Professional Documents

Culture Documents

PIPE SUPPORTS Table List

Uploaded by

CosminMarianCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PIPE SUPPORTS Table List

Uploaded by

CosminMarianCopyright:

Available Formats

SPECIFICATION – PIPING 2300-8230-SP-000-0023

PAGE 18 OF 29

PIPING SUPPORT STANDARD REV F2

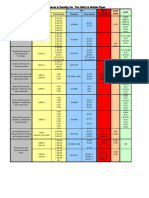

Attachment 5 – Index of Standard Pipe Support Types

Type No Description Pipe sizes Sheet Rev

PIPE ATTACHMENTS

AT – 1 Welding Lug AT 1 F1

AT – 2 Attachment Mounting AT 2 F1

Plate

AT – 3 Welding Clip AT 3 F1

AT- 4A/B Hanger Attachment AT 4 F1

AT - 5 Weldless Steel Clevis AT 5 F1

AT - 6 Turnbuckle AT 6 F1

AT-7A/B Hanger Attachment AT 7 F1

AT - 9 Hanger Attachment AT 9 F1

AT - 10 Hanger Attachment AT 10 O1

AT - 11 Weldless Eye Nut AT 11 F1

AT - 31&32 Standard U-Bolts Up to 24" AT 31 F1

AT - 34 Straight Rods AT 34 F1

Pipe Clamps for CS, Up to 24" AT 36 F1

AT - 36, 37, 42 LTCS, SS, Cr Mo &

& 43 Alloy Pipes (Mod

Load)

Pipe Clamps for CS, 6” to 24" AT 54 F1

AT - 54, 55 LTCS, SS, Cr Mo &

Alloy Pipes (Heavy

Load)

AT – 70 Wear Pad 2" to 96" AT 70 O1

AT – 72 Elbow Pad 3" to 24" AT 72 O1

AT – 73 Shear Lugs 2" to 24" AT 73 O1

AT - 98 TICO Pipe Grip Up to 8" AT 98 F1

(U-Bolt)

AT - 99 TICO Pipe Guide Up to 8" AT 99 F1

(U-Bolt)

