Professional Documents

Culture Documents

Notes 12 Envi

Uploaded by

Jxce MLeKidOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Notes 12 Envi

Uploaded by

Jxce MLeKidCopyright:

Available Formats

MIDTERM TOPIC 1 & 2 ENVIRONMENTAL OPTOMETRY

“NO OTHER PHYSICAL DEFECT IS SO Minimum standard of care

AMENABLE TO CORRECTION AS IS FAULTY

VISION, AND HARDLY ANY OTHER SO AFFECTS 1. Complete an occupational history on each adult

JOB PERFORMANCE..” patient, including assessment and

interpretation of it

VISION, in two important ways, stand apart

from other human factors related to job success 2. Identifying and diagnose conditions that may

be occupationally induced and make

The quality of visual performance can be appropriate referrals if necessary

measured quickly, comprehensively and

dependably 3. Assess their patient’s visual needs and provide

When vision is below desirable levels it can be treatment for maximizing their on-the-job

improved readily in a high percentage of cases performance

and at relatively low cost to the individual 4. Initiate preventive measures for patients and

Environmental Optometry other with the same eye and vision risk

Branch of optometry that broadly considers the PREVENTION OF EYE INJURIES

relationship of people’s eye and vision to all Optometrist has a key role in preventing eye

aspects of their environments, including home, injuries and visually related injuries to co-

school, work, recreation, transportation, workers

underwater and outer space.

1. Prescribe eye protection designed for specific

Occupational Optometry job, usually in form of safety spectacle

Branch of environmental optometry that 2. Make certain that a person has good visual skills

considers all aspects of the relationship for his or her job

between work and vision, visual performance,

eye safety, and health.

INCLUDES:

worker’s eye and visual system

worker and the workplace environment

Emphasis of occupational optometry is

high quality patient with two major

priorities:

1. Prevention of work related diseases. , injuries,

and vision disorders ; and

2. Enhanced performance of workers on the job

A secondary but important concern of

occupational optometrist is disease prevention Trends affecting Optometrists

and health promotion

1. A growing awareness that exposures to

Goals of primary care and occupational hazardous substance in workplace, home, and

optometry general environment may cause or contribute

to the origins of dse and influence its natural

1. To incorporate environmental optometry into

history

private practice and assess the impact of vision

disorders and eye diseases on the ability of 2. An increasing awareness of the effects of the

patients to work visual environment (lighting, contrast, glare

and exposure to ultraviolet, infrared, ionizing,

2. To assess the impact of work and the work

and microwave radiation) on vision, vision

environment on the performance of the worker

performance and perception.

on the job, at home, and during recreation

3. An increasing concern regarding the economic

3. To understand the relationship between health

and social costs of premature mortality and

and work and to recognize, diagnose, treat, and

preventable disability and injuries

prevent work-related illnesses and injuries.

MIDTERM TOPIC 1 & 2 ENVIRONMENTAL OPTOMETRY

4. A continuing increase in the costs of health care SURVEY (BASIC) OCCUPATIONAL

and the benefits of reducing costs through HISTORY

preventing diseases and injuries by early

detection and effective management KEY POINTS:

5. An expansion of legislation, regulation, case 1. Description of current and past jobs and

law, and labor-management agreements that occupations

increase responsibility of employers for the 2. Employment status (including unemployed,

physical and mental health of their workers. retired)

3. Exposure to hazards ; and

6. An increasing number of women in the work 4. Assessment of work-reletadness of the chief

force and concerns for the future reproductive complaint or diagnosis

health of both women and men.

Classification of hazards:

7. A transformation our economy from an

industrial to an information-based system and 1. Physical ( radiation, noise, extreme

the increasing complexity of the work place temperatures, heavy lighting and repetitive

motion)

8. An aging of the work force 2. Chemical ( lead, mercury, dust, gases, fumes,

solvents, acids, caustics)

9. An increasing insistence of workers to be 3. Biologic ( virsuses, bacteria, parasites, fungi)

informed and to participate in all areas that 4. Psychologic ( boredom, work shift fatigue, risk

affect their personal welfare of falling, repetition)

10. An increasing interest by employers, insurance 5. Ergonomic (improper tool or work area

carriers and public in health promotion and dse design, unnecessary lifting, poor vision

prevention condition)

Occupational History

- Optimal patient management requires taking DIAGNOSTIC OCCUPATIONAL HISTORY

occupational case histories: - Used when the survey occupational history

- That assess work related task increases the optometrist’s suspicion that the

patient’s signs or symptoms are related to work

- Vision requirements or the environment.

