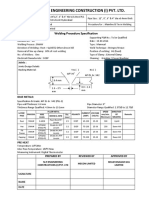

BEND EXTRADOS

3.2 Unless otherwise specified by the governing code,

TANGENT

the bending procedure, including the

T

heating/cooling cycle and post bend heat treatment,

EN Dn

NG is determined by the pipe material, diameter, wall

TA

thickness, bend radius and the required properties

after bending. Because of the many variables

R

involved, the bending procedure should be

BEND INTRADOS

determined by the fabricator.

FIGURE 2.1

D = Nominal pipe size.

Copyright Pipe Fabrication Institute

Provided by IHS Markit under license with PFI Licensee=BHP Billiton Nickel West - Perth, Kalgoolie, Kamb/8115459001, User=Pree

No reproduction or networking permitted without license from IHS Not for Resale, 12/04/2018 21:10:43 MST

PFI Standard ES-24

|Denotes Revision (Revised December 2015)

3.3 While the bending equipment used in many of the HEATING DEVICE

methods is generically the same, there may be

differences in bending procedures, material

allowances, hold and pull legs, wall thickness,

etc., between bending fabricators.

3.4 Hot bending methods

ANCHOR BOX

3.4.1 FURNACE BENDING:

In this method, the pipe is firmly packed HYDRAULIC CYLINDER

with sand and then heated in a furnace to a

temperature in the range of 2000 degrees F.

After removing from the furnace, one end of FIGURE 3.4.2

INCREMENTAL BENDING

the pipe is retained in a holding device and a

bending moment is applied at the other end.

3.4.3 INDUCTION BENDING:

The radius of the bend is controlled by dies,

The induction bending equipment is

stops or templates as the pipe is bent. For

composed of three basic components

long radius bends and/or heavy wall pipe,

consisting of a bed, a radial arm, which is set

the sand filling operation may not be

at the required radius, and an induction

necessary.

heating system. The pipe is placed in the bed

HOLDING SHOES and the front tangent is clamped to the radial

arm. The induction heating system heats a

narrow circumferential band around the pipe

to the appropriate bending temperature.

When this temperature is reached, the pipe is

continuously moved through the heating coil

while a bending moment is applied to the

heated area. After passing through the coil,

the pipe may be either forced or naturally

RADIUS STOPS cooled as required by the appropriate

(OPTIONAL)

qualified bending procedure.

PULLING DEVICE

INDUCTION COIL

FIGURE 3.4.1

FURNACE BENDING

3.4.2 INCREMENTAL BENDING:

The incremental bending equipment is

composed of an anchor box, a hydraulic

cylinder, and a moveable heating device. BED

The pipe is clamped in the anchor box and

RADIAL

the front tangent is connected to the ARM

hydraulic cylinder. The heating device heats

a narrow circumferential band on the arc to

the proper bending temperature. A force is

then applied by the hydraulic cylinder to FIGURE 3.4.3

bend the small increment a predetermined INDUCTION BENDING

amount. The heating device is then moved to

--```,`,,`,,``,,``,``,,```,,,`,`-`-`,,`,,`,`,,`---

successive segments where the process is

repeated until the required arc is attained.

After bending each increment, the heated

area is cooled as required by the appropriate

bending procedure.

Copyright Pipe Fabrication Institute

Provided by IHS Markit under license with PFI Licensee=BHP Billiton Nickel West - Perth, Kalgoolie, Kamb/8115459001, User=Pree

No reproduction or networking permitted without license from IHS Not for Resale, 12/04/2018 21:10:43 MST

PFI Standard ES-24

|Denotes Revision (Revised December 2015)

3.5 Cold bending methods FIGURE 3.5.2

RAM BENDING

3.5.1 ROTARY DRAW BENDING:

In this method, the pipe is secured to a 3.5.3 ROLL BENDING:

bending die by a clamping die. As the In roll bending, three forming rolls of

bending die rotates, it draws the pipe against approximately the same diameter arranged in

the pressure die and, if necessary to prevent a pyramid are used. The two fixed rolls

wall collapse, over an internal mandrel. The oppose the adjustable center roll. The pipe is

pressure die may remain fixed or move with passed through the rolls with the position of

the pipe. Rotary draw bending with carriage the adjustable roll controlling the bend radius.

assist or “Boost Bending” is also considered

to be Rotary Draw Bending. Boost Bending

is described as a device or system to apply a

longitudinal positive force in the direction of

bending by either clamping or pushing on

the end of the pipe being bent.

