Professional Documents

Culture Documents

Ur20 Data Sheet

Uploaded by

kodysOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ur20 Data Sheet

Uploaded by

kodysCopyright:

Available Formats

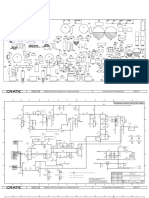

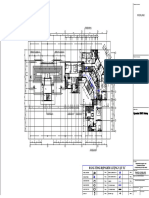

3-Position Enabling Teach Pendant Recommended hole pattern for robot base

Features

UR20 IP classification

Humidity

IP54

≤ 90% RH (non-condensing)

95 95

30°

Display resolution 1280 x 800 pixels

Technical Specification Physical

5x

The UR20, the first of our next-generation high Materials Plastic

60°

performance cobots, has been redesigned from the 300 mm x 231 mm x 50 mm +0,030

Teach pendant size (W x H x D) 8 FG8 +0,008 9,5 ±0,5

(11,8 in x 9,1 in x 1,97 in)

ground up to provide up to 30% more speed and torque,

210

Weight 1,8 kg (3.961 lbs)

advanced motion control capabilities, and first-class including 1 m of teach pendant cable +0,030

8 FG8 +0,008 x 13 9,5 ±0,5

10

user experience. Cable length 4,5 m (177,17 in)

UR cobots bring incredible versatility and unparalleled

ease of use to your applications. The UR20 is no

exception - its 20 kg payload and 1750 mm reach make it 6x 10,50 THRU ALL

an ideal match for applications ranging from palletizing Control Box

to machine loading. Mounting plate with pins for robot base

Features

4th Edition published September 2023.

5 ±1

0,05

IP Classification IP44 8 h6 0-0,009

Humidity ≤ 90% RH (non-condensing)

I/O Ports 190

Digital In 16

Digital Out 16

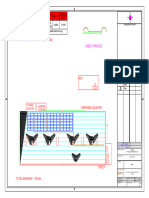

Analog In 2 UR20 tool flange

Analog Out 2

UR20 Quadrature digital inputs

I/O Power Supply

4

24V, 2A

+0,015

8 H7 0 8±0,2

0,4 D E

F A

6 x M8 - 6H 10,6

0,4 D E F 17,60

General specification Features Communication

500 Hz Control frequency

6,20

20 kg (44,1 lbs) in the IP classification IP65 Modbus TCP

Payload

entire workspace Noise < 65 dB(A) PROFINET, PROFIsafe

Reach 1750 mm (68,9 in) Arm mounting Any orientation (optional)

Degrees of freedom 6 rotating joints I/O Ports Ethernet/IP

4x

12 inch touchscreen with PolyScope Digital In 2

60

80

Programming

°

graphical user interface USB 2.0, USB 3.0

Digital Out 2

Power consumption (average) ROS/ROS2 driver support

Analog In 2 50 H7 56,50

Maximum power 750 W (optional, open source)

Tool I/O power supply voltage 12/24 V 80 ±0,1 SECTION A-A

Moderate operating settings 300 W 100 h8

Tool I/O power supply 2 A (Dual pin), 1 A (Single pin) Injection Molding Machine

Ambient temperature:

Operating temperature range Interface (IMMI, optional)

0-50˚C (32-122˚F)

Safety functions 17 configurable safety functions Power Source 100-240 VAC, 47-440 Hz

EN ISO 13849-1 (PLd Category 3) 201

In compliance with

and EN ISO 10218-1

Physical Physical

UR20 arm Footprint Ø 245 mm; 6 x M10, 60° Control Box Size (W x H x D) 460 mm x 449 mm x 254 mm

(18,2 in x 17,6 in x 10 in)

105 mm center

Performance Materials Aluminum, plastic, steel Weight 12 kg (26,5 lbs)

888

Tool flange EN ISO-9409-1-80-6-M8 Materials Powder coated steel

Force sensing, tool Connector type M8 | M8 8-pin female

728,7 159,3

Force, x-y-z Torque, x-y-z

flange/torque sensor

Cable length (robot arm) 6 m (236 in)

Range 200,0 N 20,0 Nm

Weight including cable 64 kg (141,1 lbs)

Precision 5,5 N 0,2 Nm

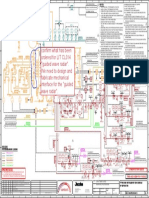

Humidity ≤ 90% RH (non-condensing) UR20 payload curve

Accuracy 10,0 N 0,1 Nm

25

Movement

862

0

20 75

R1

Typical TPC speed 2 m/s

Payload (kg)

