Professional Documents

Culture Documents

Acople J0452

Acople J0452

Uploaded by

Juan UchuyaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acople J0452

Acople J0452

Uploaded by

Juan UchuyaCopyright:

Available Formats

Service Sheet

SSJ0452

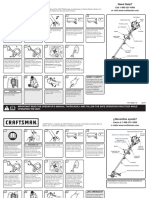

J0452 API Coupler (J0452-05* Shown)

Sheet: SSJ0452, 17/12/12, Rev: 3 As a part of a continuous commitment to product development the company reserves the right to alter the specification of its products without prior notice

NOTE: API couplers should always be used in conjunction with primary shutoff system such

as a meter with preset valve. A relief valve must be provided for the trapped product between

the primary shutoff and the API coupler. Fig. 1

WARNING care must be taken when manually operating the lugs as the sleeve is under

considerable spring pressure. Ensure that nothing will become trapped between the body

and sleeve when it moves forward.

IMPORTANT: Before you begin, drain the line of all product. This can be done by depressing

the 5 interlock claws on the coupler (23), the safety lug (24) and turning the lever (3).

Spare Part Kits Available

Part NO. Description Kit

494529 Viton Seal Kit

494531 LT Viton Seal Kit

494530 Buna Seal Kit

674227 Nose Piece & Poppet Kit

673294 Nose Ring Kit

673293 Claws & Interlock Lug Kit

673295 J0452 Lever Kit

672869 J0451/J0452 Shaft Kit

673951 Pump Viton Seal Kit

Emco Wheaton UK Limited,

Channel Road, Westwood Industrial Estate,

Margate, Kent, CT9 4JR, UK

Tel: +44 (0) 1843 22152, Fax: +44 (0) 1843 295444

assist@emcowheaton.co.uk, www.emcowheaton.co.uk

Service Sheet

SSJ0452

PART

051

052

053

ITEM QTY DESCRIPTION MATERIAL

NUMBER

1 1 ● ● ● Body 673262 Aluminum 356-T6

Sheet: SSJ0452, 17/12/12, Rev: 3 As a part of a continuous commitment to product development the company reserves the right to alter the specification of its products without prior notice