PRESSURE DIE

CLAMP

FIGURE 3.5.3

ROTATING BEND DIE

ROLL BENDING

FIGURE 3.5.1

4. Welds in Bends

ROTARY DRAW BENDING 4.1 In some instances it is not practical to utilize pipe

of sufficient length to satisfy the required arc

3.5.2 RAM BENDING: length of the bend. When it becomes necessary to

In ram bending, the pipe is held by two join lengths of pipe resulting in a circumferential

supporting dies and a force is applied by butt weld in the arc of a pipe bend, the following

means of a hydraulic ram to a forming shoe practices should be considered:

located at the center of the workpiece. The

supporting dies rotate on their mounting pins 4.1.1 Pipes to be welded should be selected to

so that they follow the pipe and maintain provide the best uniformity possible at the

external support throughout the operation. mating ends. Pipe wall thickness shall not be

SUPPORT

less than the design minimum plus bend

HYDRAULIC RAM DIE thinning allowance (see section 7.0).

4.1.2 End preparation for welding shall be in

accordance with the qualified welding

procedure to be used. Internal counterboring

should be avoided wherever possible. During

fit-up of the joint, the pipes should be rotated

FORMING SHOE or aligned as necessary to provide the least

amount of I.D. and/or O.D. mismatch and the

best transition across the weld.

4.1.3 The welding procedure must be qualified in

accordance with the governing Code for the

thermal exposures, (if any) excepted in

bending and heat treatment.

--```,`,,`,,``,,``,``,,```,,,`,`-`-`,,`,,`,`,,`---

Copyright Pipe Fabrication Institute

Provided by IHS Markit under license with PFI Licensee=BHP Billiton Nickel West - Perth, Kalgoolie, Kamb/8115459001, User=Pree

No reproduction or networking permitted without license from IHS Not for Resale, 12/04/2018 21:10:43 MST

PFI Standard ES-24

|Denotes Revision (Revised December 2015)

4.1.4 After completion of the circumferential butt exceed 3% of the nominal pipe size. (See

weld, but before bending, the O.D. and I.D. Figure 6.2, Note 1)

(where accessible) of the weld should be

(c) The minimum ratio of the distance between

ground to remove excess weld reinforcement

crests as compared to the height between

and blended smoothly into the base metal.

crests and the included valley should be 12

4.1.5 It is good practice to examine the to 1. (See Figure 6.2, Note 2)

circumferential butt weld by radiography

prior to and after bending, whether or not

such radiography is required by the applicable 2

1 3

Code.

A

5. Linear and Angular Tolerances

5.1 Bends shall be provided with a total angularity

tolerance of ± .5 degrees as determined by the

intersection of the tangent centerlines measured

by appropriate equipment.

5.2 When the fabricator is required to provide bends FIGURE 6.2

cut to a specified center-to-end dimension it shall APPLICATION OF PIPE WALL BUCKLING

be to the tolerances specified in PFI ES-3. TOLERANCES

5.3 If intermediate portions of the bend profile are Note 1 – Depth of average crest to valley is the sum of the

outside diameters of the two adjoining crests divided by two,

essential, their tolerances shall be a matter of minus the outside diameter of the valley.

agreement between the purchaser and the

fabricator.