AT - 102 End Plate for Bolted AT 102 F5

Pipe Support Bracket

AT – 105 Rubbing Bar AT 105 F1

PIPE GUIDES & LINE STOP

Guide for Insulated 2" to 12” PG 1 F2

PG - 1 Horizontal Piping

from Adjacent Steel

Guide for Insulated 14" to 24 PG 2 F4

PG – 2A & 2B Horizontal Piping

from Adjacent Steel

or Concrete beam

PG - 3A/B/C Horizontal Guide for Up to 12” PG 3 F2

Uninsulated Lines

2300-8230-SP-000-0023_Rev F2.docx DSN:3611

SPECIFICATION – PIPING 2300-8230-SP-000-0023

PAGE 19 OF 29

PIPING SUPPORT STANDARD REV F2

Type No Description Pipe sizes Sheet Rev

PG - 5 Guide for Horizontal 14" to 24" PG 5 F2

Uninsulated Lines

Guide (Stop) for Up to 3" PG 6 F1

PG - 6,7,8 & 9 Horizontal Piping

from Adjacent Steel

Guide for 2" to 8" PG 10 F1

PG - 10,11 & Uninsulated Vertical

12 Piping from Adjacent

Steel or Tower

Guide for 2" to 12" PG 13 F1

PG – 13 & 14 Uninsulated Vertical

Piping from Adjacent

Column

PG - 16A/B Multiple Guide from Up to 2" PG 16 F1

Adjacent Vessel or

Structure

PG - 17A/B From Adjacent Up to 12" PG 17 F1

Vessel or Structure

Pipe Guide from 14" to 24" PG 18 F1

PG - 18 Adjacent Vessel or

Structure

Guide for Support PG 20 F1

PG - 20A/B Adjacent to Grade or

Steel

PG - 22, 23 Stainless Steel Pipe Up to 16” PG 22 F1

Clamp

Guide for Insulated Up to 12" PG 24 F1

PG - 24A/B Vertical Pipe from

Adjacent Column

PG - 25 Cantilever Bracket 4" to 6" PG 25 F1

from Adjacent Tower

PG - 26, 27 Carbon Steel Guide Up to 16” PG 26 F1

Pipe Clamp

PG – 28 Adjustable struts PG 28 F1

Line Stops for Up to 4" PG 30.1 F4

PG - 30 Variable Height

Shoes

PG - 30 Line Stops for Up to 4" PG 30.2 F4

Uninsulated Pipes

PG - 31 Line Stops for 6” to 10" PG 31.1 F4

Variable Height

Shoes

PG - 31 Line Stops for 6” to 10" PG 31.2 F4

Uninsulated Pipes

Line Stops for 12” to 24" PG 32.1 F5

PG - 32 Variable Height

Shoes

PG - 32 Line Stops for 12” to 24" PG 32.2 F4

Uninsulated Pipes

2300-8230-SP-000-0023_Rev F2.docx DSN:3611

SPECIFICATION – PIPING 2300-8230-SP-000-0023

PAGE 20 OF 29

PIPING SUPPORT STANDARD REV F2

Type No Description Pipe sizes Sheet Rev

PG-33 Line Stops for Large

Bore Shoes 26” to 96” PG 33.1 O1

Variable Height Shoe

Line Stops for Large

PG-33 Bore Shoes 50” to 96” PG 33.2 O1

Variable Height Shoe

PG-34 Clamped Stop Up to 6” PG 34 O1

PG-35 Supporting Lug for Up to 3” PG 35 O1

Vertical Pipes

PG - 36A/B Guide for Vertical Up to 3" PG 36 F1

Piping from Adjacent

Vessel or Steel

PG-40 Compressor Pipes Up to 3” PG 40 O1

PG-44 Acoustic and 4” to 16” PG 44 O1

Compressor Pipes

PG - 45 Guide/Hold down 1" - 12" PG 45 F2

Clip

PG – 47 Shoe Guide/H.D. 1” – 24” PG 47 F2

A/B/C/D Clips

PIPE HANGERS

PH - 01/02 Hanger Assembly Up to 24" PH 1 F1

Insulated/Uninsulated

Pipe

FOUNDATION STANDARDS

PL – 1 Pipe Support PL 1 F1

Foundation

PL – 2 Pipe Support PL 2 F5

Foundation

PL – 3 Pipe Support PL 3 F1

Foundation

PL – 4 Pipe Support PL 4 F2

Foundation

PIPE REST SUPPORTS

PS 1A/B Cantilever Bracket Up to 12” PS 1 F1

from Adjacent Steel

or Vessel

PS – 2A/B Braced Cantilever Up to 12” PS 2 F1

Bracket from

Adjacent Steel or

Vessel

2300-8230-SP-000-0023_Rev F2.docx DSN:3611

SPECIFICATION – PIPING 2300-8230-SP-000-0023

PAGE 21 OF 29

PIPING SUPPORT STANDARD REV F2

Type No Description Pipe sizes Sheet Rev

PS – 3 Double Column Up to 24” PS 3.1 F2

Bracket from

Adjacent Steel or

Concrete

PS – 3 Double Column Up to 24” PS 3.2 F4

Bracket from

Adjacent Steel or

Concrete (Notes)

PS – 3 & 4 Nomograph for PS 3.3 F1

Equivalent Size by

Pipe Weight for use

with PS – 3 & PS – 4

PS – 4 Double Column Up to 24” PS 4.1 F2

Hanger from

Adjacent Steel or

Concrete

PS – 4 Double Column Up to 24” PS 4.2 F4

Hanger from

Adjacent Steel or

Concrete (Notes)

PS – 5 Single Column Up to 24” PS 5.1 F2

Bracket from

Adjacent Steel or

Concrete

PS – 5 Single Column Up to 24” PS 5.2 F4

Bracket from

Adjacent Steel or

Concrete (Notes)

PS – 6 Single Column Up to 24” PS 6.1 F2

Hanger from

Adjacent Steel or

Concrete

PS – 6 Single Column Up to 24” PS 6.2 F4

Hanger from

Adjacent Steel or

Concrete (Notes)

PS – 7A/B T – Support from PS 7.1 F1

Adjacent Steel

(Support)

