Professional Documents

Culture Documents

Petsoc 97 06 Das

Uploaded by

dirie MahamoudOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Petsoc 97 06 Das

Uploaded by

dirie MahamoudCopyright:

Available Formats

T/article-pdf/doi/10.2118/97-06-DAS/2170228/petsoc-97-06-das.

pdf/1 by King Fahd University of Petroleum &

IS THERE LIFE AFTER SAGD?

S.M. FAROUQ-ALI

this article begins on the next page F

Is There Life After Sagd? S.M. Farouq-Ali is professor of petroleum engineering at the University of Alberta since 1979. Prior to this he served at The Pennsylvania State University for 20 years. He has a B.Sc. degree in electrical engineering from Karachi University, A B.Sc. (Honours) degree in petroleum engineering from Birmingham University, and M.S. and Ph.D. degrees in petroleum and natural gas engineering from The Pennsylvania State University. He has authored over 400 papers and two books, and has supervised over 200 graduate theses on oil recovery and numerical simulation. He serves

as consultant to oil companies in Canada, U.S.A., and other countries. The answer depends on what you call -Steam-assisted Gravity Drainage+ or SAGD. In its original, pristine form, it may be the ne plus ultra of the entire repertoire of the EOR methods. In the current usage, just about any field project involving steam injection and a horizontal well, or two, is called -SAGD.+ Furthermore, from the published literature one gets the impression that the application of SAGD is more the rule than the exception. This would naturally lead to misapplications of the SAGD process, with less than

optimal results. Our purpose in this article is to show what the original concept is, what additional factors may distort it, and what are some of the limitations of the process as applied. We will not discuss variations of SAGD, such as Enhanced SAGD and Single Well SAGD. Gravity flow and segregation are an integral part of all oil recovery processes. The role of gravity in steam injection processes was first recognized by Doscher(1) for California reservoirs, typically depleted (~0.5 MPa), with high vertical permeability and gas saturations at the top. Recently, Vogel(2) provided a lucid

comparison of drive and gravity, in the context of such reservoirs. The Original Concept Figure 1 illustrates the original SAGD concept(3). Two horizontal wells, an injector above a producer, are drilled in the lower part of a formation. Both wells are at first heated by means of steam circulation. When communication is established between the two, bitumen and condensate drain along the sides of the -steam chamber.+ The rise of steam and the downward flow of oil and condensate are unsteady state processes. However, once the steam chamber is formed, the pressure (and so the temperature) in the

chamber remain constant, with steamflood residual oil saturation in the chamber. The sideways growth of the chamber is responsible for oil production. Details have been given in several papers (in particular, see Butler(4,5)). Two definitions of SAGD are worth mentioning: -In the Steam-assisted Gravity Drainage (SAGD) process, heated oil drains from around growing steam chambers, driven by gravity to lower horizontal wells.+

Butler(6) -SAGD is counter-current override, where oil moves in a direction opposite to that of steam front advance.+ Edmunds(7) Gravity provides the drive in the processes described above, otherwise the processes are quite different.

Whereas in the first case steam is the only flowing phase inside the steam chamber, in the second, countercurrent flow of steam, oil and steam condensate occurs-something like the segregation drive in conventional oil recovery. Edmund+s description is closer to the observations in numerical simulations. In an earlier paper, Edmunds, Haston, and Best(8) identified two types of drainage processes: ceiling drainage and slope drainage. Butler developed the flow equation for the above concept, as given in Reference (3), as well in previous publications in somewhat different forms. The key

variables are: steam chamber height, permeability to oil, displaceable oil saturation, and oil viscosity at steam temperature. Oil flow rate varies directly with the square root of the first three, and inversely with that of viscosity. Within its premises, the theory is elegant. Important Features and Consequences A few important points to note are: (i) the theory pertains to the flow of a single fluid, (ii) steam pressure is constant in the steam chamber,

(iii) only steam flows in the steam chamber, oil saturation being residual, and (iv) heat transfer ahead of the steam chamber to cold oil is by conduction only. One analogy of the above process is that of a reservoir made of solid wax, where an electric heating element is placed horizontally above a parallel producing well. Some consequences of the theory are:

(i) steam chamber growth is necessary for oil production-i.e., oil production would occur so long as steam is injected;

Is There Life After SAGD?

