Professional Documents

Culture Documents

ATEC Sapphire 100 - 200 PM Procedure Checklist TR-01696 - 001 - 01

Uploaded by

colladoluzangela0 ratings0% found this document useful (0 votes)

14 views6 pagesOriginal Title

ATEC Sapphire 100_200 PM Procedure Checklist TR-01696_001_01

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views6 pagesATEC Sapphire 100 - 200 PM Procedure Checklist TR-01696 - 001 - 01

Uploaded by

colladoluzangelaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

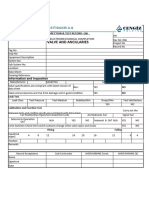

DOCUMENT

TYPE: TEST RECORD

ATEC SAPPHIRE DOCUMENT NUMBER: REV:

100/200 CONSOLE TR-01696 001

DOCUMENT REV. RELEASE DATE: 1 DEC 2017

TITLE: PREVENTIVE

MAINTENANCE SIZE A SHEET 1 OF 6

CHECKLIST

PROPRIETARY: This document contains proprietary data of Hologic, Inc. No disclosure, reproduction or use of any part thereof

may be made except by written permission from Hologic.

FSE Name: Date:

Customer# and Institution Name:

Customer Contact Name Customer Contact Title

Customer Contact Phone # Customer Contact Email

ATEC Model and Serial Number:

SR#:

Applicable TBs Performed:

Procedure ‘X’ when completed NOTES

Note: refer to Service Manual for applicable procedures to replace any parts not listed in the Preventive

Maintenance Procedure (TP-01678).

Decontamination and Power Off Checks

Remove and discard vacuum inlet

N/A

line assembly

Inspect\Replace Canister Discard and Replace if used

Clean assemblies with DisCide Handpiece connections

wipes (Quick disconnect fittings)

Vacuum line bulkhead fitting

Pinch valve

Canister well

Casters

Outside surface of the

Console

Door lock cover and door

All outside Console

surfaces

Inside door lip and edges of

base door

Inspect and Clean Footswitch If damaged, replace footswitch

Inspect Footswitch Connection

N/A

and T handle

N/A

Inspect and Clean Power Cord

ENG-0034-T52 Rev. 002

DOCUMENT

TYPE: TEST RECORD

ATEC SAPPHIRE DOCUMENT NUMBER: REV:

100/200 CONSOLE TR-01141 001

DOCUMENT REV. RELEASE DATE: 1 DEC 2017

TITLE: PREVENTIVE

MAINTENANCE SIZE A SHEET 2 OF 6

CHECKLIST

PROPRIETARY: This document contains proprietary data of Hologic, Inc. No disclosure, reproduction or use of any part thereof

may be made except by written permission from Hologic.

Check Cord Management Plate N/A

Check Handpiece connectors N/A

Check locking function of casters N/A

Check Fan Guards N/A

Check Base Bumper N/A

Install Vacuum Line Assembly N/A

Power On Pre-Service Checks

Measure and Record Ground Cord

Milli Ohms

Resistance

Measure and Record Case

microamps

Leakage Current

Power up Console\Verify Console

N/A

enters Biopsy mode

1. Upper fan blows out

Check operation of Cooling Fans 2. Lower fan blows in.

Cycles

Record Cycle Count and Hours

Hours

Perform Thumb Test/Verify Setup

Mode function/Saline Pinch Valve N/A

operation

Verify Test Mode function N/A

Verify Biopsy Mode function N/A

Verify Lavage Mode function N/A

Verify Manual Aspiration Mode

N/A

function

Measure total vacuum draw down

inHg

level and record

Measure Vacuum Switch Point inHg

Measure and record main

psi

regulator

Measure cylinder line pressure

psi

and record

Measure MRI air line pressure and

psi

record

ENG-0034-T52 Rev. 002

DOCUMENT

TYPE: TEST RECORD

ATEC SAPPHIRE DOCUMENT NUMBER: REV:

100/200 CONSOLE TR-01141 001

DOCUMENT REV. RELEASE DATE: 1 DEC 2017

TITLE: PREVENTIVE

MAINTENANCE SIZE A SHEET 3 OF 6

CHECKLIST

PROPRIETARY: This document contains proprietary data of Hologic, Inc. No disclosure, reproduction or use of any part thereof

may be made except by written permission from Hologic.

