Professional Documents

Culture Documents

SIRA Ex Poster ATEX and DSEAR compliance services

Uploaded by

Fahri AdrianOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SIRA Ex Poster ATEX and DSEAR compliance services

Uploaded by

Fahri AdrianCopyright:

Available Formats

SIRA Ex Poster.

qxd 20/12/04 9:36 am Page 1

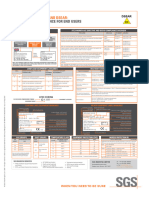

ATEX DIRECTIVE DSEAR COMPLIANCE SERVICES

Sira can certify your Ex products How safe is your workplace?

that comply with the ATEX Directive Are you meeting the new health & safety regulations?

and can also provide: Sira offers the full range of services that you might

need to comply with the Dangerous Substances &

Pre-Compliance Testing Explosive Atmosphere Regulations (DSEAR), namely:

Ex QA Certification Risk Assessment

Area Classification

IECEx Approval Inspection of Installed Equipment

ATEX 137 Directive

Hazardous Area Services

ATEX 95 Compliance with World-wide Preparation of Risk Assessment Records

Training

Directive 94/9/EC

Standards 99/92/EC & DSEAR

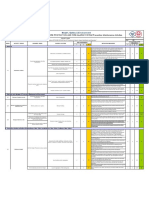

Sira can provide a range of compliance services which are PROTECTION CONCEPTS

TYPICAL EQUIPMENT MARKING tailored to meet your needs and which incorporate both

commercial and legislative issues.

Protection concept Symbol Typical CENELEC Basic concept

Electrical code used on zone(s) Standard of protection

ATEX Directive

Sira certificates

DSEAR Compliance Services

Name and address of Increased safety 3 e 1&2 EN 50019 No arcs, sparks

manufacturer Gas Group and T Class Type ‘n’ (Non-sparking) 4 nA 2 EN 50021 or hot surfaces

Training Flameproof 1 d 1&2 EN 50018 Contain the

IEC 61508 Functional Safety Systems

CE marking and number Type ‘n’ (Enclosed break) 4 nC 2 EN 50021 explosion,

of notified body Quartz/sand filled 7 q 1&2 EN 50017 quench the flame

responsible for Protection Concept

Intrinsic safety

} 2 ia 0, 1 & 2 EN 50020/39 Limit the energy

Sira Safety Compliance

production Intrinsically safe 2 ib 1&2 EN 50020/39 of sparks and

Type ‘n’ (Energy limitation) 4 nL 2 EN 50021 surface temperatures

Hazardous Area Centre

Ambient Temperature

Rake Lane, Eccleston

Series or type Pressurised 1 p 1&2 EN 50016 Keep the

(-20˚C to +40˚C if not Type ‘n’ (Restricted breathing) 4 nR 2 EN 50021 flammable

designation

Chester, CH4 9JN, England

marked) Type ‘n’ (Simple pressurised) 4 nP 2 EN50021 gas out

Encapsulation 5 m 1&2 EN 50028

Oil immersion 7 o 1&2 EN 50015

Specific marking of

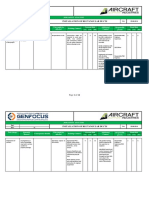

explosive protection Tel: +44 (0) 1244 670 900 Fax: +44 (0) 1244 681 330 Protection concept Symbol Typical CENELEC Basic concept

exhazard@sira.co.uk

Certificate number Non-electrical code used on zone(s) Standard of protection

www.siraservices.com

Sira certificates (*status at April 2004)

Type of explosive atmosphere

Equipment Group G - gases, vapours or mists Year of manufacture and Flow restricted enclosure 6 fr 2 prEN 13463-2* Relies on tight seals of the

serial number enclosure to restrict the

and Category D - dust Other essential information breathing of the enclosure

Flameproof enclosure 6 d 1&2 prEN 13463-3* Relies on closely matched

joints and tough enclosure

COMPLIANCE ROUTES AND EQUIPMENT SELECTION TRAINING

Inherent safety 6 g 0, 1 & 2 prEN 13463-4* Low potential energy

Zone Area Classification

Equipment

Category

Relevant ATEX Annexes

for Compliance Group Hazardous Area Characteristics Sira can offer a variety of comprehensive Constructional safety 6 c 0, 1 & 2 EN 13463-5 Ignition hazards eliminated by

