Professional Documents

Culture Documents

Burnerpro Flame Safeguard Control Replacement Version

Uploaded by

raquel.mc2Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Burnerpro Flame Safeguard Control Replacement Version

Uploaded by

raquel.mc2Copyright:

Available Formats

PRO

TECHNICAL SPECIFICATIONS

BurnerPRO

Supply Voltage: BP110UV 110 VAC (+20%, -15%) 50/60Hz

BP230UV 230 VAC (+10%, -15%) 50/60Hz Flame Safeguard Control

Power Consumption: 7 VA (replacement version)

Temperature Rating: Operating -40°C to +60°C (-40°F to 140°F)

Storage -50°C to +85°C (-58°F to 185°F)

Protection Category: IP40 (except wiring base)

Dimensions:

Control Unit: 4.0” (102mm) L x 4.0” (102mm) W x 4.4” (112mm) H

(without base)

4.15” (105mm) L x 4.15” (105mm) W x 5.0” (127mm) H

(with base)

Weight: 2.5 lbs (1.13kg)

The BurnerPRO provides the proper burner sequencing, ignition and continuous flame

monitoring for commercial heating and process equipment firing oil and gas fuels. The system

is designed for use in non-permanent operations that requires burner recycle at least once

every 24 hours. Seven SMART LEDs provide current operating status and lockout information

in the event of a safety shutdown.

BurnerPRO BP110UV-S1, S2,, S3 and BP230UV-S1, S2, S3 controls are plug and play compatible

with select Siemens LFL control models. Use existing wiring base with no external wiring changes. The

controls are also compatible with Satronic TMG controls with minor wiring changes. See the reverse

side for compatability listings.

The Combustion Control Specialists

3 Manchester Rd. • Derry, NH 03038 • USA

Tel: 603 - 432 - 4100 • Fax: 603 - 432 - 1570

www.fireye.com

BP-IN 2

SEPTEMBER 2015

REPLACING EXISTING SIEMENS LFL BURNER CONTROL REPLACING EXISTING SATRONIC TMG BURNER CONTROL

BurnerPRO is functionally compatible with the following LFL models: BurnerPRO is functionally compatible with the following TMG models:

LFL BURNERPRO TMG BURNERPRO

LFL1.322 BP230UV-S1 TMG 740-1/2/3 model 32-32 BP230UVF-S2

LFL1.322-110V BP110UV-S1 TMG 740-1/2/3 model 45-54 BP230UVF-S3

LFL1.333 BP230UV-S2

LFL1.333-110V BP110UV-S2 Replacing an existing TMG can be accomplished by following this pro-

cedure:

LFL1.335 BP230UV-S3

LFL1.335-110V BP110UV-S3

1. Identify/Order the equivalent BurnerPRO version for replacement

2. Identify/Order the BurnerPRO scanner that fits the environment (UV90L-1

Replacing an existing LFL is quite simple by following this procedure: or UV1AL-3/6).

3. Order the Fireye wiring base 60-2944-1.(Fig 3)

1. Identify/Order the equivalent BurnerPRO version for replacement. 4. In the control cabinet, remove the TMG control and wiring base.

2. Identify/Order the BurnerPRO scanner that fits the environment (UV90L-1 5. Install the Fireye wiring base and attach the wires as recommended by

or UV1AL-3/6). (Fig 1) the Fireye technical bulletin. Make sure a solid ground connection

3. Remove the LFL control from its wiring base. Install the grounding tab to is provided to the base.

the LFL wiring base provided in the shipping box. (Fig 2, Note 1) 6. Install the BurnerPRO control.

4. Remove Earth ground wire/reference to terminal 22. BurnerPRO will drive 7. On the main burner, locate the existing UV scanner and replace with the

the S1 & S2 signals to the UV scanner. (Fig 2, Note 2) BurnerPRO scanner.

5. Install the BurnerPRO control.

6. On the main burner, locate the existing UV scanner and replace with the

BurnerPRO scanner.

