Professional Documents

Culture Documents

Uxp 4mt

Uploaded by

Farid M T AhmadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uxp 4mt

Uploaded by

Farid M T AhmadCopyright:

Available Formats

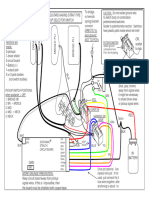

Installation Instructions

For 1/2” Annular Connectors

Connectors Supported Tools/Materials HCG-FRAMESET-1/2

UXP-DF-12 TW1412 TQ-114-F18

UXP-NM-12 Torque Wrench

N-Male

Torque Wrench

Din-Male

UXP-NF-12

HCG-CC

UXP-DRA-12

UXP-NRA-12 12” Adjustable

SP-CC

UXP-MDM-12 Wrench

UXP-MDF-12

UXP-MRA-12 Alcohol Wipe

UXP-4F-12 UXP-DM-12 RDCUTTER-S Safety Glasses

TQ-78-F8

Torque Wrench

Mini Din-Male

UXP-4MT-12

UXP-4RT-12 SP-1/2 LDF4D

Prep/Strip Tool with Bit “U”

JMA Part # CORULDF4D

T-Handle

Always wear Power Drill

Step #1: Prep

safety glasses

when operating With a few simple steps, JMA compression connectors

tools.

can be easily and consistently installed on 1/2" cable.

Straighten cable. Use RDCUT- Attach prep/strip tool to drill. Actuate drill to remove jacket

TER-S, applying even pressure and expose the center conduc-

around cable while rotating tor, then make sure the final cut

tool around cable to cut off is in the valley.

cable squarely.

Use the coring bit “U” to remove Cable will have approximately Use center conductor cleaner

dielectric until cable reaches one corrugation of dielectric (“SP-CC tool”) to remove any

stop on tool. You may option- removed. remaining dielectric material on

ally use the included T-Handle center conductor.

to prep/strip and core cable.

13109-01 revT 06-19-2015

7645 Henry Clay Blvd.

Support Tel: +1 315-431-7100 customerservice@jmawireless.com | www.jmawireless.com

Liverpool, NY 13088

Installation Instructions

For 1/2” Annular Connectors

Step #2: Install

Align outer conductor as Use alcohol wipe to clean Push connector onto cable

shown with groove on cap. inner and outer conductors until it reaches alignment

Mark cable jacket (using thoroughly. mark (until 2 clicks are

pen or marker) in line with heard/felt).

end of connector.

Step #3: Compress

Connector Frameset Insert

7-16 DIN A

RA A

N B

4.1-9.5 C

4.3-10 D

Select proper insert for con- Make sure connector is fully When fully compressed,

nector. Pull/push back the seated. Press HCG tool trig- connector will move away

Insert A Insert B Insert C Insert D insert to allow connector/ ger until gun cycles. Do not from alignment mark.

Refer to chart to select proper cable to lay flat in frame. pull or push on tool during

insert for connector type. compression.

Step #4: Torque

Series

N

Torque (in. lbs.)

14 (1.2 ft-lbs)

Hex Nut Size

3/4”

Cable preparation guide

DIN 216 (18 ft-lbs) 1-1/4"

4.1-9.5 & 4.3-10 96 (8 ft-lbs) 7/8”

Use proper torque based on the type of interface.

Mobile-enabled:

JMAqr.com

When using the torque wrench,

make sure the mating connector is

supported by an adjustable wrench.

Compare to picture to determine if

correct cable prep was performed.

Scan for install video. (For reference only)

13109-01 revT 06-19-2015

7645 Henry Clay Blvd.

Support Tel: +1 315-431-7100 customerservice@jmawireless.com | www.jmawireless.com

Liverpool, NY 13088

You might also like

- Installation Instructions for 1/2Document2 pagesInstallation Instructions for 1/2sandeep bagulNo ratings yet

- 14502-01 RevaDocument2 pages14502-01 RevaFarid M T AhmadNo ratings yet

- PPC LDF4 Install Inst - Hand ToolDocument2 pagesPPC LDF4 Install Inst - Hand ToolTower_DocNo ratings yet

- PPC Fsj4 & Scf12 Install InstDocument2 pagesPPC Fsj4 & Scf12 Install InstTower_DocNo ratings yet

- Print Wiring Diagram 5Document25 pagesPrint Wiring Diagram 5Ax LeNo ratings yet