Gas Dust NEC 505 NEC500 specification of the equipment

training courses or technical sessions

0 20 1 III and IV or V Present continuously or long periods or frequently (>1000 hours/year) Zone 0

targeted to meet the needs of the Control of ignition sources 6 b 0, 1 & 2 prEN 13463-6* Control equipment fitted to

1 21 2* III and VII or VI Likely to occur in normal operation occasionally (>10 <1000 hours/year) Zone 1 Division 1 detect malfunctions

II

manufacturer, integrator or user:

2** VIII# Pressurisation 6 p 1&2 prEN 13463-7* Enclosure purged and

● ATEX Product Directive pressurised

2 22 3 VIII Not likely to occur in normal operation or infrequently and for Zone 2 Division 2

short periods (<10 hours/year) ● DSEAR Incorporating Area Classification Liquid immersion 6 k 0, 1 & 2 EN 13463-8 Enclosure uses liquid to

M1 III and IV or V Explosive atmosphere present – equipment remains energised * Electrical equipment and internal ● Machinery, Marine, EMC and Pressure restrict ex atmosphere contact

combustion engines only Directives

Mining M2* III and VII or VI I Explosive atmosphere present – equipment de-energised ** Non-electrical equipment only ● IECEx International Certification

# and communicate the technical file APPARATUS GROUPS & TEMPERATURE CLASSES FOR

M2** VIII# ● Functional Safety and IEC 61508

to a notified body COMMON FLAMMABLE MATERIALS

≠ Alternative Route for any product ● Quality Assurance Modules for

Any Any IX≠ Any –

● Hazardous Area Equipment Gas/Vapour Apparatus Temperature Dusts Typical Ignition Temperature (˚C)

● Self Certification group class Cloud Layer

D O C U M E N TAT I O N S U P P O RT I N G C O M P L I A N C E WHEN IS DIRECTIVE 94/9/EC APPLICABLE? ● Legislation Requirements

Aluminium 590 >450

Acetic Acid llA T1

Annex Description Evidence of Compliance # All courses can be tailored to your own needs Coal dust (lignite) 380 225

Situation Analysis Result Acetone llA T1

and can be delivered at your own site Flour 490 340

III EC Type-Examination EC Type-Examination Certificate Acetylene llC T2 Grain dust 510 300

Equipment with Equipment to be Equipment where Equipment within

IV Production QA Quality Assurance Notification with relevant scope Own Potential used in or in an Intended Scope of Directive Call Sira Training on +44(0) 1244 670 900 Ammonia llA T1 Methyl cellulose 420 320

Source of Ignition Relation to Internal Explosive 94/9/EC Butane llA T2 Phenolic resin 530 >450

V Product Verification Certificate of Conformity listing serial number of product Potentially Explosive Atmosphere is

Atmosphere Present Cyclohexane llA T3 Polythene 420 (melts)

VI Conformity to Type Conformity to Type Notification with relevant scope Ethanol (ethyl alcohol) llA T2 PVC 700 >450

VII Product QA Quality Assurance Notification with relevant scope

IEC 61508 FUNCTIONAL Ethylene llB T2 Soot 810 570

A YES YES YES YES

VIII Internal Control of Production Manufacturer’s Statement

SAFETY SYSTEMS Hydrogen llC T1 Starch

Sugar

460

490

435

460

B NO YES YES NOa)b) Kerosene llA T3

IX Unit Verification Certificate of Conformity listing serial number of product IEC 61508 covers functional safety and constitutes good practice Methane (natural gas) (non-mining) llA T1

# Apart from Declaration of Conformity which is supplied with each piece of equipment C YES NO YES NO a)b) for safety systems whose failure can impact on the safety of Methanol (methyl alcohol)

Methyl ethyl ketone (MEK)

llA

llB

T2

T2

T E M P E R AT U R E C L A S S

persons and the environment.