2 1 ● ● ● Sleeve 673257 Aluminum 356-T6

3 1 ● ● ● Lever 673259 Aluminum 356-T6

4 1 ● ● ● Nose Piece 673991 Aluminum 6061-T6

5 1 ● ● ● Retractor Bale, Top Lever 673255 Aluminum 356-T6

6 1 ● ● ● Retractor Handle 673264 Stainless Steel

7 1 ● ● ● Nose Ring 673265 Aluminum 6082-T6

8 1 ● Nose Seal 672213 Viton

8 1 ● Nose Seal 672550 Buna

8 1 ● Nose Seal 672528 Low Temp Viton

9 1 ● ● ● Shaft 672319 Stainless Steel

10 1 ● ● ● Poppet 673992 Aluminum 356-T6

11 1 ● ● ● Bearing 560594 Plastic

12 1 ● ● ● Bearing 560595 Plastic

13 1 ● O-Ring 407433 Viton

13 1 ● O-Ring 564769 Buna

13 1 ● O-Ring 672548 Low Temp Viton

14 1 ● ● ● Spacer 240805203 Nylon

15 1 ● ● ● O-Ring (Dust Seal) 561320 Buna

16 1 ● ● ● Retaining Ring 408169 Steel

17 1 ● ● ● Link 408254 Stainless Steel

18 2 ● ● ● Bent Link 408262 Stainless Steel

19 2 ● ● ● Spring Pin 561852 Stainless Steel

20 4 ● ● ● Hitch Pin 560489 Stainless Steel

21 1 ● ● ● Wave Spring 564090 Stainless Steel

22 2 ● ● ● Link Pin 408252 Stainless Steel

23 5 ● ● ● Locking Claw 674213 Stainless Steel

24 1 ● ● ● Safety Lug 674190 Stainless Steel

25 6 ● ● ● Roll Pin 470078 Stainless Steel

26 4 ● ● ● M8 Thin Washer 671270 Stainless Steel

27 1 ● ● ● Safety Lug Spring 674191 Stainless Steel

28 2 ● ● ● Retractor Guide 673241 Stainless Steel

29 2 ● ● ● Retractor Spring 577205 Stainless Steel

30 1 ● O-Ring 672741 Viton - PTFE Treated

30 1 ● O-Ring 672551 Buna

30 1 ● O-Ring 672549 Low Temp Viton

31 5 ● ● ● Locking Claw Spring 673269 Stainless Steel

32 8 ● ● ● M4 x 10 C’Sunk Screw 617025 Stainless Steel

33 2 ● ● ● Cotter Pin 234131 Stainless Steel

Emco Wheaton UK Limited,

Channel Road, Westwood Industrial Estate,

Margate, Kent, CT9 4JR, UK

Tel: +44 (0) 1843 22152, Fax: +44 (0) 1843 295444

assist@emcowheaton.co.uk, www.emcowheaton.co.uk

Service Sheet

SSJ0452

J0452 Pump Variants

Sheet: SSJ0452, 17/12/12, Rev: 3 As a part of a continuous commitment to product development the company reserves the right to alter the specification of its products without prior notice

Fig. 2 Fig. 3 Fig. 4

J0452-05* Variant

• J0452-051 – Viton Seals

• J0452-052 – Buna Seals

• J0452-053 – Low Temp Viton Seals

Spares Kits

Viton Seal Kit – Part No. 494529 Buna Seal Kit – Part No. 494530

Item Qty Description Part No. Item Qty Description Part No.

8 1 Nose Seal 672213 8 1 Nose Seal 672550

11 1 Bearing 560594 11 1 Bearing 560594

12 1 Bearing 560595 12 1 Bearing 560595

13 1 O-Ring 407433 13 1 O-Ring 564769

15 1 O-Ring 561320 15 1 O-Ring 561320

19 2 Spring Pin 561852 19 2 Spring Pin 561852

21 1 Wave Spring 564090 21 1 Wave Spring 564090

25 2 Roll Pin 470078 25 2 Roll Pin 470078

30 1 O-Ring 672741 30 1 O-Ring 672551

LT Viton Seal Kit – Part No. 494531

Item Qty Description Part No. Nose Piece & Poppet Kit – Part No.

8 1 Nose Seal 672528 674227

11 1 Bearing 560594 Item Qty Description Part No.

12 1 Bearing 560595 4 1 Nose Piece 673991

13 1 O-Ring 672548 10 1 Poppet 673992

15 1 O-Ring 561320 20 2 Hitch Pin 560489

19 2 Spring Pin 561852 22 2 Link Pin 408252

21 1 Wave Spring 564090

25 2 Roll Pin 470078

30 1 O-Ring 672549

Emco Wheaton UK Limited,

Channel Road, Westwood Industrial Estate,

Margate, Kent, CT9 4JR, UK

Tel: +44 (0) 1843 22152, Fax: +44 (0) 1843 295444

assist@emcowheaton.co.uk, www.emcowheaton.co.uk

Service Sheet

SSJ0452

Nose Ring Kit – Part No. 673294 Claws & Interlock Lug Kit – Part No. 673293

Item Qty Description Part No. Item Qty Description Part No.

7 1 Nose Ring 673265 19 1 Spring Pin 561852

32 8 Screw 617025 20 2 Hitch Pin 560489

23 5 Locking Claw 674213

J0452 Lever Kit – Part No. 673295 24 1 Interlock Lug 674190

25 5 Roll Pin 470078

Sheet: SSJ0452, 17/12/12, Rev: 3 As a part of a continuous commitment to product development the company reserves the right to alter the specification of its products without prior notice

Item Qty Description Part No.

3 1 Lever 673259 27 1 Interlock Spring 674191

15 1 O-Ring No. 312 561320 31 5 Locking Lug Spring 673269

25 1 Roll Pin 470078 33 2 Cotter Pin 234131

J0451/J0452 Shaft Kit – Part No. 672869 Pump Viton Seal Kit– Part No. 673951

Item Qty Description Part No. Item Qty Description Part No.

9 1 Shaft 672319 34 0.83' Felt Packing 516046200

16 1 Ret. Ring 408169 36 1 Star Retaining Ring 244008001

19 1 Spring Pin 561852 44 1 Filter 306050200

25 1 Roll Pin 470078 52 1 U-Cup Seal 512050212

53 3 O-Ring EW-405968

54 2 O-Ring 522011234

55 2 O-Ring 522011233

To Change Nosepiece Seal – Kits 494529, 494530 & 494531 674364

1. Once fully drained, remove coupler from loading arm at

flange.