Measure US\STX air line pressure

psi

and record

Measure Cylinder Pressure Switch

psi

Point

Check cycle timing of Handpiece

seconds

and record (beep-to-beep)

Maintenance Procedure

Solenoid connections to

Manifold Valves

Pressure Dump Valve to

Fitting. Triple Elbow

Manifold Vacuum to Pump

Dump Valve

Vacuum T to Panel Quick

Disconnect

Cylinder T to Panel Quick

Disconnect

Manifold Cylinder (top) to

Needle Valve (top)

Manifold Cylinder (bottom)

to Needle Valve (bottom)

Manifold Vacuum to

Vacuum Sensor (white

tubing)

Manifold Motor (bottom) to

MRI AF10 Filter

US/STX Regulator to

US/STX AF10 Filter

Pressure Regulator

Feedback Relief to

Remove Center Shelf Assembly; Compressor Filter

Disconnect Pneumatic Tubing and 4 screws/washers on the

Electrical connections Center Shelf

Buzzer – remove the cap

and allow to hang

Remove ground wire at

front attachment screw

P-Clamp, Vacuum Dump

Remove Right Shelf Assembly; Valve to Manifold

Disconnect Pneumatic Tubing and MRI AF10 Filter to Panel

Electrical connections Quick Disconnect

ENG-0034-T52 Rev. 002

DOCUMENT

TYPE: TEST RECORD

ATEC SAPPHIRE DOCUMENT NUMBER: REV:

100/200 CONSOLE TR-01141 001

DOCUMENT REV. RELEASE DATE: 1 DEC 2017

TITLE: PREVENTIVE

MAINTENANCE SIZE A SHEET 4 OF 6

CHECKLIST

PROPRIETARY: This document contains proprietary data of Hologic, Inc. No disclosure, reproduction or use of any part thereof

may be made except by written permission from Hologic.

US/STX Filter to Panel

Quick Disconnect

Needle Valve to Pressure

Sensor, PCB

AF20 Filter Input

AF20 Filter Output

2 Screws/washers on the

Right Shelf

N/A

Replace AF10 Filter Assemblies

N/A

Replace Needle Valve

Remove/Discard Drainage Sponge N/A

Remove filter bowl from AF20 Filter

(old style only), Remove/Discard N/A

AF20 Filter Element (old style only)

Install AF20 filter element on

Compressor output (old style AF20 N/A

only)

Inspect Compressor and Vacuum

N/A

Pump isolation mounts for damage

Inspect electrical wiring for damage

N/A

or chaffing

Inspect pneumatic tubing for kinking N/A

Clean debris from inside the

N/A

Console

Reconnect disconnected

pneumatic tubing and electrical

connections previously

disconnected:

Buzzer

Ground wire

P-clamp, Vacuum Dump

Valve to Manifold

US/STX AF10 Filter to

Panel Quick Disconnect

MRI AF10 Filter to Panel

Quick Disconnect

Needle Valve to Pressure

Sensor, PCB

Install Right Shelf AF20 Filter Input

ENG-0034-T52 Rev. 002

DOCUMENT

TYPE: TEST RECORD

ATEC SAPPHIRE DOCUMENT NUMBER: REV:

100/200 CONSOLE TR-01141 001

DOCUMENT REV. RELEASE DATE: 1 DEC 2017

TITLE: PREVENTIVE

MAINTENANCE SIZE A SHEET 5 OF 6

CHECKLIST

PROPRIETARY: This document contains proprietary data of Hologic, Inc. No disclosure, reproduction or use of any part thereof

may be made except by written permission from Hologic.

AF20 Filter Output

Screws, Attachment

Replace Motor and Cylinder Valves N/A

Replace Vacuum Valve Muffler N/A

Replace Rear Manifold Muffler N/A

Replace Dump Valve Mufflers (2x) N/A

Install Drainage Sponge below

N/A

AF20 Filter Housing

Solenoid connections to

Manifold Valves

Pressure Dump Valve to

Fitting. Triple Elbow

Manifold Vacuum to Pump

Dump Valve

Vacuum T to Panel Quick

Disconnect

Cylinder T to Panel Quick

Disconnect

Manifold Cylinder (top) to

Needle Valve (top)

Manifold Cylinder (bottom)

to Needle Valve (bottom)

Manifold Vacuum to

Vacuum Sensor (white

tubing)

