Professional Documents

Culture Documents

IDPLC Lab 02 Introduction To PLC

Uploaded by

hassaan.haiderOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IDPLC Lab 02 Introduction To PLC

Uploaded by

hassaan.haiderCopyright:

Available Formats

International Islamic University, Islamabad

Faculty of Engineering and Technology

Department of Electrical and Computer

Engineering

Industrial Drives and PLC Lab

EXPERIMENT # 02: Introduction to Programmable Logic Controller

Name of Student: …………………………………..

Roll No.: ……………………………………………

Date of Experiment: ………………………………..

Objectives:

After performing this Lab you will be able to:

1. Understand function of Relays

2. Understand the background of PLCs

3. Differentiate PLC from Micro-controller

4. Understanding of Ladder Diagram

Relay Controllers:

A relay is an electrically operated switch. Current flowing through the coil of the relay

creates a magnetic field which attracts a lever and changes the switch contacts. The coil current

can be on or off so relays have two switch positions.

Figure 2.1: Relay Components

The relay's switch connections are usually labeled COM, NC and NO. COM (Common)

is reference point of the switch which is always connected. NC (Normally Closed) is the contact

where COM is connected when the relay coil is off. NO (Normally Open) is the contact where

COM is connected when the relay coil is on. So you should connect to COM and NO if you

want the switched circuit to be on when the relay coil is on and connect to COM and NC if you

want the switched circuit to be on when the relay coil is off.

Introduction to Ladder Diagram:

Ladder Diagram is also known as “Ladder Logic” is one of the simplest methods used

to program a PLC. It is a graphical programming language evolved from electrical relay

circuits. Each program statement is represented with a line, called the rung, that has all relevant

inputs to the left and the output to the right. The output device of a rung is energized if electric

power can conceptually flow from the left side of the rung to the right side. Input devices are

assumed to block the flow of power if they are not activated. During the execution of a ladder

diagram, the PLC reads the states of all inputs, then determines the states of a ladder diagram,

the PLC reads the states of all inputs, then determines the states of all outputs starting from the

rung at the top side, going down to the last rung, and finally updates the state of the output

devices.

Industrial Drives and PLC Lab Page 2

Figure 2.2: An example of typical Ladder Diagram

Introduction to PLC:

A Programmable Logic Controller (PLC) is a digital computer used for automation of

electromechanical processes, such as control of machinery on factory assembly lines, heating,

cooling or lighting fixtures. PLCs are used in many industries and machines. Unlike general-

purpose computers, the PLC is designed for multiple inputs and output arrangements, extended

temperature ranges, immunity to electrical noise, and resistance to vibration and impact.

Programs to control machine operation are typically stored in battery-backed or non-volatile

memory. A PLC is an example of a hard real time system since output results must be produced

in response to input conditions within a bounded time, otherwise unintended operation will

result.

Y0

X0

Programming Software Y1

X1

Y2

X2

.

.

.

.

Processor .

.

Y9

X13

Input Module Channel Output Module

Channel

Figure 2.3: Basic Structure of Programmable Logic Controller (PLC)

PLC processor executes a program to perform the operation specified in a ladder

diagram. The processor performs arithmetic and logic operations on input variable data and

determines the proper state of the output variables. Input module channel examine the state of

physical switches and other input devices and put their state into the form suitable for the

processor. The PLC is able to accommodate a number of inputs, called channels. The output

Industrial Drives and PLC Lab Page 3

modules supply ac power to external devices such as motors, lights, solenoids, and so on, just

as required in the ladder diagram.

PLC Operation can be considered in two modes, the I/O scan mode and the execution

mode. In I/O scan mode, the processor updated all outputs and inputs the state of all inputs one

channel at a time. In execution mode, the processor evaluates each rung of the ladder diagram

program that is being executed sequentially, starting from the first rung and proceeding to the

last rung.

Scan Time is an important characteristic of PLC which is how much time is required

for one complete cycle of I/O scan and execution. This depends upon number of I/O channels

involved, length of the ladder diagram program and the processing speed. A typical maximum

scan and execution time is 5 to 20 ms.

Advantages of PLCs over Conventional Relays, Counters and Timers

PLC has many advantages over conventional relays, counter and timers stated below:

1. The input and output variables of discrete-state control systems are binary in

nature, just as with a computer. Thereby provide fast execution.

