Professional Documents

Culture Documents

LAF Catalogue

Uploaded by

Moawiah AlwahidiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LAF Catalogue

Uploaded by

Moawiah AlwahidiCopyright:

Available Formats

PRODUCT PORTFOLIO

HOSPITAL CLIMATE CONTROL AND VENTILATION EQUIPMENT

SUPPLY AIR CEILING

OR SUPPLY AIR CEILING SYSTEM

The supply air ceiling generates a vertical, laminar flow of clean air with low resistance for all types of

operating rooms. The filters guarantee maximum operational reliability, a low germ count in the operating room

and a low concentration of harmful gases in the working area of the operating team.

CONSTRUCTION ON CLEAN ROOM SIDE

The filter frame profile is made of anodised aluminium for the fitting of the particulate air filters. The particulate

air filters correspond with Class H14 and are assembled using a double sealing location system. Fabric divid-

ers are fitted with an aluminium frame profile and are fixed onto the filter frame profile without screws. A stable,

torsion-resistant outlet frame, suitable for the fitting of air baffle plates is installed, combined with an air-tight

central OR illuminator feed.

CONSTRUCTION ON IMPURE AIR SIDE

An air-tight pressure chamber made of the material A1Mg1 is installed over the particulate air filters.

Connection supports for the outside air are built in and fixed to the pressure chamber.

AS AN OPTION (RECOMMENDED)

Differential pressure sensor for the monitoring of the particulate air filters.

Supply air ceilings may be produced in a proven standard size

or individually according to customer desires or the form of the room.

Clean air sterile area for patient, OR team and instruments

TECHNICAL DATA

CLIMATE CONTROL AND VENTILATION EQUIPMENT

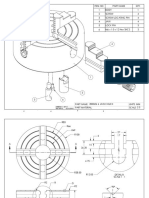

Panel filter ceilings, so-called supply air ceilings, are often used where a sufficiently large outlet sections are intended to be supplied. Type Size in mm Height in mm Particulate air Flow rate Pressure loss Connecting

They must be supplied from the air-conditioning system in accordance with the size of the ceiling. Supply air ceilings are characterised (L x W ) filter H14 at v=0.24 m/s at v=0.24 m/s supports

by maximum operational reliability and a low concentration of germs at the operating table.

FFD 12/24 1303 x 2385 mm at least. 250 mm 4 pcs 2480 m³/h approx. 60 Pa 2 pcs

The sterile air is blown into the OR protected area across the complete

FFD 14/24 1455 x 2385 mm at least. 250 mm 6 pcs 2790 m³/h approx. 60 Pa 2 pcs

air throw in a laminar manner, as an option in a varying form, at a

higher speed at the centre and a lower speed at the edges. FFD 16/24 1607 x 2385 mm at least. 250 mm 6 pcs 3090 m³/h approx. 60 Pa 2 pcs

The OR protected area includes, in addition to the operation area, FFD 18/24 1759 x 2385 mm at least. 250 mm 6 pcs 3400 m³/h approx. 60 Pa 2 pcs

the sterile clothed OR team, the patient drapes and open material

and instrument tables. FFD 20/24 1929 x 2385 mm at least. 250 mm 8 pcs 3740 m³/h approx. 60 Pa 2 pcs

FFD 22/24 2233 x 2385 mm at least. 250 mm 8 pcs 4350 m³/h approx. 60 Pa 2 pcs

The size of an LTF air outlet is individually determined by the space

required for the surgeons, the staff , the type of surgery and the sterile FFD 24/24 2385 x 2385 mm at least. 250 mm 8 pcs 4650 m³/h approx. 60 Pa 2 pcs

instruments’ place of installation. FFD 14/26 1455 x 2537 mm at least. 300 mm 6 pcs 2965 m³/h approx. 60 Pa 2 pcs

FFD 16/26 1607 x 2537 mm at least. 300 mm 6 pcs 3290 m³/h approx. 60 Pa 2 pcs

FFD 20/26 1929 x 2537 mm at least. 300 mm 8 pcs 4230 m³/h approx. 60 Pa 2 pcs

FFD 26/26 2537 x 2537 mm at least. 300 mm 8 pcs 5560 m³/h approx. 60 Pa 4 pcs

FFD 24/30 2385 x 3029 mm at least. 300 mm 14 pcs 5960 m³/h approx. 60 Pa 4 pcs

FFD 29/29 2877 x 2877 mm at least. 300 mm 24 pcs 7150 m³/h approx. 60 Pa 4 pcs

FFD 32/32 3181 x 3181 mm at least. 300 mm 24 pcs 8740 m³/h approx. 60 Pa 4 pcs

2015-10-26 \\CAD-SERVER\OP_Projk\00-SYSTEMZEICHNUNGEN\Pytha\laminar flow\Zuluftdecke.pyo