- Montare PedaleDocument9 pagesMontare PedalegiuseppeNo ratings yet

- Print Wiring Diagram 6Document31 pagesPrint Wiring Diagram 6Ax LeNo ratings yet

- Audi Q2 No. 6 / 1: Airbag Systems, (L0L)Document9 pagesAudi Q2 No. 6 / 1: Airbag Systems, (L0L)acb . bNo ratings yet

- Home Theater Speaker System: Service Manual Service ManualDocument15 pagesHome Theater Speaker System: Service Manual Service ManualmyotezaNo ratings yet

- Id CH 300 If 8000 Dual Ffreq Searchlight SonarDocument1 pageId CH 300 If 8000 Dual Ffreq Searchlight Sonararjun roy ENo ratings yet

- Mid 10-25ktl3-x Quick Guide en 202305Document2 pagesMid 10-25ktl3-x Quick Guide en 202305larionov.olejaNo ratings yet

- RRU !remote Relay UnitDocument2 pagesRRU !remote Relay UnitOussama ChriguiNo ratings yet

- DMC899 SL PDFDocument2 pagesDMC899 SL PDFKaung MyatToeNo ratings yet

- One Touch Hydraulic Punch Clamp Operator's ManualDocument21 pagesOne Touch Hydraulic Punch Clamp Operator's Manualtrung vothaiNo ratings yet

- MD-0101 SM Ver01Document23 pagesMD-0101 SM Ver01Majid AfrasiabiNo ratings yet

- Ism0536 R02Document8 pagesIsm0536 R02muhammad.wajahat194No ratings yet

- Pioneer djm-800 rrv3474 SupplementDocument2 pagesPioneer djm-800 rrv3474 SupplementjaanvanbrabantNo ratings yet

- Schematic Diagrams: DVD Receiver With MonitorDocument16 pagesSchematic Diagrams: DVD Receiver With Monitordmitry esaulkovNo ratings yet

- 08 - Circuit Description PDFDocument6 pages08 - Circuit Description PDFphetronyo ferreira de oliveiraNo ratings yet

- CONE VALVE Service ManualDocument30 pagesCONE VALVE Service ManualMathieu DouNo ratings yet

- FANUC机器人培训教材Document140 pagesFANUC机器人培训教材TommyNo ratings yet

- Eequipment ListDocument1 pageEequipment ListKresnaNo ratings yet

- IC-F5062D InstructionsDocument2 pagesIC-F5062D InstructionsCesar Del CastilloNo ratings yet

- MN 63120 2101 en dp2 Instruction PDFDocument4 pagesMN 63120 2101 en dp2 Instruction PDFHector Callejas ValdezNo ratings yet

- Crimp 234@aDocument1 pageCrimp 234@aAMT Servicios EspecializadosNo ratings yet

- Banner DEE2R 850D Datasheet PDFDocument11 pagesBanner DEE2R 850D Datasheet PDFElavariegaNo ratings yet

- Roadbook Holder 2Document1 pageRoadbook Holder 2Anonymous EVBTCXkjnpNo ratings yet

- 1SNC160019C0203 - SNA Series - Terminal BlocksDocument156 pages1SNC160019C0203 - SNA Series - Terminal Blocksbaurzhan.kunkuzhayevNo ratings yet

- Mechanical Installation:: Gnd/Ref. Gnd/Ref. Positive PositiveDocument1 pageMechanical Installation:: Gnd/Ref. Gnd/Ref. Positive PositiveJhon Mario Rendón GiraldoNo ratings yet

- For Guitars Having Strat-Type Pickup Selector SwitchDocument1 pageFor Guitars Having Strat-Type Pickup Selector Switchtanee boonmalertNo ratings yet

- Kenwood Kdc-348u kdc-4751sd Kdc-Bt41u Kdc-Bt648u Kdc-U4549 Kdc-U4549s Kdc-U549bt kdc-x395 kdc-x695Document50 pagesKenwood Kdc-348u kdc-4751sd Kdc-Bt41u Kdc-Bt648u Kdc-U4549 Kdc-U4549s Kdc-U549bt kdc-x395 kdc-x695lucasNo ratings yet

- Eaton 107898 M22 CK20 en - GBDocument4 pagesEaton 107898 M22 CK20 en - GBAchafi Moussa MahamatNo ratings yet

- A22ne-Pd A22ne-P A22e A263-E1 20 13 csm1265Document58 pagesA22ne-Pd A22ne-P A22e A263-E1 20 13 csm1265Zaenal ArifinNo ratings yet