Pose repeatability per 15

± 0,1 mm

ISO 9283

Axis movement Working range Maximum speed

236,3

Base ± 360° ± 120˚/s Contact 10

Shoulder ± 360° ± 120˚/s 245

5

Elbow ± 360° ± 150˚/s Universal Robots A/S

Wrist 1 ± 360° ± 210˚/s Energivej 25 +45 89 93 89 89

0

Wrist 2 ± 360° ± 210˚/s 5260 Odense sales@universal-robots.com 0 100 200 300 400 500 600 700 800

Wrist 3 ± 360° ± 210˚/s Denmark universal-robots.com Center of gravity offset (mm) UNLESS OTHERWISE SPECIFIED:

Dimensions are in millimeters. Tolerance ± 0,1 mm ± 0,5˚

You might also like

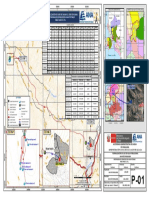

- Location MapDocument1 pageLocation MapMarc Dared CagaoanNo ratings yet

- Linease Actuator CAHB 22E - 17210 enDocument4 pagesLinease Actuator CAHB 22E - 17210 enAlvaro MunozNo ratings yet

- Lift Differnt Sze DetailDocument1 pageLift Differnt Sze Detailsumant giriNo ratings yet

- Flyer Robot MPX3500 EDocument4 pagesFlyer Robot MPX3500 Eamirtimes1372No ratings yet

- CM April 2015 An Intro To As - nzs2312.2 Part 2 Hot Dip Gal Tech NoteDocument2 pagesCM April 2015 An Intro To As - nzs2312.2 Part 2 Hot Dip Gal Tech NotemarklaforestNo ratings yet

- Appendix 13 5 6A 12 February 2013Document2 pagesAppendix 13 5 6A 12 February 2013Khawla EbrhimNo ratings yet

- BMS Table-ModelDocument1 pageBMS Table-ModelGarlapati TrinadhNo ratings yet

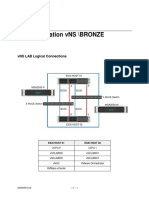

- BRONZE - VNS LAB InformationDocument6 pagesBRONZE - VNS LAB InformationClaudio SalinasNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument1 pageYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterHarish Kumar MahavarNo ratings yet

- Crate V33-212Document7 pagesCrate V33-212Danielo ErréNo ratings yet

- Smartlase C350hdplus Ds HQ b1 Markem ImajeDocument2 pagesSmartlase C350hdplus Ds HQ b1 Markem ImajeIuri FernandesNo ratings yet

- 08 Wood Handling 9 Lines-36000 GTper DayDocument1 page08 Wood Handling 9 Lines-36000 GTper DayDeniNo ratings yet

- 7) Market CCTV-ModelDocument1 page7) Market CCTV-ModelShakar LondonNo ratings yet

- L Gi LE PM T PMD 059 F138 LR 5 72 HTH 565 585 M V2 30 30 and 15 Frame Explorer V19 Fb7474efd7Document2 pagesL Gi LE PM T PMD 059 F138 LR 5 72 HTH 565 585 M V2 30 30 and 15 Frame Explorer V19 Fb7474efd7Juan Paolo CapinNo ratings yet

- Interland: PD GarbageDocument1 pageInterland: PD GarbageDuy Giáp NguyễnNo ratings yet

- Mæt B NGDocument1 pageMæt B NGbanhbaonongNo ratings yet

- 01Document1 page01ARIFINNo ratings yet

- Polamco Product Finder PDFDocument1 pagePolamco Product Finder PDFpaula09No ratings yet

- RISATowerDemo Free-Standing PDFDocument84 pagesRISATowerDemo Free-Standing PDFjesusgameboyNo ratings yet

- C2 Columns ReinforcementDocument1 pageC2 Columns ReinforcementMilad Ahmad MSTNo ratings yet

- Mt625 Easy Repair ManualDocument292 pagesMt625 Easy Repair Manualjoe100% (2)

- Flyer Robot MPX3500 E 03.2019Document4 pagesFlyer Robot MPX3500 E 03.2019stas stepanovNo ratings yet

- Specifications:: Section DDDocument1 pageSpecifications:: Section DDBharani MadamanchiNo ratings yet

- Scheda Tecnica Pannelli TSHNM-108HV-415-435W-full-blackDocument2 pagesScheda Tecnica Pannelli TSHNM-108HV-415-435W-full-blackinfoNo ratings yet

- Tsurumi Pump Model, Model Pompa CelupDocument3 pagesTsurumi Pump Model, Model Pompa Celuparfan rijalNo ratings yet

- 7Document1 page7Modasser NewazNo ratings yet

- Typical Arrangement: Shaft Section B-BDocument1 pageTypical Arrangement: Shaft Section B-Bsumant giriNo ratings yet

- Plano Piso 5 Conductos de Ventilación (Techo) LaredDocument1 pagePlano Piso 5 Conductos de Ventilación (Techo) Laredgotita55100% (1)

