Professional Documents

Culture Documents

Pile Foundations - 13-9-2022

Uploaded by

Aditya PadaviOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pile Foundations - 13-9-2022

Uploaded by

Aditya PadaviCopyright:

Available Formats

9/14/2022

PILE FOUNDATIONS

Advance Foundation Engineering –II (SE-114)

-Dr. Saloni Pandya

Assistant Professor

Civil Engineering

Navrachana University

• Pile is a slender structural member made of steel, concrete or wood.

• It is either driven into the soil or formed in-situ by excavating a hole and filling it

with concrete.

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 1

9/14/2022

Necessity of Pile Foundations

When the strata at or just below the ground surface is highly compressible and very weak to support

the load transmitted by the structure.

When the plan of the structure is irregular relative to its outline and load distribution. It would cause

non-uniform settlement, if a shallow foundation is constructed. A pile foundation is required in this

case to reduce differential settlements.

Pile foundations are required for transmission of structural loads through deep water to a firm stratum.

Pile foundations are used to resist horizontal forces in addition to support the vertical loads in earth-

retaining structures and tall structures that are subjected to horizontal forces due to wind and

earthquake.

Piles are required when the soil conditions are such that a wash out , erosion or scour of soil may

occur from underneath a shallow foundation.

Piles are used for foundations of some structures, such as transmission towers, off-shore platforms ,

which are subjected to uplift.

In case of expansive soils such as black cotton soil , which swell or shrink as water content changes,

piles are used to transfer the load below the active zone.

Collapsible soils, such as loess, have a breakdown of structure accompanied by a sudden decrease in

void ratio when there is an increase in water content. Piles are used to transfer the load beyond the

zone of possible moisture changes in such soils.

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 2

9/14/2022

Types of Piles

Material Mode of Load transfer Method of installation Based on use

Steel Piles End Bearing Piles Driven piles Load bearing piles

Concrete Piles Friction Piles Driven and Cast-in-situ Compaction piles

Timber Piles Combined end bearing piles Tension piles

and friction piles Bored and cast-in-situ Sheet piles

Composite Piles

piles

Fender piles

Screw Piles

Anchor piles

Displacement of soil Jacked Piles

Displacement piles

Non-Displacement piles

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 3

9/14/2022

Screw Piles

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 4

9/14/2022

Indian Standards on Piles

IS 2911 : Part 1 : Sec 1 : 1979 Driven cast in-situ concrete piles

IS 2911 : Part 1 : Sec 2 : 1979 Bored cast-in-situ piles

IS 2911 : Part 1 : Sec 3 : 1979 Driven precast concrete piles

IS 2911 : Part 1 : Sec 4 : 1984 Bored precast concrete piles

IS 2911 : Part 2 : 1980 Timber piles

IS 2911 : Part 3 : 1980 Under reamed piles

IS 2911 : Part 4 : 1985 Load test on piles

IS 5121 : 1969 Safety code for piling and other deep foundations

IS 6426 : 1972 Specification for pile driving hammer

IS 6427 : 1972 Glossary of Terms Relating to Pile Driving Equipment

IS 6428 : 1972 Specification for pile frame

IS 9716 : 1981 Guide for lateral dynamic load test on piles

IS 14362 : 1996 Pile boring equipment - General requirements

IS 14593 : 1998 Bored cast-in-situ piles founded on rocks - Guidelines

IS 14893 : 2001 Non-Destructive Integrity Testing of Piles (NDT) - Guidelines

Load Carrying Capacity of Piles

STATIC METHODS

Qu = Qp + Qs

Where, Qu = Ultimate Failure load, Qp = Point resistance of the pile and Qs = Shaft resistance developed by

friction.

FOR COHESIONLESS SOIL

Qp = qp * Ap (qp is the ultimate bearing capacity of soil at the pile tip and Ap is the area of the pile tip.)

Qs = fs * As (fs is the unit skin friction between sand and pile surface and As is the effective surface area of the

pile in contact with the soil.

FOR COHESIVE SOIL

Qp = qp * Ap (qp is the ultimate bearing capacity of soil at the pile tip and Ap is the area of the pile tip.)

Qs = ca * As (ca is the unit adhesion developed between cohesive soil and pile surface and As is the effective

surface area of the pile in contact with the soil.

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 5

9/14/2022

Point Load capacity of Pile: General Bearing Capacity approach

Load

• Ultimate bearing capacity of soil considering general bearing capacity equation. Shape,

inclination, and depth factors are included in bearing capacity factors

q p u c N c* q N q* 0 .5 D N *

• Since pile diameter is relatively small, third term may be dropped out

q p u c N c* q N q*

• Hence Pile load capacity qs qs

Q p u q p u . A p c N c* q N q* . A p

qp

Point Load capacity of Pile: Meyerhof’s (1976) Method

• Granular soils (Cohesionless soils):

Point bearing capacity of pile increases with depth in sands and reaches its maximum at an embedment ratio

L/D = (L/D)cr. Therefore, the point load capacity of pile is

Q p u A p . q . N q* A p . q u l

q u l 0 .5 Pa N q* t a n Pa A t m o s p h e r ic p r e s s u r e

– (L/D)cr value typically ranges from 15D for loose to medium sand to 20D for dense sands.