Fig 1. UV Scanners Fig 2. LFL Wiring Base w/ground tab Fig 3. Fireye Wiring Base

2

1

UV90L

UV1AL

60-2944-1

You might also like

- BBU3900 Installation Guide V300 17 PDFDocument58 pagesBBU3900 Installation Guide V300 17 PDFSamyr MedeirosNo ratings yet

- Functional Write Up For Start Up Burnersrev00Document5 pagesFunctional Write Up For Start Up Burnersrev00krunalNo ratings yet

- HT-S3500 (B) : 5.1Ch Home Theater System ModelDocument37 pagesHT-S3500 (B) : 5.1Ch Home Theater System ModelPaulo chagas paulo ratoNo ratings yet

- FirePro - Vinayaka Enterprises - HZL - 2m3 Storage Tank Area - Design Proposal - Offer 136 - 09.12.2019Document12 pagesFirePro - Vinayaka Enterprises - HZL - 2m3 Storage Tank Area - Design Proposal - Offer 136 - 09.12.2019ananthu.uNo ratings yet

- AN11499Document33 pagesAN11499Ícaro AndréNo ratings yet

- Service Manual: 29V-FT95S 29V-FT450SDocument53 pagesService Manual: 29V-FT95S 29V-FT450SAbilene MoralesNo ratings yet

- H.A.S-21-01-S.G (Supply and Erection) -محولDocument5 pagesH.A.S-21-01-S.G (Supply and Erection) -محولnabil beboNo ratings yet

- Fluke 190B /C: Medical FunctionsDocument13 pagesFluke 190B /C: Medical Functionsmiamor$44No ratings yet

- Fireye Flame Scanner UV1A6 (Sc-102 PDFDocument8 pagesFireye Flame Scanner UV1A6 (Sc-102 PDFld_ganeshNo ratings yet

- VX-230 UHF SM USA EXP EU EC085U90NcDocument31 pagesVX-230 UHF SM USA EXP EU EC085U90Nclaboratorio qapNo ratings yet

- Lighting Lighting: Philips UV-C Batten, The Power To ProtectDocument6 pagesLighting Lighting: Philips UV-C Batten, The Power To ProtectLOI HONo ratings yet

- Roseires I & C Status ReportDocument10 pagesRoseires I & C Status ReportSalih Ahmed ObeidNo ratings yet

- MM-40 - Final - Drawing, Design & Installation GuideDocument213 pagesMM-40 - Final - Drawing, Design & Installation GuideKyaw Swar LattNo ratings yet

- E3502E ArzatoareDocument8 pagesE3502E ArzatoarebrotaccristianNo ratings yet

- Ground Sense Comparator: DatasheetDocument56 pagesGround Sense Comparator: DatasheetEdipoNo ratings yet

- RSSWP 24mcch FRDocument4 pagesRSSWP 24mcch FRAgustin CanaveseNo ratings yet

- Aud Sharp Xlmp110eDocument100 pagesAud Sharp Xlmp110ejbNo ratings yet

- Danfoss BHO Oil Burners Control PDFDocument12 pagesDanfoss BHO Oil Burners Control PDFJose EscalonaNo ratings yet

- Fire Dampers Installation 15858Document7 pagesFire Dampers Installation 15858Aiman AliNo ratings yet

- Conf Inversores Toshiba VF - NC3Document8 pagesConf Inversores Toshiba VF - NC3Wellington CardosoNo ratings yet

- FirePro General Product Catalogue 2018 ULDocument74 pagesFirePro General Product Catalogue 2018 ULMohammedIrfanNo ratings yet

- H3BFN BGN BHNDocument24 pagesH3BFN BGN BHNKrisna Adi Saputra AdNo ratings yet

- Retail Store M&E Services Handover Checklist Form - Template NewDocument2 pagesRetail Store M&E Services Handover Checklist Form - Template Newpaul.townendNo ratings yet

- 100 Series: 100 Series Low-Profile Plug-In Smoke DetectorsDocument2 pages100 Series: 100 Series Low-Profile Plug-In Smoke DetectorsLogan Marquez AguayoNo ratings yet

- Fire and Smoke Spring Return Actuators FSLF230 (-S) US, FSLF24 (-S) USDocument2 pagesFire and Smoke Spring Return Actuators FSLF230 (-S) US, FSLF24 (-S) USSrikanth TagoreNo ratings yet

- Onkyo tx-nr3008 SM and Parts PDFDocument218 pagesOnkyo tx-nr3008 SM and Parts PDFSergey VissarionovNo ratings yet

- Control Fireye SBDocument22 pagesControl Fireye SBRogelioNo ratings yet

- FirePro General Product Catalogue 2017Document105 pagesFirePro General Product Catalogue 2017Jose Ignacio Salas B.No ratings yet

- Brosur Electrocauter - ESU-X 200NTDocument4 pagesBrosur Electrocauter - ESU-X 200NTR LNo ratings yet

- Test Unit For Burnerlogix y Controls 57yb4 5000Document4 pagesTest Unit For Burnerlogix y Controls 57yb4 5000edgarNo ratings yet

- Manual de Servicio de Camcorder Marca JVCDocument16 pagesManual de Servicio de Camcorder Marca JVCdaniel perezNo ratings yet