Downloaded from http://onepetro.org/JCPT/article-pdf/doi/10.2118/97-06-DAS/2170228/petsoc-97-06-das.pdf/1 by King Fahd University of Petroleum & Minerals, Dirie Dhahir on 05 March 2024

,-------------------------'-- --- ----

S.M. Farouq-AIi is professor of petro- :

The Original Concept

leum engineering at the University of Figure 1 illustrates the original SAGD concept(3). Two horizon-

Alberta since 1979. Prior to this he I tal wells, an injector above a producer, are drilled in the lower part

served at The Pennsylvania State i of a formation. Both wells are at first heated by means of steam

University for 20 years. He has a B.Sc. circulation. When communication is established between the two,

degree in electrical engineering from bitumen and condensate drain along the sides of the "steam cham-

Karachi University, A B.Sc. (Honours) ber." The rise of steam and the downward flow of oil and conden-

degree, in petroleum engineering from sate are unsteady state processes. However, once the steam cham-

Birmingham University, and M.S. and ber is formed, the pressure (and so the temperature) in the cham-

Ph.D. degrees in petroleum and natural ber remain constant, with steamflood residual oil saturation in the

gas engineering from The Pennsylvania State University. He chamber. The sideways growth of the chamber is responsible for

! has authored over 400 papers and two books, and has super- oil production. Details have been given in several papers (in par-

vised over 200 graduate theses on oil recovery and numerical ticular, see Butler(4.5». Two definitions of SAGD are worth

simulation. He serves as consultant to oil companies in mentioning:

Canada, U.S.A., and other countries.

"In the Steam-assisted Gravity Drainage (SAGD)

process, heated oil drains from around growing steam

The answer depends on what you call "Steam-assisted Gravity

chambers, driven by gravity to lower horizontal wells. "

Drainage" or SAGD. In its original, pristine form, it may be the ne

Butler<6)

plus ultra of the entire repertoire of the EaR methods. In the cur-

rent usage, just about any field project involving steam injection

"SAGD is counter-current override, where oil moves in a

and a horizontal well, or two, is called "SAGD." Furthermore,

direction opposite to that of steam front advance. "

from the published literature one gets the impression that the

Edmunds(7)

application of SAGD is more the rule than the exception. This

would naturally lead to misapplications of the SAGD process,

Gravity provides the drive in the processes described above,

with less than optimal results. Our purpose in this article is to

show what the original concept is, what additional factors may otherwise the processes are quite different. Whereas in the first

case steam is the only flowing phase inside the steam chamber, in

distort it, and what are some of the limitations of the process as

the second, countercurrent flow of steam, oil and steam conden-

applied. We will not discuss variations of SAGD, such as

sate occurs-something like the segregation drive in conventional

Enhanced SAGD and Single Well SAGD.

oil recovery. Edmund's description is closer to the observations in

Gravity flow and segregation are an integral part of all oil numerical simulations. In an earlier paper, Edmunds, Haston, and

recovery processes. The role of gravity in steam injection process- Best(8) identified two types of drainage processes: ceiling drainage

es was first recognized by Doscher(1) for California reservoirs, and slope drainage.

typically depleted (-0.5 :MPa), with high vertical permeability and Butler developed the flow equation for the above concept, as

gas saturations at the top. Recently, Vogel(2) provided a lucid given in Reference (3), as well in previous publications in some-

comparison of drive and gravity, in the context of such reservoirs. what different forms. The key variables are: steam chamber

height, permeability to oil, displaceable oil saturation, and oil vis-

cosity at steam temperature. Oil flow rate varies directly with the

Mechanism: square root of the first three, and inversely with that of viscosity.

• Steam condenses at interface Within its premises, the theory is elegant.

• Oil and condensate drain to well at bottom

• Flow is caused by gravity

• Chamber grows upwards and sideways Important Features and Consequences

---- -.. A few important points to note are:

(i) the theory pertains to the flow of a single fluid,

(ii) steam pressure is constant in the steam chamber,

(iii) only steam flows in the steam chamber, oil saturation

being residual, and

(iv) heat transfer ahead of the steam chamber to cold oil is by

conduction only. One analogy of the above process is that

of a reservoir made of solid wax, where an electric heat-

ing element is placed horizontally above a parallel pro-

Continuous steam ducing well.

injection into chamber Oil and condensate

G - - - drain continuously Some consequences of the theory are:

(i) steam chamber growth is necessary for oil production-

i.e., oil production would occur so long as steam is

FIGURE 1: Conceptual diagram of the steam-assisted gravity injected;

drainage process. (Courtsey R.M. Butler(6».

