Professional Documents

Culture Documents

21tad181 001D

21tad181 001D

Uploaded by

ifrimgeorge89Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

21tad181 001D

21tad181 001D

Uploaded by

ifrimgeorge89Copyright:

Available Formats

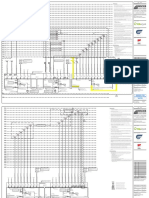

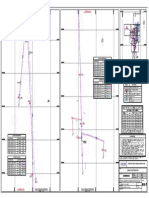

A BRIDGED 450mm Deep ALLOY BEAM

001

- Plan braced TOP chord - fixed at 1.00m centres

- Laced TOP chord at 1.00m centres

750

- Laced BOTTOM chord at 2.00m centres

- Section braced at 2.00m centres

All connection made using load bearing couplers.

700

Beam Capacities (Permissible Stress)

500

Min. Bending Moment Capacity = 15.70kN.m

Min. Shear Force Capacity = 12.70kN

CANTILEVERED 450mm Deep ALLOY BEAM

16.00kN TOTAL

UPLIFT REACTION Scaffold physically tied to the existing - Plan braced Bottom chord - fixed at 1.00m centres

1915

steel beam using paired girder couplers. Beams fixed to standards using 90° - Laced TOP chord at 2.00m centres

couplers at top and bottom chords - Laced BOTTOM chord at 1.00m centres

All tie tubes connected to standards

with a check transom to the underside - Section braced at 2.00m centres

using CLASS B 90° couplers.

315

of bottom chord.

All connection made using load bearing couplers.

Beam Capacities (Permissible Stress)

Beam support standards braced every

elevation (See Main Drawing). All Min. Bending Moment Capacity = 15.70kN.m

bracing fixed using load bearing Min. Shear Force Capacity = 12.70kN

couplers.

2215

Scaffold erected with bracing at EVERY

frame as shown. All bracing fixed using load

bearing couplers. Bracing connected no

greater than 300mm from the standard to

ledger node point. BEAM TO STANDARD

CONNECTION DETAIL

700

NTS

ALL 450mm Alloy beams fixed to support

60.00kN TOTAL standards using 90° couplers at top and bottom

REACTION (UNFACTORED) chords with a check transom fixed tight to the

2500

underside of the bottom chord connection.

Joints in standards spliced using a

butt tube with 1no. CLASS B swivel `

coupler BOTH sides of sleeve

coupler.

550

550

990

990

1000

1000

PUNCHEON & SUPPORT STANDARDS

SPLICE DETAIL

(1no. CLASS B swivel Connection)

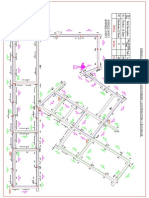

Scaffold erected with section bracing at EVERY frame THE MAIN CONTRACTOR MUST ASSESS THE REACTION

B 750 2610 500 1420 2475 B 750 2610 500 1420 2475 as shown. All bracing fixed using load bearing couplers. LOADS SHOWN AND ENSURE THE SUPPORT FLOOR AND

001 001 Bracing connected no greater than 300mm from the EXISTING STEEL BEAMS ARE SUITABLE PRIOR TO

Puncheon guardrail post fixed to standard to ledger node point. ERECTION.

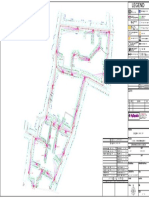

PLAN LAYOUT beams using 90° couplers at top PLAN LAYOUT ALL REACTION LOAD SHAVE BEEN SHOWN AS

All puncheons fixed to beams using 90° couplers

and bottom chords. All puncheons fixed to beams using 450mm Alloy beams fixed to support standards 'UN-FACTORED' LOADS.

LEVEL 1-1 at top and bottom chords with a check transom LEVEL 2-2 90° couplers at top and bottom using 90° couplers at top and bottom chords

A C fixed tight above the top chord connection.

chords with a check transom fixed with a check transom fixed tight to the

001 001

tight above the top chord underside of the bottom chord connection.

Scaffold erected with section bracing at EVERY frame as shown. All connection. 16.00kN UPLIFT

bracing fixed using load bearing couplers. Bracing connected no greater Denotes the Existing

Ducting Unit/Apparatus REACTION (SEE PLAN)

than 300mm from the standard to ledger node point.

