Professional Documents

Culture Documents

SGS-BASSEFA-ATEX EX Guidance-Wallchart 3-A2

Uploaded by

mikexanderOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SGS-BASSEFA-ATEX EX Guidance-Wallchart 3-A2

Uploaded by

mikexanderCopyright:

Available Formats

3

ATEX DSEAR

ATEX AND DSEAR:

GUIDANCE FOR END USERS EX

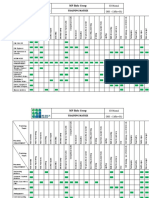

RELATIONSHIP BETWEEN EUROPEAN ATEX WORKPLACE DIRECTIVE AND DSEAR COMPLIANCE OVERVIEW

AND UK LEGISLATION

PROVISIONS DSEAR (UK) ATEX 1999/92/ GUIDANCE

ATEX EC

(ATMOSPHERE EXPLOSIBLE) Assess the risks and identify the necessary control measures Reg 5 Article 4.1 HSE ACOP L138

EMPLOYERS, Implement the necessary technical and organizational measures including suitable Reg 6, Article 3 HSE ACOP L138

WORKPLACE OWNERS

& LANDLORDS provision for accidents, incidents and emergencies Schedule 1

MANUFACTURERS

Classify the areas where potentially explosive atmospheres may exist into zones Reg 7, Schedule 2 Article 7.1 EN 60079-10-1

PRODUCT DIRECTIVE CHEMICAL AGENTS WORKPLACE EN 60079-10-2

2014/34/EU DIRECTIVE DIRECTIVE Industry Codes

(See Note) (98/24/EC) 1999/92/EC Mark the classified areas using the appropriate warning signs Reg 7, Schedule 4 Article 7.3

Inspect, assess, modify or replace the equipment on the basis of the level of risk Reg 5 & 6, Article 3 & EN 60079-14

and the ability of the equipment to create a source of ignition Schedule 1 4.1 EN 60079-17

EN 60079-19

EPSR DSEAR

Equipment and Protective Dangerous Substances and Ensure personnel at risk, and others who may be affected, receive appropriate training Reg 9 Annex II 1.1

Safety

Systems Intended for Use related Explosive Atmospheres Create and maintain an Explosion Protection Document (EPD–ATEX 99/92/EC Reg 5 Article 8 HSE ACOP L138

in Potentially Explosive aspects Regulation requirement only) or equivalent document referencing the necessary information EN60079-17

Atmosphere Regulations SI ~ 2002 NO. 2776 (UK)

(UK only) for the identified hazardous areas. Documentation must include an

SI ~ 2016 NO. 1107 (UK) SR ~ 2003 NO. 152

SR ~ 2017 NO. 90 (N. IRELAND) (N. IRELAND)

effective equipment maintenance and inspection regime

Regularly review and audit the areas and systems to ensure that they remain Reg 5 No specific HSE ACOP L138

NOTE: ATEX PRODUCT DIRECTIVE 94/9/EC HAS BEEN SUPERSEDED BY NEW DIRECTIVE effective reference

2014/34/EU, THE NEW DIRECTIVE IS APPLICABLE FROM 20/4/16. RELEVANT STATUTORY Note 1: DSEAR Reg 7(4), ATEX 99/92/EC, Annex II 2.8 Prior to new plant and facilities being used for the first time, the overall explosion safety shall be verified by a competent person

INSTRUMENTS HAVE ALSO CHANGED. Note 2: DSEAR Reg 11 Article 6, where workers from several undertakings are present in same workplace, the employer responsible for that workplace must co-ordinate the health and safety measures

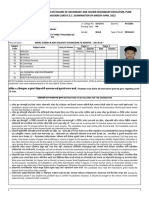

ZONES AND EQUIPMENT CATEGORIES RELEVANT STANDARDS AND GUIDANCE

Zones BROAD DEFINITIONS OF ZONES (FOR ATEX EQUIPMENT INTEGRITY AREA OF GUIDANCE STANDARD OR APPROVED CODE OF PRACTICE (ACOP)

GUIDANCE ONLY) EQUIPMENT REQUIREMENTS

Gases and Dusts CATEGORY General Guidance ACOP L138 Dangerous Substances and Explosive Atmospheres.