WARNING care must be taken when manually operating the lugs as the

sleeve is under considerable spring pressure. Ensure that nothing will

become trapped between the body and sleeve when it moves forward.

2. Depress the 5 Locking Claws (23) and the Interlock 24

Lug (24) to allow the sleeve to move forward under 23

spring pressure.

Fig. 5

Fig. 6 Fig. 7

3. Turn the Lever (3) to open the coupler to allow access to the poppet

linkage assembly. (Poppet linkage assembly consists of the Poppet

(10), Bent Links (18) and Link Pins (22).

3

Fig. 8 Fig. 9

Emco Wheaton UK Limited,

Channel Road, Westwood Industrial Estate,

Margate, Kent, CT9 4JR, UK

Tel: +44 (0) 1843 22152, Fax: +44 (0) 1843 295444

assist@emcowheaton.co.uk, www.emcowheaton.co.uk

Service Sheet

SSJ0452

4. With no tension on the poppet assembly, use 22

needle nose pliers to remove one set of the Hitch 26

Pin (20), Link Pins (22) and Washers (26). (Fig. 11) 20

5. After the pin set has been removed, remove

poppet assembly from the body bore. Carefully

Sheet: SSJ0452, 17/12/12, Rev: 3 As a part of a continuous commitment to product development the company reserves the right to alter the specification of its products without prior notice

remove the Nosepiece (4) and Wave Spring (21).

Do not nick the bore in the process. (See Fig. 12)

Fig. 10 &11

6. If replacing O-Ring (30) & Nose Piece Seal (8). 18 22 21 30 4 8 10

Without scratching the seal seats on the

Nosepiece (4), use a pick to carefully remove Nose

Seal (8) and the O-Ring (30). If not replacing O-

Ring & Nose Piece Seal Move to step 8.

7. Using a solvent, thoroughly clean the bore and

nosepiece seal grooves. Make sure all grit is

removed. Carefully assemble New O-Ring (30) &

Nose Piece Seal (8) into the Grooves. Apply Fig. 12

Parker Super Lube (or equivalent) to outside of

Nose Piece Seal once assembled.

8. If shaft seal needs replacing, go to steps 9-12 before reattaching poppet and

bent links. If not then reassemble, reversing the above steps. Once Coupler is

fully reassembled pull back Retractor Handle (6) pulling the Coupler Sleeve

back into the Uncoupled Position (Fig. 6). The Coupler is now ready for use.

To Change Shaft Seals - Kits 494529, 494530 & 494531 25

9. With Lever still open, use a hammer and punch

to remove roll pin (25) from lever (3). Slide lever

off the end of the shaft. (See Fig. 13)

10. Remove dust seal (15) with picking tool. Discard Fig. 13

dust seal. Remove retaining ring (16) with 15 16 14 13 9

retaining ring pliers. (See Fig. 14)

11. Slide shaft out to expose spacer (14) and O-

Ring (13). Remove spacer and O-Ring discard

O-Ring. Thoroughly clean the bore. If Replacing

Bearings (11&12) go to step 13.

Fig. 14

12. Lubricate New O-Ring (13) with Parker Super Lube (or equivalent) and

assemble in reverse order. Lubricate new dust seal (15) before installation.

Replace Lever (3) and using a hammer & punch install New Roll Pin (25). (See

Fig. 13) Return to step 8.

Emco Wheaton UK Limited,

Channel Road, Westwood Industrial Estate,

Margate, Kent, CT9 4JR, UK

Tel: +44 (0) 1843 22152, Fax: +44 (0) 1843 295444

assist@emcowheaton.co.uk, www.emcowheaton.co.uk

Service Sheet

SSJ0452

17 19 9

13. Use a hammer and punch to remove roll pin (19)

to free link (17) on shaft. Slide shaft (9) out of

Body and link off shaft. (See Fig. 15)

14. Remove Top Bearing (12) and Bottom Bearing

Sheet: SSJ0452, 17/12/12, Rev: 3 As a part of a continuous commitment to product development the company reserves the right to alter the specification of its products without prior notice

(11) (Fig. 16) and discard. Fig. 15

11 12

Fig. 16

15. Thoroughly clean the bores, replace Top and Bottom Bearings (11 &12).

16. Lubricate Shaft (9) with Parker Super Lube (or equivalent) as indicated in Fig.

17 and replace into bore with Link (19), push shaft all the way in. Use New

Spring Pin (19) to secure link to shaft with hammer. Return to step 12.