D YES YES NO YES Propane llA T1 (GROUP II)

AT E X C AT E G O RY 2 ( N O N E L E C T R I C A L )

S I R A C E RT I F I C AT E N U M B E R PRODUCTS SUBMISSION OF TECHNICAL Sira offers a range of functional safety Propan-1-ol (n-propyl alcohol) llB T2 Maximum T. Codes

D O C U M E N TAT I O N E NO NO YES NO a)b) services which include: Propan-2-ol (iso-propyl alcohol) llA T2 surface

SIRA 05 ATEX 1 1234 Under the ATEX Directive, manufacturers of Tetrahydrofuran (THF) llB T3 temperature CENELEC IEC

category 2 or 3 non-electrical products must follow F YES NO NO NO b) ● Certifying the overall Competence of a Toluene llA T1

the Conformity Assessment Procedures (Article 8). Company (Functional Safety Capability Xylene llA T1 450˚C T1

Serial number Annex VIII (Internal Control of Production) requires the

manufacturer to prepare ‘Technical Documentation’ G NO YES NO NO b) Assessment) 300˚C T2

Protection concept code including ● Assessing the Competency of Individual 200˚C T3

Reference to ATEX 100a directive

● General Description of the

H NO NO NO NOb) Personnel INGRESS PROTECTION CODE (IP) 135˚C T4

Year of certification ● Product Certification

Product

can provide

100˚C T5

Name of notified body performing EC-type examination ● Conceptual Design and a) but YES for products inside the internal potentially explosive atmosphere. ● Training and Consultancy in all areas of Sira can offer a full range of testing services,

Manufacturing Drawings Storage of Technical Files Moreover it has to be considered that the equipment as a whole has to be capable

85˚C T6

Functional Safety

● A List of Standards Applied Review of Files of functioning in conformity with the operational parameters established by the including Ingress Protection (IP) Testing.

Suffixes: ● Test Reports Assistance in production manufacturer and ensuring the required level of protection according to Annex II, N.B. For Group I applications apparatus

U – component certification ● Ignition Hazard Assessment of the Ignition Hazard Item I.0.I (Principles of integrated explosion safety) Sira is accredited by UKAS for the FSCA Please request an application form via email has rigid 150˚C and 450˚C limits rather

Assessment

X – special conditions for safe use apply aspects or on our website.

Training b) but YES for devices according to Article 1.2 of the directive than ‘T’ classes.

For more information visit the sira website – www.siraservices.com or www.sira.co.uk – email: exhazard@sira.co.uk – tel: +44(0) 1244 670 900 Issue 2 January 2005

You might also like

- Hazardous Area Management: Complying With The ATEX DirectivesDocument4 pagesHazardous Area Management: Complying With The ATEX DirectivesEra SutrajayaNo ratings yet

- CSA Group WallchartDocument1 pageCSA Group WallcharttuNo ratings yet

- ATEX ComplianceDocument2 pagesATEX ComplianceEfari BahchevanNo ratings yet

- Hazardous Locations: Guide To Equipment Certification Requirements ForDocument1 pageHazardous Locations: Guide To Equipment Certification Requirements ForVishnu LalNo ratings yet

- Health, Safety & Environment: Risk Assessment For FIRE PROTECTION AND FIRE ALARM SYSTEM Preventive Maintenance ActivitiesDocument2 pagesHealth, Safety & Environment: Risk Assessment For FIRE PROTECTION AND FIRE ALARM SYSTEM Preventive Maintenance Activitiesbelhareth seifeddineNo ratings yet

- DFINITI Electric Heater BrochureDocument12 pagesDFINITI Electric Heater BrochurePillai S KumarNo ratings yet