PS – 7A/B T – Support from PS 7.2 F1

Adjacent Steel

PS – 8 Cantilever Support Up to 4” PS 8 F1

from Adjacent Steel

PS – 9 Cantilever Bracket for 6” to 12” PS 9 F1

Vertical Piping from

Adjacent Steel

PS – 10A – D Single ‘L’ Support or Up to 12” PS 10 F1

Hanger Adjacent to

Steel

2300-8230-SP-000-0023_Rev F2.docx DSN:3611

SPECIFICATION – PIPING 2300-8230-SP-000-0023

PAGE 22 OF 29

PIPING SUPPORT STANDARD REV F2

Type No Description Pipe sizes Sheet Rev

PS – 11A – D Double ‘L’ Support or Up to 8” PS 11 F1

Hanger Adjacent to

Steel

PS – 12A/B Support for Vertical Up to 8” PS 12 F1

Piping from Adjacent

Vessel or Structure

PS – 13 Support for Vertical Up to 6” PS 13 F1

Piping from Adjacent

Vessel

PS – 16 Braced Cantilever 8” to 12” PS 16 F1

Bracket from

Adjacent Vessel

F1

PS – 17 Braced Cantilever Up to 8” PS 17

Bracket for Horizontal

Piping from Adjacent

Vessel

PS – 22 Two Storey Up to 8” PS 22 F1

Cantilever Bracket

from Adjacent Steel

PS – 23A/B Cantilever Bracket for Up to 10” PS 23 F1

Horizontal Piping

from Adjacent

PS – 24A – C Extension from Up to 24” PS 24 F1

Adjacent Steel

PS – 25 Cantilever Bracket 4” to 6” PS 25 F1

from Adjacent Tower

PS – 28 & 29 Steel Sleeper in Up to 8” PS 28 F1

Trench or at Grade

Structural Trunnion Up to 12” PS 30.1 F4

PS – 30A–B Support

Structural Trunnion Up to 12” PS 30.2 F4

PS – 30D–E Support

PSM - 30A-F Structural Trunnion Up to 16” PSM 30.1 F4

Support for Cr. Mo

Lines

PSM - 30A-F Structural Trunnion Up to 16” PSM 30.2 F4

Support for Cr. Mo

Lines

PS – 31 Rest Base Plate 3” to 24” PS 31 F1

PS – 32 A – C, Support for Vertical Up to 24” PS 32.1 F3

33 A – C, 34 A Piping from Adjacent PS32.2 F3

– C & 35A – C Steel

PS – 41A – F Adjustable Baseplate Up to 28” PS 41 F1

from Grade or Steel

for Trunnions

2300-8230-SP-000-0023_Rev F2.docx DSN:3611

SPECIFICATION – PIPING 2300-8230-SP-000-0023

PAGE 23 OF 29

PIPING SUPPORT STANDARD REV F2

Type No Description Pipe sizes Sheet Rev

PS – 42A /B/C Anchor Baseplate 3” to 24” PS 42 F1

from Grade

PS – 44A Cantilever Bracket Up to 8” PS44A F1

from Adjacent

Concrete

F1

PS – 44B/C Cantilever Bracket Up to 8” PS44B

from Adjacent

Concrete

PS – 46A T-Post from Grade PS46A.1 F1

(Support)

PS – 46A T-Post from Grade PS46A.2 F1

(Loading)

PS – 46B T-Post from Grade PS46B.1 F1

(Support)

PS – 46B T-Post from Grade PS46B.2 F1

(Loading)

PS – 46C T-Post from Grade PS46C.1 F1

(Support)

PS – 46C T-Post from Grade PS46C.2 F1

(Loading)

PS – 46D T-Post from Grade PS46D.1 F1

(Support)

PS – 46D T-Post from Grade PS46D.2 F1

(Loading)

PS - 53A/B, Double Column PS 53 F1

54A/B & 55A/B Bracket or Hanger for

Spring Support

PS – 56 Braced Cantilever 8” – 24” PS 56 F1

Bracket from

Adjacent Vessel

PS – 57 Braced Cantilever Up to 3” PS 57 F1

Bracket from

Adjacent Tower

PS – 59 Cantilever Bracket Up to 3” PS 59 F1

from Adjacent Tower

PS – 60& 61 Cantilever Bracket for PS 60 F1

Spring Support

PS – 62 T-Support from PS 62.1 F1

Adjacent

PS – 62 T-Support from PS 62.2 F1

Adjacent Vessel

(Loading)