Lubricate Here Lubricate Here

Fig. 17

To Change Claws & Interlock Lug – Kit 673293

WARNING care must be taken when manually operating the lugs as the

sleeve is under considerable spring pressure. Ensure that nothing will

become trapped between the body and sleeve when it moves forward.

17. Follow steps 1 & 13 to move sleeve forward and strip down coupler,

without discarding or replacing any parts. Keep removed parts to one

side for re-assembly.

6

18. Remove Cotter Pins (33) (discard) and washers

(26) from either side of Coupler. (See Fig. 18)

19. Pull Retractor Handle (6) out of Retractor Bale

(5). (See Fig. 18)

33 26 Fig. 18

Emco Wheaton UK Limited,

Channel Road, Westwood Industrial Estate,

Margate, Kent, CT9 4JR, UK

Tel: +44 (0) 1843 22152, Fax: +44 (0) 1843 295444

assist@emcowheaton.co.uk, www.emcowheaton.co.uk

Service Sheet

SSJ0452

20. Remove Hitch Pins (20) (discard) from Retractor

Guide (28) on both sides of Coupler. (Fig 19)

21. Use Pliers inside of Retractor Spring (29), depress retractor spring, grip

Retractor Guide (28) and slide guide out of the Coupler. Once retractor

guide removed, remove retractor spring. Repeat process to remove spring

Sheet: SSJ0452, 17/12/12, Rev: 3 As a part of a continuous commitment to product development the company reserves the right to alter the specification of its products without prior notice

and guide on the other side of the Coupler. Warning, be careful whilst

completing this step as the mechanism is highly sprung. The Retractor

Bale (5) will now fall away from the Coupler. (Fig. 20)

20 28

29

Fig. 19 Note: Hitch Pin pulled all the way

through when re-assembling

Fig. 20 5

22. The Coupler Sleeve (2) is now free to be slide

off the back of the Coupler Body (1). (Fig. 21)

23. Use a punch and hammer to remove Roll Pin

(25) from Body (1). The Locking Claw (23) will

now be free to remove. Repeat process for the

other 4 locking claws. Discard locking claws and

roll pins. (Fig. 22) Fig. 21 1 2

24. Insert New Locking Claw (23) into the slot in the

Body (1). Secure locking claw to body with New

Roll Pin (25) with a hammer. Repeat process for

1

other 4 Claws. (Fig. 22)

23

25. Use a punch and hammer to remove Spring Pin

(19) from Body (1). The Safety Lug (24) and

Spring (27) will now be free to remove. Discard Fig. 22 25

safety lug, spring and spring pin. (Fig. 23)

26. Insert New Safety Lug (24) into the slot in the 27

Body (1). Secure interlock lug to body with New

Spring Pin (19) with a hammer. Insert New

Spring (27). (Fig. 23)

27. Slide Coupler Sleeve (2) over Coupler Body (1)

(Fig. 21). Fig. 23 24 19

Emco Wheaton UK Limited,

Channel Road, Westwood Industrial Estate,

Margate, Kent, CT9 4JR, UK

Tel: +44 (0) 1843 22152, Fax: +44 (0) 1843 295444

assist@emcowheaton.co.uk, www.emcowheaton.co.uk

Service Sheet

SSJ0452

28. Depress 5 x Locking Claws (23) and Safety Lug (24) (Fig. 5) to allow the sleeve

to slide forward (Fig. 7).

29. Reassemble Coupler reversing steps 17 to 21 using existing parts except for

New Cotter Pins (33) and New Hitch Pins (20) to retain Retractor Guide (28).

Pull Hitch Pins all the way through (Fig. 21).

Sheet: SSJ0452, 17/12/12, Rev: 3 As a part of a continuous commitment to product development the company reserves the right to alter the specification of its products without prior notice

30. Once Coupler is fully reassembled pull back Retractor Handle (6) pulling the

Coupler Sleeve back into the Uncoupled Position (Fig. 6). The Coupler is now

ready for use.