Manifold Motor (bottom) to

MRI AF10 Filter

US/STX Regulator to

US/STX AF10 Filter

Pressure Regulator

Feedback Relief to

Compressor Filter

4 screws/washers on the

Install Center Shelf Center Shelf

Service Checks and Adjustments

Attach Handpiece and Canister N/A

Plug console into wall outlet and

N/A

Turn Power Switch to On

ENG-0034-T52 Rev. 002

DOCUMENT

TYPE: TEST RECORD

ATEC SAPPHIRE DOCUMENT NUMBER: REV:

100/200 CONSOLE TR-01141 001

DOCUMENT REV. RELEASE DATE: 1 DEC 2017

TITLE: PREVENTIVE

MAINTENANCE SIZE A SHEET 6 OF 6

CHECKLIST

PROPRIETARY: This document contains proprietary data of Hologic, Inc. No disclosure, reproduction or use of any part thereof

may be made except by written permission from Hologic.

Check all tubing for leakage N/A

Perform the Thumb Test/Verify Setup

N/A

Mode function

Verify Test Mode function N/A

Verify Biopsy Mode function N/A

Verify Lavage Mode function N/A

Verify Manual Aspiration Mode

N/A

function

Verify proper function of Saline Pinch

N/A

Valve

Measure/Adjust Total Vacuum Draw

inHg

Down

Measure/Adjust Vacuum Switch Point inHg (19.5+/-2inHg),

Measure/Adjust Main Regulator

psi (110+/-2psi)

Setting

Measure/Adjust Cylinder Line

psi (32+/-2psi)

Pressure

Measure/Adjust MRI Air Motor

psi (47+/-2psi)

Regulator

Measure/Adjust US/STX Air Motor

psi (37+/-2psi)

Regulator

Measure/Adjust Cylinder Pressure

psi (24+/-1.5psi)

Switch Point

seconds (4.2 to 5.7

Measure/Adjust Handpiece cycle time seconds, beep-to-beep)

Check user interface panel

N/A

lighting/function

Test all failure indications without

N/A

Handpiece connected

Turn off power. Disconnect/Correctly

N/A

Wrap Power Cord (cw)

Correctly wrap Footswitch (ccw) N/A

Install Access Door N/A

Clean panel external surfaces N/A

Record PM and Place Service Card

N/A

on rear of instrument

ENG-0034-T52 Rev. 002

You might also like

- Well Handover CertificateDocument1 pageWell Handover Certificateeng7mohamed7hashimNo ratings yet

- Checklist For Testing & Commissioning of Sprinkler SystemDocument2 pagesChecklist For Testing & Commissioning of Sprinkler Systembeho2000100% (6)

- Wave Solder Profile Documentation SheetDocument4 pagesWave Solder Profile Documentation SheetsmtdrkdNo ratings yet

- SKF Serv 417199 (4th Ed)Document688 pagesSKF Serv 417199 (4th Ed)Jaime castroNo ratings yet

- Instrumentation Switch ChecklistDocument9 pagesInstrumentation Switch ChecklistIñaki EseberriNo ratings yet

- Service FORMS FOR GENERATORSDocument78 pagesService FORMS FOR GENERATORSJose MoralesNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: Functional Test - Bus EarthingDocument6 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Functional Test - Bus EarthingDinesh PitchaivelNo ratings yet

- AHU FAHU - AnnuallyDocument3 pagesAHU FAHU - AnnuallyDreamliner100% (1)

- I11c Instrument Close Loop Check PG 1Document1 pageI11c Instrument Close Loop Check PG 1Momo ItachiNo ratings yet

- Distribution PanelDocument5 pagesDistribution PanelSourav RanaNo ratings yet

- MTC's ARAMCODocument17 pagesMTC's ARAMCOMotahar NajiNo ratings yet

- 88 D 340 nh3 Storage Tank Sept 10 2014 2Document9 pages88 D 340 nh3 Storage Tank Sept 10 2014 2mohamed abd eldayemNo ratings yet

- Analysis Tequiniques For Racecar Data AcquisitionDocument191 pagesAnalysis Tequiniques For Racecar Data AcquisitionAnderson Luiz Dias100% (2)

- Formatos CHECKLIST PDFDocument9 pagesFormatos CHECKLIST PDFHarold David Gil MuñozNo ratings yet

- Aries Computer Repair SolutionsDocument9 pagesAries Computer Repair SolutionsedalzurcNo ratings yet