- Introduction To Explosion Protection and Certification A4 EN 18 04Document8 pagesIntroduction To Explosion Protection and Certification A4 EN 18 04Mohd RezalNo ratings yet

- DEKRA Process Safety Experts for Risk Management and Safety ComplianceDocument8 pagesDEKRA Process Safety Experts for Risk Management and Safety ComplianceNishir Shah100% (1)

- Eaton's MTL product range and the ATEX directive explainedDocument1 pageEaton's MTL product range and the ATEX directive explainedscribdkhatnNo ratings yet

- B9018 EP TestingDocument5 pagesB9018 EP TestingMan Ga PeNo ratings yet

- New 2.hirac Matrix For ExerciseDocument9 pagesNew 2.hirac Matrix For Exercisejrchshn26No ratings yet

- Risk Assessment For Installation of Diesel Generator111111Document8 pagesRisk Assessment For Installation of Diesel Generator111111Baher Mohamed100% (1)

- Hse Induction ChecklistDocument1 pageHse Induction ChecklistSubbu AbuNo ratings yet

- JSA Template for Mechanical Piping WorkDocument10 pagesJSA Template for Mechanical Piping WorkYou1993100% (2)

- What Are The Safety Critical Elements - Ammonia Know HowDocument6 pagesWhat Are The Safety Critical Elements - Ammonia Know HowSARFRAZ ALINo ratings yet

- R1937-JSA-006 Job Safety Analysis For Material Transfer - RiggingDocument3 pagesR1937-JSA-006 Job Safety Analysis For Material Transfer - RiggingVineet Agrawal100% (1)

- 2017-06 Advance HSE Products and ServicesDocument4 pages2017-06 Advance HSE Products and ServicesAyatNo ratings yet

- HSE Inspection FormatDocument4 pagesHSE Inspection FormatAbhishek RajaNo ratings yet

- Conformity Assessment For Non-Electrical ATEX and IECEx Products - A Practical GuideDocument14 pagesConformity Assessment For Non-Electrical ATEX and IECEx Products - A Practical GuidepbaldinoNo ratings yet

- Fire prevention system sequence of operationDocument1 pageFire prevention system sequence of operationmuthazirNo ratings yet

- AERB safety code for radiation therapyDocument90 pagesAERB safety code for radiation therapyGopakumarNo ratings yet

- Installation of Rectangular DuctsDocument14 pagesInstallation of Rectangular DuctsAnandu AshokanNo ratings yet

- Management OF Radioactive WasteDocument54 pagesManagement OF Radioactive WasteSuresh KumarNo ratings yet

- Jesa-Construction of Chemical Storage Shelter For CPP RegenDocument28 pagesJesa-Construction of Chemical Storage Shelter For CPP RegenResearcherNo ratings yet

- Radiography Work 004Document6 pagesRadiography Work 004BinayNo ratings yet

- COPC V9 Final PDFDocument2 pagesCOPC V9 Final PDFMohd Ismail YusofNo ratings yet

- Hazard AreaDocument2 pagesHazard Areamohamed abourayaNo ratings yet

- Risk Assessment - Confined SpaceDocument2 pagesRisk Assessment - Confined SpaceIndermohan MehtaNo ratings yet

- Aerb DX 2016Document52 pagesAerb DX 2016hiteshNo ratings yet

- Risk Assessment: Site Facilities Larsen & Toubro Limited PT&D (I) (Africa)Document4 pagesRisk Assessment: Site Facilities Larsen & Toubro Limited PT&D (I) (Africa)Naveen GladsonNo ratings yet

- SGS-BASSEFA-ATEX EX Guidance-Wallchart 3-A2Document1 pageSGS-BASSEFA-ATEX EX Guidance-Wallchart 3-A2mikexanderNo ratings yet

- Safesite Corporate Brochure and O&M ManualDocument98 pagesSafesite Corporate Brochure and O&M ManualIbrahim SahinNo ratings yet