( OD )1 ( OD ) 3

Depth ( OD ) 2

5.4 See fig. 9.3 for an explanation of terminology 2

regarding bend tolerances. Note 2 – Ratio of distance between crests to depth is:

A 12

6. Form Tolerances Depth (per Note 1) 1

6.1 The ovality of a pipe bend shall not exceed the

ovality required by the governing code. If there is 6.3 Buckles which exceed the above tolerances will

no governing code, the difference between the be subjected to corrective action to bring them

maximum and minimum diameters shall not within tolerance.

exceed 8% of the average measured outside

diameter of the straight portion of the pipe unless 6.4 If operating conditions require tighter tolerances

by mutual agreement between the purchaser and on buckles, it may be necessary to use larger radii,

the fabricator. Where operating conditions require heavier pipe walls or a specific bending process.

less ovality it may be necessary to use larger radii,

heavier pipe walls or a specific bending method 6.5 To determine what bends can be produced with a

that will provide a closer control of ovality. satisfactory degree of quality, the Pipe Fabrication

Institute has conducted studies on carbon steel

6.2 Since there are occasions when buckles cannot be and low alloy steel hot bends to determine

avoided, the following restrictions should apply: minimum recommended bend radii for various

ratios of outside diameters to wall thickness. The

(a) All wave shapes shall blend into the pipe resulting bending range determined by these

surface in a gradual manner. studies for each of the bending processes is shown

(b) The maximum vertical height of any wave, in Figure 6.5.1 and 6.5.2.

measured from the average height of two

adjoining crests to the valley, shall not

--```,`,,`,,``,,``,``,,```,,,`,`-`-`,,`,,`,`,,`---

Copyright Pipe Fabrication Institute

Provided by IHS Markit under license with PFI Licensee=BHP Billiton Nickel West - Perth, Kalgoolie, Kamb/8115459001, User=Pree

No reproduction or networking permitted without license from IHS Not for Resale, 12/04/2018 21:10:43 MST

PFI Standard ES-24

|Denotes Revision (Revised December 2015)

(2) Enter 29.1 on the Dn/T axis of Figure 6.5.1

and move vertically to the intersection with

7

the bending range boundary.

6 (3) Then move horizontally to determine the

5 minimum recommended radius to diameter

ratio which equals approximately 4.5. For

4 practical purposes, bending radii are seldom

3

expressed in terms of fractional numbers, but

rather in terms of whole integers multiplied

2 by the nominal pipe size. Hence, the

recommended bending radius would be 5 x

1

12 = 60".

0

Example B: Determine the minimum

0 10 20 30 40 50 60 70

permissible wall thickness required

for induction bending 22" O.D.

FIGURE 6.5.1 carbon steel pipe per ASTM A 53-

FURNACE BENDING RANGE Grade B at a 3D bend radius.

(1) Enter 3 on the R/Dn axis of figure 6.5.2 and

7

move horizontally to the intersection with

6

the bending range boundary.

(2) Then move verticality to determine the

5 minimum recommended diameter to wall

thickness ratio which equals approximately

4 45. i.e. Dn/tn = 45 or tn = Dn/45 = 22/45 =

.489".

3

6.7 Figure 6.5.1 is based on extensive experience in

furnace bending carbon and low alloy steel pipe.

2

Since stainless and non-ferrous materials have

higher coefficients of expansion than carbon and

1

low alloy steels, a greater reduction in the density

of the sand fill occurs as these materials are being

0

heated to the bending temperature. As a result, the

0 25 50 75 100 125 150 sand fill does not provide the same rigidity against

flattening and buckling as it does when carbon or

FIGURE 6.5.2 low alloy steel pipe is being bent. Because of this

INDUCTION AND INCREMENTAL BENDING RANGE fundamental difference, special consideration

must be given to the selection of the minimum

6.6 Two examples are given for the determination of bending radius by the design engineer.

minimum recommended wall thickness and

bending radius combinations for a given pipe size. 6.8 Cold bending ranges can vary significantly with

the process and degree of specialized tool used.

Example A: Determine minimum permissible Figure 6.8.1 can be used to select the type of bend

bending radius required for furnace or the process required.

bending 12"-Extra Strong carbon

steel pipe per ASTM A 106-Grade

B.

