Professional Documents

Culture Documents

PSCS Ec210b

Uploaded by

Zargon RidersOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PSCS Ec210b

Uploaded by

Zargon RidersCopyright:

Available Formats

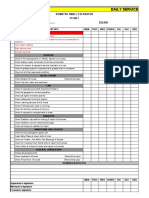

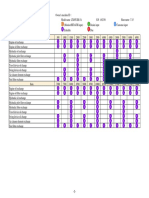

UNIT NO SMU TYPE 250 / 500 / 1000 / 2000 *

* Lingkari type service (circle the service type)

DATE TIME IN

LOCATION TIME OUT VOLVO EC210B PRIME

No

TRAINING BASIC MECHANIC PSCS Periodic Service Check Sheet

PASANG 'OUT OF SERVICE TAG' , 'DANGER TAG' & 'GANJAL BAN'(INSTALL OUT OF SERVICE TAG , DANGER TAGS & WHEEL CHOCKS)

SERVICE TYPE

Kompartemen Oli/Oil Compartment Tindakan/action

250/750 500 1000/2000

1 Final Drive RH/LH Ganti (Replace)

2 Engine Ganti (Replace)

3 Swing Machinery Case Ganti (Replace)

4 Damper Case Periksa dan Tambah jika perlu (Check Oil Level & Add if Req)

5 Hydraulic Ganti tiap 5000 Jam ‐ Sesuai Kondisi (Replace in 5000 Hrs)

SERVICE TYPE

Sample Oli/Oil Sample *) Tindakan/action

250/750 500 1000/2000

6 Engine Ambil sampel & periksa level (Take Sample & Check Level)

7 Swing Machinery Case** (Swing Drive) Ambil sampel & periksa level (Take Sample & Check Level)

8 Final Drive RH/LH Ambil sampel & periksa level (Take Sample & Check Level)

9 Hydraulic Ambil sampel & periksa level (Take Sample & Check Level)

*) Merujuk ke SOP Program Pelaksanaan SOS **)Gunakan Penamaan tersebut saat Labeling sampel

SERVICE TYPE

Filter Tindakan/action

250/750 500 1000/2000

10 Engine Ganti (Replace)

11 Fuel Filter Ganti (Replace)

12 Hydraulic Filter Element Ganti (Replace)

13 Hydraulic Tank Strainer Bersihkan pada PS 2000 (Clean up in PS 2000)

SERVICE TYPE

Saringan Pernapasan (Breather) Tindakan/action

250/750 500 1000/2000

14 Engine Bersihkan (Clean up)

15 Hydraulic Tank Breather Filter Element Ganti (Replace)

SERVICE TYPE

Tangki (Tank) Tindakan/action

250/750 500 1000/2000

16 Hydraulic Oil Tank Sump Buang endapan air & kotoran (drain water & dirt sediment)

SERVICE TYPE

Lain ‐ lain (Others) Tindakan/action

250/750 500 1000/2000

17 Saringan Udara dalam dan luar (Air Filter Outer & Inner) Bersihkan dan Ganti jika perlu (Clean up & Replace if Req)

18 AC Condenser Fins Bersihkan (Clean up)

19 Radiator, Cooler, After Cooler & Fuel Cooler Fins Bersihkan (Clean up)

20 Air Filter (AC) Bersihkan dan Ganti jika perlu (Clean up & Replace if Req)

21 Fan Belt Tension Periksa dan Ganti jika perlu (Check & Replace if Req)

22 Vibration Damper Periksa kebocoran tiap 2000 jam (Check leakage in 2000Hrs)

23 Water Pump Periksa kebocoran tiap 4000 jam (Check leakage in 4000Hrs)

24 Air Radiator (Coolant) Uji & Penuhkan jika perlu (test & Top up if nesscesary)

25 % GLYCOL/FREEZE POINT ( 0F )

26 MOLYBDATE ( MoO4 ) Hasil (Result)

27 NITRITE ( NO2 )

*)

Plug Magnet & Catat (Magnetic Plug for Particles & Record

28 Engine Final Drive RH

29 Swing Drive Final Drive LH

*)

Potong/ Periksa Saringan2 bermasalah & Catat (Cut Filter/ Inspect if Indicated failure & Record

30 Engine

31 Hydaulic

*) Merujuk ke STD Filter Cut Rating

Periksa & Catat Cylinder‐Cylinder *)