2. Many of the “control relays” of the ladder diagram can be replaced by software

which means less hardware failure.

3. It is easier to make changes in a programmed sequence of events when it is only

a change in software.

4. Special functions, such as time-delay actions and counters, are easy to produce

in software.

5. PLCs are more reliable as software bugs can be removed through software

compilers.

6. Reusability of is circuit is increased by simple one can copy a ladder diagram

circuit multiple time.

7. PLC program resides in IC chip; thereby it takes very little space as compared

to relay controller circuits.

Industrial Drives and PLC Lab Page 4

Difference between PLC & Microcontroller

PLC and Micro-controller can be chosen for some applications interchangeably. There

major differences are listed below:

1. PLC is a special microcontroller designed for industrial application used for

controlling machinery & processes whereas microcontroller is a microprocessor

that can be programmed for any type of applications.

2. PLC is programmed using ladder diagram whereas microcontroller is

programmed using C or Assembly Language.

3. PLC process is optimized to scan the inputs and determines the outputs based

on the logical conditions programmed into it by the user whereas

microcontroller is a general-purpose IC.

4. PLC come in a package of Inputs units, Output unit containing LEDs &

processing unit, whereas microcontroller comes in a simple IC.

5. PLC is more useful in high power applications whereas microcontroller is more

suitable to low power applications.

6. PLC is not efficient in extensive calculations whereas microcontroller can

perform arithmetic calculations more efficiently.

Lab Task:

1) Describe function of Relays.

2) What is the difference between Timers, Relays and Counters?

Industrial Drives and PLC Lab Page 5

You might also like

- PLC Programming Using RSLogix 500 & Industrial Applications: Learn ladder logic step by step with real-world applicationsFrom EverandPLC Programming Using RSLogix 500 & Industrial Applications: Learn ladder logic step by step with real-world applicationsRating: 5 out of 5 stars5/5 (1)

- PLC Interview Q&ADocument2 pagesPLC Interview Q&ASalah Eldeen GasimNo ratings yet

- PLC Programming Using SIMATIC MANAGER for Beginners: With Basic Concepts of Ladder Logic ProgrammingFrom EverandPLC Programming Using SIMATIC MANAGER for Beginners: With Basic Concepts of Ladder Logic ProgrammingRating: 4 out of 5 stars4/5 (1)

- Programmable Logic ControllerDocument36 pagesProgrammable Logic ControllerAnjireddy Thatiparthy100% (1)

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosFrom EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosRating: 5 out of 5 stars5/5 (1)

- PLC Interview Questions and AnswersDocument6 pagesPLC Interview Questions and AnswersJêmš NavikNo ratings yet

- Complete Adv PLC Simatic 06-02-14 CoverDocument215 pagesComplete Adv PLC Simatic 06-02-14 Coversvhanu4010No ratings yet

- PLCDocument87 pagesPLCAnoop RaviNo ratings yet

- PLC QuestionsDocument17 pagesPLC QuestionsbahyNo ratings yet

- PLC Based Sequential Batch Process CONTROL System1Document27 pagesPLC Based Sequential Batch Process CONTROL System1Ritesh Vaishnav100% (1)

- Chapter 2 PowerpointDocument86 pagesChapter 2 Powerpointhassan salehNo ratings yet

- G09145967 PDFDocument9 pagesG09145967 PDFNajim Ahmed BulbulNo ratings yet

- Programmable Logic Controllers (PLCs) Course OverviewDocument90 pagesProgrammable Logic Controllers (PLCs) Course OverviewmahmoudNo ratings yet

- Ei8761 Industrial Automation Lab Manual PDFDocument77 pagesEi8761 Industrial Automation Lab Manual PDFSoumik gamingNo ratings yet

- Automating Manufacturing Systems Presentation Rev 4Document89 pagesAutomating Manufacturing Systems Presentation Rev 4tarekamininfoNo ratings yet

- Page 1 of 94Document94 pagesPage 1 of 94amir assameurNo ratings yet

- Industrial AutomationDocument16 pagesIndustrial Automationvivek6681No ratings yet

- PLC ProgrammingDocument119 pagesPLC Programminginformation & knowledgeNo ratings yet

- CIM Lecture Notes 10Document12 pagesCIM Lecture Notes 10rzrasa100% (1)