(1) Determine the diameter to wall thickness

ratio. 12" X-Stg. is 12.75" O.D. with a .500"

nominal wall. Under ASTM A 106, the

minimum wall is .438". Therefore Dn/T =

12.75/.438 = 29.l.

--```,`,,`,,``,,``,``,,```,,,`,`-`-`,,`,,`,`,,`---

Copyright Pipe Fabrication Institute

Provided by IHS Markit under license with PFI Licensee=BHP Billiton Nickel West - Perth, Kalgoolie, Kamb/8115459001, User=Pree

No reproduction or networking permitted without license from IHS Not for Resale, 12/04/2018 21:10:43 MST

PFI Standard ES-24

|Denotes Revision (Revised December 2015)

tm

(2nd column value) – ( 1 ),

12 t

11 AW L where t =Nominal pipe wall thickness minus

10 ND DR DRE

BE

RY N manufacturing tolerance, and tm is derived from

9

LL

TA MA

RO

8 RO ITH REL equation (3) of B31.1, par. 104.1.2. The most

AND

&

W

7 LL M conservative values over that range of pipe sizes

M

BA

RA

6 LTI-

H MU and wall thicknesses where used.

WIT L

I-BAL

5 AW MULT

Y DR AW WITH IE

4 TAR RY DR D

ROTA IPER

RO ND W TABLE 7.2.1

3 REL A

MAND

2 FURNACE BENDING

1

0 Bend Minimum Thickness Factored

0 25 50 75 100 125 150 Radius Prior to Bending Thickness

FIGURE 6.8.1 6D 1.06 tm 1.03 tm

COLD BENDING RANGE 5D 1.08 tm 1.04 tm

4D 1.14 tm 1.09 tm

7. Material Allowances 3D 1.25 tm 1.19 tm

7.1 The following recommendations for material allowances TABLE 7.2.2

will vary with the bending method, material, pipe size, INDUCTION AND INCREMENTAL BENDING

bend radius and the bend fabricator's equipment. It is

suggested that the purchaser contact the fabricator for Bend Minimum Thickness Factored

specific information. Radius Prior to Bending Thickness

7.2 To compensate for wall thinning from bending, the 6Dn 1.06 tm 1.03 tm

second column, (“Minimum Thickness Prior to 5Dn 1.08 tm 1.04 tm

Bending”), in Tables 7.2.1, 7.2.2, 7.2.3, and 7.2.4 can 4Dn 1.10 tm 1.05 tm

be used as a guide for ordering pipe for the appropriate 3Dn 1.14 tm 1.08 tm

process. ASME B31.1 Power Piping, equations 2Dn 1.22 tm 1.13 tm

102.4.5(3B, 3C & 3E), and B31.3 Process Piping, 1.5Dn 1.30 tm 1.19 tm

equation 304.2.1(3c & 3e) define a minimum thickness

at the extrados of the bend that is less than the minimum TABLE 7.2.3

thickness required for straight pipe. Conversely, the ROTARY DRAW BENDING

minimum thickness for the intrados of the bend needs to

be proportionally thicker than that required for straight Bend Minimum Thickness Factored

pipe. The third column, (“Factored Thickness”), of Radius Prior to Bending Thickness

these tables lists the minimum required thickness prior

to bending factored for the allowable thinning at the 6Dn 1.09 tm 1.06 tm

extrados of the bend. Experience indicates that a 5Dn 1.14 tm 1.10 tm

minimum thickness of straight pipe shown in tables 4Dn 1.20 tm 1.15 tm

should be sufficient to meet the minimum thickness 3Dn 1.28 tm 1.22 tm

requirements after bending. Interpolation is permissible

for bending to intermediate radii. TABLE 7.2.4

RAM AND ROLL BENDING

The code formula for calculating the minimum

thickness required for the bend extrados, as defined in Bend Minimum Thickness Factored