- Profile 10 100x100 - ItemDocument1 pageProfile 10 100x100 - ItemZhangJiayongNo ratings yet

- 0.contoh Soal Uji KompetensiDocument1 page0.contoh Soal Uji KompetensiAdhe Sri MarjukiNo ratings yet

- 38 Gfc-P2c3-Tu02-Crp-Dr-Btn-73111-01-ADocument1 page38 Gfc-P2c3-Tu02-Crp-Dr-Btn-73111-01-ASUBHASH KUMARNo ratings yet

- MB Tầng 1Document1 pageMB Tầng 1Huong PhamNo ratings yet

- Enr 6.1-2Document1 pageEnr 6.1-2antonio mayaNo ratings yet

- Ki KiDocument1 pageKi Kiviktor baezNo ratings yet

- Anchor - Bolt 12 MKD' NO. 1642001ABD-0002: Grid LocationDocument1 pageAnchor - Bolt 12 MKD' NO. 1642001ABD-0002: Grid LocationGHULAM NABINo ratings yet

- Frame Alu - Cane Sun LoungeDocument1 pageFrame Alu - Cane Sun Loungefaid cvmaNo ratings yet

- Ac Cable Length - 25 MTR (Approx.) : Shed 1 ProfileDocument1 pageAc Cable Length - 25 MTR (Approx.) : Shed 1 Profilesarukh.khanNo ratings yet

- Group 00 M176en 2018-04Document24 pagesGroup 00 M176en 2018-04patitovera25% (4)

- FINETEK MAN PT76 TemperatureController enDocument2 pagesFINETEK MAN PT76 TemperatureController enMahmoud Abd-Elhamid Abu EyadNo ratings yet

- User Instruction HIC402A - 404A - 406A - 408A - 410A - 412A - 416ADocument2 pagesUser Instruction HIC402A - 404A - 406A - 408A - 410A - 412A - 416AHamd1971No ratings yet

- Semhl 22 1226 - DR001Document1 pageSemhl 22 1226 - DR001BHIYA JINo ratings yet

- Profile 8 120x120 - ItemDocument1 pageProfile 8 120x120 - ItemZhangJiayongNo ratings yet

- Cut 125797 - 2022 - Jass Inka Yaku Sector 2Document1 pageCut 125797 - 2022 - Jass Inka Yaku Sector 2Gian ORNo ratings yet

- Flyer Robot Mpl300ii - 5afd8d21c6f97Document2 pagesFlyer Robot Mpl300ii - 5afd8d21c6f97Luisito Miguelito ErazoNo ratings yet

- STC800 SanyDocument3 pagesSTC800 SanySwarup DasNo ratings yet

- Superseded LTD Rural Models (2ha+) - Continued: Model Promet and Baffle Wetback Door Glass Other PartsDocument1 pageSuperseded LTD Rural Models (2ha+) - Continued: Model Promet and Baffle Wetback Door Glass Other PartsMark TroloveNo ratings yet

- Manual Kuka KR 360 y KR 500Document4 pagesManual Kuka KR 360 y KR 500fenix5114No ratings yet

- Dew-Point Evaporative Comfort Cooling: Jesse DeanDocument39 pagesDew-Point Evaporative Comfort Cooling: Jesse DeanNaziman AzlyeNo ratings yet

- Muck Disposal Scheme - CH - KM 375+000Document1 pageMuck Disposal Scheme - CH - KM 375+000Shivendra KumarNo ratings yet

- Sturaco 7098Document1 pageSturaco 7098Tudor RatiuNo ratings yet

- Panel 1Document1 pagePanel 1chaidir ciakNo ratings yet

- JT 52 PDFDocument2 pagesJT 52 PDFSinan KeiyinciNo ratings yet

- Tabg Jec 0 000 Pro Pid 0012 - GDocument1 pageTabg Jec 0 000 Pro Pid 0012 - GAfif FadhliNo ratings yet

- Section (Post) : General NotesDocument1 pageSection (Post) : General Notesjerus lucineNo ratings yet

- Bunkers An Analysis of The Technical and Environme... - (PG 89 - 89)Document1 pageBunkers An Analysis of The Technical and Environme... - (PG 89 - 89)Clarcy CrawfordNo ratings yet

- Butterfly Valves: B. D. K. Engineering Industries LimitedDocument6 pagesButterfly Valves: B. D. K. Engineering Industries LimitedRajesh KanalaNo ratings yet

- CEGP OC053.2023 DW M 001.rev2Document1 pageCEGP OC053.2023 DW M 001.rev2Milagros MuedasNo ratings yet