- Audio/Video Multi-Channel Receiver: Order NoDocument5 pagesAudio/Video Multi-Channel Receiver: Order NojaimfcNo ratings yet

- Olympus OM-D E-M1 PT-EP11 Underwater System Chart EnglishDocument1 pageOlympus OM-D E-M1 PT-EP11 Underwater System Chart EnglishPatrick StivénNo ratings yet

- Remote Mimic Panel: Manual Revisions ListDocument17 pagesRemote Mimic Panel: Manual Revisions ListAleksei PodkopaevNo ratings yet

- Megnetrol-Kotron Smart RF-805-Level TransmitterDocument16 pagesMegnetrol-Kotron Smart RF-805-Level TransmitterSaeed VuNo ratings yet

- A005F520020-Basic Equipment (L0L) From July 2016A5Document1,795 pagesA005F520020-Basic Equipment (L0L) From July 2016A5Dmitriy GevkoNo ratings yet

- GSK983Ta-HV Connection ManualDocument34 pagesGSK983Ta-HV Connection ManualLucasNo ratings yet

- Kenwood CD-203-204 DPF-R3010-4010-5010 Service ManualDocument17 pagesKenwood CD-203-204 DPF-R3010-4010-5010 Service ManualBigg Dady100% (1)

- The Agressor DistortionDocument16 pagesThe Agressor DistortionJosé MessiasNo ratings yet

- IC-2300H Marine HM-154 QG 2Document2 pagesIC-2300H Marine HM-154 QG 2Lisnik W. F. BerrielNo ratings yet

- Digital Keyboard: Service ManualDocument45 pagesDigital Keyboard: Service ManualsugedaNo ratings yet

- REMOTE SENSOR DC2We PDFDocument11 pagesREMOTE SENSOR DC2We PDFvipvashNo ratings yet

- Panduit Modular Plug Installation InstructionsDocument2 pagesPanduit Modular Plug Installation InstructionszigbaddyNo ratings yet

- Sharp 14-21 D1S 14-21D2S - G Chassis - GA1AM Service ManualDocument40 pagesSharp 14-21 D1S 14-21D2S - G Chassis - GA1AM Service ManualMarbi Sov100% (1)

- P 200 eDocument65 pagesP 200 eRafael ZuletaNo ratings yet

- Bo Cam Bien Khech Dai Panasonic - fx501 - Instruction - enDocument4 pagesBo Cam Bien Khech Dai Panasonic - fx501 - Instruction - enHải Nhỏ丁黄海No ratings yet

- Precision Plumbing Products: "Specify With Confidence - Install With Pride"Document2 pagesPrecision Plumbing Products: "Specify With Confidence - Install With Pride"Mai Tuan AnhNo ratings yet

- Rig Com StationDocument4 pagesRig Com StationCristof Naek Halomoan TobingNo ratings yet

- ED1140158-900 (30082016 DCA Review)Document2 pagesED1140158-900 (30082016 DCA Review)mycopteraviationNo ratings yet

- Service Manual: Leading Image Processing Technology We've Been There When You NeededDocument69 pagesService Manual: Leading Image Processing Technology We've Been There When You NeededOscar AbarcaNo ratings yet

- Color Gps Plotter Gp-3300 Color Video Plotter Gd-3300Document31 pagesColor Gps Plotter Gp-3300 Color Video Plotter Gd-3300nimsNo ratings yet

- Tlm-1903 Service ManualDocument40 pagesTlm-1903 Service ManualdaldoggyNo ratings yet

- Install current sensor and connect to energy measuring unitDocument1 pageInstall current sensor and connect to energy measuring unitLucas PaulaNo ratings yet

- Service Manual Service Manual: TX-NR1008 (B) / (S)Document209 pagesService Manual Service Manual: TX-NR1008 (B) / (S)Alexandre JoseNo ratings yet

- SONNAX 45rfeDocument2 pagesSONNAX 45rfefulltransmissionNo ratings yet

- Blackmer Part List XL2BDocument2 pagesBlackmer Part List XL2Bjuan davidNo ratings yet

- Peugeot Satelis 400-500 (En)Document84 pagesPeugeot Satelis 400-500 (En)Manualles71% (7)

- NLB 225Document2 pagesNLB 225Sergio Roberto Cabrera BurgosNo ratings yet

- Bending Machine ReportDocument3 pagesBending Machine ReportJoe MunthaliNo ratings yet