32 Boom Lift Cyl RH Bucket Cyl RH Stick Cyl RH

33 Boom Lift Cyl LH Bucket Cyl LH Stick Cyl LH

*) Merujuk ke STD Cylinder Inspection Rating

Pengambilan Data Modul Elektronik *)

PLTA/F‐008l; Revisi 1.0; Ret. 3 Thn Halaman : 1 / 4

Periodic Service Check Sheet

UNIT NO SMU TYPE 250 / 500 / 1000 / 2000 * KOMATSU

* Lingkari type service (circle the service type)

DATE TIME IN PC200‐7

LOCATION TIME OUT

Lembar Servis

Service Sheet

No PASANG 'OUT OF SERVICE TAG' , 'DANGER TAG' & 'GANJAL BAN'(INSTALL OUT OF SERVICE TAG , DANGER TAGS & WHEEL CHOCKS)

34 Download VHMS

*) Merujuk ke INK Unit Conditions Download and Data Analysis

SERVICE TYPE

PELUMASAN (GREASE)

250/750 500 1000/2000

35 Penuhkan Tangki Grease (Central Lubricating ‐ Grease Container, Refilling)

36 Boom Cylinder Foot Pin

37 Boom Foot Pin

38 Boom Cylinder Rod End

39 Arm Cylinder Foot Pin

40 Boom‐Arm Coupling Pin

41 Arm Cylinder Rod End

42 Bucket Cylinder Foot Pin

43 Arm‐Link Coupling Pin

44 Link Coupling Pin

45 Bucket Cylinder Rod End

46 Bucket‐Link Coupling Pin

SERVICE TYPE

PENGECEKAN AKHIR ( FINAL INSPECTION )

250/750 500 1000/2000

47 Pastikan semua level oli pelumas (Ensure all oil level)

48 Pastikan level air coolant (Ensure coolant water level)

49 Pastikan semua refill plug kencang (Ensure all refill plugs are tight)

50 Pastikan semua drain plug kencang (Ensure all drain plugs are tight)

51 Pastikan semua filter terpasang dan kencang (Ensure all filters are fit & tight)

Dibuat Oleh, Disetujui Oleh,

Nama : __________ Nama : __________

Jabatan : Mekanik Jabatan : FM / SPV

Tanggal : __________ Tanggal : __________

PLTA/F‐008l; Revisi 1.0; Ret. 3 Thn Halaman : 2 / 4

UNIT NO TYPE 250 / 500 / 1000 / 2000 *

VOLVO EC210B-PRIME SMU * Lingkari type service

(circle the service type)

Lembar Pemeriksaan Mekanik & Kelistrikan DATE

ENGINE Tindakan/action Status Ok/Not Ok

1 Kebocoran Oli ( Oil Leaks ) Periksa kebocoran (Check leaks)

2 Kebocoran Bahan Bakar ( Fuel Leaks ) Periksa kebocoran (Check leaks)

3 Kondisi Semua Hose / Cacat ( All Hoses Fuel & Air System For Condition/Chaffing ) Periksa (Check)

4 Kebocoran Air Radiator ( Water Leaks ) Periksa kebocoran (Check leaks)

5 Kondisi Hose Radiator, Kekencangan Klam (Radiator Hoses Condition, Clamps For Tightness) Periksa & kencangkan (Check & Tighten)

6 Kekencangan dan kebocoran fuel line clamp (Fuel Line Clamp for Tightness & Leaks) Periksa & kencangkan (Check & Tighten)

7 Sirip Radiator dari Rusak & Buntu ( Radiator Core for damaged, clogged ) Periksa kebocoran (Check leaks)

8 Bagian Atas Radiator & Tutupnya ( Radiator Header Tanks & Caps ) Periksa kebocoran (Check leaks)

9 Kebocoran Sistem Pemasukkan Udara ( Induction System For Leaks, Clamps For Tightness ) Periksa kebocoran (Check leaks)

10 Kebocoran Gas Buang ( Exhaust System For Leaks ) Periksa kebocoran (Check leaks)

11 Getaran Turbo Charger, Kebocoran Gas dan Bising (Turbo Charger for Vibration, Gas Leaks, Unusual Noise) Periksa (Check)

