Professional Documents

Culture Documents

Wa0005.

Uploaded by

Aabid DiwanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wa0005.

Uploaded by

Aabid DiwanCopyright:

Available Formats

ARPIT THAKOR

LOGISTICS AND STORE EXECUTIVE Email: arpit.thakor89@gmail.com DOB : 10.07.89

Mob no: +91 9909414740 Add: Jogiwala faliya At: Maretah Po: Maneja Vadodara - 390013

CAREER OBJECTIVE

Hard-working professional with 8.2 years of experience and a proven knowledge of acquisition

management, international trade, and inventory planning and forecasting. Aiming to leverage my skills to

successfully fill the logistics and store executive role at your company.

Experience

Logistics Executive

Moflex Suspensions LLP, Halol Gujarat / Feb 2021 – Present.

Shipments tracking from the Load port to destination port and Confirm from Buyer also on timely

delivery for OEM customer and inter-unit.

Prepare Pre-Shipment Documentation as per PO, PI & LC terms

Timely arrangement of Vehicles & Containers for stuffing of Shipments

Make Export Billing & Inter-Unit Billing through TCS software

Making Proper shipment planning & co-ordinate with the Production, Marketing, Quality &

Account departments for execution of Export shipment

To prepare Daily & Monthly MIS Report

Implemented best practices for inventory control and management.

Ensure materials receipt from production.

Raising of purchase requisition for packing material by considering minimum stock level.

Warehouse handling.

Manpower management.

Logistics Executive

Duravit India pvt Ltd, Anand, Gujarat / June 2018 – Feb 2021 Duration 2.8 Years

Extremely reliable and safety conscious with solid experience in warehouse operations to include

loading and unloading trucks; shipping and receiving; order picking / packing; staging and

stocking.

Keeping accurate records of products and invoicing information

Preparing Export Invoice, Packing List, Email Correspondences, preparing related documents.

Coordinating with Customer care team, Marketing team accounts & transporter for routine

dispatch.

Managing finished goods inward from production as well as import and arrange and stack them

according to follow FIFO method of inventory management.

Work allocation to subordinate and looking after daily loading of local / full truck load or import /

export containers as per dispatch planning.

The preparation of goods for international shipping. Adequate use of space in packing area.

Ensure smooth functioning of Bar code operations in all the product of warehouse

Ensure optimized container stuffing and organize dispatch accordingly.

Arranging vehicle and finalizing transportation rate for loading, also verifying their freight bill to

process in accounts and also preparing their MIS.

Raising of purchase requisition for packing material by considering minimum stock level.

Preparing stock report on monthly basis and maintain against DIAS stock.

Monitor operations to ensure inventory is properly handled in loading and unloading

investigate and approve transit damages Claim and Coordinate with HOD and Customer Care.

Additional Job Profile at Store: -

Reviews daily inventory activity; maintains accurate inventory master files, manufacturer and item numbers,

minimums and material descriptions.

Maintains adequate levels of inventory stock of all critical spare parts for each machines.

Prepares re-order reports with quantities required for inventory stock and forwards to Purchase department

for ordering.

Identified and eliminated stagnant and slow-moving materials, reducing overhead while freeing up valuable

Store space.

Supervises Physical Inventory Count. Provides proper accounting for year-end stock taking and proper

accounting to General Ledger

Reviews Delivery records, monitor GRN, file until invoice is received.

Reconciles invoices with correct GRN, then forwards both to accounts for payments

Work closely with Purchase department and vendor for quick delivery and services

Issues supplies, materials and equipment to required department employees.

Organizes and maintains storage and inventory areas for efficient material storage and handling, including

labelling/tagging, stocking and organizing stock items on shelving

Works closely with maintenance and production department to understand various requirements of parts

and consumables.

Identifies the reason for the extra consumption of the raw material by collecting information from the

production department.