- Guide on Predisposal Management of Low and Intermediate Level Radioactive WasteDocument53 pagesGuide on Predisposal Management of Low and Intermediate Level Radioactive WasteAnuj DeoNo ratings yet

- IECEx-Brochure-System-SOCIAL MEDIADocument8 pagesIECEx-Brochure-System-SOCIAL MEDIAPetrus Amid SimanungkalitNo ratings yet

- Risk Assessment (RA) : Part 1: Location DetailsDocument3 pagesRisk Assessment (RA) : Part 1: Location DetailsPandu BirumakovelaNo ratings yet

- Sheikh Jaber Causeway Subcontract No.: KUSC-SC-S-0600: Activity/Task: Installation of Cable TrayDocument7 pagesSheikh Jaber Causeway Subcontract No.: KUSC-SC-S-0600: Activity/Task: Installation of Cable Traywaseem kausarNo ratings yet

- JOB ANALISYS SAFETY All WorkDocument11 pagesJOB ANALISYS SAFETY All WorkMansur SaifudinNo ratings yet

- ATEX Explosion Protection and Gas 9044988 enDocument1 pageATEX Explosion Protection and Gas 9044988 enttkxxoqflwonqhxguqNo ratings yet

- Ledw0020 03Document9 pagesLedw0020 03Serban StefanNo ratings yet

- 3-RA Cement PlasteringDocument5 pages3-RA Cement Plasteringhsem Al EimaraNo ratings yet

- QATAR Legal & Other Requirements Evaluation and Compliance Register TemplatesDocument3 pagesQATAR Legal & Other Requirements Evaluation and Compliance Register TemplatesRevaugh BierNo ratings yet

- Jesa FGDDocument26 pagesJesa FGDResearcherNo ratings yet

- Ss-Cse - Civil Engineering StructuresDocument61 pagesSs-Cse - Civil Engineering Structuresdebabrata duttaNo ratings yet

- Appendix 2 - INTRINSIC SAFETY ATEX DIRECTIVESDocument11 pagesAppendix 2 - INTRINSIC SAFETY ATEX DIRECTIVESTaktakWalidNo ratings yet

- Jesa-Scaffolding WorksDocument17 pagesJesa-Scaffolding WorksJoyce GordonioNo ratings yet

- Moving and Installing Toilets SafelyDocument4 pagesMoving and Installing Toilets SafelyHammamNurKholisNo ratings yet

- Lase Align Ex - Laser AllignmentDocument12 pagesLase Align Ex - Laser Allignmentazayfathir100% (1)

- Fire Rated Ductwork - Available Options Comparison Summary ConclusionDocument1 pageFire Rated Ductwork - Available Options Comparison Summary ConclusionHazem AbdelmonemNo ratings yet

- Catalogue - Bertin - Complet - NHP - Eng WebDocument40 pagesCatalogue - Bertin - Complet - NHP - Eng WebWELLINGTON VASCONCELOSNo ratings yet

- CSA Group Hazloc GuideDocument1 pageCSA Group Hazloc GuideMátyás DalnokiNo ratings yet

- Gas Welding Risk AssessmentDocument8 pagesGas Welding Risk AssessmentvictorNo ratings yet

- 3 - RA FF System InstallationDocument6 pages3 - RA FF System Installationhsem Al EimaraNo ratings yet

- Predisposal Management OF High Level Radioactive Waste: Aerb Safety GuideDocument45 pagesPredisposal Management OF High Level Radioactive Waste: Aerb Safety GuideAnuj DeoNo ratings yet

- TRA 003-010 (1) - RemovedDocument7 pagesTRA 003-010 (1) - RemovedrashidNo ratings yet

- Co EXDocument2 pagesCo EXPeter BridgeNo ratings yet

- Catalogue - Flame Detectors - Rezontech - ATEX FM Approved.Document4 pagesCatalogue - Flame Detectors - Rezontech - ATEX FM Approved.Altayyeb AlfaryjatNo ratings yet