PS – 69 Support Brace for Up to 2” PS 69.1 O1

Small Bore Pipe

Branches

PS – 69 Support Brace for Up to 2” PS 69.2 O1

Small Bore Pipe

Branches

2300-8230-SP-000-0023_Rev F2.docx DSN:3611

SPECIFICATION – PIPING 2300-8230-SP-000-0023

PAGE 24 OF 29

PIPING SUPPORT STANDARD REV F2

Type No Description Pipe sizes Sheet Rev

PS – 82A/B Knee Brace Support Up to 12” PS 82 F1

at Relief Valve

PS – 85 Support from Drain PS 85 F1

PS – 86A – E Variable Brace PS 86 F1

PS – 90A Support Frame from PS 90A F1

Adjacent Concrete

PS – 90B Support Frame from PS 90B F1

Adjacent Concrete

PS – 91 Adjustable Support PS 91 F1

from Grade

PS – 92A/B Support from 2”-12” PS 92 F1

Adjacent Concrete

PS – 94 Support Frame from PS 94 F1

Adjacent Concrete

PS – 95A/B/C Bracket from PS 95 F1

Adjacent Steel to

guide vertical pipes

PS – 96A/B/C Bracket from PS 96 F1

Adjacent Concrete to

Guide Vertical Pipes

PS – 98A/B/C Adjustable Support Up to 24” PS 98 F5

from Steel or Grade

PS – 99 Pipe Support Stool 2” to 16” PS 99 F5

A/B/C/D from Grade

PS – 100 Pipe Supports and PS 100 F1

Platform Penetrations

PS – 101 Braced Cantilever Up to 30” PS 101.1 F2

Bracket From

Adjacent Steel or

Concrete Column

PS – 101 Braced Cantilever Up to 30” PS 101.2 F2

Bracket From

Adjacent Steel or

Concrete Column

(Loading)