- determining the need for vision and eye Four Key Steps in taking diagnostic

protection, also; history (occupational):

- Risk from environmental hazards 1. A listing of all jobs

2. Identification of all places of employment and

- Impact of current eye disease and vision dso. products manufactured where appropriate.

on job performance 3. Description of all operations performed on the

- Diagnose work-related occupational disease job

4. Assessment of illnesses in other workers similar

Occupational Health History to those of the patient

- Is fundamental to the assessment of the work- Task analysis

relatedness of health problems and should

become a routine component of any A detailed assessment of patient’s work related

comprehensive health history tasks. The assessment is done to maximize

vision performance and minimize or eliminate

Two components: eye and vision hazards

Done to maximize vision performance and

1.) The survey or basic occupational history minimize or eliminate eye and vision hazards

- if needed, the diagnostic occupational Task analysis requires the assessment of

history the following data:

2.) The task analysis 1. Job Description

2. Distance from the worker’s eyes to the work

areas

MIDTERM TOPIC 1 & 2 ENVIRONMENTAL OPTOMETRY

3. Work movement

4. Work area size, centrally and peripherally

5. Visual attention requirements Factors which determine the toxicity of a

6. Work and surround area illumination substance

7. Color discrimination requirements a) Composition of chemicals

8. Stereoacuity requirements b) Physical state

9. Position of work surface c) Amount

10. Eye and vision hazards d) Concentration

11. Size of task details e) Particular size

12. Peripheral vision requirements f) Route of absorption (oral, topical,

injection, inhalation, etc.)

Duration of Exposure

Dangers (Hazards) to Vision

1. Acute – exposure is very short (within

minutes or few days)

Mechanical Hazards 2. Sub-acute – longer than and up to 90

days

- A type of general confined space 3. Chronic – exposure fpr many days or

hazard that exist when electrical or over a month or years

mechanical equipment may be

accidentally activated BIOLOGICAL HAZARDS

- Mechanical agents are normally

described as: - People who work in health related field

Large (>2mm) or Small (2mm - Doctors, nurses, and dentist

or less) - Hepatitis B Virus

Blunt (Edges that rip or tear - HIV

tissue) or Sharp (Edges that - COVID 19

make a smooth cut or puncture ERGONOMIC HAZARDS

in tissue)

Fast moving or Slow moving Definition:

Stationary

Any combinations of the given - Study of the engineering aspects of the

4 relationship between human workers and

their working environment

Mechanical hazards are agents that are

likely to cause: Good posture

Poor lifting technique

Penetrating laceration – puncture Poor fitting of progressives

Non-penetrating laceration – cut Neck ache

Abrasion – scratch/scrape Poor posture

Contusion – damage from pressure

exerted by the material PSYCHOSOCIAL

Common MECHANICAL injury - Stress

- Communication breakdown

a) Chiseling ; hammering - Job overload

b) Woodworking - Boredom

c) Grinding - Burnout

d) Nailing - Job uncertainty

e) Drill and lathe use - Noise pollution

f) Automobile accidents - Poor ventilation

g) Explosives

Radiation

Chemical Hazards

- Electromagnetic radiation outside the

Toxicology – the science concerned with range of 400-700 nanometer(nm) does

poisons and how they affect the body not significantly contribute to visual

perception and some may be harmful

to ocular tissue

MIDTERM TOPIC 1 & 2 ENVIRONMENTAL OPTOMETRY

a) UV-A – 315-400nm(less damage to

body)

b) UV-B – 280 -315nm Chemical Splash Goggles

c) UV-C – 100-280nm - Tight fitting eye protection that

d) IR-A -extending 760-780nm-1400nm completely covers the eyes, eye socket

e) IR-B -1400nm-3000nm and facial area surrounding the eyes

f) IR-C – 3000nm-1mm - Provides protection from impact, dust

PERSONAL PROTECTIVE EQUIPMENT and splashes

Definition: An equipment worn to

minimize exposure to hazards that cause

serious workplace injuries and illnesses

• Ability to protect against specific

workplace hazards

American National Standards Institute

(ANSI) standard Z87.1-1989 Dust goggles- sometimes called direct

ventilated goggles, are tight fitting eye

Testing Process protection designed to resist the passage of

large particles into the goggles

- Basic and high-impact for lenses and

frames

- Exposure to non-ionizing radiation and

chemicals

- Durability to flammables and corrosion

Minimum Requirements of Eyes and Face

Protective Equipment

1. Provide adequate protection against

the particular hazard for which they are Fluid Resistant Shield – the shield is fluid