B31.1 2007 is: Radius Prior to Bending Thickness

R

4 1

tm

PDo

A where Do 6Dn 1.08 tm 1.05 tm

I

SE R 5Dn 1.10 tm 1.06 tm

2 Py 4 2 4Dn 1.13 tm 1.08 tm

I Do 3Dn 1.17 tm 1.11 tm

The formula used to calculate the third column is:

--```,`,,`,,``,,``,``,,```,,,`,`-`-`,,`,,`,`,,`---

Copyright Pipe Fabrication Institute

Provided by IHS Markit under license with PFI Licensee=BHP Billiton Nickel West - Perth, Kalgoolie, Kamb/8115459001, User=Pree

No reproduction or networking permitted without license from IHS Not for Resale, 12/04/2018 21:10:43 MST

PFI Standard ES-24

|Denotes Revision (Revised December 2015)

7.3 Since the start of the bend is somewhat dependent on which results in more footage of straight pipe being

factors not completely within the control of the bender, required than that determined from the developed

some additional length must be added to insure that length. To provide for this compression the

overall center-to-end dimensions can be met. To purchaser of induction bends should add 5% to the

compensate for this factor, the purchaser should add 6 theoretical arc length. The compression of the

inches to the total of the required straight tangent material may leave a hump, or bump, at the

lengths. beginning of the bend on the inside radius which is

not detrimental to the bend.

7.4 Because induction heated bends are produced under

pressure, a compression of the material takes place

Nominal pipe size 1" thru 2" 2½" thru 3½" 4" thru 48"

Pulling End 6" 8" 2D (10" min)

Holding End 6" 8" 1.5D (10" min)

Tangent Between Bends (Tm) 6" 9" 1D (12" min)*

*Note: 9" min for 4" pipe. 10" min for 5" pipe.

TABLE 7.5.1

MINIMUM TANGENT LENGTHS FOR FURNACE BENDS

7.5 In order to produce a bend properly, minimum

straight tangents are required on both ends of the VARIES

arc for holding and/or pulling purposes.

Characteristic minimum tangent lengths for the

R

various processes are given in Tables 7.5.1, 7.5.2, R

and 7.5.3. Definition of these tangent lengths can

be seen in Figure 7.5.4. Minimum tangent lengths

required for incremental bending should be TM

VARIES

obtained from the fabricator. Longer tangents

should be utilized wherever possible and should

be considered in the piping design. In cases where

tangents must be kept short, it should be realized FIGURE 7.5.4

that an out-of-round condition may exist at the TANGENT LENGTHS

pipe ends.

8. Material Requirements for Hot Bending

Nominal Pipe Size 2" thru 24" 26" thru 66"

8.1 Pipe to be bent should be protected from the

Front Tangent OD+ 6" OD+ 6"

contamination of harmful materials such as the

Rear Tangent 72" 132"

Tangent Between Bends (Tm) 24" 60"

low melting temperature alloys of copper, brass

and lead.

TABLE 7.5.2 8.2 Stainless steel pipe suspected of being

MINIMUM TANGENT LENGTHS contaminated with ferrous metals or other harmful

FOR INDUCTION BENDING materials should be cleaned prior to bending to

remove the contaminants.

Nominal Pipe Size 1" thru 10"

Front Tangent 2XD 8.3 Stainless steel pipe should be furnished in the

Rear Tangent 3XD solution annealed condition.

Tangent Between Bends (Tm) 2XD

TABLE 7.5.3

MINIMUM TANGENT LENGTHS FOR COLD BENDING

--```,`,,`,,``,,``,``,,```,,,`,`-`-`,,`,,`,`,,`---

Copyright Pipe Fabrication Institute

Provided by IHS Markit under license with PFI Licensee=BHP Billiton Nickel West - Perth, Kalgoolie, Kamb/8115459001, User=Pree

No reproduction or networking permitted without license from IHS Not for Resale, 12/04/2018 21:10:43 MST

PFI Standard ES-24

|Denotes Revision (Revised December 2013)