(ii) the higher the temperature, the higher is the oil production

20 The Journal of Canadian Petroleum Technology

----- -------------------------------------

Unit 8 - MosUy Shale

--- --- ------------ -------- -- - - - --- - -

Unit C - 30 "Shale

- ---

- - -- - - - - - - - - - - - - - - - - - -- - - - - - - - - - - - - - - - - - --

Downloaded from http://onepetro.org/JCPT/article-pdf/doi/10.2118/97-06-DAS/2170228/petsoc-97-06-das.pdf/1 by King Fahd University of Petroleum & Minerals, Dirie Dhahir on 05 March 2024

~~----------------- ------

Unit H - Umesione

, '

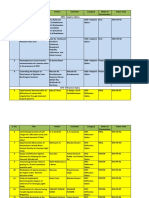

FIGURE 2: The growth of steam chamber observed in Phase A of the UTF project. (Courtsey Ito and Suzuki(lO».

, 'rate(9); and that convection is far more important than conduction. The

~, (iii) at a given steam temperature the oil with the lowest vis- author's own results support that view, and a close examination of

, 'cosity (usually the highest API gravity) would exhibit the Ito and Suzuki's numerical results shows that the observed con-

highest production response. vection is not numerical dispersion.

Conclusion (li) follows from the assumption of a constant tem-

perature at the "interface," viz. the steam condensation surface. Geology

Gravity drainage of conduction-heated oillbitumen occurs ahead

of this interface. It matters little how the steam chamber is formed Geology of the formation can have a profound influence on

or what it contains, so long as it contains residual oil, and its tem- steam chamber growth, as the performance of UTF Phase A

p,erature is constant. Clearly steam injection is the way to achieve shows. The observed steam chamber was oblate, as shown in

these conditions. Because the latent heat content (fstLv, pressure Figure 2, and expanded sideways rather than vertically to the top

dependent) is important for steam zone formation, temperature of the formation. This is attributed to small differences in forma-

(i.e., steam pressure) cannot be increased without limit. According tion characteristics, as well as convection in the lower part of the

to the basic equation, the oil rate would be highest at the critical formation. The pressure gradient in a gravity drive is constant

pressure of steam, at which latent heat is zero, and of course no (rg), but relatively small, and consequently flow would follow the

steam chamber will form. The experimental and theoretical treat- path of higher conductivity. Ito and Suzuki were able to match the

ments of steam chamber ,growth from horizontal or vertical wells, observed steam chamber.

and associated phenomena, summarized in Reference (3), are

based on conductive heat,transfer. 20 vs. 3D

Conclusion (iii) impijes that the oil production response would

be greater in mobile heavy oil formations than in bitumen-bearing The SAGD theory, and much of the reported experimental

oil sands. This is discussed further in the section on Conventional work, are based on a two-dimensional cross-sectional visualiza-

Heavy,Oils. , tion of the process. Two important missing factors are flow in the

two horizontal wells, and the effect of wellbore, when the wells

are drilled from surface rather than from tunnels, as in UTF (one

Variations of. SAGO pair of wells in Phase B is drilled from surface)(lI). Steam and

fu qne vari!\tion of the original SAGD concept, the horizontal fluid flow behaviour for the horizontal sections of the two wells

steam injector is, t;eplaced by one, or more, vertical injectors. can be observed from numerical simulations, or from approximate

St~am injec;rion into these, would lead to the formation of a steam analytical methods. Examples of this type can be seen from the

chaml?~r, and oil would'drain into the horizontal producer. paper by Edmunds and Gittins(l2). Uneven steam distribution

App1,ic,ation of the theory in this case would depend on a number along the injection well would lead to formation of separate steam

of additional factors, s1,lch as the geometry of the wells, which chambers. Moreover, precise production control is important: too

would determine the shape of the steam chamber as well as fluid little production would lead to drowning of the steam chamber,

flow rate~, steam injection pressure w:ith regard to frac pressure while too much would cause channelling of steam. Such "steam

(formatioI]., failure pr~ss~re), reservoir geology and other factors, trap" control is much more difficult when operating the wells

such as the existence of a high gas saturation, or a contiguous from surface, because of large hydrostatic heads (or lack thereof).

water leg. A few of these situations are discussed in Field The authors also examined the effect of variability in the spacing

Examples. between the two horizontal wells, as a drilling constraint.