designed or intended resistant or impervious and provide splash

2. Be reasonably comfortable to use protection from biological material, such as

3. Fit snugly and shall not unduly interfere human or non-human primate body fluids

with the movements of the user

4. Durable, easily cleaned and capable of

disinfected

5. Be kept clean and in good condition

6. Made of non-combustible or slow-

burning materials

7. Distinctively marked as industrial safety

wear with the manufacturer’s name or

trademark on the lenses

8. Should provide unrestricted vision and Face Shield- the shield extend from the

movement eyebrows to below the chin and across the

9. Should allow unrestricted functioning width of the employee’s head

of any other required PPE

• Face shields protect against potential

Safety glasses splashes or sprays of hazardous liquids.

When worn for protection against UV,

- have safety frames constructed of must be specifically designed to protect

metal or plastic and impact-resistant the face and eyes from hazardous

lenses. Side protection is required radiation

MIDTERM TOPIC 1 & 2 ENVIRONMENTAL OPTOMETRY

Helmet – a rigid device worn by the operator

which shield the eyes, the face, the neck and

the portion or all of the other parts of the head,

and is held in place by suitable means

Laser Eyewear – Protective eyewear is

required for Class 3 and 4 laser use where

radiation of the eye is possible

Welding Shield

- Constructed of vulcanized fiber or

fiberglass and fitted with a filtered lens,

welding shields protect eyes from burns

caused by infrared or intense radiant

light

- Also protect both the eyes and the face

from flying sparks, metal splatter and

slag chips produced during welding,

brazing, soldering and cutting

operations

Face mask - Device worn before the eyes and

a portion or all of the face, whose predominant

function is to protect the face

Hood - hand rigid device which completely

covers the head, and portion of the shoulder

You might also like

- Chapter 4 - Occupational Health & HygieneDocument19 pagesChapter 4 - Occupational Health & Hygiene2023131173No ratings yet

- Chapter 3.1 Introduction To Industrial Hygiene and Occupational HealthDocument27 pagesChapter 3.1 Introduction To Industrial Hygiene and Occupational HealthHafizudin DaudNo ratings yet

- Chapter 5 - Occupational Health & HygieneDocument19 pagesChapter 5 - Occupational Health & Hygieneheykoolkid0No ratings yet

- Osha3092Document5 pagesOsha3092Vadyan Haz KamalNo ratings yet

- Industrial Safety and HygieneU1Document45 pagesIndustrial Safety and HygieneU1María MonterrubioNo ratings yet

- Biomarkers, Screening and EthicsDocument4 pagesBiomarkers, Screening and Ethicsarif_amininNo ratings yet

- Lesson Plan 4Document5 pagesLesson Plan 4Jessica Carisma100% (2)

- BoshDocument7 pagesBoshKate CatabuiNo ratings yet

- OH Module For STOs1Document6 pagesOH Module For STOs1Majhi PeraltaNo ratings yet

- BOSH Reviewer PDFDocument6 pagesBOSH Reviewer PDFPamela Nicole BakingNo ratings yet

- BOSH Week 1Document14 pagesBOSH Week 1Marion DominoNo ratings yet

- Health and Safety of People Engaged in Work or EmploymentDocument7 pagesHealth and Safety of People Engaged in Work or EmploymentReg LagartejaNo ratings yet

- 2018 Chapter 3-1 2018 Introduction To Industrial Higiene & Occupational Health PDFDocument59 pages2018 Chapter 3-1 2018 Introduction To Industrial Higiene & Occupational Health PDFLove StrikeNo ratings yet

- Fitness For Work PolicyDocument18 pagesFitness For Work PolicyNaba majeadNo ratings yet

- Ccupational and Environmental OptometryDocument20 pagesCcupational and Environmental OptometryRachana KafleNo ratings yet

- Industrial Hygiene: by - Iram Danish SEMT-48Document33 pagesIndustrial Hygiene: by - Iram Danish SEMT-48Ultrapure AnalytichemNo ratings yet

- Occupational Health Module in The Basic OSH TrainingDocument6 pagesOccupational Health Module in The Basic OSH TrainingBob ReadNo ratings yet