Identifies the emergency requirements of the materials and arranges supplies for the same

Warehouse Supervisor

UGC Supply chain solution pvt ltd (FAG Bearing India Ltd) Vadodara, Gujarat / Aug-2015 to June-2018

Duration 2.9 Years

Worked as a Supervisor Finished bearing stores at FAG Bearing India LTD, Vadodara.

Inward all FG materials with T-Code VL02N in SAP as per Production Delivery Note& also

check physically verification of Quantity, FG type and Quality.

Verification of all outgoing invoice and FG product domestic with the help of Loading List

generating from SAP using Z code.

Ensure FG materials should be dispatch on same day against invoice. Daily

downloading Shipment Reports from SAP and cross check with Invoice generated for

the day.

Conduct monthly inventory of FG parts and analyses shortage and excess materials.

Inspected physical condition of FG warehouse and equipment and prepared work orders

for repair and requisitions for replacement of equipment.

Performed safety audits and ensured compliance to all warehouse safety standards

Supervise the activities of all subordinates in the Warehouse operation

including daily work schedules and all related personnel issues.

Some SAP transaction which are used regularly VL02N, MB51, VL06P, VL71, VF01, VF31,

LT12, LS24 etc.

EDUCATION

Indian Institute of Export (IIE) Vadodara

Export Import Management (2023) with Second class

Indian Institute of Materials Management (IIMM) Vadodara, Gujarat

Graduate Diploma in Materials Management (GDMM) (2017) With first

class

Maharaja Sayajirao University Vadodara, Gujarat

Bachelor of Arts (B.A) Economics (2012) With Pass Class

Higher Secondary Certificate Education Board Shanti Niketan School

Vadodara 12th commerce With Second class pass in 2007

The Secondary School Certificate Shanti Niketan School Vadodara,

Gujarat 10th with Pass class in 2005

KEY SKILLS

Extensive knowledge of supply chain management

Familiarity with warehousing and distribution concepts

Procurement of materials, storages, transportation and distribution of the finished product.

The ability to think creatively.

Ability to manage sea and air cargo operations.

Achievements

Highest dispatch in one month achieved in Dec – 2020 (35 Containers for export and

Domestic dispatched) at Duravit Warehouse.

Resolve customer complaints against received of dusty item at Duravit Warehouse.

Cost reduces in new box purchase at Duravit store.

Transparency in daily truck load as per transporter. At FAG

Special Delivery tracking system (Air & train). At FAG

Improvement in marking system as per transporter. At FAG

You might also like

- A Varactor Tuned Indoor Loop AntennaDocument12 pagesA Varactor Tuned Indoor Loop Antennabayman66No ratings yet

- Moparm Action - December 2014 USADocument100 pagesMoparm Action - December 2014 USAenricoioNo ratings yet

- Woodward GCP30 Configuration 37278 - BDocument174 pagesWoodward GCP30 Configuration 37278 - BDave Potter100% (1)

- Spa ClaimsDocument1 pageSpa ClaimsJosephine Berces100% (1)

- Pet Care in VietnamFull Market ReportDocument51 pagesPet Care in VietnamFull Market ReportTrâm Bảo100% (1)

- Optimization of Crude Oil DistillationDocument8 pagesOptimization of Crude Oil DistillationJar RSNo ratings yet

- Mentorship ICT at A GlanceDocument5 pagesMentorship ICT at A GlanceTeachers Without Borders0% (1)

- SADHAN - KUMAR JHA - Resume - 21-02-2023-15-25-56Document4 pagesSADHAN - KUMAR JHA - Resume - 21-02-2023-15-25-56Aadarsh PillaiNo ratings yet

- Sachin More Resume Feb 2024Document3 pagesSachin More Resume Feb 2024SBW CFS-ExportNo ratings yet

- S Nidgunde - CVDocument3 pagesS Nidgunde - CVmanisha guptaNo ratings yet

- Gaurav Midha's ResumeDocument3 pagesGaurav Midha's Resumegaurika midhaNo ratings yet