- PLC LDSC QB 2 MarkDocument13 pagesPLC LDSC QB 2 Markthirusakthimurugan4737No ratings yet

- Industrial Training Report: Rishiraj Institute of Technology, IndoreDocument36 pagesIndustrial Training Report: Rishiraj Institute of Technology, IndoreAbhishek PathakNo ratings yet

- R. V. College of Engineering, Bangalore Department of Electrical and Electronics EngineeringDocument12 pagesR. V. College of Engineering, Bangalore Department of Electrical and Electronics EngineeringbalajigururajNo ratings yet

- Act10 InstrumentationDocument4 pagesAct10 InstrumentationErvin MedranoNo ratings yet

- Programmable Logic ControllersDocument11 pagesProgrammable Logic ControllersLoriedel GondaNo ratings yet

- Een23 (Exp 1) - Rojas, Emmanuel A - Bsee IV GiDocument12 pagesEen23 (Exp 1) - Rojas, Emmanuel A - Bsee IV GiRojas EmmanNo ratings yet

- PLC Programmable Logic ControllersDocument14 pagesPLC Programmable Logic ControllersStefan BotaNo ratings yet

- Learning Objectives Upon Completion of This Chapter, Student Should Be Able ToDocument31 pagesLearning Objectives Upon Completion of This Chapter, Student Should Be Able Tormfaisalarafat1108No ratings yet

- Introducion To PLC and Relay Logic-1Document50 pagesIntroducion To PLC and Relay Logic-1eyoule abdiNo ratings yet

- Mechatronics CHAPTER 5Document61 pagesMechatronics CHAPTER 5NahomNo ratings yet

- PLCDocument41 pagesPLCmgmohit723No ratings yet

- PLC and SCADADocument77 pagesPLC and SCADAIshwari GhuleNo ratings yet

- Learn The Basics and Hardware Components of PLC 2. Understand Configuration of PLC 3. Study Various Building Blocks of PLCDocument5 pagesLearn The Basics and Hardware Components of PLC 2. Understand Configuration of PLC 3. Study Various Building Blocks of PLCAdarsh SriwastvaNo ratings yet

- What Is A PLC-introductionDocument18 pagesWhat Is A PLC-introductionUma100% (1)

- EEE 4706 Control System Engineering LabDocument4 pagesEEE 4706 Control System Engineering LabNawshad Uddin Ahmad ChowdhuryNo ratings yet

- PLC Interview QuestionsDocument2 pagesPLC Interview QuestionsSushant100% (1)

- Programmable Logic Controller: What Is A PLC?Document22 pagesProgrammable Logic Controller: What Is A PLC?Shuaib AbdulmuhizNo ratings yet

- PLCDocument36 pagesPLCsonhack96No ratings yet

- PLC Timers and Counters ExplainedDocument24 pagesPLC Timers and Counters ExplainedSantosh Vishnu100% (1)

- PLC Programming and Control ManualDocument59 pagesPLC Programming and Control Manualyourwish1992No ratings yet

- Syeda HusnaDocument31 pagesSyeda HusnaSyeda HusnaNo ratings yet

- PLC System OverviewDocument30 pagesPLC System Overviewvan hangNo ratings yet

- Manufacturing Automation Using PLCs - Chapter 02Document15 pagesManufacturing Automation Using PLCs - Chapter 02beer18No ratings yet

- What Is A PLCDocument8 pagesWhat Is A PLChafizarslanmushtaq0No ratings yet

- Mechatronics Experiment Ladder Diagram SimulationDocument14 pagesMechatronics Experiment Ladder Diagram SimulationAakash VirdheNo ratings yet

- PLC Scada ReportDocument50 pagesPLC Scada ReportAbhijeet KumarNo ratings yet

- What Is Programmable Logic Controllers (PLCS) ?Document6 pagesWhat Is Programmable Logic Controllers (PLCS) ?Md Omar FaruqueNo ratings yet

- Programmable Logic Controller Applications and UsesDocument5 pagesProgrammable Logic Controller Applications and Usessumit100% (1)

- Control Engineering Lab Semester: Winter 2021 Session: FALL 2018Document5 pagesControl Engineering Lab Semester: Winter 2021 Session: FALL 2018abdullah anwarNo ratings yet