– Correlation of limiting point resistance with SPT value

L

q u l 0 .4 N 4 Pa N

D

N“ value shall be taken as an average for a zone ranging from 10D above to 4D below the pile point.

qu = unconfined

• Saturated Clays: compression strength = =>

Cu = undrained cohesion Cu = qu/2

Q p u N c .c u . A p 9 .c u . A p

*

UC test or Vane shear test Su = cu

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 6

9/14/2022

Methods of determination of unit skin friction in Cohesionless

soils

• The unit skin friction for the straight-sided pile depends upon the soil pressure acting

normal to the pile surface and the coefficient of friction between the soil and pile

material

• Soil pressure normal to vertical pile Horizontal pressure (h)

h = K v

• K = earth pressure coefficient ; v = Effective vertical pressure at that depth

• The unit skin friction (fs) acting at any depth :

fs = K v tan (tan = coefficient of friction between sand and pile material)

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 7

9/14/2022

GL

Z

Area of vertical stress diagram = 0.5 * Z2

The above equation can be written as:

The ultimate load for the pile can be written as: (Cohesionless

soils)

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 8

9/14/2022

• Load i.e. coming on pile

• Tentative dimensions of pile

• See the soil investigation data Cohesionless or Cohesive Near by depth rock or very dense soil Point

bearing piles or

Friction piles neither deep nor shallow Both

Ultimate load carrying capacity of pile (QU) (using soil data, end bearing or friction and tentative dimensions)

Fos = Qu / Q(pile load from superstructure) > 4 Dimensions selected ; load transfer mechanism selected is

absolutely correct

Example 1: A concrete pile, 30 cm diameter is driven into a medium dense sand ( = 35), = 21

kPa and K = 1.0, tan =0.70, for a depth of 8 m. Estimate the safe load, taking a FOS

= 2.50. Also, Determine the safe load for the pile, if the water table rises to 2m below

the ground surface. Take w = 10 kN/m3.

Dia = 0.3 m Qu = Q p + Q s

= 35 deg

= 21 kN/m3 Qp = qp * Ap

Pile is driven from the G L to a depth = 8 m

Fos = 2.5

K = 1.0 K = 1- sin

Tan = 0.70 = Coefficient of friction between soil and pile

material = 2/3

Driven Pile

Medium dense sand Cohesionless soil

It is End bearing as well as friction

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 9

9/14/2022

Qp = qp * Ap

q p u c N c* q N q*

8m

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 10

9/14/2022

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 11

9/14/2022

2m

8m

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 12

9/14/2022

Methods of determination of unit skin friction in Cohesive

soils

The skin resistance (Qs) of the pile can be expressed as:

Value of

consistency of clay

ca = unit adhesion developed between clay and pile shaft

NC soils and soils

having cu < 50 kN/m2; unit adhesion (ca) is related to unit cohesion by :

=1

OC soils ; = 0.3

For D 25 m ; above method is very conservation for such cases unit skin friction depends upon over

burden pressure (Vijayvergia and Focht Method)

= friction capacity factor; v = mean effective overburden pressure for the embedment length ;

c = undrained cohesion (obtained from UC test)

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 13

9/14/2022

IS 2911 Part I Section 3 Clause B2

Range of Adhesion Factor ()

SPT (N) Consistency cohesion

(kN/m2) Driven Bored

<4 Soft to very soft 1 to 25 > 1.0 Reduce the

4 to 8 Medium Stiff 25 to 50 0.7 – 0.4 driven values by

factor 0.8

8 to 15 Stiff 50 to 100 0.4 – 0.3

15 Stiff to hard 100 0.3 – 0.25

0.5

If 1, then 0.5 0.5

(c / v )

If > 1, then 0.5 0.25

For bored piles the value of as obtained above is to be multiplied by 0.8

Correction for pile length as affecting Adhesion in clays (F)

• Tomlinson has explained that research in offshore piles has shown that the two important factors that

influence adhesion in heavily loaded piles driven to deep penetration in clays are the following :

1. The over consolidation ratio of the soil as already explained.

2. The slenderness or aspect ratio (also called length L/B ratio).

The effect of the length factor F has been found to be as follows:-

F =1 for L/B 50

F = 0.7 for L/B 120

Intermediate values can be assumed to be linear. The following formula will give the adhesion between shaft of

pile and clay in terms of the two factors, and F.