- Mohan P: Work ExperienceDocument3 pagesMohan P: Work ExperienceEr Chinmoy NandaNo ratings yet

- Dimas Wijil Parikesit: Perum Rose Garden Blok C No. 2 - Sukatani, Tapos, 1 6 9 5 4Document10 pagesDimas Wijil Parikesit: Perum Rose Garden Blok C No. 2 - Sukatani, Tapos, 1 6 9 5 4Green Sustain EnergyNo ratings yet

- Resume - Harikrishnan KDocument7 pagesResume - Harikrishnan KHarikrishnan KNo ratings yet

- Naukri panapakamSathishKumar (4y 0m)Document4 pagesNaukri panapakamSathishKumar (4y 0m)E jyothibasNo ratings yet

- Curriculum Vitae: Shashanka Singh SisodiaDocument3 pagesCurriculum Vitae: Shashanka Singh SisodiaRahul TRIPATHINo ratings yet

- Alkesh Pandya: Supply Chain Manager / Logistics / WarehousingDocument5 pagesAlkesh Pandya: Supply Chain Manager / Logistics / WarehousingChandanGuptaNo ratings yet

- Zabeen Farook Dubai 4.00 YrsDocument3 pagesZabeen Farook Dubai 4.00 YrsHR RecruiterNo ratings yet

- Mateen Khan Updated C.VDocument4 pagesMateen Khan Updated C.VMustafa KhanNo ratings yet

- Malaya - CV - Senior StorekeeperDocument3 pagesMalaya - CV - Senior StorekeepermkbayeeNo ratings yet

- Abdul Hye ForeignDocument6 pagesAbdul Hye ForeignAbdulhye Hye NiloyNo ratings yet

- Job Role Materials Requirements PlannerDocument3 pagesJob Role Materials Requirements PlannerAmol PatilNo ratings yet

- Dinesh CVDocument2 pagesDinesh CVNagappan PlNo ratings yet

- Muhammad Farooq: Work Experience: Advanced Metal Works (AMW)Document4 pagesMuhammad Farooq: Work Experience: Advanced Metal Works (AMW)Farooq MalikNo ratings yet

- Mohazar Rahiman. B: International Transportation & LogisticsDocument3 pagesMohazar Rahiman. B: International Transportation & LogisticsMohazar RahimanNo ratings yet

- Resume Template 2Document4 pagesResume Template 2anwar0sadat-3No ratings yet

- VijayDocument3 pagesVijayDheeraj MenonNo ratings yet

- Jamison Resume 2022Document4 pagesJamison Resume 2022Krishna RebelsNo ratings yet

- Resume: Ritesh Chandrakant RanaDocument4 pagesResume: Ritesh Chandrakant RanaCHANDRAKANT RANANo ratings yet

- GS CVDocument5 pagesGS CVpreet_simarNo ratings yet

- Shakti Hastir Sharma Mobile: +91 9560233309 E MailDocument3 pagesShakti Hastir Sharma Mobile: +91 9560233309 E MailShakti SharmaNo ratings yet

- Curriculum Vitae: Objective: Educational QualificationDocument3 pagesCurriculum Vitae: Objective: Educational QualificationJayprakash BamboleNo ratings yet

- Arvind Mishra Executive SCM VardhmanDocument1 pageArvind Mishra Executive SCM VardhmanHarendra Singh RawatNo ratings yet

- Nand KishoreDocument5 pagesNand KishoreAadarsh PillaiNo ratings yet

- Syed IhtehsamDocument10 pagesSyed Ihtehsamfaiza minhasNo ratings yet

- Update MayankDocument3 pagesUpdate MayankAabid DiwanNo ratings yet

- Saif Ullah: Personal ProfileDocument5 pagesSaif Ullah: Personal Profilesaif ullahNo ratings yet

- Vijay 1 ResumeDocument5 pagesVijay 1 Resumebalaji_pimpareNo ratings yet

- Vendor Management InventoryDocument14 pagesVendor Management InventoryTravis WrightNo ratings yet