- AC GENERATOR WIRING DIAGRAMDocument15 pagesAC GENERATOR WIRING DIAGRAMAndriano Dasri100% (15)

- PWV 10 COMP Atwoods MachineDocument5 pagesPWV 10 COMP Atwoods MachineSandi WiarsanaNo ratings yet

- Parts Manual: CMP15/18/20s L FX15/18 L-2Document157 pagesParts Manual: CMP15/18/20s L FX15/18 L-2Marcio50% (2)

- Effect of Temperature On Wind Forces On Tall Building Using Numerical Approach - Computational Fluid Dynamics (CFD)Document6 pagesEffect of Temperature On Wind Forces On Tall Building Using Numerical Approach - Computational Fluid Dynamics (CFD)Jay KasodariyaNo ratings yet

- 6020B Slow Return Check ValveDocument3 pages6020B Slow Return Check Valvezawmoe aungNo ratings yet

- General BoRexRC2 Re95310 2009-01 enDocument12 pagesGeneral BoRexRC2 Re95310 2009-01 enEduardo Aguero ValdezNo ratings yet

- Meterial Take Off for Lightning Protection and EarthingDocument4 pagesMeterial Take Off for Lightning Protection and EarthingjmohammadrezaNo ratings yet

- Geotechnical Engineering RRLDocument21 pagesGeotechnical Engineering RRLLeBron JamesNo ratings yet

- Module 5 NotesDocument9 pagesModule 5 NotesShashank ShastriNo ratings yet

- DFW Fluid End Expendables Line SheetDocument4 pagesDFW Fluid End Expendables Line SheetriskvisionNo ratings yet

- SopDocument3 pagesSopanon_437292096No ratings yet

- 555 Audio Alarm ChartDocument4 pages555 Audio Alarm Chartnasty_beerNo ratings yet

- 239-Article Text-665-1-10-20190607Document10 pages239-Article Text-665-1-10-20190607saulolmNo ratings yet

- Why The Interest in Hybrid Technology?: Bryan Nelson - Caterpillar, IncDocument11 pagesWhy The Interest in Hybrid Technology?: Bryan Nelson - Caterpillar, IncAnoj pahathkumburaNo ratings yet

- Time Dilation: The Theory of RelativityDocument8 pagesTime Dilation: The Theory of RelativityJashwanth saiNo ratings yet

- Fluidization behaviour of gas-liquid systemsDocument11 pagesFluidization behaviour of gas-liquid systemsمروان الشباليNo ratings yet

- ASTM D1599 - 99 (Reapproved 2011) PDFDocument3 pagesASTM D1599 - 99 (Reapproved 2011) PDFsamanehNo ratings yet

- Connecting Rod Bolts Torque (Converted)Document4 pagesConnecting Rod Bolts Torque (Converted)Nasser Ayoub100% (1)

- Ipc2022-88362 - Know Your Enemy - Improvements in Managing The Threat of Hard SpotsDocument11 pagesIpc2022-88362 - Know Your Enemy - Improvements in Managing The Threat of Hard SpotsOswaldo MontenegroNo ratings yet

- Hdca 1971 M WVD 270 GPM Corralillo 3035Document5 pagesHdca 1971 M WVD 270 GPM Corralillo 3035Jesus HernandezNo ratings yet

- Manual de Partes Excavadora 324DDocument676 pagesManual de Partes Excavadora 324DOswaldo Andrade100% (2)

- As 1988.1-2006 Welding of Ferrous Castings Steel CastingsDocument8 pagesAs 1988.1-2006 Welding of Ferrous Castings Steel CastingsSAI Global - APACNo ratings yet

- TPE - 322302 - AFABQQEFWB - Cipta MandiriDocument5 pagesTPE - 322302 - AFABQQEFWB - Cipta MandiriTrisna RamadhanNo ratings yet

- Paper of Adrian BejanDocument21 pagesPaper of Adrian BejanshamoonjamshedNo ratings yet

- DTH Drilling MachineDocument8 pagesDTH Drilling MachineREL PromoNo ratings yet

- Composites Data SheetDocument2 pagesComposites Data Sheetvlade naumovskiNo ratings yet

- Design of Pressed Steel Tank PDFDocument8 pagesDesign of Pressed Steel Tank PDFEr Harsh Mahajan89% (19)