9. Ordering Information 9.3 Suggested Bending Tolerances:

9.1 The Pipe Bend Order Form, (Form 9.1), provides Radius of Bend ---------------- ± 1% of Dim “C”

the recommended information required for the Degree of Bend --------------- 0.5 Degree

purchase pipe bends. Plane of Bend------------------ 1.0 Degree

9.2 The applicability and acceptance criteria of each Flat Plane of Bend ------------ 1% of Dim “C”

field, as defined by the Pipe Bend Order Form, Linear Dimensions ------------ 1/8”, 12” & under

shall be determined by the applicable codes, 3/16”, over 12”

specifications and fabrication requirements. Ovality in Bent Area --------- 8% of Diameter

after Bend

Ovality at End Prep. ---------- ASME B16.9

9.4 The miscellaneous remarks area and the space

provided at the bottom of the pipe bend order

form can be used to address additional

requirements such as, Piece Marking, Centerline

Scribing, Bend Heat Treatment, Butt Welds in

Linear Bends Area, etc.

Dimension

Linear Tangent

Dimension Length

Radius of

Bend (Dim C) Plane of Bend

(Angle between

Two Bend Planes)

Plan View End View

Ovality Tolerence :

Minor The difference

Dia. between the major

e

n

and minor axis (percent)

Flat Plane i

L

tn Nom. Major

of Bend e

g Dia. Dia.

n

a

T

Degree of

Bend

Ovality

(2 x size)

Tangent Line

Elevation

Figure 9.3

Tolerences

--```,`,,`,,``,,``,``,,```,,,`,`-`-`,,`,,`,`,,`---

Copyright Pipe Fabrication Institute

Provided by IHS Markit under license with PFI Licensee=BHP Billiton Nickel West - Perth, Kalgoolie, Kamb/8115459001, User=Pree

No reproduction or networking permitted without license from IHS Not for Resale, 12/04/2018 21:10:43 MST

PFI Standard ES-24

|Denotes Revision (Revised December 2013)

PIPE BEND ORDER FORM

FORM 9.1

--```,`,,`,,``,,``,``,,```,,,`,`-`-`,,`,,`,`,,`---

Copyright Pipe Fabrication Institute

Provided by IHS Markit under license with PFI Licensee=BHP Billiton Nickel West - Perth, Kalgoolie, Kamb/8115459001, User=Pree

No reproduction or networking permitted without license from IHS Not for Resale, 12/04/2018 21:10:43 MST

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ps1791s WELD SCREWS PROJECTION WELDINGDocument10 pagesps1791s WELD SCREWS PROJECTION WELDINGWinb SunNo ratings yet

- ASME B31.1 Interpretation For BendDocument1 pageASME B31.1 Interpretation For Bendkiho sungNo ratings yet

- Final Examination #1: Open Book Questions (1 50)Document29 pagesFinal Examination #1: Open Book Questions (1 50)kiho sung100% (1)

- MU IV: For Welding of Tube To Tube Joints, Tube To Elbow JointsDocument5 pagesMU IV: For Welding of Tube To Tube Joints, Tube To Elbow Jointskiho sungNo ratings yet

- Review Qualifications Agreement PrintDocument2 pagesReview Qualifications Agreement Printkiho sungNo ratings yet

- Indipco ManualDocument53 pagesIndipco Manualنايفف بن عبداللهNo ratings yet

- Industrial Materials and Processes HandoutDocument1 pageIndustrial Materials and Processes HandoutRoland Emerson100% (1)

- Consumable LasDocument35 pagesConsumable LasAfifYantoMutuHNo ratings yet

- Kleiberit 761.8Document12 pagesKleiberit 761.8Muhammad AhsanNo ratings yet

- PLUMBINGDocument5 pagesPLUMBINGhadjie ansayNo ratings yet

- Gas Metal Arc WeldingDocument20 pagesGas Metal Arc WeldingSarveshSailNo ratings yet

- STS QAC SOP 007 Repair Procedure For Carbon SteelDocument6 pagesSTS QAC SOP 007 Repair Procedure For Carbon Steelmohd as shahiddin jafriNo ratings yet