Vapours

DSEAR Compliance Available as free download here

0 20 Explosive atmosphere is present 1 Equipment must be safe under

continuously, for long periods or frequently normal operation, expected and rare

Hazardous area EN 60079-10-1 – Classification of hazardous areas for explosive gas atmospheres

malfunction

classification EN 60079-10-2 – Classification of areas where combustible dusts are or may be present

1 21 Explosive atmosphere is likely to occur 2 Equipment must be safe under

under normal operation, occasionally normal operation, expected

Electrical installation of EN 60079-14 Explosive atmospheres – Part 14: Electrical installations design,

malfunction

equipment selection and erection

2 22 Explosive atmosphere is unlikely to occur 3 Equipment must be safe under

in normal operation and, if it does, will normal operation Electrical equipment EN 60079-17 Explosive atmospheres – Part 17: Electrical installations inspection and

persist for a short period only inspection maintenance

EN/ISO 80079-36 Non-electrical equipment for potentially explosive atmospheres.

Non-electrical equipment

Basic method and requirements

ignition hazard assessment

Note: This standard relates to new equipment but is useful for retrospective assessment of existing equipment

ATEX CODING

© SGS United Kingdom Ltd – 2019 – All rights reserved - SGS is a registered trademark of SGS Group Management SA 5607/0419 - BAS-WS-003 - Issue 2 - May 2019

PD CLC/TR 60079-32-1: Explosive atmospheres

EU EXPLOSIVE ATMOSPHERE SYMBOL II 2GD

ATEX EQUIPMENT CATEGORY Electrostatics Part 32-1: Electrostatic hazards, guidance

EQUIPMENT GROUP (See part 32-2 for testing)

EXISTING LABEL EQUIPMENT MARKINGS NEWER EQUIPMENT LABEL MARKINGS

Protection Concept IECEx Certificate No.

Protection Concept

Gas Group Equipment Protection Levels

Gas Group IECEx Certificate No. Maximum External Surface Temperature

Temperature Class

Temperature Class under 250mm of dust

Ambient Range – 20°C to 40°C

IECEx BAS 19.1111X Ingress Protection

IECEx BAS 05.1111X unless stated on label

Maximum External Surface Temperature

Ex db eb IIC T4 Gb

Ex tb IIIC T135ºC T250 180ºC Db IP66 Ambient Range –20°C to 40°C

Ex de IIB T4 -30ºC < Ta < 50ºC unless stated on label

Tamb -30ºC to + 50ºC

Manufacturer’s Name and Address

ABC Engineering

240V ac Electrical Parameters ABC Engineering Manufacturer’s Name and Address

Buxton, SK17 9RZ, UK

5A Buxton, SK17 9RZ, UK 240V ac Electrical Parameters

Product Identification

Type XYZ Solenoid 5A

Ingress Protection Type XYZ Solenoid Product Identification

2005 s/n 1234 IP66

Serial No. and Year of Manufacture 2019 s/n 1234

II 2G II 2GD Serial No. and Year of Manufacture

ATEX Notified Body Identification No. Baseefa19ATEX1111X 1180

Baseefa05ATEX1111X 1180

ATEX Notified Body Identification No.

ATEX Coding ATEX Certificate No.

ATEX Coding ATEX Certificate No.

Dust Group

GAS GROUPS DUST GROUPS TEMPERATURE CLASS EQUIPMENT PROTECTION LEVEL INGRESS PROTECTION (IP)

GAS REPRESENTATIVE TEST DUST MAXIMUM SURFACE EQUIPMENT PROTECTION LEVEL ZONE TYPE OF PROTECTION IP RATING

T CLASS

GROUP GAS GROUP TEMPERATURE Ga 0 Hazardous area equipment typically requires a minimum IP rating of

I Methane (mining only) T1 450°C Gb 1 IP54 but may be assessed and tested to the higher ratings below:

Combustible

IIIA Gc 2 Dust Dust Protected IP5x

IIA Propane flyings T2 300°C

Da 20 Dust Tight IP6x

IIB Ethylene

T3 200°C Db 21 Water Protection against – splashing water IPx4

IIC Hydrogen Non-conductive

IIIB Dc 22 Protection against – water jets IPx5

dust T4 135°C

Ma Energized* Protection against – powered water jets IPx6

Gases are classified according to the ignitability Protection against – temporary immersion IPx7

T5 100°C Mb De-energized*

of gas-air mixture. Refer to EN 60079-20-1 for

classification of common gases and vapours. IIIC Conductive dust Protection against – continuous immersion IPx8

T6 85°C G=gas, D=dust, M=mining *in presence of explosive atmosphere

See IEC/EN 60529 for full definitions of IP ratings

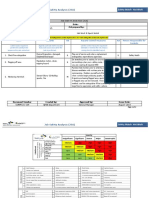

SGS BASEEFA SERVICES •• IEC 61508 certification SGS BASEEFA LIMITED tel. +44 (0)1298 766600

•• Training and technical advice

•• ATEX and IECEx equipment/component fax. +44 (0)1298 766601

•• Quality system approval •• IECEx service facility certification Rockhead Business Park,

certification e-mail: baseefa@sgs.com

•• Assistance with DSEAR •• Technical file storage Staden Lane, Buxton, SK17 9RZ

•• IECEx certificate of personnel competence (ATEX user directive) implementation www.sgs.co.uk/sgsbaseefa

•• Testing

You might also like

- Atexdsear GuideDocument1 pageAtexdsear GuidemretatasteelNo ratings yet

- Wallchart - SIRADocument1 pageWallchart - SIRAFahri AdrianNo ratings yet

- Atexor ATEX GUIDELINESDocument1 pageAtexor ATEX GUIDELINESDhiven VesNo ratings yet

- Dungs International Approvals 2012 Products A - ZDocument26 pagesDungs International Approvals 2012 Products A - ZSergej SchlegelNo ratings yet

- Avoid Damage Pipe Cable FlyerDocument2 pagesAvoid Damage Pipe Cable FlyerJack TouNo ratings yet

- Pulsioximetro VeridianDocument2 pagesPulsioximetro VeridianJuliana TorresNo ratings yet

- En 30148901v010902sDocument45 pagesEn 30148901v010902smike lassenNo ratings yet

- SGS-BASSEFA-ATEX EX Guidance-Wallchart 1-A2Document1 pageSGS-BASSEFA-ATEX EX Guidance-Wallchart 1-A2mikexanderNo ratings yet

- KC LABS LAYOUT-1 ModelDocument1 pageKC LABS LAYOUT-1 ModelManabendra SahaNo ratings yet

- Regulations: European Atex Directive International Scheme: IecexDocument5 pagesRegulations: European Atex Directive International Scheme: IecexWidiaNo ratings yet

- ATEX Explosion Protection and Gas 9044988 enDocument1 pageATEX Explosion Protection and Gas 9044988 enttkxxoqflwonqhxguqNo ratings yet

- The European Aviation Safety Agency: ConclusionDocument5 pagesThe European Aviation Safety Agency: ConclusionpannNo ratings yet

- 2022 EMC Testing GuideDocument53 pages2022 EMC Testing Guidemarcelo.lacknerNo ratings yet

- The European Standards For Roads and Railways Noise Barriers: State of The Art 2015Document6 pagesThe European Standards For Roads and Railways Noise Barriers: State of The Art 2015joe briffaNo ratings yet

- I I I Semester ElectricalDocument24 pagesI I I Semester Electricalunknowninsaan27No ratings yet

- NDT On CompositesDocument33 pagesNDT On CompositesSteven J. Selcuk100% (2)

- It600 Wiring Centre Kl08rf 028 v9Document2 pagesIt600 Wiring Centre Kl08rf 028 v9NataLeeNo ratings yet

- AE For Buried LPG TanksDocument8 pagesAE For Buried LPG TanksSaif EldinNo ratings yet