216 HT GROUP – PRODUCT PORTFOLIO HT GROUP – PRODUCT PORTFOLIO 217

You might also like

- Introduction to Fly-By-Wire Flight Control SystemsFrom EverandIntroduction to Fly-By-Wire Flight Control SystemsRating: 5 out of 5 stars5/5 (1)

- Sullair Diesel Compressors - Sullair S115Document2 pagesSullair Diesel Compressors - Sullair S115=IceBurn=No ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Pressure Cut-Off For Linde BPV Pumps Bulletin No. BPV 000 03.89/001/06Document5 pagesPressure Cut-Off For Linde BPV Pumps Bulletin No. BPV 000 03.89/001/06Y.Ebadi100% (2)

- 200MM 4 Jaw Chuck PDFDocument11 pages200MM 4 Jaw Chuck PDFluisNo ratings yet

- BHA PicturesDocument29 pagesBHA PicturesimampranadipaNo ratings yet

- Akronex Icaf Sodurme SistemleriDocument4 pagesAkronex Icaf Sodurme Sistemlerigopi.falconfireNo ratings yet

- Al KoDocument24 pagesAl KostomakosNo ratings yet

- Jet-Pulse Compact Cartridge Type Dust Collector: Eco SeriesDocument8 pagesJet-Pulse Compact Cartridge Type Dust Collector: Eco SeriesErinc CelikNo ratings yet

- Supply Air Ceiling PDFDocument20 pagesSupply Air Ceiling PDFHoang TungNo ratings yet

- Downloaded File-25Document2 pagesDownloaded File-25Jose Paulino Soria OliverosNo ratings yet

- ALUP Linefilters ENG 6999640480Document7 pagesALUP Linefilters ENG 6999640480Eng.issam AlrshdanNo ratings yet

- 2023-LECTURE 5-Common Health Safety Features of Commercial Buildings1Document4 pages2023-LECTURE 5-Common Health Safety Features of Commercial Buildings1Joshua C. JosonNo ratings yet

- (FM CBMTEC) 240123#catalog For Air Compressors and Vacuum PlantsDocument6 pages(FM CBMTEC) 240123#catalog For Air Compressors and Vacuum PlantsslimaniNo ratings yet

- Caryaire Whisper-Air Fan SystemDocument4 pagesCaryaire Whisper-Air Fan Systemcalvin.bloodaxe4478No ratings yet

- Car-Ii: Constant Airflow RegulatorDocument4 pagesCar-Ii: Constant Airflow RegulatorLuis GiaganteNo ratings yet

- Mantenimiento Compresor ScrollDocument8 pagesMantenimiento Compresor ScrollHugovillarruelNo ratings yet

- Brochures WZ-EDocument16 pagesBrochures WZ-EHector TosarNo ratings yet

- Axis P Data Sheet 2020 11Document13 pagesAxis P Data Sheet 2020 11humayra.tasneem1No ratings yet

- Aircycle 3.1 - Heat Recovery UnitDocument6 pagesAircycle 3.1 - Heat Recovery UnitValentin MalihinNo ratings yet

- Eng CSCDocument6 pagesEng CSCAshraf m aliNo ratings yet

- Inventor of The Thrust Ventilation SystemDocument4 pagesInventor of The Thrust Ventilation SystemKrishna PATELNo ratings yet

- Critical EnvironmentsDocument16 pagesCritical EnvironmentsEduardo RivasNo ratings yet

- Polaris LRDocument11 pagesPolaris LRDavid Lionel Fernandez ValdiviaNo ratings yet

- Centrifugal Damper Cat PDFDocument8 pagesCentrifugal Damper Cat PDFcassindromeNo ratings yet

- Bladder Tanks & Foam Chambers CompressedDocument2 pagesBladder Tanks & Foam Chambers Compressedมธุรส สังข์วรรณะNo ratings yet

- CLCP Product CatalogsDocument46 pagesCLCP Product CatalogsHasan67% (3)