PS– 102A/B Support Frame from PS 102 F1

Adjacent Concrete

PS – 105 Small Bore Pipe Up to 1 ½” PS 105 F1

Supports for Pipes

1 ½” and Below

PS – 125 Cantilever bracket for 4”-8” PS 125 F1

pipe guides from

adjacent tower/vessel

PS – 130A/B Parasite Support Up to 3” PS 130 O1

PSX – 12A/B Clamped anchor for Up to 8” PSX 12 O1

vertical Piping

PSX – 13 Support with Clamps Up to 6” PSX 13 O1

for vertical Piping

from adjacent vessel

2300-8230-SP-000-0023_Rev F2.docx DSN:3611

SPECIFICATION – PIPING 2300-8230-SP-000-0023

PAGE 25 OF 29

PIPING SUPPORT STANDARD REV F2

Type No Description Pipe sizes Sheet Rev

PSX – 30A/B/C Support from grade Up to 24” PSX 30 O1

or steel with Clamps

PSX – 82A/B Clamped knee brace Up to 12” PSX 82 O1

PIPE SHOES

S – 1A/B Welded Shoe for Up to 1½” S1 O1

Small Bore Piping

S-2/S-3 Welded Shoes 2” to 12” S2 F4

Varying Heights&

Lengths

S – 4 to S - 12 Welded Shoes 14” to 24” S 4.1 O1

Varying Heights&

Lengths

S – 4 to S - 12 Welded Shoes 14” to 24” S 4.2 O1

Varying Heights&

Lengths

S - 15 Welded Shoes 26” to 48” S 15.1 O1

Varying Heights&

Lengths

S - 15 Welded Shoes 26” to 48” S 15.2 O1

Varying Heights&

Lengths

S - 16 Welded Shoes 26” to 48” S 16.1 O1

Varying Heights&

Lengths

S - 16 Welded Shoes 26” to 48” S 16.2 O1

Varying Heights&

Lengths

S - 17 Welded Shoes 50” to 96” S 17.1 O1

Varying Heights&

Lengths

S - 17 Welded Shoes 50” to 96” S 17.2 O1

Varying Heights&

Lengths

S - 17 Welded Shoes 50” to 96” S 17.3 O1

Varying Heights&

Lengths

S - 18 Welded Shoes 50” to 96” S 18.1 O1

Varying Heights&

Lengths

S - 18 Welded Shoes 50” to 96” S 18.2 O1

Varying Heights&

Lengths

S - 18 Welded Shoes 50” to 96” S 18.3 O1

Varying Heights&

Lengths

2300-8230-SP-000-0023_Rev F2.docx DSN:3611

SPECIFICATION – PIPING 2300-8230-SP-000-0023

PAGE 26 OF 29

PIPING SUPPORT STANDARD REV F2

Type No Description Pipe sizes Sheet Rev

S - 18 Welded Shoes 50” to 96” S 18.4 O1

Varying Heights&

Lengths

SX – 1A/B Shoe for Small Bore Up to 1 ½” SX1 O1

Piping with Clamps

SX – 2 / SX – 3 Shoe with Clamps 2” to 12” SX2.1 O1

SX – 2 / SX – 3 Shoe with Clamps 2” to 12” SX2.2 O1

SX – 4 to Shoe with Clamps for 14” to 24” SX4-1 O1

SX-12 larger Bore Piping

SX – 4 to Shoe with Clamps for 14” to 24” SX4-2 O1

SX-12 larger Bore Piping

Variable Height &

SX – 16 Length Shoe for 26” to 48” SX16 O1

Large Bore Piping

Variable Height &

SX – 19 to Length Shoe for 26” to 48” SX19 O2

SX - 21 Large Bore Piping

with hold down

guides

SX – 27 Hot Clamp Shoes Up to 24” SX27 O1

Line Stop

SX – 99 Isolation Barrier for Up to 24” SX99 O1

SS and Alloy Pipe

SXM - 2 Clamped Shoes for ½” to 8” SXM2.1 O1

Cr Mo Lines

SXM - 2 Clamped Shoes for ½” to 8” SXM2.2 O1

Cr Mo Lines

SXM - 3 Clamped Shoes for 10” to 12” SXM3 O1

Cr Mo Lines

SXM - 4 Clamped Shoes for 14” to 16” SXM4 O1

Cr Mo Lines

SXM - 5 Clamped Shoes for 18” to 24” SXM5 O1

Cr Mo Lines

LOW FRICTION SUPPORTS

SU - 1 PTFE / TICO Slide SU 1 F1

Unit

SU - 2 Slide Unit SU 2 F1

SU - 3 Slide Unit SU 3 F3

PIPE TRUNNION DETAILS (Non-preferred)

Do not use without Lead Engineer approval

TR- 1/2/13 &14 Horizontal Elbow Up to 38” TR 1 F1

Trunnions

TR- 3/4/ & 15 Base Trunnions Up to 38” TR 3 F1

TR- 5/6/7 & 8 Pipe Trunnion Detail Up to 38” TR 5 F1

2300-8230-SP-000-0023_Rev F2.docx DSN:3611

SPECIFICATION – PIPING 2300-8230-SP-000-0023

PAGE 27 OF 29

PIPING SUPPORT STANDARD REV F2

Type No Description Pipe sizes Sheet Rev

TR- 9 Line Stop for TR 9 F1

Horizontal Piping

TR – 10 Flat Turn Elbow Up to 38” TR 10 F1

TR – ALL Pipe Trunnion T14 F1

Calculation Sheet

TR – ALL Pipe Trunnion T15 F1

Selection Chart

SUPPLEMENTARY BEAMS

TS – 1 Supplementary Steel TS 1 F1

Beams

2300-8230-SP-000-0023_Rev F2.docx DSN:3611

You might also like

- Scania DC12 Operator's ManualDocument65 pagesScania DC12 Operator's ManualAlex Renne Chambi100% (3)

- Geography Grade 11 ANotes and Worksheet On Topography Associated With Horozontally Layered RocksDocument13 pagesGeography Grade 11 ANotes and Worksheet On Topography Associated With Horozontally Layered RocksTheo MolotoNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- The Trend Trader Nick Radge On Demand PDFDocument8 pagesThe Trend Trader Nick Radge On Demand PDFDedi Tri LaksonoNo ratings yet

- 600 # ANSI Piping DataDocument16 pages600 # ANSI Piping DataMekar MeinaNo ratings yet

- PLP Dulmison PDFDocument329 pagesPLP Dulmison PDFRoberto Velarde AlvaradoNo ratings yet

- Visibility of NursesDocument17 pagesVisibility of NursesLuke ShantiNo ratings yet