Qi = (Fc)*Asi

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 14

9/14/2022

Example 2: A 30 cm diameter concrete pile is driven into a homogeneous consolidated clay

deposit (cu = 40kPa, =0.7). If the embedded length is 10 m estimate the safe load. (FOS =

2.5)

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 15

9/14/2022

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 16

9/14/2022

Capacity of piles in c- soil by static formula

IS 2911 does not recommend any specific static formula for the load carrying capacity of piles in soils with c-

values. Using the fundamental properties with such soils, it is customary to use one of the following methods.

Method 1: If the soil has small value of treat it as purely cohesive soil. Similarly if the cohesion is small and is

large than treat the soil as being cohesionless.

Method 2: Where the soil has large values of both c and (as for a true c - soil), we should use the conservative

Terzaghi’s bearing capacity factors to determine the load carrying capacity.

Qu = [ cNc+vbNq+0.5DN] * Ap + (c + Kvi tan)* Asi

Where, Nc, Nq, N = Terzaghi’s bearing capacity factors

vb; v = effective overburden pressure of base and pile shaft, irrespective of the critical depth.

Allowable Load (Qall)

• Qall = Qu / FOS

• The factor of safety to be used in the static formula should depend on many factors such as

the following :

─ Reliability of soil parameters used for calculations

─ The manner in which load is transferred to the soil

─ The importance of the structure

─ Allowable total and differential settlement tolerated by the structure.

• FOS = 2.5 to 4 ; depending upon the uncertainties involved in the computation of ultimate

load

• Acc to IS: 2911-1979; the minimum factor of safety on the static formula shall be 2.5.

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 17

9/14/2022

Negative Skin Friction

Qu = Qu - Qnsf

Qu = net ultimate load

Qnsf = negative skin friction

The soil layer surrounding a portion of

pile shaft settles more than the pile, a

downward drag occurs on the pile. The

drag is known as negative skin friction.

It imposes an extra downward load on

the pile due to increase in the skin

friction

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 18

9/14/2022

Site conditions where negative skin friction could occur (IS 2911, Part I, Sec 3)

When the pile is installed in a fill, which will undergo consolidation

In the soil which will be disturbed or remoulded thoroughly during the pile installation.

In piles installed in soft clay with surcharge loading on it.

In soils where lowering or variation of ground water can occur, thus leading to significant settlement of

soil strata around the pile.

In cases where the piles are driven through a strata of soft clay into firmer soils and the soft clay tends to

settle relative to the pile.

In piles in a clay stratum which undergoes shrinkage settlement.

As negative skin friction is due to consolidation, it takes place slowly and increases with time. Hence, its

effects are not felt in pile load tests.

Sleeve

If a large amount of downward drag on the pile is anticipated A protective

sleeve or coating for the section which is surrounded by settling soil.

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 19

9/14/2022

DYNAMIC FORMULAE

The Load carrying capacity of a driven pile can be estimated from the resistance against penetration

developed during driving operation.

The methods is accurate for free draining sands and hard clays

The dynamic formulae are based on the assumption that the kinetic energy delivered by the hammer

during driving operation is equal to the work done on the pile.

W h h = R x S

W = Weight of hammer (kN), h = height of ram drop (cm), h = efficiency of pile hammer, R = pile resistance

(kN) and S = pile penetration per blow or set (cm)

Engineering News Record Formula

The ultimate load is given by:

C = 2.54 (Drop Hammer) and C = 0.254 cm (Steam Hammer)

h = 0.75 (Single acting hammer); 0.85 (Double acting hammer); 0.80 to 0.90 (Diesel hammer)

W x h = En (rated energy of hammer)

The factor of safety of 6 is usually recommended.

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 20

9/14/2022

Hiley Formula

The coefficient of

restitution (COR), also

denoted by (e), is the ratio of

the final to initial relative

velocity between two objects

after they collide.

In order that the top of the pile is not damaged during

driving it is protected by packing material, generally

layers of hard wood, over which is placed a steel cap or

dolly.

Anvil is the bottom part of a hammer that receives the impact

of the ram and transmits the energy to the pile.

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 21

9/14/2022

Simplex Formula For Friction Piles

• The skin friction component also of the pile capacity is introduced into an empirical expression in the

simplex formula by measuring the total hammer blows for the full driving of the pile. The formula is

expressed as:-

N WH L

R P x x

L 2.54 s 2.36

• R = ultimate driving resistance in kN

• Np = total number of blows to drive the pile

• L = length of the pile

• W = weight of the hammer, kN

• H = height of free fall in meters

• s = average set.

Dynamic Pile Formula: Janbu Formula

1 WH

RU

kU s Units: kN and m.

RU Ultimate capacity (FS)

Efficiency factor (0.7 to 0.4, depending on driving conditions)

.W .H

kU Cd 1 1 c Cd Cd 0.75 0.15 P W c

A.E.S 2

W Weight of hammer/ram

P Weight of pile

H Height of free fall in meters.