Continuous temperature measurements along the length of the

wells could lead to better control of surface drilled wells, but are

not available at this time, although work is in progress in this

Concerns direction.

Condensate Flow

Geomechanical Effects

,; ,For6most 'aino~g the concerns with regard to the application of

the original SAGD theorytb oil sands and heavy oil alike is the A different type of problem is posed by geomechanical effects

role of steam condensate flow, with a volume two to five times as in steam injection into the viscous oils and bitumens of Alberta.

large' as the volume of oil. 'The condensate will flow inside the These not only encompass formation failure and associated

steam charriber-if such a chamber forms-and the heat from the effects, but also the changes in petrophysical properties and in situ

steam will' be used 'to heat the condensate first, and then the stresses induced by temperature changes. Ito and Suzuki(10) found

adjoining oilo~ bitumen. With so much condensate flowing, con- such effects to be significant. The extensive instrumentation of

vection' woulCl be expected to be the dominant heat transfer mech- UTF Phase A showed considerable thermally induced stresses and

anism. Numerical simulations by Ito and Suzuki(lO) clearly show resulting strains.

June 1997, Volume 36, No.6 21

Downloaded from http://onepetro.org/JCPT/article-pdf/doi/10.2118/97-06-DAS/2170228/petsoc-97-06-das.pdf/1 by King Fahd University of Petroleum & Minerals, Dirie Dhahir on 05 March 2024

Downloaded from http://onepetro.org/JCPT/article-pdf/doi/10.2118/97-06-DAS/2170228/petsoc-97-06-das.pdf/1 by King Fahd University of Petroleum & Minerals, Dirie Dhahir on 05 March 2024

Downloaded from http://onepetro.org/JCPT/article-pdf/doi/10.2118/97-06-DAS/2170228/petsoc-97-06-das.pdf/1 by King Fahd University of Petroleum & Minerals, Dirie Dhahir on 05 March 2024

You might also like

- An Integrated Model For Asphaltene Deposition in Wellbores/pipelines Above Bubble PressuresDocument22 pagesAn Integrated Model For Asphaltene Deposition in Wellbores/pipelines Above Bubble PressuresDavid Reyes GonzálezNo ratings yet

- Integrated One-Dimensional Modeling of Asphaltene Deposition in Wellbores/pipelinesDocument7 pagesIntegrated One-Dimensional Modeling of Asphaltene Deposition in Wellbores/pipelinesDavid Reyes GonzálezNo ratings yet

- Articulo 2 One PetroDocument10 pagesArticulo 2 One PetroAnonymous zSO2St77No ratings yet

- Petroleum: Original ArticleDocument16 pagesPetroleum: Original ArticleazuhalNo ratings yet

- AppliedThermalEngineering 2022 Page1 SharelinkDocument3 pagesAppliedThermalEngineering 2022 Page1 SharelinkArsfrNo ratings yet

- Detailed Analysis of Toe-To-Heel Air Injection For Heavy Oil ProductionDocument14 pagesDetailed Analysis of Toe-To-Heel Air Injection For Heavy Oil ProductionMejbahul SarkerNo ratings yet

- Petroleum: Mahdi Zeinali Hasanvand, Mohammad Ali Ahmadi, Reza Mosayebi BehbahaniDocument7 pagesPetroleum: Mahdi Zeinali Hasanvand, Mohammad Ali Ahmadi, Reza Mosayebi Behbahanimarcoesteban97No ratings yet

- Foamy Oil Flow in Heavy Oil ReservoirsDocument4 pagesFoamy Oil Flow in Heavy Oil ReservoirsAfsar AliNo ratings yet

- Rheology of Waxy Crude Oil by BenkreiraDocument13 pagesRheology of Waxy Crude Oil by BenkreiraBenkreiraNo ratings yet

- Engineers: Automobile Division Proceedings of The Institution of MechanicalDocument10 pagesEngineers: Automobile Division Proceedings of The Institution of Mechanicalacar1No ratings yet

- Akhondzadeh-Fattahi2015 Article ImpactOfWellConfigurationOnPerDocument13 pagesAkhondzadeh-Fattahi2015 Article ImpactOfWellConfigurationOnPerdandi ivandiNo ratings yet