2000

2345

2345

DETAIL 1

750 700 500 1915 2215 2500 550 990 1000

1000 990 550 2500 2215 1915 500 700 750

750 2610 500 1420 2475

3360 Max Cantilever Beams fixed to the support

puncheon using 90° couplers at the

top and bottom chords with a check

ELEVATION A-A 60.00kN TOTAL REACTION

ELEVATION B-B transom positioned tight to the SECTION C-C (UNFACTORED - SEE PLAN)

underside of the bottom hcord.

D 01/11/2022 Scaffold Layout Amended as Client Email M.E R.P

Scaffold physically tied to the C 21/02/2022 Scaffold Layout Amended as Client Email M.E R.P

existing steel beam using paired B 21/02/2022 Scaffold Layout Amended as Client Email M.E R.P

girder couplers. All tie tubes GENERAL NOTES Wind Loading

A 18/02/2022 Scaffold Layout Amended as Per Site Visit M.E R.P

Rev Date Revision Description Prepared by Checked by

connected to standards using This drawing is the Intellectual property of TAD Ltd. No unauthorised use, copy or disclosure is to be made without Wind loads have been generated in accordance with BS EN 1991-1-4: 2005. Kentledge

written consent. Peak Velocity Pressure (Qp): 0.690kN/m² Kentledge Loads should be positioned on the scaffold as per the drawing.

CLASS B 90° couplers. Main Contractor to ensure wind loads are adequate. Kentledge Load Per Bay: N/A

CDM Regulations 2015 Leg Loads Kentledge should be applied to scaffold on completion of first lift. Office: (+44) (0) 02921 660126

TAD LTD have understood and conformed with the responsibilities imposed by the Construction (Design & Maximum Axial Load: See Drawing Web: www.tad-designs.co.uk

Management) Regulations 2015. The Contractor should be aware of their duties imposed by the CDM Regulations Support Scaffolds Info@tad-designs.co.uk

2015. Standards founded on steel base plates (150 x 150mm) and 38mm thick soleboards unless stated otherwise. TAD Ltd will not pass comment on the condition of the existing building fabric. It is the contractors responsibility to 9 Bradenham Place, Penarth

Main Contractor to ensure the foundations are capable of supporting the leg loads stated. ensure that the existing structure will safely span between scaffold supports, and can be safely supported in the way

Design Guidance Vale of Glamorgan

Where the scaffold is supported or suspended from an additional structure the main contractor must ensure that the indicated.

This drawing has been prepared in accordance with the following Standards and Technical Guidance: structure is capable of supporting the imposed loads. CF64 2AG

- NASC TG20:21 Temporary Roofs/Shelters

- BS EN 12811-1 Tie Loads TAD Ltd cannot ensure temporary roofs are erected watertight.

- BS 5975:2019 Temporary works procedures and the permissible stress design of falsework. Maximum Tie Load: See Drawing for Steel Work All ties indicated on the drawing must be installed prior to the construction of the roof structure. Job Title

-

-

BS EN 1991-1-4 : 2005 Wind Actions

BS EN 1991-1-3 : 2003 Snow Loads

Maximum Tie Load (Tensile):

Required Test Load (2.00 FoS):

10.00kN (5.00kN Per Band & Plate 2.50kN Per Anchor/Bolt)

5.00kN Per Anchor/Bolt

For mono-pitch temporary roofs, the minimum slope angle of the roof sheeting is 5° when using CI sheets.

For all roof systems the manufacturers guidance should be followed.

Finsbury Square - London

- SG4:15 - Preventing Falls in Scaffolding Operations Maximum Butt Load: N/A

Joints in standards spliced using a - Working at Height Regulations 2005. Cladding

Client

The Main Contractor is responsible for ensuring the existing structure is capable of supporting the imposed loads. No sheeting, signboards or hoarding, unless already shown, should be added to the scaffold without the written

butt tube with 1no. CLASS B swivel Loading The Contractor should consult with anchor specialist prior to selection. permission from TAD Ltd. Hawk Scaffolding Ltd

coupler BOTH sides of sleeve All Self-weights of materials comply with the loads stated within the TG20:21 and BSEN12811-1.