- And Environmental (Hse) Pt. Pertamina RuDocument35 pagesAnd Environmental (Hse) Pt. Pertamina RuAisyah AisyeeNo ratings yet

- TVL-CapsLET - ANI - Week2b (OHS) - Palis, MaryGayDocument15 pagesTVL-CapsLET - ANI - Week2b (OHS) - Palis, MaryGayArthur ManaloNo ratings yet

- Occupational Health1Document40 pagesOccupational Health1BesHoy SaBryNo ratings yet

- Eight Hour Mandatory Modules 1 To 4 - 1Document147 pagesEight Hour Mandatory Modules 1 To 4 - 1ds-nurse100% (1)

- A-06. Human Factors in Safety (Ergonomics)Document127 pagesA-06. Human Factors in Safety (Ergonomics)Rommhel ColiatNo ratings yet

- 2 1industrialhygieneDocument33 pages2 1industrialhygieneAizm DinaniNo ratings yet

- Evaluation Activity N°1Crucigrama2021siDocument4 pagesEvaluation Activity N°1Crucigrama2021siScribdTranslationsNo ratings yet

- Occupational HealthDocument7 pagesOccupational HealthRakhi Sarkar100% (1)

- SOM RTW Guide Health Professionals COVID-19 FINALDocument22 pagesSOM RTW Guide Health Professionals COVID-19 FINALAlma RosaNo ratings yet

- Occupational Health and SafetyDocument30 pagesOccupational Health and SafetyAdakun SamuelNo ratings yet

- Safe Working EnvironmentDocument16 pagesSafe Working EnvironmentDawud AsnakewNo ratings yet

- Understanding and Performing Economic Assessments at The Company LevelDocument46 pagesUnderstanding and Performing Economic Assessments at The Company LevelКонстантин КрахмалевNo ratings yet

- 1.1 Overview Occupational HealthDocument36 pages1.1 Overview Occupational HealthPrasetya Hadi Nugraha100% (1)

- Exams LFOM Syllabus 2016Document11 pagesExams LFOM Syllabus 2016Farrukh QureshiNo ratings yet

- Chapter 4Document1 pageChapter 4Sheriellen X. MedinaNo ratings yet

- Ehs Incident Investigation and Reporting ProcedureDocument6 pagesEhs Incident Investigation and Reporting ProcedurecheremyndikumNo ratings yet

- Dec. 5, 2019Document2 pagesDec. 5, 2019RODELYN PAGSIATNo ratings yet

- Basic Occupational Health and Safety (Lecture) : Earning OduleDocument8 pagesBasic Occupational Health and Safety (Lecture) : Earning OduleRussel Renz de MesaNo ratings yet

- TUTORIAL BATCH 30 Occupational HealthDocument6 pagesTUTORIAL BATCH 30 Occupational HealthRajitha DissanayakaNo ratings yet

- Basic Occupational Safety and HealthDocument12 pagesBasic Occupational Safety and HealthHaide Garcia100% (1)

- Reviewer On Safety PrelimsDocument1 pageReviewer On Safety PrelimsPatrick Paul PalacolNo ratings yet

- Lecture 9Document28 pagesLecture 9Justin JannatiNo ratings yet

- bns10203-OHH CHAP 1Document30 pagesbns10203-OHH CHAP 1aimanamirah13No ratings yet

- BHE - 2022 - Corporate DoctorDocument9 pagesBHE - 2022 - Corporate DoctorAnky CahyoNo ratings yet

- Ergonomic Methods For Assessing Exposure To RiskDocument10 pagesErgonomic Methods For Assessing Exposure To RiskJuan Carlos VelasquezNo ratings yet

- ENS 190 BOSH Part 1Document43 pagesENS 190 BOSH Part 1ML's Trendy ShopNo ratings yet

- The Overload at Work and Outside of WorkDocument5 pagesThe Overload at Work and Outside of WorkJosé Luis Guerra JácomeNo ratings yet

- 0 BOSH FrameworkDocument18 pages0 BOSH Frameworkharold fontiveros100% (1)

- 32-282 Medical Surveillance ProcedureDocument28 pages32-282 Medical Surveillance ProcedureMatshilario60% (5)

- Light: VisionDocument1 pageLight: VisionreacharunkNo ratings yet

- المشروع Copy 2.Ar.enDocument32 pagesالمشروع Copy 2.Ar.enAhmed AhmedNo ratings yet