To Change the Nose Ring – Kit 673294 32 7

31. Undo the 8 screws (32) on the front of the

coupler using a 2.5mm allen key. (Fig. 24)

32. Remove the nose ring (7) and discard. If the

nose ring is difficult to remove, use a

screwdriver to lever the ring off. (Fig. 24)

33. Replace nose ring and fit new retaining screws.

Use one drop of a medium strength thread

locking compound such as loctite 241/2/3, on

each screw. (Fig. 24) Fig. 24

To Change the Lever– Kit 673295

34. Follow steps 1 to 3 to open Coupler.

35. Using a hammer and punch, remove roll pin (25) from lever (3). Slide lever off

the end of the shaft. (See Fig. 13)

36. Remove dust seal (15) with picking tool. Discard dust seal. Lubricate New Dust

Seal (15) with Parker Super Lube (or equivalent) before replacing. (See Fig. 14)

37. Replace New Lever (3) and using a hammer & punch install New Roll Pin (25).

(See Fig. 13)

38. Turn Lever (3) back to the closed position and pull back Retractor Handle

(6) pulling the Coupler Sleeve back into the Uncoupled Position (Fig. 6).

The Coupler is now ready for use.

To Change shaft – Kit 672869

39. Follow steps 1 to 13 to remove current Shaft (9) without discarding any

parts except for the Retaining Ring (16).

Emco Wheaton UK Limited,

Channel Road, Westwood Industrial Estate,

Margate, Kent, CT9 4JR, UK

Tel: +44 (0) 1843 22152, Fax: +44 (0) 1843 295444

assist@emcowheaton.co.uk, www.emcowheaton.co.uk

Service Sheet

SSJ0452

40. Lubricate New Shaft (9) with Parker Super Lube (or equivalent) as

indicated in Fig. 17 and replace into bore with Link (17), push shaft all the

way in. Use New Spring Pin (19) to secure link to shaft with hammer.

41. See Fig. 14: Lubricate O-Ring (13) with Parker Super Lube (or

equivalent) and assemble in reverse order, use New Retaining Ring (16)

Sheet: SSJ0452, 17/12/12, Rev: 3 As a part of a continuous commitment to product development the company reserves the right to alter the specification of its products without prior notice

before assembling Dust Seal (15). Lubricate dust seal before installation.

Return to step 8.

To Change Nose Piece & Poppet – Kit 674227

42. Follow steps 1 to 5 to detach Poppet Assembly from Coupler.

43. Discard Poppet (10), Nose Piece (4), Hitch Pins (20) and Link Pins (22)

and replace with New Items. Remove Seals (30 & 8) carefully using a pick

and transfer to New Nose Piece if not using with a Seal Kit. Make sure

Nose Piece Grooves are free from any grit and dirt. (Fig. 10 & 12)

44. Reverse Step 42 then pull back Retractor Handle (6) pulling the Coupler

Sleeve back into the Uncoupled Position (Fig. 6). The Coupler is now ready

for use.

Emco Wheaton UK Limited,

Channel Road, Westwood Industrial Estate,

Margate, Kent, CT9 4JR, UK

Tel: +44 (0) 1843 22152, Fax: +44 (0) 1843 295444

assist@emcowheaton.co.uk, www.emcowheaton.co.uk

You might also like

- GM 4L60-E, 4L65-E, 4L70-E Sure Cure KIT: Installation DiagramDocument13 pagesGM 4L60-E, 4L65-E, 4L70-E Sure Cure KIT: Installation DiagramHola ValdeNo ratings yet

- Valfe 60 50 t13Document10 pagesValfe 60 50 t13Zafer IlhanNo ratings yet

- 6T40 Manual PDFDocument10 pages6T40 Manual PDFJesus Teodoro Mendoza Guerra100% (3)

- Illustrated Parts List: RTLO-18918A-AS3 November 2012Document47 pagesIllustrated Parts List: RTLO-18918A-AS3 November 2012AnGel Amaya100% (1)

- ETM For Heavy Duty Truck (13MY)Document252 pagesETM For Heavy Duty Truck (13MY)LorenzoNo ratings yet