- Hermes - GodDocument19 pagesHermes - GodAvocadoraNo ratings yet

- Welding MapDocument10 pagesWelding MapWiwik HaryadiNo ratings yet

- CT Nut Forged GGCDocument32 pagesCT Nut Forged GGCanderson_bicudoNo ratings yet

- BoqDocument4 pagesBoqShashi RanjanNo ratings yet

- U00034-PL-MTO-0001 - MTO For Export PipelinesDocument7 pagesU00034-PL-MTO-0001 - MTO For Export PipelinesThiên KhánhNo ratings yet

- Product CatalogDocument106 pagesProduct CatalogAri AzadNo ratings yet

- REF CODE: JS0012-75650100-SPC-001, REV. R0: Project: 35Mw Co-Gen Plant at Bhusanoor - Electrical PackageDocument32 pagesREF CODE: JS0012-75650100-SPC-001, REV. R0: Project: 35Mw Co-Gen Plant at Bhusanoor - Electrical Packageganesh_dgNo ratings yet

- Balon CompleteCatalogDocument106 pagesBalon CompleteCatalogJemmyNo ratings yet

- Julia Kristeva IntroDocument7 pagesJulia Kristeva IntroShweta SoodNo ratings yet

- External Cooling Unit ACS - 1000Document133 pagesExternal Cooling Unit ACS - 1000mabdelaal2090No ratings yet

- The Promised Land PDFDocument12 pagesThe Promised Land PDFnazim2851No ratings yet

- Step Buying Process in LazadaDocument4 pagesStep Buying Process in LazadaAfifah FatihahNo ratings yet

- 150 # ANSI Piping DataDocument21 pages150 # ANSI Piping DataMekar MeinaNo ratings yet

- Air Torque 4THGU-E-06Document26 pagesAir Torque 4THGU-E-06agrovado0% (1)

- BOQ PIPING Total DetailDocument16 pagesBOQ PIPING Total Detailsuria qaqcNo ratings yet

- Pipe Support StandardDocument32 pagesPipe Support StandardHema Nandh100% (1)

- Mooney 2 LP FLowgrid Shutoff ValveDocument2 pagesMooney 2 LP FLowgrid Shutoff ValveLuis mario Castillo olveraNo ratings yet

- Beric Forged Steel ValvesDocument32 pagesBeric Forged Steel ValvesKit AnnoncerNo ratings yet

- Inq. 4502Document27 pagesInq. 4502srave_k07No ratings yet

- New Microsoft Excel WorksheetDocument3 pagesNew Microsoft Excel WorksheetharshNo ratings yet

- Accessories: End StopsDocument1 pageAccessories: End StopsigrewawtileNo ratings yet

- Intraxx Part ListDocument8 pagesIntraxx Part Listcristian picadoNo ratings yet

- Attachment-A1 - SBB ValvesDocument3 pagesAttachment-A1 - SBB Valvesbsnegi111No ratings yet

- The - Comparison - Table of - StandardsforthepipesDocument1 pageThe - Comparison - Table of - StandardsforthepipesNitesh katariaNo ratings yet

- Parts List: Intraax Aat - 23K, 25K, 30KDocument8 pagesParts List: Intraax Aat - 23K, 25K, 30KJoelNo ratings yet

- CPM FMR 22 002Document1 pageCPM FMR 22 002Mark Darrel AranasNo ratings yet

- PneumaticsDocument31 pagesPneumaticsvikramchowdaryNo ratings yet

- Data Sheet - UPRV R2-5Document4 pagesData Sheet - UPRV R2-5vipulsingh130No ratings yet

- BOM Mechanical - Relocate WHA PP Plant 3000012186Document1 pageBOM Mechanical - Relocate WHA PP Plant 3000012186Ibnu KoharNo ratings yet

- Section9 - Double Block and Bleed ValveDocument6 pagesSection9 - Double Block and Bleed ValveFarras Surya NugrahaNo ratings yet

- SteelbarDocument11 pagesSteelbarAndrewNo ratings yet

- 52000427BD-Alliance-Airport Expansion (R-2) - EmailDocument3 pages52000427BD-Alliance-Airport Expansion (R-2) - EmailTanveer AzizNo ratings yet