- إجابات نماذج السلامه المهنيهDocument13 pagesإجابات نماذج السلامه المهنيهmohammedhosney99999No ratings yet

- Hs Committees Part1Document30 pagesHs Committees Part1Tan Chi SianNo ratings yet

- SITXWHS001 Assessment 1 - Short AnswersDocument13 pagesSITXWHS001 Assessment 1 - Short AnswersNasir BilalNo ratings yet

- Occupational Health & Safety: by Assist. Prof. Maytham AL-NasrawiiDocument18 pagesOccupational Health & Safety: by Assist. Prof. Maytham AL-Nasrawiiمحمد محمدNo ratings yet

- BOSH Manual 061320aDocument144 pagesBOSH Manual 061320aAngelo AmayNo ratings yet

- RACGP Managing WellbeingDocument36 pagesRACGP Managing Wellbeinghan tianNo ratings yet

- Occupational Health and Safety 1Document8 pagesOccupational Health and Safety 1Idris IbrahimNo ratings yet

- Occupational Safety and Health Services: By: Joshua Mar S. MelgarDocument51 pagesOccupational Safety and Health Services: By: Joshua Mar S. MelgarChloe Olazo100% (1)

- Core Competencies in Ergonomics Units Elements and Performance CriteriaDocument10 pagesCore Competencies in Ergonomics Units Elements and Performance CriteriaFernandoNo ratings yet

- And Injury by Management of The WorkDocument3 pagesAnd Injury by Management of The WorkAntonette CaparaNo ratings yet

- Ethics Topic PrelimsDocument3 pagesEthics Topic PrelimsJxce MLeKidNo ratings yet

- Midterms Pedia Examination of Preschool and School Aged ChildrenDocument49 pagesMidterms Pedia Examination of Preschool and School Aged ChildrenJxce MLeKidNo ratings yet

- Biostatistics Problem Set (Frequency Distribution Table)Document8 pagesBiostatistics Problem Set (Frequency Distribution Table)Jxce MLeKidNo ratings yet

- 7epidemiology and Public HealthDocument47 pages7epidemiology and Public HealthJxce MLeKidNo ratings yet

- TANGARAN - OPTO 61B - Group Dynamics in OrganizationDocument2 pagesTANGARAN - OPTO 61B - Group Dynamics in OrganizationJxce MLeKidNo ratings yet

- Tangaran - OPTO 61B - Case Study - Culture of OrganixationsDocument6 pagesTangaran - OPTO 61B - Case Study - Culture of OrganixationsJxce MLeKidNo ratings yet

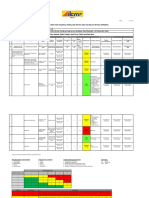

- #010 Hotwork-Cutting in Pump Room - 01-03-10Document6 pages#010 Hotwork-Cutting in Pump Room - 01-03-10Tolias EgwNo ratings yet

- HIRARC FORM 2023 - Tugasan Start Up and Shut Down OPPDocument4 pagesHIRARC FORM 2023 - Tugasan Start Up and Shut Down OPPMuhammad 'Aizat PaimanNo ratings yet

- PTWCDocument168 pagesPTWCMarlon OriarteNo ratings yet

- Biogenic SE 374: Sustainable Solutions For Health, Productivity and The EnvironmentDocument10 pagesBiogenic SE 374: Sustainable Solutions For Health, Productivity and The EnvironmentDwi Cahyo NugrahantoNo ratings yet

- Reis Dialog III ControlDocument122 pagesReis Dialog III ControlBojan MarinkovicNo ratings yet

- DDDDDocument13 pagesDDDDMyo Thant AungNo ratings yet

- CBC Shielded Metal Arc Welding NC IDocument87 pagesCBC Shielded Metal Arc Welding NC IMarlon Ty Manalo88% (16)

- Water Cooled Flooded Vertical Screw ChillersDocument96 pagesWater Cooled Flooded Vertical Screw ChillersaftabNo ratings yet

- Jsa For Gypsum Fixing & DismentlingDocument5 pagesJsa For Gypsum Fixing & DismentlingSushil Kumar YadavNo ratings yet

- Methylene BlueDocument5 pagesMethylene BlueHerman FelaniNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDocument3 pagesSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthNo ratings yet

- Rivoningo T Safety ConsultantsDocument4 pagesRivoningo T Safety ConsultantsZiadSutton100% (1)