- 6t40 Gen2 Zip inDocument10 pages6t40 Gen2 Zip inLuiz FernandoNo ratings yet

- Engineering FeaturesDocument18 pagesEngineering FeaturessrinivaschakriNo ratings yet

- Fire Extinguisher Inspection Record Jan-2021Document12 pagesFire Extinguisher Inspection Record Jan-2021Sarmad HussainNo ratings yet

- Raymarine ST40 Instruments Service ManualDocument70 pagesRaymarine ST40 Instruments Service ManualOkan Taktakoğlu100% (1)

- Spare Parts ListDocument2 pagesSpare Parts ListJohn Yang100% (1)

- Sample Civil BoqDocument57 pagesSample Civil Boqkvamshi_1971No ratings yet

- Primavera Project Planner Sample Project: Prepared By: Luay Dwaikat, Msc. Construction ManagementDocument3 pagesPrimavera Project Planner Sample Project: Prepared By: Luay Dwaikat, Msc. Construction ManagementkrajeshkumarxNo ratings yet

- Torsional - Analysis of Steel MembersDocument75 pagesTorsional - Analysis of Steel MemberskirubaNo ratings yet

- PROBLEM NO. 1: Multi-Storey Apartment Building: Statement of The ProblemDocument4 pagesPROBLEM NO. 1: Multi-Storey Apartment Building: Statement of The ProblemMarvs CalingacionNo ratings yet

- Horizontal Pressure VesselDocument36 pagesHorizontal Pressure VesselAdugna Gosa100% (1)

- Instruction Sheet Lightcrimp Plus SC Simplex Connector Kits 5492643-, 6278079-, 6588291-, and 6693276-1Document17 pagesInstruction Sheet Lightcrimp Plus SC Simplex Connector Kits 5492643-, 6278079-, 6588291-, and 6693276-1Jose SenderoNo ratings yet

- Service Bulletin: Washing 2520Document1 pageService Bulletin: Washing 2520Torozan RomicaNo ratings yet

- 13338-Orbit Mist Kit ManualDocument2 pages13338-Orbit Mist Kit ManualJaime VelezNo ratings yet

- How To Use This Manual: General InformationDocument1 pageHow To Use This Manual: General InformationNerio MoralesNo ratings yet

- Installation Instructions Fisher Iso Seal Packing Installation Instructions en 135700Document2 pagesInstallation Instructions Fisher Iso Seal Packing Installation Instructions en 135700jestin1947No ratings yet

- Troca Da Mola Do Motor de PassoDocument2 pagesTroca Da Mola Do Motor de PassoRoberto OliveiraNo ratings yet

- How To Use This Manual: General InformationDocument3 pagesHow To Use This Manual: General InformationJosemar AgostinhoNo ratings yet

- Oversized Primary Pulley Regulator Valve Kit: Jatco/Nissan JF015E (RE0F11A)Document2 pagesOversized Primary Pulley Regulator Valve Kit: Jatco/Nissan JF015E (RE0F11A)marranNo ratings yet

- Installation Instructions: Honda Dealer: Please Give A Copy of These Instructions To Your Customer. InstallationDocument6 pagesInstallation Instructions: Honda Dealer: Please Give A Copy of These Instructions To Your Customer. InstallationGaborNo ratings yet

- Installation Instructions: Honda Dealer: Please Give A Copy of These Instructions To Your Customer. InstallationDocument6 pagesInstallation Instructions: Honda Dealer: Please Give A Copy of These Instructions To Your Customer. InstallationR BNo ratings yet

- 18 Kty IXPnf BH U7 yDocument12 pages18 Kty IXPnf BH U7 yalex cabezaNo ratings yet

- Casing Packer Setting Tool (CPST) : Parts Lists and Exploded ViewsDocument14 pagesCasing Packer Setting Tool (CPST) : Parts Lists and Exploded ViewsJose Antonio Acosta100% (1)

- Spare Parts List: Nitrogen Generation Package - 00Document1 pageSpare Parts List: Nitrogen Generation Package - 00lenova lNo ratings yet

- Installation Instructions: Keep This Information in The Glove Box For Future ReferenceDocument4 pagesInstallation Instructions: Keep This Information in The Glove Box For Future ReferenceluqueNo ratings yet

- Eatonroadranger RTO-14609B PDFDocument48 pagesEatonroadranger RTO-14609B PDFnetemma97No ratings yet