12 Kondisi & Pengencang Belt Kipas ( Fan Belt Tensioner & Condition ) Periksa & kencangkan (Check & Tighten)

13 Dudukan (Mountings ) Periksa & kencangkan (Check & Tighten)

14 Semua Baut Pengikat ( All Retaining Bolts ) Periksa & kencangkan (Check & Tighten)

15 Periksa Pelumasan Awal (Check Pre‐Lube Operation) Periksa (Check)

16 Buang air dan kotoran dari fuel filter dan water separator Drain (Buang)

PUMP TRANSFER ( PTO ) Tindakan/action Status Ok/Not Ok

17 Mounting & Retaining Bolts ( Dudukan & Baut Pengikat ) Periksa kebocoran (Check leaks)

18 Oil Leaks ( Kebocoran Oli ) Periksa kebocoran (Check leaks)

HYDRAULIC Tindakan/action Status Ok/Not Ok

19 Kebocoran Oli ( Oil Leaks ) Periksa kebocoran (Check leaks)

20 Silinder Hidrolik & Batang Silinder ( Attach. Cylinders, Rods ) Periksa kebocoran (Check leaks)

21 Pin & Bushing ( Pins & Bushing ) Periksa (Check)

22 Sambungan, Dudukan & Baut Pengikatnya ( Linkages, Mountings & Bolts ) Periksa & kencangkan (Check & Tighten)

23 Selang2, Pipa & Pengikatnya ( Hoses, Pipes & Clamps ) Periksa (Check)

24 Control Valve ( Control Valves ) Periksa kebocoran (Check leaks)

SWING DRIVE Tindakan/action Status Ok/Not Ok

25 Kebocoran Oli ( Oil Leaks ) Periksa kebocoran (Check leaks)

26 Keretakan Pada Rangka & Dicatat ( Frame for Crack & Recorded ) Periksa (Check)

27 Selang2, Pipa & Pengikatnya ( Hoses, Pipes & Clamps ) Periksa (Check)

28 Dudukan & Pengikat Motors & Gear Boxes (Mountings & Bolts) Periksa & kencangkan (Check & Tighten)

FINAL DRIVE Tindakan/action Status Ok/Not Ok

29 Kebocoran Oli ( Oil Leaks ) Periksa kebocoran (Check leaks)

30 Keretakan Pada Rangka & Dicatat ( Frame for Crack & Recorded ) Periksa (Check)

31 Dudukan & Baut Pengikatnya ( Mountings & Bolts ) Periksa & kencangkan (Check & Tighten)

32 Selang2, Pipa & Pengikatnya ( Hoses, Pipes & Clamps ) Periksa (Check)

33 Motors & Final Drive ( Motors & Final Drive ) Periksa kebocoran (Check leaks)

UNDERCARRIAGE Tindakan/action Status Ok/Not Ok

34 Track Tension ( Ketegangan Track ) Periksa (Check)

35 Track Pins Retaining Bolts and Nuts Periksa & kencangkan (Check & Tighten)

36 Track Pins Periksa & kencangkan (Check & Tighten)

37 Track Pads Periksa & kencangkan (Check & Tighten)

38 Carrier Rollers Periksa (Check)

39 Track Rollers Periksa (Check)

40 Idlers Periksa (Check)

41 Retak & Keausan Tumblers ( Tumblers for Wear & Crack ) Periksa (Check)

42 Track Adjuster Periksa (Check)

43 Keretakan Pada Rangka & Dicatat (Frame for Crack & Recorded) Periksa (Check)

44 Baut Dudukan Track Frame (Track Frame Mounting Bolts) Periksa & kencangkan (Check & Tighten)

ELECTRICAL Tindakan/action Status Ok/Not Ok

46 Isolation swicth bekerja & dalam kondisi yg baik (Isolation switch operation & condition ) Periksa (Check)

47 Emergency switch bekerja & dalam kondisi yg baik (Emergency swicth operation & condition ) Periksa (Check)

48 Alarm Jalan ( Travel Alarm ) Periksa (Check)

49 Semua gauge & control panel indicator berfungsi(All gauges & control panel indicators for normal working) Periksa (Check)