All Self-weights of proprietary equipment are in accordance with manufacturer's information.

Tie selection should be made by the contractor using guidance from TG4. All sheeting should be fixed externally to the scaffold unless otherwise stated on the drawing.

Ties should be tested in accordance with TG4.

coupler. Main Contractor to ensure that no ties are removed without the written approval of TAD LTD. Erection/Modification Drawing Title

Platform Loading

Scaffold platform loads are in accordance with the TG20:21 and BSEN12811-1. Scaffold Boards

This design has been prepared from information supplied to us by the Contractor. The Contractor should check that

their requirements have been correctly interpreted and depicted in a practicable design solution prior to erection. Cantilevered Access Scaffold

BOARDED LIFT LEVEL LEDGERS Load Class: 2 All Scaffold boards to comply with BS2482:2009. The contractor should verify all site dimensions and notify TAD Ltd of any discrepancies prior to erection.

1no. Lift at: 1.50kN/m² All scaffold boards are to be restrained. See TG12 for restraint guidance. No alterations are to be made to the scaffold structure detailed on this drawing without written consent from TAD Ltd.

SPLICE DETAIL 1no. Lift at: N/A (1no. Lift Loaded at Any one Time) All Written dimensions shall take precedence over scaled dimensions. Drawing Number Rev Prepared By Checked By

(1no. CLASS B swivel Connection) DETAIL 1 - GIRDER COUPLER TO Inside Boards:

No. of Boarded Lifts:

0.75kN/m²

2

Tube/Fittings

All scaffolding materials and fittings are to comply with TG20:21 and BS EN 12811-1. Drawing Status

21/TAD/181-001 D R.P M.E

EXISTING STEEL CONNECTION Main contractor to ensure the live load allowance is adequate prior to erection.

Scaffold tube has been taken as BS EN 39 type 4 'new' condition.

All scaffold fittings taken as load-bearing CLASS B fittings unless otherwise stated on the drawing. FOR DISCUSSION

NTS No alteration to the live load allowance should be made without the written consent of TAD Ltd. All proprietary equipment has been designed in accordance with the manufacturers specifications. Not For Construction Scale @ A1

1:50

Date

17/08/2021 CHECK CATEGORY (BS5975) 2

You might also like

- Reliance General Insurance Company Limited: Reliance Private Car Package Policy-ScheduleDocument9 pagesReliance General Insurance Company Limited: Reliance Private Car Package Policy-ScheduleFarhana PervinNo ratings yet

- Bomba Grindex Master NDocument20 pagesBomba Grindex Master Ncarlos sanabria ninamango100% (3)

- Customer Management Glossary - E3.0Document34 pagesCustomer Management Glossary - E3.0José Manuel Pulido100% (2)

- NotesDocument1 pageNotesassis alihNo ratings yet

- Tsps-Loc-353-Al Safa FirstDocument1 pageTsps-Loc-353-Al Safa FirstZakariya KhanNo ratings yet

- SEWAGE LAYOUT 29-12-18-Layout1Document1 pageSEWAGE LAYOUT 29-12-18-Layout1Vignesh WaranNo ratings yet

- Nas 2 XX16 WW030 0001 SD 03 15 R00Document1 pageNas 2 XX16 WW030 0001 SD 03 15 R00Syed Munawar AliNo ratings yet

- A202 Moo MooDocument1 pageA202 Moo MooHdo AliNo ratings yet

- Struct. Metallique Du HangarDocument1 pageStruct. Metallique Du HangarNourreddine HabibNo ratings yet

- NuevitooooDocument1 pageNuevitoooodiversidadcristianprimeNo ratings yet

- Plans 2Document3 pagesPlans 2rnz mrnNo ratings yet

- Trial PlotDocument1 pageTrial PlotArmand Mikhail TempladoNo ratings yet

- NTR Final 3259 Plot-1Document1 pageNTR Final 3259 Plot-1seoresercherNo ratings yet

- PB02-LPS-001 Low Pressure Steam System: Saudi Arabian Oil CompanyDocument1 pagePB02-LPS-001 Low Pressure Steam System: Saudi Arabian Oil CompanyzhangNo ratings yet