Hammer fall efficiency as mentioned for modified Hiley’s formula

A Area of pile

E Elastic modulus of pile

s Set per blow

L Length of pile 44

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 22

9/14/2022

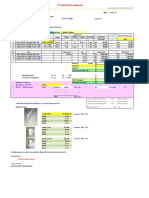

Example 1:

A precast concrete pile (35 cm x 35 cm) is driven by a single acting steam hammer. Estimate the allowable load using

(a) Engineering News Record Formula (FOS = 6); (b) Hiley Formula (FOS= 4). Use following information given

below.

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 23

9/14/2022

Example 2:

A 400 x 400 mm R.C. pile 20 m long weighing 74 kN is driven as a bearing pile with a set of 30 mm for last 10

blows using a drop hammer 30 kN in weight falling through 1.5 m. Determine the capacity of the pile assuming a

weight of dolly, helmet, packing is 4 kN. Hammer is single acting and efficiency is 0.9. Use Janbu formula.

1 WH

RU

kU s

Example 3:

A 300 mm dia. 20 m long pile is driven by a 3.75 ton hammer with a drop of 1 m. The total number of blows for 20 m

penetration is 550 and the last penetration reading was 60 blows for 1 m penetration. Estimate the capacity of the pile

use Simplex formula for friction piles.

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 24

9/14/2022

GROUP ACTION OF PILES

Structural loads are supported by various piles acting as a group

The loads are transferred to the pile group through a reinforced concrete slab

structurally tied to the pile tops such that piles act as a single unit

Slab PILE CAP

Load carrying capacity of piles Sum of capacity of each piles

It’s a function of space between the piles

When the piles are placed at sufficient distance apart, the group capacity

may approach the sum of individual piles

If the piles are closely placed Stresses transmitted by the piles may

overlap reduces the load carrying capacity of piles

The spacing between piles The centre to centre

is selected in such a distance between 2.5 B

manner that the 100% to 3.5 B; where , B is the

efficiency is reached. diameter of the pile.

Overlapping

of

transmitted

stresses

The efficiency of a group of piles is equal to the ratio of the ultimate load of the group to the sum of

individual ultimate loads.

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 25

9/14/2022

PILE GROUP IN SAND AND GRAVEL

DRIVEN PILES

End bearing piles:

For spacing greater than or equal to 3B

For spacing less than 3B, the group capacity would be evaluated for the block of piles.

Friction piles:

Group efficiency of friction piles in sand is obtained from the following expression:

If the centre to centre spacing is large, the group efficiency (g) may be more than 100%. The piles will behave as

individual piles.

If g is less than 100%;

The group efficiency can also be obtained from converse- Lebarre equation given below:

BORED PILES:

For bored piles in sand at conventional spacing of 3B the group efficiency is taken as 2/3 or ¾ times the sum of

individual capacities for both the end-bearing and friction piles. Thus,

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 26

9/14/2022

PILE GROUP IN CLAYS

The lesser of the two values is the actual capacity

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 27

9/14/2022

Q p u q p u . A p c N c* q N q* . A p

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 28

9/14/2022

SETTLEMENT OF PILE GROUPS

COHESIONLESS SOILS

(A) Skempton’s method

Sg – Settlement of group

S0 – Settlement of

individual pile

Curve can be used for

driven and bored both

the piles

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 29

9/14/2022

COHESIONLESS SOILS

(B)Meyerhof’s Method

For the elastic settlement of pile

COHESIVE SOILS

Generally 2: 1 distribution is assumed from the level at which load acts. 2/3 D Frictional Piles

and pile tip end bearing piles

In the combine action the frictional component is assumed to act at 2/3 D and bearing component at

the tip.

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 30

9/14/2022

For 2: 1 distribution the stress increase at the middle of the each layer is calculated as :

Where, i = qi

END BEARING PILES G.L

Silty Sand

Silty Sand

1 zi

Hi

2

Clay

Rock

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 31

9/14/2022

Example : A group of friction piles of 30 cm diameter is subjected to a net load of 2000 kN, as shown in the figure

below. Estimate the consolidation settlement.

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 32

9/14/2022

Load Tests on Piles

Note:

Piles used for initial testing are loaded to failure or at least twice the design

load. Such piles are generally not used in the final construction.

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 33

9/14/2022

Load Tests on Piles

During this test pile should be loaded upto one and half times the working (design) load and the

maximum settlement of the test should not exceed 12 mm.

These piles may be used in the final construction

Pile Load Test

The most reliable method for pile load capacity

evaluation

The distance between anchor piles and test piles

should be 3B or 2.5 m.

Test is conducted after rest period of 3 Days (after

installation of test piles) for cohesionless soils and

1 month in silts and clays

Load is applied in increments of 20% of the

allowable load

Settlements are recorded by three dial gauges

Under each load increment the settlements are

recorded at 0.5, 1, 2, 4, 8, 12, 16, 20 and 60

minutes.

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 34

9/14/2022

Safe load is load at which the total settlement is 10% of the pile diameter

Gross settlement should not be more than 25mm.