- Mac Puarsa MRL OthyssoneDocument254 pagesMac Puarsa MRL OthyssoneVilla Robert Ramoa100% (1)

- Inspection Report Insulation Check: Inspectors Ceri Name: Signature: Date: Gama Consortium Consortium StegDocument1 pageInspection Report Insulation Check: Inspectors Ceri Name: Signature: Date: Gama Consortium Consortium StegRamzi Zoghlami100% (1)

- Checklist For T&C of Chemical Fire Suppression SystemDocument2 pagesChecklist For T&C of Chemical Fire Suppression Systembeho2000No ratings yet

- 639-2017 - Forms (ITP)Document9 pages639-2017 - Forms (ITP)george stanley paceteNo ratings yet

- ITP For Sprinkler and Spary SystemDocument6 pagesITP For Sprinkler and Spary System梁奇龙100% (2)

- NPT10111-PE-V-DS-621101-033 - R1 - Dial Type Level GaugeDocument5 pagesNPT10111-PE-V-DS-621101-033 - R1 - Dial Type Level Gaugekkumar_717405No ratings yet

- Instrument Commissioning Checklist PDFDocument9 pagesInstrument Commissioning Checklist PDFBrijesh Srivastav100% (1)

- FDASDocument22 pagesFDASAly Bueser67% (3)

- Instrument Check List PDFDocument9 pagesInstrument Check List PDFIgor PaivaNo ratings yet

- Instrument Check List PDFDocument9 pagesInstrument Check List PDFBrijesh Srivastav100% (1)

- Function Test 132kv Avc PanelDocument9 pagesFunction Test 132kv Avc PanelratheeshkumardNo ratings yet

- PM Check List - CB & BusbarDocument7 pagesPM Check List - CB & BusbarRizky VidiyanaNo ratings yet

- Commissioning of Electrical SystemsDocument14 pagesCommissioning of Electrical SystemsRatheesh Kumar100% (1)

- TS-PTX-QUA-049-E-R03 Rotary Bushing Cat IIIDocument3 pagesTS-PTX-QUA-049-E-R03 Rotary Bushing Cat IIIict petrexNo ratings yet

- Air Cooled Heat Exchanger: General InformationDocument2 pagesAir Cooled Heat Exchanger: General Informationcorey jacobsNo ratings yet

- Sample Data Sheet For Pressure Safety Valve As Per API 597Document16 pagesSample Data Sheet For Pressure Safety Valve As Per API 597Yurizki LhzNo ratings yet

- Pre-Commissioning Check Sheet: InstrumentsDocument1 pagePre-Commissioning Check Sheet: InstrumentshrimklimNo ratings yet

- Laptop/Software/Firmware: Concerns With Updates. Customer Permission Is Required To Perform UpdatesDocument3 pagesLaptop/Software/Firmware: Concerns With Updates. Customer Permission Is Required To Perform UpdatesMuhammad RezaNo ratings yet

- Smoke Stop Fire Fighting Lobby Pressurization Test QCCD FormDocument2 pagesSmoke Stop Fire Fighting Lobby Pressurization Test QCCD FormSamir AminNo ratings yet

- ITP FORMAT - PSV Modified FormateDocument1 pageITP FORMAT - PSV Modified Formatemurthy challapalliNo ratings yet

- Report On-Off Valve - HydrolineDocument3 pagesReport On-Off Valve - HydrolinePeerasut ChaisrimaneepanNo ratings yet

- TG Control Oil Filter Isolation - Cleaning Charging ProcedureDocument8 pagesTG Control Oil Filter Isolation - Cleaning Charging ProcedurePurna NayakNo ratings yet

- Two Hand Control Valve: SeriesDocument8 pagesTwo Hand Control Valve: SeriesFlávio LemeNo ratings yet

- GE Healthcare Carestation 600 SeriesDocument9 pagesGE Healthcare Carestation 600 SerieshailongwangNo ratings yet

- Design Guide Introduction To Automated Test FixturesDocument13 pagesDesign Guide Introduction To Automated Test FixturesCang_leNo ratings yet

- As Per The Schematic Drawings The Contents in This Test Format Can Be ModifiedDocument12 pagesAs Per The Schematic Drawings The Contents in This Test Format Can Be ModifiedAlexNo ratings yet

- Instrumentation Switch ChecklistDocument9 pagesInstrumentation Switch ChecklistAli Mukhtar ShigriNo ratings yet