- Manual I&O NBSDocument47 pagesManual I&O NBSEduardo SolisNo ratings yet

- Eaton Rto 11909all Transmission Illustrated Parts List en UsDocument47 pagesEaton Rto 11909all Transmission Illustrated Parts List en UspowermanagerNo ratings yet

- Call 1-888-331-4569Document2 pagesCall 1-888-331-4569JohnNo ratings yet

- Not For Reproduction: Illustrated Parts List 10T800Document16 pagesNot For Reproduction: Illustrated Parts List 10T800narciso84traninNo ratings yet

- Oversized Kit Valvula Lock Up AmarokDocument1 pageOversized Kit Valvula Lock Up AmarokautomaticosbrasilNo ratings yet

- Spare and Wear Part Catalog For Airbalancer - ENGDocument17 pagesSpare and Wear Part Catalog For Airbalancer - ENGJhon Henry Pinzon AlmonacidNo ratings yet

- SITONDocument8 pagesSITONnareshNo ratings yet

- Cat Trailer 1 Trailer Catalog en Part44Document1 pageCat Trailer 1 Trailer Catalog en Part44soicanhavefriendsNo ratings yet

- Feature Supplement: For Sl94 EgoDocument7 pagesFeature Supplement: For Sl94 EgoLuis BastardesNo ratings yet

- F 99026 PDFDocument1 pageF 99026 PDFingjfhpNo ratings yet

- BVA J Series Manual Maintenance SetDocument12 pagesBVA J Series Manual Maintenance SetTitanplyNo ratings yet

- Bearing-Conn Rod Kit IR COMPDocument1 pageBearing-Conn Rod Kit IR COMPmohamed Helal0% (1)

- PDP S21 LR - RRV3010Document5 pagesPDP S21 LR - RRV3010zanildoNo ratings yet

- Not For Reproduction: Illustrated Parts List 10T500Document16 pagesNot For Reproduction: Illustrated Parts List 10T500rogerioNo ratings yet

- G457 HELICOPTER REFUELING NOZZLE 2014 - ScreenDocument2 pagesG457 HELICOPTER REFUELING NOZZLE 2014 - ScreencasandraNo ratings yet

- PC400-7 (BT04133A) (SN Eng) (WM)Document26 pagesPC400-7 (BT04133A) (SN Eng) (WM)Анатолий ЩербаковNo ratings yet

- Refrigeração WastgateDocument4 pagesRefrigeração WastgateRoberto OliveiraNo ratings yet

- Rtlo-16918a SsDocument44 pagesRtlo-16918a SsLuis FigueroaNo ratings yet

- Installation Kit Part No 1250MD-4Document1 pageInstallation Kit Part No 1250MD-4Roberto Torres ArancibiaNo ratings yet

- Mi Fka104Document4 pagesMi Fka104soul.cro24No ratings yet

- Service N ValveDocument30 pagesService N ValvemecambNo ratings yet

- Installation Instructions: Keep This Information in The Glove Box For Future ReferenceDocument4 pagesInstallation Instructions: Keep This Information in The Glove Box For Future ReferenceTimothy PNo ratings yet

- Kosiarka - Birgs - Spare-PartsDocument12 pagesKosiarka - Birgs - Spare-Partsallegro.ds.spinNo ratings yet

- Partes de Freno Polipasto YALEDocument4 pagesPartes de Freno Polipasto YALELuis Eduardo Arellano HernandezNo ratings yet

- 04a.PROTON DVR SAGA INSTALLATION MANUAL - REV00 - 03.04.2023Document14 pages04a.PROTON DVR SAGA INSTALLATION MANUAL - REV00 - 03.04.2023afzal nizam abdullah thaniNo ratings yet

- AX-VAL-123+K-CP Installation Guides WEBDocument6 pagesAX-VAL-123+K-CP Installation Guides WEBChaaru PunianiNo ratings yet

- LP008Document20 pagesLP008Rojas RudyNo ratings yet

- Bath Drain: Before You Begin Before You BeginDocument6 pagesBath Drain: Before You Begin Before You Beginarizarmani10No ratings yet

- SEARS Craftsman Leaf Blower Mulcher ManualDocument12 pagesSEARS Craftsman Leaf Blower Mulcher ManualCraig nelsonNo ratings yet