- COMBINE HEAT MAP AS-BUILT (01-02-24) - CompressedDocument6 pagesCOMBINE HEAT MAP AS-BUILT (01-02-24) - CompressedDomie Neil Bucag SalasNo ratings yet

- Notes: A-ACN-120409Document1 pageNotes: A-ACN-120409Hakim BukenyaNo ratings yet

- Geotechnical DrawingsDocument21 pagesGeotechnical DrawingsWaleed FayezNo ratings yet

- Kshethra Farms - Westwoods Phase - 2 - Plots Layout With Areas and Dim - Dated 015.12.2023-ModelDocument1 pageKshethra Farms - Westwoods Phase - 2 - Plots Layout With Areas and Dim - Dated 015.12.2023-Modelmanan.maheshwari298No ratings yet

- Comparison Design - As-Built 3Document1 pageComparison Design - As-Built 3abm2irzathNo ratings yet

- Buz Con BRG Gad 834 2 - V13 - Approve - P55Document1 pageBuz Con BRG Gad 834 2 - V13 - Approve - P55PadmalavMahatoNo ratings yet

- Oil InterceptorDocument3 pagesOil InterceptorOkudetum RaphealNo ratings yet

- Structural DrawingsDocument3 pagesStructural Drawingskwoshaba pidsonNo ratings yet

- 5076-Al Wasl-Plot - 38 - 3000 SERIES - ELEVATIONSDocument2 pages5076-Al Wasl-Plot - 38 - 3000 SERIES - ELEVATIONSdubai eyeNo ratings yet

- NAS-6-RA04-EE030-0004-SD-01-01-R02-Code BDocument1 pageNAS-6-RA04-EE030-0004-SD-01-01-R02-Code BVijayan Thekke VeeduNo ratings yet

- Ban Do KCN Tan HuongDocument1 pageBan Do KCN Tan HuongĐẶNG NGUYỄN TRƯỜNG GIANGNo ratings yet

- VRF Ikea TumamahDocument1 pageVRF Ikea TumamahRonald TernateNo ratings yet

- Sd-Msp-El-Pd-204 Mall Lantai m2 Instalasi Penerangan r.3 Maw Coment-Layout1Document1 pageSd-Msp-El-Pd-204 Mall Lantai m2 Instalasi Penerangan r.3 Maw Coment-Layout1slamet santosoNo ratings yet

- PHJ Alc PRC Pid Dis - R10 - 25.11.2023Document37 pagesPHJ Alc PRC Pid Dis - R10 - 25.11.2023Guddus J AmeenNo ratings yet

- Msar MHT Pa Ic Zn1 Bs02 Det DWG STR 0608 02Document1 pageMsar MHT Pa Ic Zn1 Bs02 Det DWG STR 0608 02柔道—Ibn MasudNo ratings yet

- SCH Public Address System Ipsec Sample 2020Document1 pageSCH Public Address System Ipsec Sample 2020Zubair Abdurrauf Az'zahabiyNo ratings yet

- Jubail 4&6 OverallDocument1 pageJubail 4&6 Overallnazih sedrakNo ratings yet

- PB02-STG-001 Steam Turbine System (A10-P-2001)Document1 pagePB02-STG-001 Steam Turbine System (A10-P-2001)zhangNo ratings yet

- 230620-Mesin Olah J2-Jalur Ladder & Cable TrayDocument1 page230620-Mesin Olah J2-Jalur Ladder & Cable TrayWulan NursyifaNo ratings yet

- Franklin Architectural PlanDocument6 pagesFranklin Architectural PlanTim Foldy-PortoNo ratings yet

- Pmi 735Document4 pagesPmi 735api-3703813No ratings yet

- 141 CS 257 02008 02 - QDocument1 page141 CS 257 02008 02 - QIkramNo ratings yet

- Jal 04Document1 pageJal 04Ar Gurpal KaurNo ratings yet

- Sector 230Document1 pageSector 230Mohit SinghNo ratings yet

- Zone-7: (Building-7)Document1 pageZone-7: (Building-7)tarique mohammedNo ratings yet