- Tar Removal With A Wet Electrostatic Precipitator (Esp) A Parametric StudyDocument8 pagesTar Removal With A Wet Electrostatic Precipitator (Esp) A Parametric StudyDeepankar KhawasNo ratings yet

- Combined Removal of From Simulated Flue Gas Using Pulsed Streamer CoronaDocument8 pagesCombined Removal of From Simulated Flue Gas Using Pulsed Streamer CoronaAyush KushwahaNo ratings yet

- Training The Aerobic Capacity of Distance Runners .5Document4 pagesTraining The Aerobic Capacity of Distance Runners .5LevyNo ratings yet

- 3D Air Shower Simulations Using CONEX in CORSIKA: Tanguy Pierog, Ralph Engel, and Dieter HeckDocument4 pages3D Air Shower Simulations Using CONEX in CORSIKA: Tanguy Pierog, Ralph Engel, and Dieter HeckOmar SiddikNo ratings yet

- FLEX B10087 00 7600 WS Atex 8S ENDocument2 pagesFLEX B10087 00 7600 WS Atex 8S ENShruthi RavichandranNo ratings yet

- Catalogue - Flame Detectors - Rezontech - ATEX FM Approved.Document4 pagesCatalogue - Flame Detectors - Rezontech - ATEX FM Approved.Altayyeb AlfaryjatNo ratings yet

- SGSCRSDS51 Non Electrical WallchartHRA2EN1602 PDFDocument1 pageSGSCRSDS51 Non Electrical WallchartHRA2EN1602 PDFEdin MujanovićNo ratings yet

- Ec Declaration of Conformity: PremanaDocument1 pageEc Declaration of Conformity: PremanaDaniel Andres Diaz EspitiaNo ratings yet

- ATEXDocument1 pageATEXmigelNo ratings yet

- ATEX GuideDocument44 pagesATEX GuideAbhijitNo ratings yet

- EME2 Pavement and Mix DesignDocument13 pagesEME2 Pavement and Mix DesignЯн ПыригNo ratings yet

- ATEX and IEC Standards For Intrinsically Safe Load Cells For Hazardous AreasDocument4 pagesATEX and IEC Standards For Intrinsically Safe Load Cells For Hazardous AreasArafat Lomangcolob BauntoNo ratings yet

- IV Semester ElectricalDocument30 pagesIV Semester ElectricalSpectre ZeroNo ratings yet

- Teos Plus+2017 CRPDocument26 pagesTeos Plus+2017 CRParya_85No ratings yet

- Valencia Anchor StationDocument1 pageValencia Anchor StationErnesto Lopez BaezaNo ratings yet

- Spie2008 ADC PosterDocument1 pageSpie2008 ADC PostergastromonoNo ratings yet

- Irish Standard: I.S. EN 60942:2003Document20 pagesIrish Standard: I.S. EN 60942:2003Gustavo AguirreNo ratings yet

- Product - Gallery - 2019 05 31 - 14 56 001Document82 pagesProduct - Gallery - 2019 05 31 - 14 56 001chellaliNo ratings yet

- Eraspec Bro en WebDocument6 pagesEraspec Bro en WebDavcons ConsultoresNo ratings yet

- ZP00960 GB 1Document116 pagesZP00960 GB 1al bauerNo ratings yet

- Eldada 1992Document7 pagesEldada 1992Miles FernsbyNo ratings yet

- Wolf Safety Lamp Company - Atex Explained Leaflet Issue March 2018Document1 pageWolf Safety Lamp Company - Atex Explained Leaflet Issue March 2018Dhrubajyoti BoraNo ratings yet

- PHOTOMETER DustTrak DRX Theory of OperationDocument4 pagesPHOTOMETER DustTrak DRX Theory of OperationSebastian Lar. 【ViolinxBass】No ratings yet

- WH - Fire ProDocument2 pagesWH - Fire ProBerlin Andrew SionNo ratings yet

- CSA Group Hazloc GuideDocument1 pageCSA Group Hazloc GuideMátyás DalnokiNo ratings yet