- TU-045 - AS-RBP - 9-5.8 inDocument4 pagesTU-045 - AS-RBP - 9-5.8 inAtom InsideNo ratings yet

- F 99099 PDFDocument1 pageF 99099 PDFingjfhpNo ratings yet

- ENG DS 2356672-1 FDBA-HDBA-series 0719 PDFDocument17 pagesENG DS 2356672-1 FDBA-HDBA-series 0719 PDFnayanamooNo ratings yet

- Samsung dvdp230Document37 pagesSamsung dvdp230André LeftNo ratings yet

- E87 Series: Model/Modelo E87S450Document1 pageE87 Series: Model/Modelo E87S450José Luis Gómez JiménezNo ratings yet

- Steering Damper For Yamaha R1M: Otee! Otee!Document4 pagesSteering Damper For Yamaha R1M: Otee! Otee!Daniel GranilloNo ratings yet

- Latest CV (Anish Nair)Document21 pagesLatest CV (Anish Nair)AnishNo ratings yet

- Kegagalan Struktur S1-1Document32 pagesKegagalan Struktur S1-1Aldi BrahmantyaNo ratings yet

- Fig 4923 GDocument1 pageFig 4923 GAsmaaNo ratings yet

- Technical Data Sheet: LOXEAL 58-11Document3 pagesTechnical Data Sheet: LOXEAL 58-11Homam Haj HasanNo ratings yet

- TK Series Gear OperatorsDocument2 pagesTK Series Gear OperatorsdharmendrabholeNo ratings yet

- CAT 4135 CV CheckValves Dec2010Document60 pagesCAT 4135 CV CheckValves Dec2010Dragan LazicNo ratings yet

- 40HW SpecsDocument1 page40HW SpecsGrace HuiNo ratings yet

- Relief Valves FlyerDocument1 pageRelief Valves FlyerAkhil JoseNo ratings yet

- Technical Memorandum (Bridges) Shear Key Decks: The Highways Agency Be 23Document52 pagesTechnical Memorandum (Bridges) Shear Key Decks: The Highways Agency Be 23Anonymous jLLjBdrNo ratings yet

- Chap-5 Framed StructuresDocument12 pagesChap-5 Framed StructurestekalignNo ratings yet

- Faculty Load and Course 2019Document6 pagesFaculty Load and Course 2019chayrenetNo ratings yet

- Sismmm 2.0Document3 pagesSismmm 2.0Valmaq Prestação Serviço LdaNo ratings yet

- Project Job Number Engineer: Error: Section Overstressed Warning: KL/R 200 (AISC E2)Document2 pagesProject Job Number Engineer: Error: Section Overstressed Warning: KL/R 200 (AISC E2)JohnNo ratings yet

- Executive SummaryDocument4 pagesExecutive Summarysuk25No ratings yet

- Ecogreen Air Cooler System Pemanfaatan Phase Change Material Sebagai Alternatif PenggantiDocument8 pagesEcogreen Air Cooler System Pemanfaatan Phase Change Material Sebagai Alternatif PenggantiDicky ElnurNo ratings yet

- FLAT NO. 303 & 304: Side SideDocument1 pageFLAT NO. 303 & 304: Side SideKrupali ThakkarNo ratings yet

- Summer Training Report PP TDocument53 pagesSummer Training Report PP TPrashant JainNo ratings yet

- Data Sheet EPS 300Document2 pagesData Sheet EPS 300De ExiroNo ratings yet

- Investment in PSX Project. Investment Portfolio Management.: Group Members. Rabee Shahzad Zahid Ch. Arslan WattooDocument50 pagesInvestment in PSX Project. Investment Portfolio Management.: Group Members. Rabee Shahzad Zahid Ch. Arslan WattooAhmad MalikNo ratings yet

- Compressive Strength of Mortar CubeDocument6 pagesCompressive Strength of Mortar CubeAngel MouriNo ratings yet

- Engineering Geology AssignmentDocument8 pagesEngineering Geology Assignmentliny GNo ratings yet

- Aalco CatalogueDocument92 pagesAalco CatalogueNigin ParambathNo ratings yet

- Ehland PDFDocument251 pagesEhland PDFmochammad baagilNo ratings yet