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 35

9/14/2022

MINIMUM SPACING OF PILES

IS 2911 Part I Sec. 2 (1979) Clause 5.6, gives the following as the minimum spacing of piles to

be adopted in practice in terms of d, the diameter of the pile.

1. Bearing piles (general) 2.5 d

2. Bearing piles on rock 2.0 d

3. Friction piles 3.0 d

The Norwegian Code of Practice recommends the following values for spacing of piles.

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 36

9/14/2022

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 37

9/14/2022

Methods to Determine Lateral Strength of Piles

Some of the theoretical and empirical methods used to determine the lateral capacity of piles are

given below.

Method 1: Use of active and passive earth pressure theories. It is applicable only to short piles undergoing rigid rotation.

Also as the movement necessary for mobilizing full passive pressures is large, the results should be used with sufficient

safety factor. This method gives ultimate values.

Method 2: Use of modulus of horizontal subgrade reaction theory. We can either form closed form solutions or solve

each problem by computer methods. However as coefficient of subgrade reaction of the soil is not a fundamental property

of the soil, the results should be used with judgement. This method gives elastic analysis.

Method 3: Use of elastic continuum theory applied to soils. Because of the complexity of the problem, it can be solved

satisfactory only by computer. Due to the difficulty of determining the exact soil properties results of this method should be

verified by field tests.

Method 4: Empirical methods. These methods combine the results of method 2 and also the experimental data obtained

from laboratory/field tests to obtain readymade charts for design. Charts published by IS and Broms belong to this

category.

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 38

9/14/2022

Laterally Loaded Piles:IS-2911

Laterally Loaded Piles:IS-2911

78

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 39

9/14/2022

IS 2911 METHOD FOR LATERAL RESISTANCE OF PILES

A non-dimensional quantity called Relative Stiffness Factor to predict the behavior of piles.

Case 1: Where the modulus of horizontal subgrade reaction is constant along the depth as in over consolidated clays they

recommended factor R.

Case 2: Where the modulus of horizontal subgrade reaction increases with depth as in sand deposits and in normally

consolidated clays, they recommended factor T.

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 40

9/14/2022

IS 2911 Part I /Sec. 3 —Appendix D classifies piles as follows (This is similar to Broms method)

Free headed piles (piles unrestrained at the top)

Fixed headed piles or restrained piles connected to pile caps at the top.

Each of these piles can be again classified as long piles and short piles depending on their relative stiffness

factors.

While the short piles unrestrained at top fail by rotation as a rigid body about a centre of rotation, the same pile, when restrained at the top is

assumed to fail by translation .

As regards long piles, both restrained and unrestrained piles behave as an elastic beam member as the lower end cannot rotate but is fixed in

position.

Hence in the case of long piles the failure will be by fracture of the pile at the point of maximum moment or by shear. However, while the

free end of an unrestrained long pile acts as a cantilever, the fixed end long pile acts as a fixed beam, with both ends fixed, developing

moments both at top and bottom. Accordingly, the maximum moment developed in the long restrained pile will be only one half that of the

cantilever.

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 41

9/14/2022

Laterally Loaded Piles: Stiffness Factors

83

Criteria for classification of piles into short rigid piles or long elastic

piles

• If L ≤ 2T or ≤ 2R, the pile is short and rigid; (L/T or L/R ≤ 2).

• If L ≥ 4T or ≥ 3.5R, the pile is long and elastic; (L/T ≥ 4 or L/R ≥ 3.5).

• If L > 5T or > 4.5R, the pile is definitely long; (L/T > 5 or L/R > 4.5).

• The intermediate cases indicate the behavior between the two.

• For constant soil modulus, free head L = 3.5R and fixed head L = 2R

• For linearly increasing soil modulus, free head L = 4T and fixed head L = 2T

• The method described in IS 2911 is applicable for long piles only.

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 42

9/14/2022

Laterally Loaded Piles: IS-2911: Depth of Fixity

The IS method is

suitable only for

relatively small

lateral loads

acting on long

piles.

Taking e as the length

above ground level, we

enter e/R or e/T and read

off zf /R or zf /T from

the diagram. It gives the

value zf the depth of

fixity.

85

Calculation of ultimate value of H

• The ultimate value of the lateral load H should be either the maximum resistance that can be offered

by the soil or the ultimate moment of resistance of the pile, whichever is the lesser of the two.

• For long piles in IS 2911 method the ultimate value of H is taken as the load at which the moment of

the pile is equal to its ultimate moment capacity

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 43

9/14/2022

Laterally Loaded Piles:

IS-2911: Reduction

Factors for Moment

Calculation

87

Deflection of pile at ground level

• For long piles in which the lateral resistance is high, it will be as follows as given in

IS 2911.