50 Semua Tombol berfungsi dengan baik (All application switches fuction) Periksa (Check)

51 Periksa klakson bekerja & dalam kondisi yg baik (Check Horn operation & condition ) Periksa (Check)

52 Lampu rotary berfungsi(Rotary lamp function) Periksa (Check)

53 Lampu penerangan bekerja & dalam kondisi baik (Working lamp operation & condition ) Periksa (Check)

54 Radio komunikasi bekerja & dalam kondisi yg baik (2 way radio condition & operation) Periksa (Check)

55 System pembersih kaca bekerja & dalam kondisi baik(Window wiper system operation & condition) Periksa (Check)

56 Kondisi sekering ,kotak sekring & pemutus arus(Condition of fuses,fuse box & circuit breakers) Periksa (Check)

57 Battery ,sambungan & switch bekerja serta dalam kondisi yg baik (Battery,connection ,swicth operation & condition ) Periksa (Check)

58 Sambungan & harnes sensor,switch & solenoid dalam kondisi baik (Connectors & cables of sensor,switch & solenoid condition ) Periksa (Check)

59 Pendingin kabin bekerja & dalam kondisi yg baik (AC condition & operation) Periksa (Check)

60 Sistem charging bekerja dengan baik (Charging system for normal operation) Periksa (Check)

61 Sistem starting bekerja dengan baik (Starting system for normal operation) Periksa (Check)

SAFETY CHECK AND GENERAL Tindakan/action Status Ok/Not Ok

62 Semua petunjuk safety tersedia & jelas (Safety sign are fitted & clear) Periksa (Check)

63 Kondisi dan isi pemadam api (Condition and insert of fire extinguisher Periksa (Check)

64 Tangga untuk naik operator (Ladder for damaged) Periksa (Check)

65 Semua tutup & pengaman ada dan lengkap (All guards and covers are in place and secure) Periksa (Check)

STATUS

ITEM DEFECT

Ok* Backlog**

* Ok Defect terkerjakan saat Service Berlangsung.

**Backlog Defect dibuatkan orderannya sebagai Backlog.

Dibuat Oleh, Disetujui Oleh,

Nama : __________ Nama : __________

Jabatan : Mekanik Jabatan : FM / SPV

Tanggal : __________ Tanggal : __________

PLTA/F‐008l; Revisi 1.0; Ret. 3 Thn Halaman : 3 / 4

BACKHOE ATTACHMENT INSPECTION SHEET

2000 HOURS VOLVO

EC210B PRIME

Catatan ( Note ) :

Periksa semua sambungan pengelasan untuk keretakan ( Tanda panah)

( Check all weld joint between casting & fabricated section for cracks ‐ shown by arrow )

Secara seksama periksa seluruh bagian frame/pin/bushing thd keretakan atau tanda2 perubahan bentuk. Tandai pd gambar diatas.

( Carefully inspect the entire track frame/pin/bushing for crack damage or sign of distortion. Mark each problem found on the frame diagram )

FRAME ( Pict. 1 ~ 3 )

Item Condition Remarks

1

2

3

4

5

6

7

8

9

10

11

12

13

14

PINS & BUSHINGS (Pict. 4) ‐ Periksa Jarak/Gerak bebas Pin & Bushing ( Check for Pin & Bushing clearance/Movements)

Item Condition Remarks Item Condition Remarks

A G

B H

C I

D J

E K

F

Dibuat Oleh, Disetujui Oleh,

Jabatan : Mekanik Jabatan : FM / SPV

Tanggal : __________ Tanggal : __________

PLTA/F‐008l; Revisi 1.0; Ret. 3 Thn Halaman : 4 / 4

You might also like

- Maintenance - Terex Franna AT22Document6 pagesMaintenance - Terex Franna AT22FergiKalesaran0% (1)

- JCB VM115 Single Drum RollerDocument9 pagesJCB VM115 Single Drum Roller江柄宏100% (1)

- Instrumentarium Dental OP-200 Dental Panorama X-Ray - Troubleshooting ManualDocument112 pagesInstrumentarium Dental OP-200 Dental Panorama X-Ray - Troubleshooting Manualoleg100% (1)

- Buderus Logasol SK Pump Station User ManualDocument56 pagesBuderus Logasol SK Pump Station User Manuale-ComfortUSANo ratings yet

- 7" Decu Excavator Error Code List 7" Decu Excavator Error Code List 7" Decu Excavator Error Code List 7" Decu Excavator Error Code ListDocument2 pages7" Decu Excavator Error Code List 7" Decu Excavator Error Code List 7" Decu Excavator Error Code List 7" Decu Excavator Error Code ListCHIK0% (1)