- DFINITI Electric Heater BrochureDocument12 pagesDFINITI Electric Heater BrochurePillai S KumarNo ratings yet

- Electrostatic PrecipitatorDocument47 pagesElectrostatic PrecipitatorarisNo ratings yet

- MP Birla Group: Training MatrixDocument3 pagesMP Birla Group: Training MatrixAprilia kusumaNo ratings yet

- 1 s2.0 S1875389210005262 MainDocument8 pages1 s2.0 S1875389210005262 MainsoroushNo ratings yet

- Adulteration Detection Using SoundDocument7 pagesAdulteration Detection Using SoundManoj KavediaNo ratings yet

- Basic AerodynamicsDocument57 pagesBasic Aerodynamicsmuhammad al afiqNo ratings yet

- 028 Ece 2 SemDocument181 pages028 Ece 2 SemKailash BishtNo ratings yet

- Te1fu MetricDocument1 pageTe1fu MetricTareq JildehNo ratings yet

- Angew Chem Int Ed - 2013 - S NzeDocument4 pagesAngew Chem Int Ed - 2013 - S NzeMCG GroupNo ratings yet

- Laser Mass Spectrometry For Environmental and Industrial Chemical Trace AnalysisDocument16 pagesLaser Mass Spectrometry For Environmental and Industrial Chemical Trace AnalysisTamara WahidNo ratings yet

- Ultrasonic Measurements of Solid Propellant Burning Rates in Nozzleless Rocket MotorsDocument8 pagesUltrasonic Measurements of Solid Propellant Burning Rates in Nozzleless Rocket MotorsSharat ChandraNo ratings yet

- 1q04 New Packaging SensorsDocument5 pages1q04 New Packaging SensorsscribdkhatnNo ratings yet

- A1 Iter DivertorDocument1 pageA1 Iter DivertorVirak BaglioneNo ratings yet

- WolfH251AiiUsersManual477599 1095170146Document1 pageWolfH251AiiUsersManual477599 1095170146omidNo ratings yet

- Modular TAA00000RS-exp 2027 12 26Document3 pagesModular TAA00000RS-exp 2027 12 26mikexanderNo ratings yet

- 6EP13333BA10 Datasheet enDocument5 pages6EP13333BA10 Datasheet enmikexanderNo ratings yet

- SGS-BASSEFA-ATEX EX Guidance-Wallchart 1-A2Document1 pageSGS-BASSEFA-ATEX EX Guidance-Wallchart 1-A2mikexanderNo ratings yet

- Arc Flash Risk ManagementDocument20 pagesArc Flash Risk ManagementmikexanderNo ratings yet

- ELEC1008: Digital Circuits and Microprocessors: Answers To Assignment ..........Document2 pagesELEC1008: Digital Circuits and Microprocessors: Answers To Assignment ..........mikexanderNo ratings yet

- Computing and CAD: Professor Jan SykulskiDocument74 pagesComputing and CAD: Professor Jan SykulskimikexanderNo ratings yet

- Case Study 5 Dengue Fever CorrectedDocument11 pagesCase Study 5 Dengue Fever CorrectedApril Marie MolenoNo ratings yet

- Urinary CatheterizattionDocument85 pagesUrinary Catheterizattionbajaoc100% (6)

- Safety Officer: Curriculam Viate Shahid HussainDocument3 pagesSafety Officer: Curriculam Viate Shahid HussainabdullahNo ratings yet

- Ineffective Breathing PatternDocument1 pageIneffective Breathing Patternimneverwrong249280% (5)

- EVALUATE Match Each Subfield of Psychology With The Issues or Questions Posed BelowDocument2 pagesEVALUATE Match Each Subfield of Psychology With The Issues or Questions Posed BelowAlexandra TorresNo ratings yet

- Definition and Concept Art 774. Succession Is A Mode of Acquisition byDocument39 pagesDefinition and Concept Art 774. Succession Is A Mode of Acquisition byFrancis Kyle Cagalingan SubidoNo ratings yet