• y = H(e + z)3/3EI for free head pile as a cantilever

= H(e + z)3/12EI for fixed head pile

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 44

9/14/2022

Brom’s Charts

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 45

9/14/2022

Ultimate lateral resistance of short piles in Cohesive soils (Type 1 soils)

For short piles for type 1 soils:

The ultimate lateral resistance is related to

embedded length.

K = modulus of subgrade reaction in MN/m3

Ultimate lateral resistance of long piles on Cohesive (Type 1) soils

The ultimate lateral resistance is related to the ultimate

resistance moment of the pile, whose ultimate moment of

resistance is MU.

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 46

9/14/2022

Lateral deflection at ground level for piles in Cohesive (Type 1) soils under working loads

Chart for estimating the ultimate lateral resistance of short piles in Cohesionless Soils (Type 2 soils)

The ultimate lateral resistance related to the

embedded length.

= unit weight of soil.

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 47

9/14/2022

Chart for estimating the ultimate lateral resistance of long piles in Type 2 (Cohesionless soils)

Ultimate lateral resistance related to

the ultimate moment of resistance of

piles.

Note : Unless very refined values are needed,

we usually assume that the lateral resistance of

a group of piles is equal to a multiple of the

strength of a single pile.

Chart for estimating the lateral deflection at ground level of piles in Type 2 (granular) soils under working loads

Lateral deflection yo at ground

surface of horizontally loaded

pile

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 48

9/14/2022

Example A:

A 300 mm square wooden pile is driven 5 m below ground level in pre-loaded clay. The load to be applied is 1 m above the

ground. Determine the ultimate load that can be applied on a pile with MU = 100 kN-m. Assume Kh = 15 MN/m2, E = 10 x 102

MN/m2, and cohesion of clay = 1 kg/cm2.

Example B:

A concrete pile 900 mm diameter and 6 m long is installed in a clay soil with cohesion, 1.2 kg/cm2 (N value 12). Estimate the

ultimate lateral resistance if the load is applied at a point situated at 4 m above the ground level. Assume K1 = 25.0 MN/m3 and

Ec = 26 kN/mm2. If the allowable deflection at ground level is only 25 mm, estimate the load that it can take.

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 49

9/14/2022

Thank you

Advance Foundation Engineering -II (SE-

114)_NUV_Autumn 2022 50

You might also like

- Profound Meditation User ManualDocument21 pagesProfound Meditation User ManualJon Rossiter100% (2)

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Deep FoundationsDocument23 pagesDeep FoundationsMushaid Ali SyedNo ratings yet

- Pile Foundation TGDocument83 pagesPile Foundation TGabhijitroy333No ratings yet

- Analysis of Raft Pile Raft Foundation Using Safe Software IJERTV9IS070032 PDFDocument5 pagesAnalysis of Raft Pile Raft Foundation Using Safe Software IJERTV9IS070032 PDFKousalya MkNo ratings yet

- Analysis and Design of Foundation SystemsDocument31 pagesAnalysis and Design of Foundation SystemsJAY PATELNo ratings yet

- FastenersDocument178 pagesFastenersthulasi_krishna100% (6)

- Pile Foundation DesignDocument143 pagesPile Foundation DesignVirendra Kumar Pareek100% (2)

- Design of Oneway SlabsDocument5 pagesDesign of Oneway SlabsOsama TamariNo ratings yet

- Chapter 5 Shallow FoundationDocument47 pagesChapter 5 Shallow FoundationLi Jun ChuaNo ratings yet

- Foundation Designs and Geotechnical AspectsDocument70 pagesFoundation Designs and Geotechnical AspectsAnasua GuharayNo ratings yet

- Testing & Commissioning Manual SECDocument125 pagesTesting & Commissioning Manual SECmissle2007100% (6)

- Engineering Mechanics by Dhiman and KulshereshthaDocument23 pagesEngineering Mechanics by Dhiman and KulshereshthaAnil DhimanNo ratings yet

- 2-Days Course Santa Cruz Per PDFDocument440 pages2-Days Course Santa Cruz Per PDFAmilcar Reynaldo Vargas RamosNo ratings yet

- Pile Construction, U.S. Army Field Manual (FM 5-134)Document176 pagesPile Construction, U.S. Army Field Manual (FM 5-134)Taj DeluriaNo ratings yet

- Public Health Risk Assessment - EhraDocument28 pagesPublic Health Risk Assessment - EhraElga Melani RohmawatiNo ratings yet

- Physics 2003 P2Document14 pagesPhysics 2003 P2Rishi GopieNo ratings yet

- Nickel Chromium PlatingDocument10 pagesNickel Chromium Platingselvamuthukumar100% (1)

- Filler in ConcreteDocument8 pagesFiller in ConcretecuibaprauNo ratings yet

- SukanyaKarmakar 74Document23 pagesSukanyaKarmakar 74sukanya karmakarNo ratings yet

- Unit 6 (Part 1) Pile Foundation-Types of PileDocument45 pagesUnit 6 (Part 1) Pile Foundation-Types of PileNikitaNo ratings yet