- SPE-199933-MS Introduction of Steam-Assisted Gravity-Drainage Oil Rate Prediction Using The 5-LINE ModelDocument19 pagesSPE-199933-MS Introduction of Steam-Assisted Gravity-Drainage Oil Rate Prediction Using The 5-LINE Modeldandi ivandiNo ratings yet

- Journal of King Saud University - Engineering Sciences: Martins Obaseki, Paul T. ElijahDocument9 pagesJournal of King Saud University - Engineering Sciences: Martins Obaseki, Paul T. ElijahEdi Agurto CarrascoNo ratings yet

- Predicting Transformer Temperature Rise and Loss oDocument10 pagesPredicting Transformer Temperature Rise and Loss odevcharuNo ratings yet

- Energies 15 04816 v2Document15 pagesEnergies 15 04816 v2ORLANDO GONZALEZNo ratings yet

- Muk Ha Met Shina 2014Document16 pagesMuk Ha Met Shina 2014Ridwan Al-KhandiNo ratings yet

- A New Approach To The Modelling of Steam-Assisted Gravity Drainage R.M. ButlerDocument11 pagesA New Approach To The Modelling of Steam-Assisted Gravity Drainage R.M. Butlerhafizul furqanNo ratings yet

- Predicting Transformer Temperature Rise and Loss of Life in The Presence of Harmonic Load CurrentsDocument10 pagesPredicting Transformer Temperature Rise and Loss of Life in The Presence of Harmonic Load Currentssametb_1No ratings yet

- Wu 1977Document12 pagesWu 1977Carlos Andres Torres MolanoNo ratings yet

- 10.1021 Acs - Jced.5b00088Document8 pages10.1021 Acs - Jced.5b00088aminbm.pt24No ratings yet

- Chemical Engineering Journal: Abarasi Hart, Malcolm Greaves, Joseph WoodDocument11 pagesChemical Engineering Journal: Abarasi Hart, Malcolm Greaves, Joseph WoodFarah Talib Al-sudaniNo ratings yet

- Effect of Reservoir Pay Thickness On The PerformanDocument14 pagesEffect of Reservoir Pay Thickness On The PerformanAbassyacoubouNo ratings yet

- SPE-195254-MS Anionic Surfactant and Heavy Oil Interaction During Surfactant-Steam ProcessDocument13 pagesSPE-195254-MS Anionic Surfactant and Heavy Oil Interaction During Surfactant-Steam ProcessSilvana SerranoNo ratings yet

- A Transient Two-Phase Fluid-And Heat-Flow Model For Gas-Lift-Assisted Waxy-Crude Wells With Periodical Electric HeatingDocument11 pagesA Transient Two-Phase Fluid-And Heat-Flow Model For Gas-Lift-Assisted Waxy-Crude Wells With Periodical Electric Heatingmohamed fathyNo ratings yet

- A Prediction Method of Natural Gas Hydrate Formation in Deepwater Gas Well and Its ApplicationDocument5 pagesA Prediction Method of Natural Gas Hydrate Formation in Deepwater Gas Well and Its ApplicationLOLA PATRICIA MORALES DE LA CUBANo ratings yet

- In Situ: Upgrading of Athabasca Tar Sand Bitumen Using ThaiDocument9 pagesIn Situ: Upgrading of Athabasca Tar Sand Bitumen Using ThaimohsenNo ratings yet

- Asphaltene PrecipitationDocument17 pagesAsphaltene PrecipitationAli K. Al-MalikiNo ratings yet

- Development ChronologyDocument14 pagesDevelopment ChronologyJay PatelNo ratings yet

- Energy and Buildings: Madhavi Indraganti, Djamel BoussaaDocument5 pagesEnergy and Buildings: Madhavi Indraganti, Djamel BoussaaKumbamNo ratings yet

- A Simulation Study of The Sarir Field - Tobruk Terminal Crude Oil PipelineDocument6 pagesA Simulation Study of The Sarir Field - Tobruk Terminal Crude Oil PipelineteaNo ratings yet

- 1 s2.0 S0263876220301696 MainDocument15 pages1 s2.0 S0263876220301696 MainSayan HalderNo ratings yet

- Gregory 1975Document7 pagesGregory 1975Warren PuthNo ratings yet

- A Laboratory Investigation of Carbon Dioxide Enhanced Oi - 2019 - Egyptian JournDocument6 pagesA Laboratory Investigation of Carbon Dioxide Enhanced Oi - 2019 - Egyptian JournAmeer TalibNo ratings yet