- Angle Grinder ChecklistDocument4 pagesAngle Grinder Checklistshakti123456789No ratings yet

- Ajustes 622B PDFDocument178 pagesAjustes 622B PDFabel75% (4)

- Toolbox Talk PpeDocument3 pagesToolbox Talk Ppeanon_348105361No ratings yet

- Basic Concepts On Laboratory Biosafety & Biosecurity: Marilou O. Honculada, RMT, M A Liceo de Cagayan UniversityDocument88 pagesBasic Concepts On Laboratory Biosafety & Biosecurity: Marilou O. Honculada, RMT, M A Liceo de Cagayan UniversityEpaphras Joel MilitarNo ratings yet

- Safety On Transmission Tower Erection, Cable Stringing & CommissioningDocument28 pagesSafety On Transmission Tower Erection, Cable Stringing & CommissioningAshutosh Dubey100% (5)

- SOW-C-Pond WW Treatment - EOIDocument15 pagesSOW-C-Pond WW Treatment - EOIAlok SinghNo ratings yet

- 26166V2 Ab PDFDocument169 pages26166V2 Ab PDFgonzaloNo ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument11 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingGouse MohideenNo ratings yet

- HF Emer Response Guidance - Final - Jan 2019 PDFDocument40 pagesHF Emer Response Guidance - Final - Jan 2019 PDFarnoldxridleyNo ratings yet

- Baracarb® 25Document10 pagesBaracarb® 25Nural MuradliNo ratings yet

- Practice Occupational Safety and Health ProceduresDocument4 pagesPractice Occupational Safety and Health ProceduresJanice GalorioNo ratings yet

- Solution 1: Material Safety Data SheetDocument5 pagesSolution 1: Material Safety Data SheetMaged alkubatiNo ratings yet

- hsg177 - Managing Health and Safety in DockworkDocument29 pageshsg177 - Managing Health and Safety in Dockworkchelios2No ratings yet

- 1760 - RA - 010 - Risk Assessment - Installation of Electrical Equipment and Panels 26FEB15Document8 pages1760 - RA - 010 - Risk Assessment - Installation of Electrical Equipment and Panels 26FEB15NirmalKumarSelvarajNo ratings yet

- Dye Tracing MSDS ENVIRORedi Orange PowderDocument3 pagesDye Tracing MSDS ENVIRORedi Orange PowderPromagEnviro.comNo ratings yet

- Alkaline Iodide Azide Reagent MSDSDocument4 pagesAlkaline Iodide Azide Reagent MSDSPatrick TshisandNo ratings yet

- Guide To Vietnamese Labor Law For The Garment Industry: (Fifth Edition, 2017)Document85 pagesGuide To Vietnamese Labor Law For The Garment Industry: (Fifth Edition, 2017)LeNamYenNo ratings yet

- Bismuth Subnitrate - MSDSDocument6 pagesBismuth Subnitrate - MSDSdiah dwiNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Marine Rudders and Control Surfaces: Principles, Data, Design and ApplicationsFrom EverandMarine Rudders and Control Surfaces: Principles, Data, Design and ApplicationsRating: 4.5 out of 5 stars4.5/5 (3)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)

- Laws of UX: Using Psychology to Design Better Products & ServicesFrom EverandLaws of UX: Using Psychology to Design Better Products & ServicesRating: 5 out of 5 stars5/5 (9)

- Design Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessFrom EverandDesign Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessNo ratings yet

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tFrom EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tRating: 4.5 out of 5 stars4.5/5 (27)

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsFrom EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsRating: 5 out of 5 stars5/5 (1)

- Designing for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionFrom EverandDesigning for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionNo ratings yet

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneFrom EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneRating: 4.5 out of 5 stars4.5/5 (5)

- Iconic Advantage: Don’t Chase the New, Innovate the OldFrom EverandIconic Advantage: Don’t Chase the New, Innovate the OldRating: 4 out of 5 stars4/5 (1)

- Design Recipes for FPGAs: Using Verilog and VHDLFrom EverandDesign Recipes for FPGAs: Using Verilog and VHDLRating: 2 out of 5 stars2/5 (1)

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Pressure Vessels Field Manual: Common Operating Problems and Practical SolutionsFrom EverandPressure Vessels Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (12)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- Build Better Products: A Modern Approach to Building Successful User-Centered ProductsFrom EverandBuild Better Products: A Modern Approach to Building Successful User-Centered ProductsNo ratings yet