- Chair Based Exercises For Older AdultsDocument38 pagesChair Based Exercises For Older AdultsPascha ParamurthiNo ratings yet

- Florendo vs. Philam Plans, Inc., G.R. No. 186993, 2012Document5 pagesFlorendo vs. Philam Plans, Inc., G.R. No. 186993, 2012ChiiBiiNo ratings yet

- Skinner & Piek 2001 PDFDocument22 pagesSkinner & Piek 2001 PDFCharitini PetridouNo ratings yet

- UNKNOWNDocument13 pagesUNKNOWNnhayrahdicunugunNo ratings yet

- Dela Rosa 2A MCN-Module 04Document4 pagesDela Rosa 2A MCN-Module 04Atsu MiyaNo ratings yet

- Methodological Issues and Strategies in Clinical RDocument2 pagesMethodological Issues and Strategies in Clinical RAndres CajamarcaNo ratings yet

- Concept Map f21 FinishedDocument5 pagesConcept Map f21 Finishedapi-601070065No ratings yet

- What Is An Intravenous Pyelogram (IVP) ?: X-Ray Ureters Bladder Contrast MaterialDocument6 pagesWhat Is An Intravenous Pyelogram (IVP) ?: X-Ray Ureters Bladder Contrast MaterialVirgz PalNo ratings yet

- Theories of Motivation Worksheet!: (Answers!)Document2 pagesTheories of Motivation Worksheet!: (Answers!)Evanisse Ramirez-CedenoNo ratings yet

- Social Work Dissertation Examples UkDocument6 pagesSocial Work Dissertation Examples UkWriteMyPaperApaFormatToledo100% (1)

- Mental Health Problems in College FreshmenDocument28 pagesMental Health Problems in College FreshmenPhillip MendozaNo ratings yet

- SafeStayGuidelinesV11 0803022 0Document11 pagesSafeStayGuidelinesV11 0803022 0Bibin RajNo ratings yet

- Maharashtra State Board of Secondary and Higher Secondary Education, Pune Admission Card H.S.C. Examination of March-April 2022Document3 pagesMaharashtra State Board of Secondary and Higher Secondary Education, Pune Admission Card H.S.C. Examination of March-April 2022PANKAJ WANDHARENo ratings yet

- JSA-020-Safety Watch-Hot WorkDocument2 pagesJSA-020-Safety Watch-Hot WorkNishad MuhammedNo ratings yet

- Lesson 2-Technology As A Way of RevealingDocument2 pagesLesson 2-Technology As A Way of RevealingJemalyn Hinggo100% (1)

- Wickford Meats Sanitation Standard Operating Procedure (SSOP)Document11 pagesWickford Meats Sanitation Standard Operating Procedure (SSOP)yoiber jimenezNo ratings yet

- The Gender Variant Phenomenon: A Developmental ReviewDocument9 pagesThe Gender Variant Phenomenon: A Developmental ReviewDeadWitnessNo ratings yet

- Cues Nursing Diagnosis Background Knowledge Goal and Objective Nursing Interventions & Rationale EvaluationDocument4 pagesCues Nursing Diagnosis Background Knowledge Goal and Objective Nursing Interventions & Rationale Evaluationtherese BNo ratings yet

- PQS E08-E013 Manufacturer Guide1.4Document23 pagesPQS E08-E013 Manufacturer Guide1.4saberNo ratings yet

- Facebook and YouTube Addiction The Usage Pattern of Malaysian StudentsDocument6 pagesFacebook and YouTube Addiction The Usage Pattern of Malaysian StudentsReyNo ratings yet

- VENUS An Edu Erotic MagazineDocument34 pagesVENUS An Edu Erotic MagazineEfe MenaNo ratings yet

- Session 9 Interpersonal Relationships - FIRO BDocument9 pagesSession 9 Interpersonal Relationships - FIRO BPuneet Singh DhaniNo ratings yet

- MSDS UreaDocument4 pagesMSDS UreaSharjeel AhmedNo ratings yet

- BIBLIOGRAPHYDocument5 pagesBIBLIOGRAPHYmongzkieNo ratings yet