- Foundation Engineering-IiDocument45 pagesFoundation Engineering-IiDaniel SolomonNo ratings yet

- CE 632 Pile Foundations Part-1Document42 pagesCE 632 Pile Foundations Part-1Hiren ThakkarNo ratings yet

- Pilings and CaissonsDocument8 pagesPilings and CaissonsJoshua C. JosonNo ratings yet

- Fundations PilesDocument14 pagesFundations PilesOMAR SURCO MAMANINo ratings yet

- GRP 2 - Soil - Foundation PilesDocument74 pagesGRP 2 - Soil - Foundation PilesFELICITY MONTEFALCONo ratings yet

- Pile FoundationDocument82 pagesPile FoundationNfs TarTonNo ratings yet

- Laboratory Evaluation of End Bearing Capacity of DifferentDocument31 pagesLaboratory Evaluation of End Bearing Capacity of DifferentWaheed SahilNo ratings yet

- 1-Pile FoundationsDocument32 pages1-Pile FoundationshannaNo ratings yet

- تصميم الخوازيقDocument82 pagesتصميم الخوازيقali jamiilNo ratings yet

- Factors Affecting Cast-In-situ Pile Foundation.Document5 pagesFactors Affecting Cast-In-situ Pile Foundation.Gaurav Dhang100% (1)

- Foundations (S-D) 2015Document32 pagesFoundations (S-D) 2015hannaNo ratings yet

- Deep FoundationsDocument37 pagesDeep FoundationsMd. Kibria FerdousNo ratings yet

- Design of Pile Foundation in Black Cotton Soil by Using STAAD. FoundationDocument7 pagesDesign of Pile Foundation in Black Cotton Soil by Using STAAD. FoundationbereketNo ratings yet

- Lecture 1 Chapter 1 IntrodiuctionDocument9 pagesLecture 1 Chapter 1 Introdiuctionsnc.miccpNo ratings yet

- Substructures - Pidilite Ind - Nirma Uni - July 02 2021Document41 pagesSubstructures - Pidilite Ind - Nirma Uni - July 02 2021BATMANNo ratings yet

- Pile Foundation Tos Assignment - 2 Amey DeshmukhDocument13 pagesPile Foundation Tos Assignment - 2 Amey DeshmukhAmey Deshmukh100% (1)

- Piling Tugasan1Document29 pagesPiling Tugasan1MDanish AimanNo ratings yet

- Lect 1 Pile FoundationDocument34 pagesLect 1 Pile FoundationPaulNo ratings yet

- Classification of Pile FoundationDocument1 pageClassification of Pile FoundationSacademicusNo ratings yet

- The Sinking of Well Foundations in Difficult Situations 28.3.07Document13 pagesThe Sinking of Well Foundations in Difficult Situations 28.3.07NehaSinghNo ratings yet

- Different Methods of Deep Foundation DesignDocument7 pagesDifferent Methods of Deep Foundation DesignMuhammad ArhamNo ratings yet

- Precast Concrete PilesDocument4 pagesPrecast Concrete PilesFreddie KooNo ratings yet

- BridgeAbutmentTechnicalPaper Aligarh PKG - 3Document10 pagesBridgeAbutmentTechnicalPaper Aligarh PKG - 3Gajendra BishtNo ratings yet

- Deep FoundationsDocument6 pagesDeep FoundationsMarielle G. CastilloNo ratings yet

- Retaining WallDocument30 pagesRetaining WallMohd IdreesNo ratings yet

- Deep FoundationDocument14 pagesDeep FoundationNabeelNo ratings yet

- Deep FoundationDocument61 pagesDeep FoundationAlfaizs Vi Afkara100% (1)

- Building Components and StructuresDocument15 pagesBuilding Components and Structuresxasoke2145No ratings yet

- Deep Foundations, Single Pile Load Transfer Mechanism & Ultimate CapacityDocument21 pagesDeep Foundations, Single Pile Load Transfer Mechanism & Ultimate CapacityDaanial KhanNo ratings yet

- Design of Piles: Rosalem, Glyra BDocument41 pagesDesign of Piles: Rosalem, Glyra BGlyra RosalemNo ratings yet

- Ir Sammy Cheung HKIE GD Workshop 2015Document60 pagesIr Sammy Cheung HKIE GD Workshop 2015Haywood CheungNo ratings yet

- Presented By:, Shivam Gandhi AhmedabadDocument43 pagesPresented By:, Shivam Gandhi AhmedabaddhivyaNo ratings yet

- Study On Installation and Pullout of Suction Caisson Foundation For OWTDocument5 pagesStudy On Installation and Pullout of Suction Caisson Foundation For OWTDang Quang MinhNo ratings yet

- A Review of Pile Machines and Their Selection CritDocument14 pagesA Review of Pile Machines and Their Selection CritNitaiGauranga108No ratings yet

