Professional Documents

Culture Documents

Engineering Specification of Cyclone

Engineering Specification of Cyclone

Uploaded by

Joe Grosir0 ratings0% found this document useful (0 votes)

9 views5 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views5 pagesEngineering Specification of Cyclone

Engineering Specification of Cyclone

Uploaded by

Joe GrosirCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

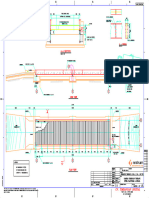

PEMBANGUNAN PABRIK ALF 3 - I

Owner

PT PETROKIMIA GRESIK

Location

GRESIK ~ EAST JAVA,

ob No

ENGINEERING SPECIFICATION aeON 2018 eee

Eee OF Document No. | A

34-JM-01-42-3000-

CYCLONE 74

5 Sheets (With Cover)

eee diel

Project

wsveron constwveron | aoaeanis | A

ot

ISSUED FOR APPROVAL 17-07-2019 | ‘Foy

pw

KH

REV

Description Date Prepared

Checked

Approved

‘THE INFORMATION CONTAINED HEREIN IS CONFINDENTIAL AND THE PROPERTY OF PT PETROKIMIA GRESIK AND NOT FOR

PUBLICATION, THE INFORMATION IS ISSUED ON THE UNDERSTANDING THAT NO PART THERE OF SHALL BE COPIED OR

‘COMMUNICATED TO A THIRD PARTY WITHOUT AUTHORIZATION IN WRITING FROM PT PETROKIMIA GRESIK

eb No

& raclania vciiceais sP=ceCALLOn peaoean Rev

cna ce ware LAN

Sheet : 1 of

CONTENTS

ae |

1. General 2 |

2. Codes and Standards 2 |

3. Cyclone Parts 2

4, Design and Construction 2

5. Guarantees 3

6. Document to be Submitted 3

7. Fabrication, Inspection and Test 3

8. Packing and Marking 4

ENGINEERING SPECIFICATION oe ae

PeTROKIMIA SI eae A

chek placa sesmararsoo2¢ |

enuaers

General

This specification defines the minimum requirement for supply included design,

materials (package), fabrication & inspection test of Cyclone.

Codes & Standards

‘The codes and standards specified in the Engineering Specification shall form a part

of the requirements of the Engineering Specification, in the manner and to the

extent indicated in the respective Engineering Specification,

Codes and standards, listed below, of the latest edition at the effective date of the

contract shall apply to the design, fabrication, manufacturing, assembling,

inspection and test of the materials and the equipment.

Typically but not limited to:

AIsc : American Institute of Stee! Construction

ANSI : American National Standards institute

ASTM : American Society for Testing and Materials.

Ast : American Iron and Steel Institute

Iso : International Standards Organization

sts Japanese Industrial Standards

SN : Standard National Indonesian

ssPC : Steel Structural painting Council

cyclone Part

The minimum parts of cyclone shall be included in design supply, as follows:

= Shell, head, cone

+ Support Cyclone

* Chain for self Cleaning

= Nozzle, Manhole

= Support Lug

+ Lifting Lug

= Bolt and nut

"Packing

* Other accessories such as ladder, platform

Design and Construction

4.1. The Cyclone should be designed accordance with requirement on data sheet

and purchaser drawing

4.2 When Cyclone design pressure below than atmospheric pressure should be

calculated in the full vacuum condition.

4.3. The Cyclone should be completed with chain for internal cleaning / minimize

build-up dust at internal cyclone.

4.4 The cyclone shall be designed for adequate stiffness to minimize vibration and

noise generation. Stiffeners shall be continuously welded to the casing

]iobNe

wy, ENGINEERING SPECIFICATION 24-NON-2019 Rev

resi oF [Document no. |

CYCLONE 34-1M-01-42-2000-24 L\

Sheet: 30f4

4.5 Casing shall be completed with access door to change the Man Hole or other

inside maintenance and repair work.

4.6 The door shall be sealed with suitable packing.

4.7 Materials for shell, nozzle, flange and structural components shall be in

accordance with ASTM and ASME standards

48 Painting.

49 Unless otherwise stated on data sheet, refer to Engineering Specification for

Painting.

5. Guarantees

5.1 The contractor shall guarantee that the equipment and materials to be

supplied are free form fault and defect, in design, workmanship and materials

are of sufficient quality and of proper materials to full fill the function.

5.2 Mechanical guarantee shall apply for 1 (one) year after provisional acceptance

or for period not to exceed 18 months after shipping.

6. Document to be Submitted

6.1 Contractor shall submit the detail drawing.

6.2 _ English language shall be used in all documents.

63 Metric system shall be used as measurement unit unless otherwise specified.

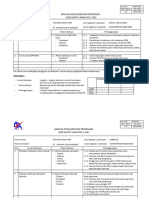

7. _ Fabrication, Inspection and Test

71 General

Fabrication, Inspections and tests shall be performed base on manufacturer's

specification and data sheet, the procedures and the acceptance standards of

inspection and test shall follow code and standard.

7.2 Welding inspection

Welding inspection shall be performed to assure first quality workmanship and

adherence to penetration requirements during process and final welding.

Static liquid testing shall be performed.

7.3. Fabrication

Fabrication activities should be conformed with Manufacture.

Fabrication Procedure which approved by Purchaser.

7.4 Visual and Dimensional inspection

Straighteners and flatness shall be inspected for all surfaces, any burrs shall be

removed and given a workman like finish. Dimensional inspection shall be carried

out for all parts of equipment and shall be recorded. Dimensional tolerances as

follow

= Length :-0 & +3 mm

= Wall thickness : -0 & +2 mm

= Roundness : + 0.04%

ENGINEERING SPECIFICATION 24-NON-2019 iw

PerROKMia S teen oz | A

GRESIK CYCLONE 34-JM-01-42-3000-24

7.5 Shop Inspection & Test

(1) Shop inspection and test shall be carried out in accordance with

manufactory standard inspection & test procedure including inspection &

testitems.