- Whirlpool Gas Dryer Conversion Kit Instructions W10301479ADocument4 pagesWhirlpool Gas Dryer Conversion Kit Instructions W10301479ASamurai Appliance Repair ManNo ratings yet

- Model G2 Sprinkler Guard, Model WS-2 Shield, and Model WSG-2 Sprinkler Guard With Shield Series ELO-231, ELO-231B, and ELO-231FRB SprinklersDocument4 pagesModel G2 Sprinkler Guard, Model WS-2 Shield, and Model WSG-2 Sprinkler Guard With Shield Series ELO-231, ELO-231B, and ELO-231FRB SprinklersAchraf BoudayaNo ratings yet

- Manual RFM 300+Document80 pagesManual RFM 300+saomigasNo ratings yet

- F-AERPROR - FPC-2 - Technical Manual 2018 - Rev1 - FULL - ResizedDocument15 pagesF-AERPROR - FPC-2 - Technical Manual 2018 - Rev1 - FULL - ResizedjacquesgelderblomNo ratings yet

- Service Manual: NSX-BL54 NSX-BL54E NSX-BL57Document34 pagesService Manual: NSX-BL54 NSX-BL54E NSX-BL57YaraNo ratings yet

- LGK 16 Control BurnerDocument24 pagesLGK 16 Control Burnerronny arwanaP3No ratings yet

- Thermostick - Cavo Termosensibile (UL Certificate)Document1 pageThermostick - Cavo Termosensibile (UL Certificate)SlimNo ratings yet

- Sharp Error l1-00 Al-ArDocument2 pagesSharp Error l1-00 Al-ArsydrousNo ratings yet

- Ime34070m 2 Far FR2835SDocument80 pagesIme34070m 2 Far FR2835Ssrinu1984No ratings yet

- AC Switch Disconnectors 18072022Document26 pagesAC Switch Disconnectors 18072022jdbNo ratings yet

- Samsung ln26b450c4m ln32b450b2m ln37b450b2m ln40b450b2m ln40b460b2m ln32b530p2m ln37b530p2m ln40b530p2m Chassis N70aDocument179 pagesSamsung ln26b450c4m ln32b450b2m ln37b450b2m ln40b450b2m ln40b460b2m ln32b530p2m ln37b530p2m ln40b530p2m Chassis N70aDaniel Norberto DemariaNo ratings yet

- Manual de PartesDocument26 pagesManual de Partesmaria herreraNo ratings yet

- Pl-021 Burner Control Operation Supplement: For U.S. Production Fan-HeatersDocument8 pagesPl-021 Burner Control Operation Supplement: For U.S. Production Fan-HeatershyperkrizNo ratings yet

- Ot Iii 962-0512Document142 pagesOt Iii 962-0512Kien TranNo ratings yet

- FPC 2 Panel PDFDocument11 pagesFPC 2 Panel PDFMiguel ContrerasNo ratings yet

- tmg740 3Document6 pagestmg740 3tespakNo ratings yet

- T05123001 TitleDocument35 pagesT05123001 TitleFabianoNo ratings yet

- Abre-7tsp2e r0 enDocument9 pagesAbre-7tsp2e r0 enEmre Sunay GebesNo ratings yet

- TBG 85 MeDocument124 pagesTBG 85 MeJOEL ANTAURCO VILLARREALNo ratings yet

- Smart InfrastructureDocument31 pagesSmart InfrastructureAxx JackNo ratings yet

- Hioki CM 4371-4372-4373-4374Document314 pagesHioki CM 4371-4372-4373-4374flavio torresNo ratings yet

- Mu r4343d e sz20r0414Document12 pagesMu r4343d e sz20r0414gavo vargoNo ratings yet

- Julabo-Service Manual Shaking Water Bath SW21cDocument20 pagesJulabo-Service Manual Shaking Water Bath SW21cAugusto Vieira100% (1)

- Brahma MF2 PDFDocument4 pagesBrahma MF2 PDFamicarelliNo ratings yet

- Burner Controls: Building Technologies DivisionDocument28 pagesBurner Controls: Building Technologies DivisiongigicorsicanuNo ratings yet

- RV Svn01a enDocument10 pagesRV Svn01a enarmando jesus cedeñoNo ratings yet

- Across The Line Combination: StartersDocument74 pagesAcross The Line Combination: Startersalexis oliveraNo ratings yet

- High Efficiency RF and Microwave Solid State Power AmplifiersFrom EverandHigh Efficiency RF and Microwave Solid State Power AmplifiersRating: 1 out of 5 stars1/5 (1)