- Sound PDFDocument7 pagesSound PDFSelva Kumar Selva KumarNo ratings yet

- GA30-90C BrochureDocument12 pagesGA30-90C BrochureSunil KambleNo ratings yet

- CLCP - Folleto Comercial (Inglés)Document2 pagesCLCP - Folleto Comercial (Inglés)ITAMI FARRERANo ratings yet

- Polaris Brochure - CATALOGUEDocument11 pagesPolaris Brochure - CATALOGUEKarthikeyan VisvakNo ratings yet

- EMW Filtertechnik - GT (GB)Document9 pagesEMW Filtertechnik - GT (GB)Nguyễn Kim HùngNo ratings yet

- Steritec Product - 2013 PDFDocument2 pagesSteritec Product - 2013 PDFabcNo ratings yet

- FAN SpecificationDocument6 pagesFAN SpecificationSithuNo ratings yet

- Zhuowei Catalog 2016 - Fan Filter Units SeriesDocument3 pagesZhuowei Catalog 2016 - Fan Filter Units Seriesinnovameq.ingenieriaNo ratings yet

- Trane Cta ComfortDocument8 pagesTrane Cta ComfortenergeticchairNo ratings yet

- Mobilair M 43/M 50: KompressorenDocument8 pagesMobilair M 43/M 50: KompressorenahmedNo ratings yet

- John Crane Replacement Filter Elements Sell SheetDocument2 pagesJohn Crane Replacement Filter Elements Sell SheetAZZAF ChannelNo ratings yet

- Jet Fan 1Document5 pagesJet Fan 1nghialuNo ratings yet

- CSC 30 - 40 - 50 - 60 - 75 - 100 HP: Otary Crew OmpressorDocument6 pagesCSC 30 - 40 - 50 - 60 - 75 - 100 HP: Otary Crew OmpressorVolodymуr VorobetsNo ratings yet

- HVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part47Document1 pageHVAC-PLUMBING-GUIDE-BOOK - Cleaned (1) - Part47gfhf dgdNo ratings yet

- BBM Air Intake and Cooling SystemDocument6 pagesBBM Air Intake and Cooling SystemsyahmisyamirNo ratings yet

- Ventilation: MDM Nurul Aini/Qus 3206Document22 pagesVentilation: MDM Nurul Aini/Qus 3206Anonymous bymBquNo ratings yet

- Astm F558 - 13Document17 pagesAstm F558 - 13Jesús Luis Arce Guillermo100% (1)

- Application Guide: Solution Air-Handling Units Dual Fan OptionsDocument4 pagesApplication Guide: Solution Air-Handling Units Dual Fan Optionssde mmxNo ratings yet

- 82191C Brochure APPL ADV200-HVAC ENDocument20 pages82191C Brochure APPL ADV200-HVAC ENbaros07No ratings yet

- Quirofanos en 15Document6 pagesQuirofanos en 15Abdullah.N FAAliNo ratings yet

- Saiver AHUDocument12 pagesSaiver AHUNorsyafiqah RoziNo ratings yet

- Wolter Jetfan Broschuere English 2017 PDFDocument15 pagesWolter Jetfan Broschuere English 2017 PDFViệt Đặng XuânNo ratings yet

- Ce Marked Smoke Extract - en Tested Fire Rated Kitchen Extract and Pressurisation - Installed Under Third-Party Certifiers FirasDocument12 pagesCe Marked Smoke Extract - en Tested Fire Rated Kitchen Extract and Pressurisation - Installed Under Third-Party Certifiers FirasirfanNo ratings yet

- Ducting System V2Document5 pagesDucting System V2Kamran BozgadNo ratings yet

- Approval Standard For Air Pressure Maintenance Device: Class Number 1032Document6 pagesApproval Standard For Air Pressure Maintenance Device: Class Number 1032osama alabsiNo ratings yet

- UniJet BrochureDocument10 pagesUniJet BrochureZaid SamhaNo ratings yet

- AtriumDocument4 pagesAtriumMehdi BeygNo ratings yet

- AIRCENTER CatálogoDocument8 pagesAIRCENTER CatálogojesuskohNo ratings yet

- Universal Air Shield/Flange Mount Assembly Model Q1118: DescriptionDocument4 pagesUniversal Air Shield/Flange Mount Assembly Model Q1118: DescriptionSyed SamsamuddinNo ratings yet

- Ruskin Fire DamperDocument4 pagesRuskin Fire DamperRAGANNo ratings yet

- Compact, Radialseal, Medium-Duty Air Cleaner: Designed For Horizontal InstallationDocument8 pagesCompact, Radialseal, Medium-Duty Air Cleaner: Designed For Horizontal InstallationjuanNo ratings yet