- 04 Samss 041Document6 pages04 Samss 041Awais CheemaNo ratings yet

- Extrusion ProcessesDocument20 pagesExtrusion ProcessesNur AiniNo ratings yet

- Pakistan Steel - Grooving To The Construction Beat (AKD Detailed ReportS...Document16 pagesPakistan Steel - Grooving To The Construction Beat (AKD Detailed ReportS...farrukhNo ratings yet

- Presentation Chp30 2Document31 pagesPresentation Chp30 2azemmmNo ratings yet

- Medieval Copper Alloy Production and West African Bronze Analyses Part 2Document30 pagesMedieval Copper Alloy Production and West African Bronze Analyses Part 2STNo ratings yet

- Strain-Age Cracking of Alloy 601 Tubes at 600 C: Henrik StahlDocument4 pagesStrain-Age Cracking of Alloy 601 Tubes at 600 C: Henrik Stahlvaratharajan g rNo ratings yet

- Evaluating Corrosion Properties of Wrought Iron-And Nickel-Based Corrosion Resistant Alloys For Chemical Process IndustriesDocument6 pagesEvaluating Corrosion Properties of Wrought Iron-And Nickel-Based Corrosion Resistant Alloys For Chemical Process IndustriesNav TalukdarNo ratings yet

- Kov'R-Kote: Premium, Nonmetallic Thread Compound For Use On Drill Collars, Drill Pipe, Tubing, & CasingDocument1 pageKov'R-Kote: Premium, Nonmetallic Thread Compound For Use On Drill Collars, Drill Pipe, Tubing, & CasingJeremias UtreraNo ratings yet

- Auruna 500 LC: Operating InstructionsDocument4 pagesAuruna 500 LC: Operating InstructionsShadow Fox0% (1)

- ES9-58 Standard Paint Program Tubomachinery Rev WDocument11 pagesES9-58 Standard Paint Program Tubomachinery Rev WganeshNo ratings yet

- Proposed WPS For API 5LDocument1 pageProposed WPS For API 5LMecon HyderabadNo ratings yet

- AJR Breif ProfileDocument13 pagesAJR Breif ProfilesajalNo ratings yet

- DR Ramaswamy and Marimuthu Patent Journa No 38 2020 Dated 18 09 2020Document1 pageDR Ramaswamy and Marimuthu Patent Journa No 38 2020 Dated 18 09 2020PerumalMarimuthuNo ratings yet

- Success - Story - HCR6000 - Shandong - China - Alu - March 2017Document2 pagesSuccess - Story - HCR6000 - Shandong - China - Alu - March 2017Sanjay RajawatNo ratings yet

- Lathe Machine (PDF) - Definition, Parts, Types, Operations & Specifications PDFDocument43 pagesLathe Machine (PDF) - Definition, Parts, Types, Operations & Specifications PDFmalyn gorospeNo ratings yet

- Steel Mesh Supplier in India.Document44 pagesSteel Mesh Supplier in India.tech.infrakeysNo ratings yet

- Astm A48 PDFDocument5 pagesAstm A48 PDFPhan Linh100% (1)

- Lee Spring CatalogDocument391 pagesLee Spring CatalogDGWNo ratings yet

- Bailey Clip Shop Brochure (FINAL 12-2021)Document64 pagesBailey Clip Shop Brochure (FINAL 12-2021)Armenak BaghdasaryanNo ratings yet

- 1000W Dual Drive Sheet Metal Laser Cutting MachineDocument3 pages1000W Dual Drive Sheet Metal Laser Cutting MachineAbayNo ratings yet

- 10.the Specialised Belt ConveyorDocument3 pages10.the Specialised Belt ConveyorGerman RestrepoNo ratings yet

- DIVISION 4 - Assignment Technical SpecificationsDocument4 pagesDIVISION 4 - Assignment Technical SpecificationsPatrisha SantosNo ratings yet