- Fsa 1204 F1Document1 pageFsa 1204 F1Nagamani ManiNo ratings yet

- 2111 122 PVM P 002 - 04 Taken For Information 5Document1 page2111 122 PVM P 002 - 04 Taken For Information 5barnalipani1985No ratings yet

- MR Regis N MRS Dorcas Taruvinga - 050209Document1 pageMR Regis N MRS Dorcas Taruvinga - 050209pzarchitectural99No ratings yet

- WC Layout Level 6: SCALE:1/350Document13 pagesWC Layout Level 6: SCALE:1/350lengchhanun893No ratings yet

- MMD 94 XX DR Ar 0140 01 - C06 - 220926 - 182711Document2 pagesMMD 94 XX DR Ar 0140 01 - C06 - 220926 - 182711Edy SanyoNo ratings yet

- Feb Tower at BFH (Mixed Use Development) : Lead ConsultantDocument4 pagesFeb Tower at BFH (Mixed Use Development) : Lead Consultantbhima irabattiNo ratings yet

- Hisense tf2908d - Tmpa8897 Tmpa8809, fscq1265rt, La780 SCHDocument1 pageHisense tf2908d - Tmpa8897 Tmpa8809, fscq1265rt, La780 SCHSilomo-saka MambaNo ratings yet

- Marlow Series 580: In-Line Mounted Centrifugal PumpDocument32 pagesMarlow Series 580: In-Line Mounted Centrifugal PumpCarlosama MarioNo ratings yet

- Nas 2 XX16 WW030 0001 SD 07 15 R00Document1 pageNas 2 XX16 WW030 0001 SD 07 15 R00Syed Munawar AliNo ratings yet

- PB02-STG-001 Steam Turbine System (A10-P-2001)Document1 pagePB02-STG-001 Steam Turbine System (A10-P-2001)zhangNo ratings yet

- cc2202 13 Pergola1660741306520Document1 pagecc2202 13 Pergola1660741306520Ramees MalikNo ratings yet

- Camana: Cuadro de MetradosDocument1 pageCamana: Cuadro de MetradosJohann Nick Flores AparicioNo ratings yet

- SL802 - Phase 2 Line Shops - Lot 2 - Ground Floor Slab Layout, Walkway Sections and DetailsDocument1 pageSL802 - Phase 2 Line Shops - Lot 2 - Ground Floor Slab Layout, Walkway Sections and Detailsn0188741wNo ratings yet

- Hse Dema's Invoice02-09-2413-02-43Document1 pageHse Dema's Invoice02-09-2413-02-43stayinmyhome0828No ratings yet

- Myrep Penggilingan Cakung RW17 v3.1Document1 pageMyrep Penggilingan Cakung RW17 v3.1Huang DongNo ratings yet

- Jamundi Project F24S New Proposal Level 2Document1 pageJamundi Project F24S New Proposal Level 2mariconsuelo rosa melanoNo ratings yet

- Secondary Road-J: DRAWING LIMIT N 9357.500Document1 pageSecondary Road-J: DRAWING LIMIT N 9357.500billNo ratings yet

- Block #5 Block #4 Block #4 Block #5: DRAWING LIMIT N 9590.000Document1 pageBlock #5 Block #4 Block #4 Block #5: DRAWING LIMIT N 9590.000billNo ratings yet

- Ugt DetailDocument1 pageUgt DetailPRIAMCON PMCNo ratings yet

- The Election of 1896 The Fall of The Peoples Party An AnnotateDocument7 pagesThe Election of 1896 The Fall of The Peoples Party An AnnotateEdward the BlackNo ratings yet

- Aboriginal-And-Culturally-Responsive-Pedagogies-Assessment 2Document9 pagesAboriginal-And-Culturally-Responsive-Pedagogies-Assessment 2api-435769530No ratings yet

- 2021 Sustainability FinalDocument36 pages2021 Sustainability FinalLovely ChoudharyNo ratings yet

- Xv. Petition To Annul or Suspend ProclamationDocument15 pagesXv. Petition To Annul or Suspend ProclamationRina TruNo ratings yet