- Vehicular Emissions TrinidadDocument4 pagesVehicular Emissions Trinidadstephen_debique9455No ratings yet

- Atomic Absorption SpectrosDocument8 pagesAtomic Absorption SpectrosKeshavVashisthaNo ratings yet

- Anshu Welding PDFDocument45 pagesAnshu Welding PDFAnshu SourabhNo ratings yet

- Exp 05Document11 pagesExp 05Zharlene SasotNo ratings yet

- INBAR-2023-Combating Climate Change With BambooDocument24 pagesINBAR-2023-Combating Climate Change With BambooKay-Uwe SchoberNo ratings yet

- Instruction Manual Professional Timing Light Instruction Manual Professional Timing LightDocument1 pageInstruction Manual Professional Timing Light Instruction Manual Professional Timing LightJohn DePNo ratings yet

- Nucleophilic SubstitutionDocument3 pagesNucleophilic SubstitutionDaniel McDermott0% (1)

- Kryotech Problem StatementDocument2 pagesKryotech Problem StatementMohammed MohsinNo ratings yet

- Datasheet For On/Off Valve (Xv-001) Datasheet For On/Off Valve (Xv-001)Document2 pagesDatasheet For On/Off Valve (Xv-001) Datasheet For On/Off Valve (Xv-001)usama666No ratings yet

- 5070 s03 QP 1 PDFDocument16 pages5070 s03 QP 1 PDFAnonymous wFLGHQ6ARNo ratings yet

- RIL - RPL MergerDocument13 pagesRIL - RPL Mergermoduputhur7418No ratings yet

- Poleas en V - Narrow - Ultra-VDocument70 pagesPoleas en V - Narrow - Ultra-VVladimir SepulvedaNo ratings yet

- Report WISHDocument51 pagesReport WISHNss Aissms Coe PuneNo ratings yet

- Petition No. 164/MP/2018 &ors. Page 1 of 48Document48 pagesPetition No. 164/MP/2018 &ors. Page 1 of 48Bhupendra CharanNo ratings yet

- Electronic Electrical Measurement & Measuring Instruments Mcq-2Document6 pagesElectronic Electrical Measurement & Measuring Instruments Mcq-2chetana100% (1)

- Air Cycle RefrigerationDocument15 pagesAir Cycle RefrigerationSyed Wajih Ul HassanNo ratings yet

- Super Critical Fluids and Its Application Seminar PresentationDocument12 pagesSuper Critical Fluids and Its Application Seminar PresentationParth BrahmbhattNo ratings yet

- Renewable Energy Sources: Answer AnswerDocument2 pagesRenewable Energy Sources: Answer AnswerPrathap VuyyuruNo ratings yet

- Symmetrical Semi ConverterDocument4 pagesSymmetrical Semi ConverterAdi JohnsonNo ratings yet

- 4VOL R01ipDocument9 pages4VOL R01ipzhyhhNo ratings yet

- Sandvik DU311 ITH - Descripción Técnica - EnglishDocument4 pagesSandvik DU311 ITH - Descripción Técnica - EnglishErix Alcayaga GonzálezNo ratings yet

- AHSP - SDA - Basis Permen 28 TH 2016Document16 pagesAHSP - SDA - Basis Permen 28 TH 2016BagusPrambudiNo ratings yet

- 0411 001Document8 pages0411 001None None NoneNo ratings yet

- MP EM Ass 12: DC CircuitsDocument10 pagesMP EM Ass 12: DC CircuitsBlueAstroNo ratings yet

- BS 7346-8 - Smoke VentilationDocument56 pagesBS 7346-8 - Smoke VentilationHelen Othen100% (1)

- Operation & Maintenance Manual Sebu9100-01-00-AllDocument120 pagesOperation & Maintenance Manual Sebu9100-01-00-AllecrNo ratings yet

- VMC Ideo 325Document9 pagesVMC Ideo 325Patrick CarapinhaNo ratings yet

- Sector Bending Blurring Lines Between Non-Profit and For-ProfitDocument13 pagesSector Bending Blurring Lines Between Non-Profit and For-ProfitKevNo ratings yet

- Plant Structure and Function PDFDocument2 pagesPlant Structure and Function PDFPT.Susan Angwyn Gemilang 8No ratings yet

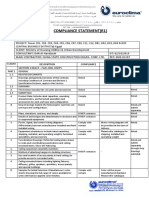

- compliance sheet of euroclima加承包商Document9 pagescompliance sheet of euroclima加承包商Li Liu100% (1)