- SB15 Spare PartsDocument2 pagesSB15 Spare PartsProdajapasaonlineNo ratings yet

- 61.MIG Adapters, Sockets & Quick Disconnect.10-03-2023Document1 page61.MIG Adapters, Sockets & Quick Disconnect.10-03-2023maintenance sagaNo ratings yet

- Instruction Manual: Please Read This Manual Before Installation and UseDocument14 pagesInstruction Manual: Please Read This Manual Before Installation and UseCuong PhanNo ratings yet

- Antisism Sargent Description: Friendly Service.. Powerful SolutionDocument3 pagesAntisism Sargent Description: Friendly Service.. Powerful SolutionALEXANDER CANALESNo ratings yet

- Molde Soldadura SSDocument1 pageMolde Soldadura SSMarcos Ivan Ramirez AvenaNo ratings yet

- HanSun Pipe FittingsDocument35 pagesHanSun Pipe Fittingspurav_patel20079232No ratings yet

- Coatings Guide: Air Intake Air Intake Exhaust Compressor Compressor Combustor Combustor Turbine TurbineDocument1 pageCoatings Guide: Air Intake Air Intake Exhaust Compressor Compressor Combustor Combustor Turbine TurbinefrdnNo ratings yet

- Cross Reference: Instrumentation Tube FittingsDocument32 pagesCross Reference: Instrumentation Tube FittingsJuanVargasNo ratings yet

- GLT Gate Valve SW, NPTDocument2 pagesGLT Gate Valve SW, NPTblloewyNo ratings yet

- 0344-MI20-00S1-0110-01-0-spec G1Document1 page0344-MI20-00S1-0110-01-0-spec G1KadufigueiredoNo ratings yet

- Dry-Barrel Fire Hydrant FIG.F0733-250Document2 pagesDry-Barrel Fire Hydrant FIG.F0733-250mohamed KotpNo ratings yet

- Catalogo AskaDocument44 pagesCatalogo AskaMilton Damián Cornejo ReyesNo ratings yet

- Weld Chart 1Document4 pagesWeld Chart 1ravi00098No ratings yet

- Plant Projects & Engineering Services Depatment: Sr. No Part Name Item Description Size QtyDocument4 pagesPlant Projects & Engineering Services Depatment: Sr. No Part Name Item Description Size QtyShamil AhzanNo ratings yet

- Completion Diagram: SchlumbergerDocument2 pagesCompletion Diagram: SchlumbergerKevin RichardhoNo ratings yet

- General - Tooling: ContentDocument38 pagesGeneral - Tooling: ContentKaiser46Li206No ratings yet

- 300 # ANSI Piping DataDocument13 pages300 # ANSI Piping DataMekar MeinaNo ratings yet

- Estimation Replacement Line Cw1 Centac, Install Valve & StrainerDocument1 pageEstimation Replacement Line Cw1 Centac, Install Valve & Strainerarifinzaky27No ratings yet

- Consumables For SSDocument14 pagesConsumables For SSELongLeeNo ratings yet

- Sl. No Sheet No. Rev. P&Id Size SCH/THK Rating Description Material Item Unit Qty Status/Remarks Emec DWG NoDocument3 pagesSl. No Sheet No. Rev. P&Id Size SCH/THK Rating Description Material Item Unit Qty Status/Remarks Emec DWG NoAnonymous UZFenDTNMNo ratings yet

- Trade Price List: September 2016Document28 pagesTrade Price List: September 2016Jhon SanfraNo ratings yet

- 003-036 Thread Turning InsertsDocument34 pages003-036 Thread Turning InsertsGuntis KolcsNo ratings yet

- Tecnoplast SRL - Product ListDocument44 pagesTecnoplast SRL - Product Listbarino1966No ratings yet

- Accesorios STS 2.Document2 pagesAccesorios STS 2.DanaNo ratings yet

- Fig. 315 / 330 G Fig. 415 / 430: Ball Valves PN 20/50 (Class 150/300) AIT & IIT ConstructionDocument5 pagesFig. 315 / 330 G Fig. 415 / 430: Ball Valves PN 20/50 (Class 150/300) AIT & IIT ConstructionBureau VeritasNo ratings yet

- Jl. Perak Timur 102 Surabaya: Weight SummaryDocument74 pagesJl. Perak Timur 102 Surabaya: Weight SummaryhajarNo ratings yet