- Fatigue Design According To Standards BS EN, SANS and IIW Bulletin 520Document88 pagesFatigue Design According To Standards BS EN, SANS and IIW Bulletin 520Evelin StefanovNo ratings yet

- F 008n - Plta Pscs Pc1250 7Document6 pagesF 008n - Plta Pscs Pc1250 7TaufikNo ratings yet

- F 008am - Plta Pscs Pc1250 8Document6 pagesF 008am - Plta Pscs Pc1250 8TaufikNo ratings yet

- F-008 - Plta Pscs Pc2000Document6 pagesF-008 - Plta Pscs Pc2000TaufikNo ratings yet

- Sheet Service - SKT90SDocument2 pagesSheet Service - SKT90SAnanda risaNo ratings yet

- Unit Engine Model Serial No. Code No. Model: Beri Tanda " V " Jika Kondisi Baik Dan " X " Jika Kondisi Tidak BaikDocument6 pagesUnit Engine Model Serial No. Code No. Model: Beri Tanda " V " Jika Kondisi Baik Dan " X " Jika Kondisi Tidak BaikkkmechNo ratings yet

- 0010 - Check Sheet PS PC400-7 KOMATSUDocument2 pages0010 - Check Sheet PS PC400-7 KOMATSUsahruna japurNo ratings yet

- 0010 - Check Sheet PS PC400-7 KOMATSU 2Document2 pages0010 - Check Sheet PS PC400-7 KOMATSU 2sahruna japurNo ratings yet

- Sheet Service - SANY SKT105SDocument4 pagesSheet Service - SANY SKT105SAnanda risaNo ratings yet

- RPG S Series Combines s760 s770 s780 CombinesDocument3 pagesRPG S Series Combines s760 s770 s780 Combinesfabio cacciatoriNo ratings yet

- Adt e b40 b45 RSG Rev 5Document3 pagesAdt e b40 b45 RSG Rev 5wingchow282828228No ratings yet

- CompactorDocument8 pagesCompactorkkmech100% (1)

- 2019-11-20 - UD Trucks - Biodiesel FAME, Service RecommendationsDocument2 pages2019-11-20 - UD Trucks - Biodiesel FAME, Service RecommendationsMaintenance PlannerNo ratings yet

- 06 DrivelineDocument9 pages06 DrivelineAriel Farinon100% (1)

- New NXT Mechine Servicing SecduleDocument111 pagesNew NXT Mechine Servicing SecduleDiwash ShahNo ratings yet

- Manual Kyron - Completo WhatsDocument2,530 pagesManual Kyron - Completo WhatsHamilton ManféNo ratings yet

- General InformationDocument15 pagesGeneral InformationEmilio Arce BrenesNo ratings yet

- CAT 305 (Final)Document4 pagesCAT 305 (Final)maquidraulicaNo ratings yet

- Uptime Maintenance Planner: Service IntervalsDocument2 pagesUptime Maintenance Planner: Service IntervalsJohn GrayNo ratings yet

- PSCS - PC200-8Document6 pagesPSCS - PC200-8mahmudiNo ratings yet

- Kyron PDFDocument1,105 pagesKyron PDFDamir MilisaNo ratings yet

- IsuzuDocument1 pageIsuzuFarhan Sheikh100% (1)

- Cat 308Document5 pagesCat 308George PlishkoNo ratings yet

- Laporan Pms Engine Tug BoatDocument14 pagesLaporan Pms Engine Tug Boatk684ryjm8vNo ratings yet

- Nissan 370Z: 3.7 PETROL Periodic MaintenanceDocument3 pagesNissan 370Z: 3.7 PETROL Periodic MaintenanceMichael KaneNo ratings yet

- Mantenimiento PreventivoDocument2 pagesMantenimiento PreventivoKetzadilis Johana PérezNo ratings yet

- The 8 Series Utility Range: What Do You Integrate?Document4 pagesThe 8 Series Utility Range: What Do You Integrate?Asad AijazNo ratings yet

- Pm. Dozer d85ssDocument20 pagesPm. Dozer d85ssIqmal WahabNo ratings yet

- ISX15 X15 500 605hp RV QRGDocument2 pagesISX15 X15 500 605hp RV QRGyohan jaimes huamanNo ratings yet

- 04 Kobelco Hidraulic ComponentsDocument32 pages04 Kobelco Hidraulic ComponentsEnrique Barrios Nuevo100% (1)