- 07f664388d1880CV PriteshDocument3 pages07f664388d1880CV Priteshsnpksingh8765No ratings yet

- Warehouse & Logistics Planning ManagerDocument5 pagesWarehouse & Logistics Planning ManagerAshish KaulNo ratings yet

- CV 2021 EbadDocument3 pagesCV 2021 EbadTarfawi MNo ratings yet

- Akhilesh (10 0)Document4 pagesAkhilesh (10 0)Roman ReignesNo ratings yet

- C. v. Ajay MishraDocument6 pagesC. v. Ajay MishraAjai MishraNo ratings yet

- Osamah Nasser Mohammed ElewaihDocument3 pagesOsamah Nasser Mohammed Elewaihosamah nasserNo ratings yet

- Akinboboye Omotola D.: Substantial Warehouse ExperienceDocument4 pagesAkinboboye Omotola D.: Substantial Warehouse ExperienceAkinboboye OmotolaNo ratings yet

- 221ACC104 Materials MaterialDocument6 pages221ACC104 Materials MaterialLACONSAY, Nathalie B.No ratings yet

- Amir Rashid KhanDocument4 pagesAmir Rashid KhanAryanNo ratings yet

- ACFrOgCEzUrJ 7swiZxvM1btLqyleLLhwN0ePieyTWka bvPGN5odmCmKIfzw-QPJQ3nR9C5BmL2LcJ9LGQV7qNtQpgtv1aHXyXADfzs-KReFbY1RShr 0NAqHT6am5vAFEzyVb9LPrCF8O I4JDocument2 pagesACFrOgCEzUrJ 7swiZxvM1btLqyleLLhwN0ePieyTWka bvPGN5odmCmKIfzw-QPJQ3nR9C5BmL2LcJ9LGQV7qNtQpgtv1aHXyXADfzs-KReFbY1RShr 0NAqHT6am5vAFEzyVb9LPrCF8O I4JGaurav SainiNo ratings yet

- Vishal Mudgal: Executive ProfileDocument2 pagesVishal Mudgal: Executive ProfileVishal MudgalNo ratings yet

- PPPPPPPPDocument9 pagesPPPPPPPPAndhika HardiansyahNo ratings yet

- Hari OmDocument2 pagesHari OmHariom YadavNo ratings yet

- CV (3) - 3-2Document2 pagesCV (3) - 3-2BH SECURITYNo ratings yet

- Kunal Nanda: Customer. Availability of StockDocument4 pagesKunal Nanda: Customer. Availability of StockRocky BisNo ratings yet

- Sunil K TomarDocument6 pagesSunil K Tomarvipul8800No ratings yet

- 53b62ffd97327-Resume PradeepDocument4 pages53b62ffd97327-Resume PradeepVishal MokalNo ratings yet

- George Allen: ObjectiveDocument2 pagesGeorge Allen: ObjectiveMukut NandaNo ratings yet

- Akinboboye Omotola D.: : No 8, Oremeji Street, Iyana-Ipaja, Lagos. : +234-8166315984Document4 pagesAkinboboye Omotola D.: : No 8, Oremeji Street, Iyana-Ipaja, Lagos. : +234-8166315984Akinboboye OmotolaNo ratings yet

- Professional Resume: Accomplished Supply Chain Management/ Logistics/ SAP MM, WM, EWM Executive SummaryDocument5 pagesProfessional Resume: Accomplished Supply Chain Management/ Logistics/ SAP MM, WM, EWM Executive Summaryprakash rayNo ratings yet

- Nirzar ResumeDocument3 pagesNirzar ResumeAabid DiwanNo ratings yet

- Resume: Ensuring Material Availability As Per Schedules To Avoid Project DelayDocument4 pagesResume: Ensuring Material Availability As Per Schedules To Avoid Project DelayAnonymous cyRdz1YrNo ratings yet