- Instrumentation Switch ChecklistDocument9 pagesInstrumentation Switch Checklistgeorge stanley paceteNo ratings yet

- 6month (Idins) - Control Valve Function Test and Positioner CalibrationDocument3 pages6month (Idins) - Control Valve Function Test and Positioner CalibrationJAGDEV PANESARNo ratings yet

- ElectroMechanical Completion VALVE and ANCILLARIESDocument1 pageElectroMechanical Completion VALVE and ANCILLARIEShuseyinyuksel1903No ratings yet

- Breathing Apparatus-List-SCBA-06072020-GR PDFDocument1 pageBreathing Apparatus-List-SCBA-06072020-GR PDFwarikhNo ratings yet

- Electrical Equipment InspectionDocument1 pageElectrical Equipment InspectionMarthin PurbaNo ratings yet

- 9-Material Treacibility PDFDocument64 pages9-Material Treacibility PDFmamounsdNo ratings yet

- Inspection: AIR Winch Ingersoll RandDocument19 pagesInspection: AIR Winch Ingersoll RandAbdou BoucheritNo ratings yet

- 835-Pre-Commissioning of Vessels, Columns, Tanks and Heat ExcDocument3 pages835-Pre-Commissioning of Vessels, Columns, Tanks and Heat ExcFolarin AyodejiNo ratings yet

- 7.2 TW09166 CMTR-FlangeDocument3 pages7.2 TW09166 CMTR-FlangeYair Sánchez blancoNo ratings yet

- Astor Accreditation Certificate 2022 (Id 1361648)Document6 pagesAstor Accreditation Certificate 2022 (Id 1361648)Dalibor84No ratings yet

- WSR1611 1 5 15K规格书Document6 pagesWSR1611 1 5 15K规格书paranthaman dNo ratings yet

- 02.04.01 CONTROL VALVE - Datasheet JS-855-V001 - 0Document3 pages02.04.01 CONTROL VALVE - Datasheet JS-855-V001 - 0abdelmalek boudjemaaNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: Functional Test - FeederDocument8 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Functional Test - FeedererstendrainNo ratings yet

- OGC-FIC-002-I-Control Valve Calibration Stroke Test Report-Field Installation ChecklistDocument2 pagesOGC-FIC-002-I-Control Valve Calibration Stroke Test Report-Field Installation ChecklistTaylor100% (1)

- Expansion TankDocument2 pagesExpansion TankSHARAFUDHEEN TKNo ratings yet

- NIBprime Failed Due To Deactivation Bottle Buffer 25 Aug 21Document4 pagesNIBprime Failed Due To Deactivation Bottle Buffer 25 Aug 21Shweta YadavNo ratings yet

- Construction Checklist: Information and InspectionDocument1 pageConstruction Checklist: Information and InspectionSathishKumar SubbarajNo ratings yet

- 5.2. Internal Light & Wiring Device Function TestDocument2 pages5.2. Internal Light & Wiring Device Function TestMariam AwadNo ratings yet

- Construction Check Sheet Control & Relay Panel E-025A: ElectricalDocument1 pageConstruction Check Sheet Control & Relay Panel E-025A: ElectricalhrimklimNo ratings yet

- Motor Operated Valves2Document2 pagesMotor Operated Valves2Kareem HelmyNo ratings yet

- Cupiagua CPF: UPS Inverter and Static Switch Function Test CertificateDocument1 pageCupiagua CPF: UPS Inverter and Static Switch Function Test CertificateKhaled FatnassiNo ratings yet

- Cosmo Instruments PresentationDocument23 pagesCosmo Instruments PresentationNguyễn Văn ĐộNo ratings yet

- Numbers Sheet Name Numbers Table NameDocument50 pagesNumbers Sheet Name Numbers Table NameMehul ShuklaNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: Function Test - AccsDocument11 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Function Test - AccsDinesh PitchaivelNo ratings yet

- Practical Evaluation of Hologic Tomosynthesis BiopsyDocument62 pagesPractical Evaluation of Hologic Tomosynthesis BiopsycolladoluzangelaNo ratings yet

- C-View v1.0 DICOM Conformance Statement (MAN-02865) English Rev - 001 02 - 12Document27 pagesC-View v1.0 DICOM Conformance Statement (MAN-02865) English Rev - 001 02 - 12colladoluzangelaNo ratings yet