- Design Parameters and Behavior of Helical Piles in Cohesive Soils-A ReviewDocument15 pagesDesign Parameters and Behavior of Helical Piles in Cohesive Soils-A ReviewHaha ZazaNo ratings yet

- Design Parameters and Behavior of Helical Piles in Cohesive SoilsDocument15 pagesDesign Parameters and Behavior of Helical Piles in Cohesive SoilsAgung Dwi NugrohoNo ratings yet

- Analysis and Design of Shell Foundation Is 9456 1980 ProvisionDocument6 pagesAnalysis and Design of Shell Foundation Is 9456 1980 ProvisionAhmed salahNo ratings yet

- Lect-1 Intro 2014 Web 000Document45 pagesLect-1 Intro 2014 Web 000Junayed Khan100% (1)

- Training ReportDocument21 pagesTraining ReportMonaliza SenNo ratings yet

- A Study of Pile Foundation To Enhance Soil Bearing Capacity For The StructureDocument12 pagesA Study of Pile Foundation To Enhance Soil Bearing Capacity For The StructurearjunNo ratings yet

- FDN Engg Chapter 7Document39 pagesFDN Engg Chapter 7Jelminda AlfaroNo ratings yet

- Foundation Engineering and Design: GroundDocument74 pagesFoundation Engineering and Design: Groundمحمد السروريNo ratings yet

- Settlement Prediction and Back Analysis of Young's Modulus and Dilation Angle of Stone ColumnsDocument14 pagesSettlement Prediction and Back Analysis of Young's Modulus and Dilation Angle of Stone ColumnsZOUABINo ratings yet

- Deep Foundation - WikipediaDocument9 pagesDeep Foundation - WikipediaABHAY SHRIVASTAVANo ratings yet

- Design of Flexible Pavements For An ExisDocument6 pagesDesign of Flexible Pavements For An ExisSokheng HourNo ratings yet

- Pile Foundation - DXDocument94 pagesPile Foundation - DXvigil vigilNo ratings yet

- Snuffler 1301Document8 pagesSnuffler 1301schwa1234No ratings yet

- AC 16 Colorimetric Analysis For Lab NotebookDocument7 pagesAC 16 Colorimetric Analysis For Lab Notebookch_ymyaaNo ratings yet

- Assignment 1-Strut and Tie ModelDocument5 pagesAssignment 1-Strut and Tie ModelYUK LAM WONGNo ratings yet

- AmplifierDocument63 pagesAmplifierSaravanakumar Pichumani100% (1)

- Exercise11th GradeDocument2 pagesExercise11th GradesheillahermantoNo ratings yet

- Pergo Universal TDSDocument1 pagePergo Universal TDSravikumarNo ratings yet

- Remainder TheoremDocument3 pagesRemainder TheoremMax EeNo ratings yet

- App 014 Combining KISSsys FEMDocument8 pagesApp 014 Combining KISSsys FEMalexNo ratings yet

- Work, Energy, and PowerDocument13 pagesWork, Energy, and Powerエンジェル リンNo ratings yet

- Physics II - Lab 1 - Coulomb's LawDocument4 pagesPhysics II - Lab 1 - Coulomb's LawKestin ComeauxNo ratings yet

- 5125 - Quot Raveza - To UD ABS SP10 T.H10L60 - White ColourDocument1 page5125 - Quot Raveza - To UD ABS SP10 T.H10L60 - White ColourJulius SunarkoNo ratings yet

- 122Document10 pages122Bayangan HatiNo ratings yet

- InductionDocument13 pagesInductionVigneshNo ratings yet

- 2811 Jan 04MSDocument7 pages2811 Jan 04MSmichael hengNo ratings yet

- PrecipitationDocument18 pagesPrecipitationPoriNo ratings yet

- Tpi 252 de en Lubricators PDFDocument94 pagesTpi 252 de en Lubricators PDFRodrigo Jechéla BarriosNo ratings yet

- ANSWER KEY CCT V - April 2020Document4 pagesANSWER KEY CCT V - April 2020Great Ashur YTNo ratings yet

- EEE 209 Presentation 2 (Electrical Circuits)Document130 pagesEEE 209 Presentation 2 (Electrical Circuits)Mert YılmazNo ratings yet

- Elitmus Problem Solving & Reasoning Questions: Number of Questions Difficulty Level Average Time To SolveDocument2 pagesElitmus Problem Solving & Reasoning Questions: Number of Questions Difficulty Level Average Time To SolveSloka RoyNo ratings yet

- Instruction: Chapter Four: Imperfections in Solids Part OneDocument2 pagesInstruction: Chapter Four: Imperfections in Solids Part OnedebelaNo ratings yet

- Biomechanical Analysis of Human Tibia Bone Based On FEADocument7 pagesBiomechanical Analysis of Human Tibia Bone Based On FEAB01Aadarsh SharmaNo ratings yet