- Parker Origa LieferprogrammDocument843 pagesParker Origa LieferprogrammdeepaNo ratings yet

- Copie de GS - EP - PVV - 112 - EN 1Document13 pagesCopie de GS - EP - PVV - 112 - EN 1Tien HaNo ratings yet

- Materials: All Components Are Surface Treated and ProtectedDocument4 pagesMaterials: All Components Are Surface Treated and ProtectedAnonymous 80HAPYsoNo ratings yet

- Piping Isometric - 5Document1 pagePiping Isometric - 5CosminMarianNo ratings yet

- Piping Isometric - 7Document1 pagePiping Isometric - 7CosminMarianNo ratings yet

- Piping Isometric - 9Document1 pagePiping Isometric - 9CosminMarianNo ratings yet

- Piping Isometric - 3Document1 pagePiping Isometric - 3CosminMarianNo ratings yet

- Piping Isometric - 6Document1 pagePiping Isometric - 6CosminMarianNo ratings yet

- Piping Isometric - 8Document1 pagePiping Isometric - 8CosminMarianNo ratings yet

- Docs Grails Org 4 0 0 Guide Single HTMLDocument296 pagesDocs Grails Org 4 0 0 Guide Single HTMLlicface13No ratings yet

- Henry's Bench: Keyes Ky-040 Arduino Rotary Encoder User ManualDocument4 pagesHenry's Bench: Keyes Ky-040 Arduino Rotary Encoder User ManualIsrael ZavalaNo ratings yet

- Cognitive Benefits of Language LearningDocument11 pagesCognitive Benefits of Language LearningIlhamdi HafizNo ratings yet

- Discovering JerusalemDocument134 pagesDiscovering JerusalemDzhel DezjayNo ratings yet

- Exercise 3 - Wireframe Geometry Creation and Editing - Rev ADocument33 pagesExercise 3 - Wireframe Geometry Creation and Editing - Rev AdevNo ratings yet

- How To Draw The Platform Business Model Map-David RogersDocument5 pagesHow To Draw The Platform Business Model Map-David RogersworkneshNo ratings yet

- Chapter 12 Fraud and ErrorsDocument3 pagesChapter 12 Fraud and ErrorsMajoy BantocNo ratings yet

- A Lonely Quest For Facts On Genetically Modified CropsDocument5 pagesA Lonely Quest For Facts On Genetically Modified Cropsbrkica2011No ratings yet

- Armenotech PCIDSS AOCDocument13 pagesArmenotech PCIDSS AOCHakob ArakelyanNo ratings yet

- Classification by Depth Distribution of Phytoplankton and ZooplanktonDocument31 pagesClassification by Depth Distribution of Phytoplankton and ZooplanktonKeanu Denzel BolitoNo ratings yet

- Brunswick Manual Preinstalacion GSXDocument33 pagesBrunswick Manual Preinstalacion GSXroberto dominguezNo ratings yet

- Dassault Systems Academic CalenderDocument5 pagesDassault Systems Academic CalenderSarath KumarNo ratings yet

- Letter of IntentDocument2 pagesLetter of Intentmansoorstanikzai4No ratings yet

- A 268 - A 268M - 01 Qti2oc0wmq - PDFDocument6 pagesA 268 - A 268M - 01 Qti2oc0wmq - PDFMan98No ratings yet

- 12 - Chepter 5Document11 pages12 - Chepter 5KhaireddineNo ratings yet

- Papaer JournelDocument6 pagesPapaer JournelsonalisabirNo ratings yet

- LinuxSocials RoadmapDocument12 pagesLinuxSocials RoadmapShrutiNo ratings yet

- HLSS 310 Critical Infrastructure ProtectionDocument12 pagesHLSS 310 Critical Infrastructure ProtectionMoffat HarounNo ratings yet

- Za Deloitte Intelligent Mining InfographicDocument4 pagesZa Deloitte Intelligent Mining InfographicAgung SupriyantoNo ratings yet

- TelemetryDocument8 pagesTelemetryKristin WiseNo ratings yet

- Kinetika Kimia Pada Laju ReaksiDocument25 pagesKinetika Kimia Pada Laju ReaksiWardahNo ratings yet

- The Macquarie Australian Slang DictionarDocument7 pagesThe Macquarie Australian Slang DictionarnetshidoNo ratings yet