(2) Purchaser inspector shall has the right to access at any time to

manufacturer's shop to check his quality control & inspection activity

8 Packing and Marking

8&1 Packing

(1) Packing shall be designed in consideration of local subtropical conditions

and period of storage in open yards at site (max 6 months)

(2) All equipment must be carefully and properly prepared secured and

packed to ensure adequate protection until delivered at final destination,

according to the method of transport selected storage specified and

accordance with any special provisions contained in the requisition.

(3) All items shall be suitably packed, securely fastened and protected from

damage during transportation.

82 Marking

All materials (parts) separately shall be properly tagged or marked with the

item and serial number for which it is intended. Special marking shall be

marked to aid in handling.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Datasheet For Safety Device ConveyorDocument6 pagesDatasheet For Safety Device ConveyorJoe GrosirNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Datasheet For Rotary Valve (V-3164)Document1 pageDatasheet For Rotary Valve (V-3164)Joe GrosirNo ratings yet

- Datasheet For Hopper (D-3103)Document1 pageDatasheet For Hopper (D-3103)Joe GrosirNo ratings yet

- Fabric Expansion JointDocument20 pagesFabric Expansion JointJoe GrosirNo ratings yet

- ContentsDocument10 pagesContentsJoe GrosirNo ratings yet

- ContentsDocument10 pagesContentsJoe GrosirNo ratings yet

- Approval Kabel Metal PT. Wiguna-04Document1 pageApproval Kabel Metal PT. Wiguna-04Joe GrosirNo ratings yet

- Engineering Specification For GroundingDocument8 pagesEngineering Specification For GroundingJoe GrosirNo ratings yet

- Induction Motor & Load List (Low Voltage)Document6 pagesInduction Motor & Load List (Low Voltage)Joe GrosirNo ratings yet

- Datasheet For Table Feeder Splitter Gate (M-3107-1)Document1 pageDatasheet For Table Feeder Splitter Gate (M-3107-1)Joe GrosirNo ratings yet

- Engineering Specification of Hot and Cold InsulationDocument9 pagesEngineering Specification of Hot and Cold InsulationJoe GrosirNo ratings yet

- Ufd Domestic Water CampDocument1 pageUfd Domestic Water CampJoe GrosirNo ratings yet

- Prepare Bbs Fp-1Document1 pagePrepare Bbs Fp-1Joe GrosirNo ratings yet

- Construction Drawing of Sl500fc B-Door UpdateDocument5 pagesConstruction Drawing of Sl500fc B-Door UpdateJoe GrosirNo ratings yet

- 60 Ton - 18 M X 3 M Pitless Type Rinstrum - R420 + BM14G + J600 Deck Module - 2501-12.RDocument2 pages60 Ton - 18 M X 3 M Pitless Type Rinstrum - R420 + BM14G + J600 Deck Module - 2501-12.RJoe GrosirNo ratings yet

- Expansion Joint No-8&10Document1 pageExpansion Joint No-8&10Joe GrosirNo ratings yet

- Datasheet For Weigh Feeder (M-3131)Document1 pageDatasheet For Weigh Feeder (M-3131)Joe GrosirNo ratings yet

- Drawing Mechanical Pt. TiaDocument43 pagesDrawing Mechanical Pt. TiaJoe GrosirNo ratings yet

- Layout Flow and Crowd Control Mandalika - GP - 01 - A0 Scale 6500mtrDocument1 pageLayout Flow and Crowd Control Mandalika - GP - 01 - A0 Scale 6500mtrJoe GrosirNo ratings yet

- TKDN Pipa20230912 - 240122 - 120234Document5 pagesTKDN Pipa20230912 - 240122 - 120234Joe GrosirNo ratings yet

- Stop Kontak Ex ScheiderDocument26 pagesStop Kontak Ex ScheiderJoe GrosirNo ratings yet

- Drawing Steel Structure Kapasitas 60 Ton Pitless Type 18 M X 3 M - 1 Dari 5Document1 pageDrawing Steel Structure Kapasitas 60 Ton Pitless Type 18 M X 3 M - 1 Dari 5Joe GrosirNo ratings yet

- Company Profile Wiguna Djaya Mandiri - Copy 2Document9 pagesCompany Profile Wiguna Djaya Mandiri - Copy 2Joe GrosirNo ratings yet

- Analisa Keselamatan Pekerjaan (Job Safety Analysis / Jsa) : KeteranganDocument5 pagesAnalisa Keselamatan Pekerjaan (Job Safety Analysis / Jsa) : KeteranganJoe GrosirNo ratings yet

- Rencana Anggaran Biaya (Rab) Jasa Renovasi BangunanDocument48 pagesRencana Anggaran Biaya (Rab) Jasa Renovasi BangunanJoe GrosirNo ratings yet

- 20-07-2023 - Layout Infrastruktur Mandalika - On Review-Arrc-update FlowDocument1 page20-07-2023 - Layout Infrastruktur Mandalika - On Review-Arrc-update FlowJoe GrosirNo ratings yet

- Mech Calculation of ConveyorDocument20 pagesMech Calculation of ConveyorJoe Grosir100% (1)

- Panel PolosDocument2 pagesPanel PolosJoe GrosirNo ratings yet

- Report System Ba 1 Dan 2 Ombilin R1Document4 pagesReport System Ba 1 Dan 2 Ombilin R1Joe GrosirNo ratings yet

- 30Document1 page30Joe GrosirNo ratings yet