- Stranger Visitor Lead Promoter Customer: YouthDocument1 pageStranger Visitor Lead Promoter Customer: YouthMedawuevahacerotro HDer MontoyaNo ratings yet

- Effectiveness of Hand Wash and Sanitizer: COVID19: Bulletin of Pure & Applied Sciences-Zoology January 2020Document5 pagesEffectiveness of Hand Wash and Sanitizer: COVID19: Bulletin of Pure & Applied Sciences-Zoology January 2020CarolineNo ratings yet

- Network Security ProjectDocument3 pagesNetwork Security Projectapi-534274226No ratings yet

- Report of The Archaeological Fieldwork Carried Out On The Island of Raivavae in May - June 2007Document20 pagesReport of The Archaeological Fieldwork Carried Out On The Island of Raivavae in May - June 2007Alexandra EdwardsNo ratings yet

- CAN190 Addendum - Menard - Fall 2022Document10 pagesCAN190 Addendum - Menard - Fall 2022Gautam GandotraNo ratings yet

- ART Integrated Project On Ladakh (Class - 10) - Presented by Ankit BhaduriDocument21 pagesART Integrated Project On Ladakh (Class - 10) - Presented by Ankit BhaduriShyam Shankar DasNo ratings yet

- Consortium of National Law Universities: Provisional 5th List - CLAT 2021 - UGDocument6 pagesConsortium of National Law Universities: Provisional 5th List - CLAT 2021 - UGSikandar KahlonNo ratings yet

- Activity 7.4.2: Challenge DHCP and NAT ConfigurationDocument5 pagesActivity 7.4.2: Challenge DHCP and NAT ConfigurationLorena Sierra BNo ratings yet

- ARK Tindal Staff Handbook 2012-2013 V4 Sc-1Document71 pagesARK Tindal Staff Handbook 2012-2013 V4 Sc-1arktindalNo ratings yet

- Logic Brain TeasersDocument5 pagesLogic Brain TeasersSharif Jan0% (1)

- WHO Guideline On Acceptable Medical Reasons For Use of Breast-Milk SubstitutesDocument12 pagesWHO Guideline On Acceptable Medical Reasons For Use of Breast-Milk SubstitutesMedarabiaNo ratings yet

- Harta Metrou LondraDocument2 pagesHarta Metrou LondraAle Bizdu100% (1)

- KRIT AVIONOM Program Putovanja Leto 2023 PDFDocument6 pagesKRIT AVIONOM Program Putovanja Leto 2023 PDFDušan JovanovićNo ratings yet

- M19124 EcoAssignment MadhulikaTaksandeDocument7 pagesM19124 EcoAssignment MadhulikaTaksandeMadhulika TaksandeNo ratings yet

- NAME: - Neha. Rahul. Ghosh ROLL NO: - 51. Batch: - B. Academic Year: - 2017 - 2018Document5 pagesNAME: - Neha. Rahul. Ghosh ROLL NO: - 51. Batch: - B. Academic Year: - 2017 - 2018Tushar NikamNo ratings yet

- Rina Affidavit MarriageDocument1 pageRina Affidavit Marriagereeny_sala3812No ratings yet

- SikaranDocument4 pagesSikaranEly Ver Vargas RomantcoNo ratings yet

- Australian National Broadband NetworkDocument252 pagesAustralian National Broadband NetworkRachmat ViewNo ratings yet

- Title X - Crimes Against PropertyDocument26 pagesTitle X - Crimes Against PropertyLeyCodes LeyCodesNo ratings yet

- Abay Vs Montesino (2003)Document6 pagesAbay Vs Montesino (2003)happymabeeNo ratings yet

- Organised Crime Economy 2005Document298 pagesOrganised Crime Economy 2005mrFateNo ratings yet

- 1.1 Prehistoric Times and Malay Kindom of MalaccaDocument20 pages1.1 Prehistoric Times and Malay Kindom of MalaccahemanathanharikrishnNo ratings yet

- Kostishak v. Mannes, 4th Cir. (1998)Document11 pagesKostishak v. Mannes, 4th Cir. (1998)Scribd Government DocsNo ratings yet

- Helene Cixous Sorties PDFDocument7 pagesHelene Cixous Sorties PDFPrafulla NathNo ratings yet