- Horizon User Guide (MAN-04871) English Rev - 012 01-2020Document164 pagesHorizon User Guide (MAN-04871) English Rev - 012 01-2020colladoluzangelaNo ratings yet

- Affirm Prone v1.0 Stereotactic Ref. Sheet (MAN-04862) English Rev - 001 06 - 16Document2 pagesAffirm Prone v1.0 Stereotactic Ref. Sheet (MAN-04862) English Rev - 001 06 - 16colladoluzangelaNo ratings yet

- Ather Specifications SheetDocument2 pagesAther Specifications SheetKarthikeyan VenkatesanNo ratings yet

- AVX A R134a 50 60Hz - MS04102B 0416 - Cs - Lo PDFDocument40 pagesAVX A R134a 50 60Hz - MS04102B 0416 - Cs - Lo PDFEnrique EndoNo ratings yet

- UNIT 2 A Typical PCDocument8 pagesUNIT 2 A Typical PCNurul Fadilah Nainanda Putri Chaniago100% (1)

- Respironics Evergo Manual de ServicoDocument36 pagesRespironics Evergo Manual de ServicowillNo ratings yet

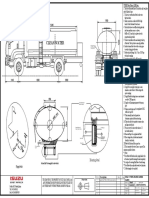

- FVR90L WATER TANKER MAAIF-ModelDocument1 pageFVR90L WATER TANKER MAAIF-ModelAvi AtoNo ratings yet

- CSP-P Seismic Energy Source: Applied Acoustic Engineering LTDDocument2 pagesCSP-P Seismic Energy Source: Applied Acoustic Engineering LTDDadang KurniaNo ratings yet

- Design and Construction of A Solar Powered Metro Vehicle. (Update) (2) .Docx 31-1-2019Document52 pagesDesign and Construction of A Solar Powered Metro Vehicle. (Update) (2) .Docx 31-1-2019kawsar ahmmedNo ratings yet

- TMB Switchgear ProductsDocument3 pagesTMB Switchgear Productskazem shakeriNo ratings yet

- 4606 Z PDB enDocument10 pages4606 Z PDB enMagenNo ratings yet

- Mir250 User Guide 1.4 - enDocument224 pagesMir250 User Guide 1.4 - envictor.ciudad.carpelNo ratings yet

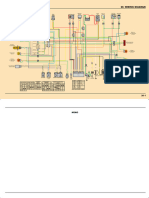

- Yzem 3001Document14 pagesYzem 3001Juan JJNo ratings yet

- 17 Termografia de PV Con Flir Tau 640 y Drone PDFDocument2 pages17 Termografia de PV Con Flir Tau 640 y Drone PDFOscar ChilcaNo ratings yet

- 2023 Beta Xtrainer Service ManualDocument120 pages2023 Beta Xtrainer Service ManualPASCONo ratings yet

- 8-Bit Xmega A Microcontroller Xmega A ManualDocument445 pages8-Bit Xmega A Microcontroller Xmega A Manualpunisher454No ratings yet

- DashDocument2 pagesDashJesse Alonso100% (1)

- SB As 350800007 enDocument11 pagesSB As 350800007 enDouglas de OliveiraNo ratings yet

- Practical No. 3: Use Measuring Instruments: Ammeter, Voltmeter, and WattmeterDocument4 pagesPractical No. 3: Use Measuring Instruments: Ammeter, Voltmeter, and Wattmeter166CMYashvardhan ShindeNo ratings yet

- Schindler 3100 MRL Elevator BrochureDocument20 pagesSchindler 3100 MRL Elevator Brochureali7hedayatiNo ratings yet

- To11c5 e 00 PDFDocument526 pagesTo11c5 e 00 PDFGradimir MilanovicNo ratings yet

- Penawaran Dump Truck English Ibu Dinar (Terbaru)Document7 pagesPenawaran Dump Truck English Ibu Dinar (Terbaru)Nasha ALNo ratings yet

- WEG Hydrogenerators Gh20 14824113 Manual EnglishDocument51 pagesWEG Hydrogenerators Gh20 14824113 Manual EnglishGuilherme RosaNo ratings yet

- 8107 Decap279 Office Automation ToolsDocument272 pages8107 Decap279 Office Automation ToolsNihanth MunnaNo ratings yet

- Desenllantadora Marca Coseng Modelo Cd540aDocument42 pagesDesenllantadora Marca Coseng Modelo Cd540ajhan123j100% (1)