- 260E PIN 1DW260EX F677827 708124 310E PIN 1DW310EX F677827 708124 Uptime Maintenance PlannerDocument4 pages260E PIN 1DW260EX F677827 708124 310E PIN 1DW310EX F677827 708124 Uptime Maintenance PlannerNelson Andrade VelasquezNo ratings yet

- Daily Service: Komatsu Small ExcavatorDocument9 pagesDaily Service: Komatsu Small ExcavatorHebert SozinyuNo ratings yet

- Filter Overview With Service Intervals and CapacitiesDocument2 pagesFilter Overview With Service Intervals and CapacitiesMohammad DahabNo ratings yet

- Periodical Service Ud Truck Cwe370: Maintenance SheetDocument2 pagesPeriodical Service Ud Truck Cwe370: Maintenance SheetIkipiyeNo ratings yet

- Claas Note 1Document8 pagesClaas Note 1RiyadhNo ratings yet

- MgR09 Specification PDFDocument10 pagesMgR09 Specification PDFAbdul Waheed AwanNo ratings yet

- Chklist HEXDocument3 pagesChklist HEXluisNo ratings yet

- John Deere 300GLC - T357633X19 Maintenance PlannerDocument2 pagesJohn Deere 300GLC - T357633X19 Maintenance PlannerGeorge PlishkoNo ratings yet

- ALF400 To 900, ALT-5/-9: Auto Feed Lube, Auto Feed TankDocument7 pagesALF400 To 900, ALT-5/-9: Auto Feed Lube, Auto Feed TankHéctor EnriqueNo ratings yet

- Unit Engine Model Serial No. Code No. Model: Beri Tanda " V " Jika Kondisi Baik Dan " X " Jika Kondisi Tidak BaikDocument15 pagesUnit Engine Model Serial No. Code No. Model: Beri Tanda " V " Jika Kondisi Baik Dan " X " Jika Kondisi Tidak BaikkkmechNo ratings yet

- Maintenance Interval ScheduleDocument4 pagesMaintenance Interval ScheduleRoberto Hernández DiegoNo ratings yet

- Chassis PDFDocument1,037 pagesChassis PDFDamir MilisaNo ratings yet

- 8400 Replacement Parts GuideDocument4 pages8400 Replacement Parts GuideOleksandr YermolenkoNo ratings yet

- Vol 15033b-22x34 Mack Service at A Glance Poster v8 PDFDocument1 pageVol 15033b-22x34 Mack Service at A Glance Poster v8 PDFJenMicMarAguNo ratings yet

- 6 Series Tractors 6405 and 6605 Tractors South America Edition Filter Overview With Service Intervals and CapacitiesDocument2 pages6 Series Tractors 6405 and 6605 Tractors South America Edition Filter Overview With Service Intervals and CapacitiesYeison NavasNo ratings yet

- Nama Alat: Wheel Loader Merk Dan Type: Komatsu, WA380z-6 Kode Alat: WL-03Document5 pagesNama Alat: Wheel Loader Merk Dan Type: Komatsu, WA380z-6 Kode Alat: WL-03gumNo ratings yet

- Toyota PickupDocument11 pagesToyota Pickupalexberhane3No ratings yet

- Nissan Micra: 1.2 & 1.5 PETROL Periodic MaintenanceDocument3 pagesNissan Micra: 1.2 & 1.5 PETROL Periodic MaintenanceSubrata KunduNo ratings yet

- Dump Truck VOLVODocument20 pagesDump Truck VOLVOkkmechNo ratings yet

- VolvoserviceataglanceDocument1 pageVolvoserviceataglancePAULO SOUZANo ratings yet

- Volvo ServiceAtaGlanceDocument1 pageVolvo ServiceAtaGlanceأبو خالد الأثرىNo ratings yet

- Nissan Almera: 1.5 PETROL Periodic MaintenanceDocument3 pagesNissan Almera: 1.5 PETROL Periodic Maintenancekucai hunterNo ratings yet

- 3512 Engine MaintenanceDocument30 pages3512 Engine Maintenancekhir khirNo ratings yet

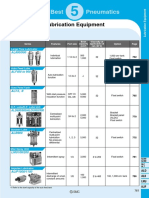

- Pneumatics Best: Lubrication EquipmentDocument1 pagePneumatics Best: Lubrication Equipmentfauzi daryantoNo ratings yet