- 1 GoodDocument2 pages1 GoodamolkingNo ratings yet

- Gaurav Bhati: Purchase & Supply Chain ProfessionalDocument2 pagesGaurav Bhati: Purchase & Supply Chain ProfessionalThe Cultural CommitteeNo ratings yet

- Imran Ul Hassan: ABU DHABI, United Arab Emirates. Cell Phone: 050-5114753Document3 pagesImran Ul Hassan: ABU DHABI, United Arab Emirates. Cell Phone: 050-5114753Angel MoonNo ratings yet

- UjjwalaVivekShirodkar (15,0)Document2 pagesUjjwalaVivekShirodkar (15,0)Pallavi Raj100% (1)

- Contact: 96568017888. AddressDocument4 pagesContact: 96568017888. AddressMacha SaiNo ratings yet

- RrrahulDocument3 pagesRrrahulAabid DiwanNo ratings yet

- SanjanaCVDocument2 pagesSanjanaCVAabid DiwanNo ratings yet

- Resume - Dipak DabhiDocument4 pagesResume - Dipak DabhiAabid DiwanNo ratings yet

- Yuvrajsinh Raj ResumeDocument3 pagesYuvrajsinh Raj ResumeAabid DiwanNo ratings yet

- BE Chemical + Shift Engineer +Document1 pageBE Chemical + Shift Engineer +Aabid DiwanNo ratings yet

- Rameshwar CVDocument1 pageRameshwar CVAabid DiwanNo ratings yet

- PravinSDurgale (14 - 0) - ConsentedDocument3 pagesPravinSDurgale (14 - 0) - ConsentedAabid DiwanNo ratings yet

- Senthilprabu (13 0)Document4 pagesSenthilprabu (13 0)Aabid DiwanNo ratings yet

- Umakumar 11122023Document4 pagesUmakumar 11122023Aabid DiwanNo ratings yet

- Rajeshkukkala (10 0)Document2 pagesRajeshkukkala (10 0)Aabid DiwanNo ratings yet

- Curriculum Vittae: Kanu J.Kavad Correspondence AddressDocument4 pagesCurriculum Vittae: Kanu J.Kavad Correspondence AddressAabid DiwanNo ratings yet

- Dushyant Rana - AECSDocument5 pagesDushyant Rana - AECSAabid DiwanNo ratings yet

- Jobaam PresentationDocument6 pagesJobaam PresentationAabid DiwanNo ratings yet

- Rajeshkukkala (10 0)Document2 pagesRajeshkukkala (10 0)Aabid DiwanNo ratings yet

- Starting Plastics Injection Moulding Manufacturing PlantDocument6 pagesStarting Plastics Injection Moulding Manufacturing PlantAabid DiwanNo ratings yet

- Areis Empower Consulting ServicesDocument14 pagesAreis Empower Consulting ServicesAabid DiwanNo ratings yet

- Questionnaire - OAILDocument1 pageQuestionnaire - OAILAabid DiwanNo ratings yet

- 2014 Cahgjghmpus Recruitment RegardingDocument1 page2014 Cahgjghmpus Recruitment Regardingkumar.1982No ratings yet

- Appointment Letter by KevzDocument4 pagesAppointment Letter by Kevzkreyan16No ratings yet

- Aabid Diwan - Team Leader RecruitmentDocument3 pagesAabid Diwan - Team Leader RecruitmentAabid DiwanNo ratings yet

- Sandeep Singh Ankleshwar 15.06 YrsDocument2 pagesSandeep Singh Ankleshwar 15.06 YrsAabid DiwanNo ratings yet

- AC RPO WP FINAL 72dpi PDFDocument8 pagesAC RPO WP FINAL 72dpi PDFAabid DiwanNo ratings yet

- Udhaya Kumar Chennai 12.04 YrsDocument8 pagesUdhaya Kumar Chennai 12.04 YrsAabid DiwanNo ratings yet