- Hazard Impact Risk Assessment For InstallationDocument20 pagesHazard Impact Risk Assessment For InstallationUsama TariqNo ratings yet

- Hazard Identification, Risk Assessment and Risk Control FormDocument1 pageHazard Identification, Risk Assessment and Risk Control Formusman4428No ratings yet

- CTRA-22-STM-133-TK-11-995 - CS-Cleaning-1st ENTRYDocument3 pagesCTRA-22-STM-133-TK-11-995 - CS-Cleaning-1st ENTRYMohamed RizwanNo ratings yet

- Overlord, Vol. 1 - The Undead King PDFDocument237 pagesOverlord, Vol. 1 - The Undead King PDFbobNo ratings yet

- Amendment TOR Proyek EPC Terminal Regasifikasi LNG Cilacap RevDocument8 pagesAmendment TOR Proyek EPC Terminal Regasifikasi LNG Cilacap RevFahri AdrianNo ratings yet

- Application Notes AC-output Vs DC-outputDocument1 pageApplication Notes AC-output Vs DC-outputFahri AdrianNo ratings yet

- Cfeea Energy Specialist ManualDocument4 pagesCfeea Energy Specialist ManualFahri AdrianNo ratings yet

- Application Notes Dual System SetupDocument1 pageApplication Notes Dual System SetupFahri AdrianNo ratings yet

- Lightning Protection of Electronic Data Processing SystemsDocument4 pagesLightning Protection of Electronic Data Processing SystemsFahri AdrianNo ratings yet

- The Lightning Protection International Standard - PaperDocument6 pagesThe Lightning Protection International Standard - PaperFahri AdrianNo ratings yet

- Lightning SafetyDocument1 pageLightning Safetysalekojic5332No ratings yet

- Enclosed Vs Clad Job Aid UpdatedDocument1 pageEnclosed Vs Clad Job Aid UpdatedFahri AdrianNo ratings yet

- New Zealand Fire Service Fire Alarm Monitoring System AgreemDocument5 pagesNew Zealand Fire Service Fire Alarm Monitoring System AgreemJohn simpsonNo ratings yet

- DEHN Spark - Gap CHARACTERISTICS PDFDocument81 pagesDEHN Spark - Gap CHARACTERISTICS PDFggrapsas100% (1)

- What Is A Lightning ArresterDocument20 pagesWhat Is A Lightning ArresterFahri AdrianNo ratings yet

- RFPsloped CeilingsDocument2 pagesRFPsloped CeilingsFahri AdrianNo ratings yet

- Standards For Contractors Fire Alarm and Associted Control SDocument6 pagesStandards For Contractors Fire Alarm and Associted Control SJohn simpsonNo ratings yet

- Virginia Polytechnic Institute and State University ResidencDocument3 pagesVirginia Polytechnic Institute and State University ResidencJohn simpsonNo ratings yet

- System Basis 4.1 GeneralDocument2 pagesSystem Basis 4.1 GeneralFahri AdrianNo ratings yet

- Name of Protected Property Address - Representative of Protected Property (Name/phone) Authority Having Jurisdiction Address/telephone NumberDocument5 pagesName of Protected Property Address - Representative of Protected Property (Name/phone) Authority Having Jurisdiction Address/telephone NumberFahri AdrianNo ratings yet

- Addressable Loop Powered Interface ModulesDocument1 pageAddressable Loop Powered Interface ModulesFahri AdrianNo ratings yet

- KFC Hero Archetype ProjectDocument3 pagesKFC Hero Archetype ProjectFatima AsimNo ratings yet

- Spain Resizes Clothes For WomenDocument2 pagesSpain Resizes Clothes For WomenMaría Lozano GarcíaNo ratings yet

- Chemical Reactor Analysis and DesignDocument5 pagesChemical Reactor Analysis and DesignCarlos Jose Vilca AlarconNo ratings yet

- Sample Citation For Plaques and CertificatesDocument3 pagesSample Citation For Plaques and CertificatesJenifer MangalusNo ratings yet