- Nico Javier Marte Fernandez 2018-6211.: Practica #XXDocument1 pageNico Javier Marte Fernandez 2018-6211.: Practica #XXGabriel PaulinoNo ratings yet

- VW - US Tiguan - 2014Document13 pagesVW - US Tiguan - 2014leboncoinmoncompteNo ratings yet

- Mm-22 No. 1, 2 H. F. O. Purifier Sj-30gDocument44 pagesMm-22 No. 1, 2 H. F. O. Purifier Sj-30gdeli34No ratings yet

- Android Online Test 1Document14 pagesAndroid Online Test 1Kumara SNo ratings yet

- The Role of Late Byzantine Thessalonike in Church Architecture in The Balkans - Slobodan CurcicDocument67 pagesThe Role of Late Byzantine Thessalonike in Church Architecture in The Balkans - Slobodan CurcicSonjce Marceva100% (2)

- Revamping Ammonia ConverterDocument5 pagesRevamping Ammonia ConverterHsein WangNo ratings yet

- T09 IADC Equipment List March Ver 1 - 2013Document90 pagesT09 IADC Equipment List March Ver 1 - 2013Them Bui XuanNo ratings yet

- ELK-04 145 Flyer 1HDX580104 en 0315Document2 pagesELK-04 145 Flyer 1HDX580104 en 0315MarkNo ratings yet

- Google Safe Browsing v2 API: Implementation NotesDocument17 pagesGoogle Safe Browsing v2 API: Implementation NotesJulien SobrierNo ratings yet

- iC60H Circuit Breakers (Curve B, C, D)Document4 pagesiC60H Circuit Breakers (Curve B, C, D)Abdullrahim AlastalNo ratings yet

- Siemens Simos18.10 Irom tc1791 384 SSM VagDocument5 pagesSiemens Simos18.10 Irom tc1791 384 SSM VagAbdou Abu FrowNo ratings yet

- Fault Code 426 SAE J1939 Data Link CommunicationDocument6 pagesFault Code 426 SAE J1939 Data Link CommunicationMrjhon RuizNo ratings yet

- List of CollegesDocument3 pagesList of Collegesarchana_anuragi50% (2)

- 1101 MNB CH 32+340 R2 UpdatedDocument1 page1101 MNB CH 32+340 R2 UpdatedSatyavijet ChilakapatiNo ratings yet

- Sfa 1610-JbeDocument6 pagesSfa 1610-JbeHung NguyentheNo ratings yet

- Negative Refractive Index and MetamaterialsDocument10 pagesNegative Refractive Index and MetamaterialsNikita PawarNo ratings yet

- Understanding The High-Speed Counter InstructionsDocument14 pagesUnderstanding The High-Speed Counter InstructionsbertandNo ratings yet

- Hydrogels in Sensing ApplicationsDocument42 pagesHydrogels in Sensing ApplicationsMasihullah J KhanNo ratings yet

- Schedule of Products WaterMarkDocument46 pagesSchedule of Products WaterMarkBo boNo ratings yet

- Matse 280: Introduction To Engineering Materials: ©D.D. Johnson 2004/2006-2010Document45 pagesMatse 280: Introduction To Engineering Materials: ©D.D. Johnson 2004/2006-2010Sabir AliNo ratings yet

- TADANO 1746 - ATF600G-8 - EM4 - 1 - Highlights - EN - 032018 - 1Document17 pagesTADANO 1746 - ATF600G-8 - EM4 - 1 - Highlights - EN - 032018 - 1PHÁT NGUYỄN THẾNo ratings yet

- TQM Sample QuestionsDocument12 pagesTQM Sample QuestionsArmel AbarracosoNo ratings yet

- 9103796-105CN - Techn Descr SC 45Document139 pages9103796-105CN - Techn Descr SC 45happyNo ratings yet

- Bosch GCO220 User ManualDocument72 pagesBosch GCO220 User Manualmichael manzanoNo ratings yet

- HSG264 Asbestos Survey GuideDocument74 pagesHSG264 Asbestos Survey GuideEdwinHanNo ratings yet

- Project Manager ResumeDocument4 pagesProject Manager ResumeJesse Bucholtz100% (2)

- Tarun 6767Document2 pagesTarun 6767Tarun AgarwalNo ratings yet

- HR Schema Queries and PL SQL ProgramsDocument3 pagesHR Schema Queries and PL SQL Programschakri_vc25% (4)

- Classification of DGR For Transport by AirDocument5 pagesClassification of DGR For Transport by AirPaolo CeruttiNo ratings yet

- PivsuexDocument7 pagesPivsuextthenryNo ratings yet

- Lab ReportDocument12 pagesLab Reportbotakmbg6035No ratings yet

- 15BC51900223 Parts BookDocument363 pages15BC51900223 Parts BookDavid Joel Davis Miranda100% (1)