- Mumbai PresentationDocument2 pagesMumbai PresentationAabid DiwanNo ratings yet

- Starting Plastics Injection Moulding Manufacturing PlantDocument6 pagesStarting Plastics Injection Moulding Manufacturing PlantAabid DiwanNo ratings yet

- Job Opening For MNC Infrastructure Consulting CompanyDocument2 pagesJob Opening For MNC Infrastructure Consulting CompanyAabid DiwanNo ratings yet

- Employment Application FormDocument10 pagesEmployment Application FormAabid DiwanNo ratings yet

- Design of Open Channels US Department of Agriculture SCSDocument293 pagesDesign of Open Channels US Department of Agriculture SCSMiguelGuavitaRojasNo ratings yet

- SWOT AnalysisDocument6 pagesSWOT AnalysisSSPK_92No ratings yet

- Computerized AccountingDocument14 pagesComputerized Accountinglayyah2013No ratings yet

- Options Trading For Beginners Aug15 v1Document187 pagesOptions Trading For Beginners Aug15 v1Glo BerriNo ratings yet

- Land Use Paln in La Trinidad BenguetDocument19 pagesLand Use Paln in La Trinidad BenguetErin FontanillaNo ratings yet

- 01 RFI Technical Form BiodataDocument8 pages01 RFI Technical Form BiodataRafiq RizkiNo ratings yet

- Solved - in Capital Budgeting, Should The Following Be Ignored, ...Document3 pagesSolved - in Capital Budgeting, Should The Following Be Ignored, ...rifa hanaNo ratings yet

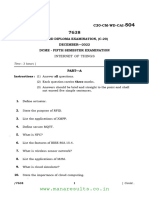

- WWW - Manaresults.co - In: Internet of ThingsDocument3 pagesWWW - Manaresults.co - In: Internet of Thingsbabudurga700No ratings yet

- WhatsNew 2019 enDocument48 pagesWhatsNew 2019 enAdrian Martin BarrionuevoNo ratings yet

- Journalism Cover Letter TemplateDocument6 pagesJournalism Cover Letter Templateafaydebwo100% (2)

- Best Practices in Developing High PotentialsDocument9 pagesBest Practices in Developing High PotentialsSuresh ShetyeNo ratings yet

- SCHEDULE OF FEES - FinalDocument1 pageSCHEDULE OF FEES - FinalAbhishek SunaNo ratings yet

- Mathematical Geophysics: Class One Amin KhalilDocument13 pagesMathematical Geophysics: Class One Amin KhalilAmin KhalilNo ratings yet

- Contemp World Module 2 Topics 1 4Document95 pagesContemp World Module 2 Topics 1 4Miguel EderNo ratings yet

- Sena BrochureDocument5 pagesSena BrochureNICOLAS GUERRERO ARANGONo ratings yet

- Unit 10-Maintain Knowledge of Improvements To Influence Health and Safety Practice ARDocument9 pagesUnit 10-Maintain Knowledge of Improvements To Influence Health and Safety Practice ARAshraf EL WardajiNo ratings yet

- Ril Competitive AdvantageDocument7 pagesRil Competitive AdvantageMohitNo ratings yet

- To Syed Ubed - For UpdationDocument1 pageTo Syed Ubed - For Updationshrikanth5singhNo ratings yet

- Seminar Report of Automatic Street Light: Presented byDocument14 pagesSeminar Report of Automatic Street Light: Presented byTeri Maa Ki100% (2)

- CC Anbcc FD 002 Enr0Document5 pagesCC Anbcc FD 002 Enr0ssierroNo ratings yet

- Grace Strux Beton PDFDocument33 pagesGrace Strux Beton PDFmpilgirNo ratings yet

- Opel GT Wiring DiagramDocument30 pagesOpel GT Wiring DiagramMassimiliano MarchiNo ratings yet

- A Study On Effective Training Programmes in Auto Mobile IndustryDocument7 pagesA Study On Effective Training Programmes in Auto Mobile IndustrySAURABH SINGHNo ratings yet