- Formative Parenting: Cultivating Character in ChildrenDocument2 pagesFormative Parenting: Cultivating Character in ChildrenAlex BongNo ratings yet

- Math 25 Course GuideDocument5 pagesMath 25 Course GuideLyka Jane De Guzman100% (2)

- Lopez, Azzia-Stem-IngenuityDocument30 pagesLopez, Azzia-Stem-IngenuityALLIA LOPEZNo ratings yet

- My Professional PhilosophyDocument2 pagesMy Professional Philosophyapi-351301989No ratings yet

- CERTIFICATESDocument12 pagesCERTIFICATESRhoda Mae DelaCruz YpulongNo ratings yet

- Isulan National High SchoolDocument2 pagesIsulan National High SchoolAlodie Dela Raiz AsuncionNo ratings yet

- Cycle 5 - Arch. in Indian ContextDocument77 pagesCycle 5 - Arch. in Indian ContextHAREVISWAN R (RA1911201010031)No ratings yet

- Doctor in the House Exam AnalysisDocument1 pageDoctor in the House Exam AnalysisAbdel MalekNo ratings yet

- Null and Alternative Hypothesis: I. ObjectivesDocument5 pagesNull and Alternative Hypothesis: I. ObjectivesJohn ClausNo ratings yet

- Gaya Kepemimpinan dan Kepuasan Kerja Kinerja Pegawai PerumahanDocument17 pagesGaya Kepemimpinan dan Kepuasan Kerja Kinerja Pegawai PerumahanBurhannudin, S.E., M.M.No ratings yet

- EPT Tir 1401 FastZabanDocument19 pagesEPT Tir 1401 FastZabandigitalmediaarbNo ratings yet

- Sci Lesson 17Document42 pagesSci Lesson 17syniemontillaNo ratings yet

- INT2-004 - Comparative MGT - Admin.Document7 pagesINT2-004 - Comparative MGT - Admin.Tega NesirosanNo ratings yet

- 4 1 e A SoftwaremodelingintroductionvideoDocument7 pages4 1 e A Softwaremodelingintroductionvideoapi-291536844No ratings yet

- Curriculum ReformDocument27 pagesCurriculum ReformGamas Pura JoseNo ratings yet

- Tna Gad PDFDocument5 pagesTna Gad PDFjoesuaNo ratings yet

- P.E and Health WHLP G12 Q1 Week 1 and 2Document2 pagesP.E and Health WHLP G12 Q1 Week 1 and 2Brad DradNo ratings yet

- MG University B Tech (Scheme & Syllabi) 2002-2003Document562 pagesMG University B Tech (Scheme & Syllabi) 2002-2003hotchapgopu50% (4)

- Advanced Negotiation Skills - Course OutlineDocument9 pagesAdvanced Negotiation Skills - Course OutlineClutch And FlywheelNo ratings yet

- United States Patent: Sharma Et Al. (10) Patent N0.: (45) Date of PatentDocument18 pagesUnited States Patent: Sharma Et Al. (10) Patent N0.: (45) Date of Patentdavid19775891No ratings yet

- Teaching/learning ModelsDocument12 pagesTeaching/learning ModelsEka Wahyudi Al- Madina100% (2)

- Teacher's Lesson Plan for Teaching YogamayaDocument20 pagesTeacher's Lesson Plan for Teaching YogamayaShree Krishna DahalNo ratings yet

- Doctorate Regulations 2020: of The University of AmsterdamDocument40 pagesDoctorate Regulations 2020: of The University of AmsterdamkosakatasdNo ratings yet

- Self StudyDocument33 pagesSelf StudySalim DanielaNo ratings yet

- Module 1 Week 7 &8Document33 pagesModule 1 Week 7 &8Desiree AmodiaNo ratings yet

- 1 Questionnaire-Voting BehaviorDocument2 pages1 Questionnaire-Voting BehaviorAriful Islam69% (16)