- The Impact of Marine Environment On Jackup Rig Stability: October 2020Document17 pagesThe Impact of Marine Environment On Jackup Rig Stability: October 2020Kerim İlgin ERTAŞNo ratings yet

- Treatmentof Waxy Oil 3Document65 pagesTreatmentof Waxy Oil 3jasminaNo ratings yet

- Selecting of Vaporizer in LNG Regasification Plant: M. Ebrahimi Gardeshi, M. A. ShobeiriDocument7 pagesSelecting of Vaporizer in LNG Regasification Plant: M. Ebrahimi Gardeshi, M. A. ShobeiriundungNo ratings yet

- Need of Flow Assurance For Crude Oil PropertiesDocument8 pagesNeed of Flow Assurance For Crude Oil Propertiesvande852001No ratings yet

- Steam Injection in Fractured Carbonate Reservoirs PDFDocument2 pagesSteam Injection in Fractured Carbonate Reservoirs PDFlinda feibe rawisNo ratings yet

- Paper 3 Management of Evaporation Losses of GasolinesDocument6 pagesPaper 3 Management of Evaporation Losses of GasolinesAisah Cory PrasonoNo ratings yet

- Masoud Riazi, Abdolah Golkari: ArticleinfoDocument9 pagesMasoud Riazi, Abdolah Golkari: ArticleinfoSahib QafarsoyNo ratings yet

- Cipc 2009-014Document14 pagesCipc 2009-014Ralf JonesNo ratings yet

- Paraffin Wax Deposition: (The Challenges Associated and Mitigation Techniques, A Review)Document8 pagesParaffin Wax Deposition: (The Challenges Associated and Mitigation Techniques, A Review)Jit MukherheeNo ratings yet

- 2016اسس هندسة النفطDocument33 pages2016اسس هندسة النفطWaxenNo ratings yet

- Optimization of Surfactant Polymer Flooding For Enhanced Oil RecoveryDocument15 pagesOptimization of Surfactant Polymer Flooding For Enhanced Oil RecoveryMinh LeNo ratings yet

- Spe 172813 MS PDFDocument9 pagesSpe 172813 MS PDFSajad FalahNo ratings yet

- Spe 171295 MsDocument9 pagesSpe 171295 MsAlfonso RamosNo ratings yet

- Jamialahmadi 2009Document11 pagesJamialahmadi 2009nashat90No ratings yet

- Ge Numerical 2014Document8 pagesGe Numerical 2014Ahmed Ali AlsubaihNo ratings yet

- Greaves 2011Document19 pagesGreaves 2011Alejandro Duvan Lopez RojasNo ratings yet

- Researchpaper GAS HYDRATE APPLICATIONS AND PROBLEMS IN OIL AND GAS INDUSTRY1Document6 pagesResearchpaper GAS HYDRATE APPLICATIONS AND PROBLEMS IN OIL AND GAS INDUSTRY1Hai LinhNo ratings yet

- Rod Lift Offshore SafetyDocument7 pagesRod Lift Offshore SafetyMohamed GhareebNo ratings yet

- Paper46 Hazards 23Document9 pagesPaper46 Hazards 23Nadia AfifahNo ratings yet

- Researchpaper GAS HYDRATE APPLICATIONS AND PROBLEMS IN OIL AND GAS INDUSTRY1Document6 pagesResearchpaper GAS HYDRATE APPLICATIONS AND PROBLEMS IN OIL AND GAS INDUSTRY1Walter NomboraNo ratings yet

- Petroleum Science and TechnologyDocument26 pagesPetroleum Science and TechnologyPranav KulkarniNo ratings yet

- A Numerical Analysis of The SW-SAGD ProcessDocument20 pagesA Numerical Analysis of The SW-SAGD ProcessmaxjuliNo ratings yet

- Spe 3349 MsDocument8 pagesSpe 3349 MswillNo ratings yet

- Ijetr022621 PDFDocument4 pagesIjetr022621 PDFerpublicationNo ratings yet

- Thermomechanical Assessment Coke Drum - Shell1 1Document9 pagesThermomechanical Assessment Coke Drum - Shell1 1scg1234No ratings yet

- SPE-187349-MS High Pressure Tertiary-CO2 Flooding in A Fractured Chalk ReservoirDocument27 pagesSPE-187349-MS High Pressure Tertiary-CO2 Flooding in A Fractured Chalk ReservoirAllanNo ratings yet