- ZX85USB-5A MaintenancePeriodicaDocument2 pagesZX85USB-5A MaintenancePeriodicaNuno OliveiraNo ratings yet

- 200CLC 230CLC 270CLC Excavators Uptime Maintenance PlannerDocument4 pages200CLC 230CLC 270CLC Excavators Uptime Maintenance PlannerJaime MurilloNo ratings yet

- Eng GB SP SD110 BSIII - FDocument4 pagesEng GB SP SD110 BSIII - FImam MuhhudaNo ratings yet

- Service ProtocolDocument3 pagesService Protocolrudy oktaNo ratings yet

- Gas Atomization of Chemical Grade SiliconDocument6 pagesGas Atomization of Chemical Grade SiliconCorina EsanuNo ratings yet

- 01 FSD60 MFSD60Document10 pages01 FSD60 MFSD60Lan ĐinhNo ratings yet

- File Name From MailDocument11 pagesFile Name From MailsuhailNo ratings yet

- Professional Audio LPR 35Document5 pagesProfessional Audio LPR 35dNo ratings yet

- DeepLay Eks 2022 184 Comparing Wave SpectrumDocument10 pagesDeepLay Eks 2022 184 Comparing Wave SpectrumGunawan SuwarnoNo ratings yet

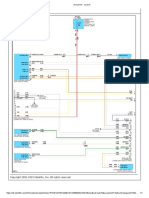

- Diagram 1 A/C Heater ModuleDocument1 pageDiagram 1 A/C Heater ModuleEnrique Arevalo LeyvaNo ratings yet

- Case Study Report On AutomobileDocument18 pagesCase Study Report On AutomobileSayaliRewaleNo ratings yet

- Tech 1 PDFDocument5 pagesTech 1 PDFdhiyaa januuNo ratings yet

- JEE Main 2019 Chemistry April Attempt Shift - 1 (08th April, 2019)Document16 pagesJEE Main 2019 Chemistry April Attempt Shift - 1 (08th April, 2019)Resonance Eduventures83% (24)

- Lesson 7: Internet Security: ObjectivesDocument56 pagesLesson 7: Internet Security: ObjectivesWilliam C RounsavilleNo ratings yet

- Ansi C37.54-2002 (R2010)Document46 pagesAnsi C37.54-2002 (R2010)Mochamad Beta AuditamaNo ratings yet

- DML P 3 StatementDocument2 pagesDML P 3 StatementJavierCornejoCarpioNo ratings yet

- Specialist Services: Heavy Oil Production Facility at Umm Niqa (15049) CONTRACT NO. 15052398Document1 pageSpecialist Services: Heavy Oil Production Facility at Umm Niqa (15049) CONTRACT NO. 15052398Naresh KumarNo ratings yet

- Admission Brochure Nsut Mba2019Document15 pagesAdmission Brochure Nsut Mba2019himanshuNo ratings yet

- Sound IdsDocument422 pagesSound IdsKieren ShepherdNo ratings yet

- AC Servo Nutrunner E 1908Document2 pagesAC Servo Nutrunner E 1908Petar PavićNo ratings yet

- Repair Basics TGDocument14 pagesRepair Basics TGbroNo ratings yet

- Carpenter Center For The Visual Arts - Harvard University - Le CorbusierDocument21 pagesCarpenter Center For The Visual Arts - Harvard University - Le CorbusierAparna KulshresthaNo ratings yet

- Visual KVDocument10 pagesVisual KVChong Kean WahNo ratings yet

- BPR MethodologiesDocument29 pagesBPR MethodologiesOsamah S. Alshaya100% (1)

- Mysella XL 40 - TDSDocument2 pagesMysella XL 40 - TDSTayyab IftikharNo ratings yet

- Hyundai HD78 Wabco ABS (Тормозная Система)Document322 pagesHyundai HD78 Wabco ABS (Тормозная Система)Bigfair HD7888% (8)

- RCC Design of Bus Shelter at VelpuruDocument81 pagesRCC Design of Bus Shelter at VelpuruD.V.Srinivasa RaoNo ratings yet

- BOQ FormatDocument10 pagesBOQ FormatnewattelectricNo ratings yet

- RS422 RS485 Application Guide EbookDocument137 pagesRS422 RS485 Application Guide EbookshashirajNo ratings yet

- Gorenje K 337 2 MelaDocument18 pagesGorenje K 337 2 Meladjdr1No ratings yet