- Fumehood Efa Brochure A4 VC LRDocument12 pagesFumehood Efa Brochure A4 VC LRYusmi NoernithdaNo ratings yet

- Dubai Green Building System: Version 2.0 - 2020Document40 pagesDubai Green Building System: Version 2.0 - 2020harikollam1981No ratings yet

- The Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationFrom EverandThe Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationRating: 1 out of 5 stars1/5 (1)

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- HMC Maintenance: Machine ToolsDocument175 pagesHMC Maintenance: Machine Toolswega7777No ratings yet

- Ivi 5VM2R 8NF 8NF SS6Document1 pageIvi 5VM2R 8NF 8NF SS6Ganesh ZambreNo ratings yet

- DWD Accessories 09Document4 pagesDWD Accessories 09Mario Allesina JuniorNo ratings yet

- Assortment Monitoring Form Ver 1.0Document4,128 pagesAssortment Monitoring Form Ver 1.0Ary WidyantoNo ratings yet

- 07 Rawlbolts Plugs AnchorsDocument1 page07 Rawlbolts Plugs AnchorsLincolnNo ratings yet

- Brown and Sharpe Catalog 135Document46 pagesBrown and Sharpe Catalog 135peter100% (1)

- Sauermann Catalogue 2008Document8 pagesSauermann Catalogue 2008António SousaNo ratings yet

- Project Ruby: As Built DrawingDocument1 pageProject Ruby: As Built DrawingTôn Huỳnh ĐoànNo ratings yet

- Gear Pumps PartsDocument41 pagesGear Pumps PartsKudanthai Senthilkumar100% (1)

- Basics of Machining 2010 2011Document189 pagesBasics of Machining 2010 2011Steven DNo ratings yet

- Knurling Grooving and Form TurningDocument33 pagesKnurling Grooving and Form TurningTareef Hash100% (1)

- Boiler Maintenance ChecklistDocument2 pagesBoiler Maintenance ChecklistRidwanAlwi50% (4)

- DW402 - Pulidor DewaltDocument3 pagesDW402 - Pulidor DewaltJorge Adalberto Lugo QuinteroNo ratings yet

- SingerValve NewSRD EmailableDocument4 pagesSingerValve NewSRD EmailableMateo Jaramillo EcheverriNo ratings yet

- Filtri ManitouDocument2 pagesFiltri ManitouNicoloNo ratings yet

- MCQ in Machine Design and Shop Practice Part 18 ME Board ExamDocument13 pagesMCQ in Machine Design and Shop Practice Part 18 ME Board ExamRobert V. AbrasaldoNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- SKI Chaincase - 4-Stroke (Line-Up) - Supplement mmr2017-119Document12 pagesSKI Chaincase - 4-Stroke (Line-Up) - Supplement mmr2017-119Erne Lange OlsenNo ratings yet

- Crane HoistDocument31 pagesCrane HoistJamatindo PutraNo ratings yet

- Schematic: 311C U Excavator Hydraulic SystemDocument2 pagesSchematic: 311C U Excavator Hydraulic SystemJulio VeraNo ratings yet

- Metric Socket Head Cap Screws1 PDFDocument2 pagesMetric Socket Head Cap Screws1 PDFRavi BabaladiNo ratings yet

- H-10 PRO: Refrigerant Leak DetectorDocument2 pagesH-10 PRO: Refrigerant Leak DetectoriwanNo ratings yet

- 5 Use Hand Tools 5Document47 pages5 Use Hand Tools 5International Technology Center IncNo ratings yet

- 2010 Catalog: Made Proudly in America God Bless Our Fighting Men & WomenDocument28 pages2010 Catalog: Made Proudly in America God Bless Our Fighting Men & WomenBalaclava CotidianoNo ratings yet

- SF99 Servo Bore Repair System:: Northland Transmission IncDocument4 pagesSF99 Servo Bore Repair System:: Northland Transmission IncFrancisco Javier Hernandez LanderoNo ratings yet

- Section 35 - Hydraulic System - Chapter 10Document36 pagesSection 35 - Hydraulic System - Chapter 10احمد الشبراوى الشبراوىNo ratings yet

- MP Hydraulic Lift Equipment 1 " 1 ": Bvin / Bvin A3Document43 pagesMP Hydraulic Lift Equipment 1 " 1 ": Bvin / Bvin A3Coil98No ratings yet