- Exp Tank SizingDocument5 pagesExp Tank Sizinghasanadel88No ratings yet

- Loss Calculation of Contraction and Enlargement - FlowDocument10 pagesLoss Calculation of Contraction and Enlargement - FlowDhammikaDharmasenaNo ratings yet

- Applied Catalysis B: EnvironmentalDocument10 pagesApplied Catalysis B: EnvironmentalnguyencyberchemNo ratings yet

- Slamming Guide Dec21Document52 pagesSlamming Guide Dec21philipgeorge1993No ratings yet

- L-1 Bituminous Mix DesignDocument86 pagesL-1 Bituminous Mix DesignrajibchattarajNo ratings yet

- SBBSBDocument130 pagesSBBSBRam KumarNo ratings yet

- Foam Mat DryingDocument28 pagesFoam Mat DryingASHUTOSH TRIPATHYNo ratings yet

- Course 6Document17 pagesCourse 6Carrisya AzahraNo ratings yet

- Controlling Hot Sand To Ensure Mold, Casting QualityDocument3 pagesControlling Hot Sand To Ensure Mold, Casting QualityLucianoNo ratings yet

- MAE 589 Heat Transfer Syllabus (Spring 2015)Document8 pagesMAE 589 Heat Transfer Syllabus (Spring 2015)Pratik SankheNo ratings yet

- Lug Analysis - MechaniCalcDocument21 pagesLug Analysis - MechaniCalcArunkumar RackanNo ratings yet

- EAS 354 - ConnectionsDocument51 pagesEAS 354 - ConnectionsNasrulNo ratings yet

- Ultimate Lateral Load of Slope-Stabilising Piles: Géotechnique Letters September 2017Document9 pagesUltimate Lateral Load of Slope-Stabilising Piles: Géotechnique Letters September 2017ValerioNo ratings yet

- Refinements To The Neher-McGrath Model 00483997Document19 pagesRefinements To The Neher-McGrath Model 00483997Gilberto Mejía100% (1)

- Strengthening of Existing Composite Beams Using LRFD ProceduresDocument8 pagesStrengthening of Existing Composite Beams Using LRFD Proceduresalbertoxina100% (3)

- Hardness TestDocument10 pagesHardness Testbadawi2No ratings yet

- 8989 Ijmme IjensDocument16 pages8989 Ijmme IjensjeovanNo ratings yet

- Structural SectionsDocument45 pagesStructural SectionsAlex SinclairNo ratings yet

- Lab 12 - Molar Volume of A GasDocument6 pagesLab 12 - Molar Volume of A GasAnonymous WI0nbsNo ratings yet

- Vibration DampingDocument13 pagesVibration Dampingnadeem UddinNo ratings yet

- DBR of Ventilation System 162Document10 pagesDBR of Ventilation System 162pukhrajsoniNo ratings yet

- X Ray DiffractionDocument42 pagesX Ray Diffractionatiyorockfan9017No ratings yet

- (Dr. Andreas Kling, Prof. Fernando J. C. Baräo, P PDFDocument1,200 pages(Dr. Andreas Kling, Prof. Fernando J. C. Baräo, P PDFJessicaRezendeGraff100% (1)

- Module 2 Lateral Earth Pressure CDocument19 pagesModule 2 Lateral Earth Pressure Cbhupender ghosliyaNo ratings yet

- H112-Heat Transfer Service UnitDocument3 pagesH112-Heat Transfer Service UnitJuan David mosquera garciaNo ratings yet

- ACI 318-08 Development and Splices of ReinforcementDocument6 pagesACI 318-08 Development and Splices of ReinforcementRal GLNo ratings yet

- CHEN 4460 - Process Synthesis, Simulation and OptimizationDocument28 pagesCHEN 4460 - Process Synthesis, Simulation and Optimizationmppatilmayur1679No ratings yet

- CONCLUSION-food AnalysisDocument2 pagesCONCLUSION-food AnalysisFadhlin Sakinah100% (1)

- Heat Exchanger Strength Calculation: Shell Side Design Data Tube Side Design DataDocument2 pagesHeat Exchanger Strength Calculation: Shell Side Design Data Tube Side Design DataSteve MoonNo ratings yet

- A 470 - 03 Piezas ForjadasDocument8 pagesA 470 - 03 Piezas ForjadasWILLIAM ROMERONo ratings yet