- PLC Course Intro Covers Controls ApplicationsDocument25 pagesPLC Course Intro Covers Controls ApplicationsSafielNo ratings yet

- Linear Distributed Contron Systems Question Bank For Anna University StudentsDocument13 pagesLinear Distributed Contron Systems Question Bank For Anna University StudentssathyaramNo ratings yet

- PNEUMATICSDocument33 pagesPNEUMATICSAllysa Grace SobradoNo ratings yet

- Xee Oe1 Unit 4Document160 pagesXee Oe1 Unit 4Vigha Omnica IyerNo ratings yet

- PLC IntroDocument36 pagesPLC IntroRajat100% (2)

- Programmable Logic Controller BasicsDocument28 pagesProgrammable Logic Controller BasicsMOHAMMED RAHEELNo ratings yet

- MSD Exp3 PDFDocument11 pagesMSD Exp3 PDFSkNo ratings yet

- Lecture Notes For Programmable Logic ControllerDocument32 pagesLecture Notes For Programmable Logic ControllerDenny TarembaNo ratings yet

- PLCDocument31 pagesPLC01parthNo ratings yet

- PLC and PLC TechnologiesDocument28 pagesPLC and PLC Technologieskatjinomasa kavetuNo ratings yet

- 1.0 Introduction To PLCDocument78 pages1.0 Introduction To PLCAnonymous Syw0JqJarL100% (1)

- Apc 3 Module Notes - PLC and SCADA: Use of Relays in Process ControlDocument9 pagesApc 3 Module Notes - PLC and SCADA: Use of Relays in Process Control447 KusumanjaliNo ratings yet

- DSPKGDocument364 pagesDSPKGYuhua ZhengNo ratings yet

- Interview PDFDocument33 pagesInterview PDFPraveen Kumar100% (4)

- Self-Assessment Form Instructions For Applicants: Page 1 of 12Document12 pagesSelf-Assessment Form Instructions For Applicants: Page 1 of 12ahmedNo ratings yet

- CSEC Physics Review - Introduction To Logic GatesDocument16 pagesCSEC Physics Review - Introduction To Logic GatesKevin Small100% (4)

- Seagate U Series 5 HDD ReviewDocument10 pagesSeagate U Series 5 HDD Reviewπ. Βασίλειος ΠαπασωτηρόπουλοςNo ratings yet

- HP NB - Retail - Price - List - July'11Document16 pagesHP NB - Retail - Price - List - July'11shonk11No ratings yet

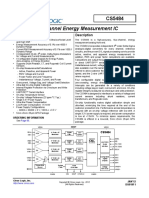

- Four Channel Energy Measurement IC: & DescriptionDocument66 pagesFour Channel Energy Measurement IC: & DescriptionrosaNo ratings yet

- Ladder Logic For Bottle Filling SystemDocument3 pagesLadder Logic For Bottle Filling SystemArunNo ratings yet

- List of Intel MicroprocessorsDocument46 pagesList of Intel MicroprocessorsnirajbluelotusNo ratings yet

- Advanced CMOS Process Technology Part 1 and 2 Dr. Lynn FullerDocument51 pagesAdvanced CMOS Process Technology Part 1 and 2 Dr. Lynn FullerPauloConstantinoNo ratings yet

- Poweredge r730 - Owners Manual2 - en UsDocument201 pagesPoweredge r730 - Owners Manual2 - en UsANthonyNo ratings yet

- Msi Z77a-G45Document88 pagesMsi Z77a-G45rzezniccNo ratings yet

- Bio Human BodyDocument34 pagesBio Human BodyAll Engineering ElectronicsNo ratings yet

- BCM20734Document51 pagesBCM20734Vincenzo CerbinoNo ratings yet

- ECM-5410 5th Manual PDFDocument147 pagesECM-5410 5th Manual PDFEduard Barrios G.No ratings yet

- Time: 3 Hours Max. Marks: 70Document3 pagesTime: 3 Hours Max. Marks: 70Syed MoinNo ratings yet

- ECO Timing Optimization Using Spare CellsDocument31 pagesECO Timing Optimization Using Spare CellsSiva RaoNo ratings yet

- Digital Lab: Adder and Counter SimulationDocument10 pagesDigital Lab: Adder and Counter SimulationMuhammad Feisal IliasNo ratings yet

- ATtiny424 426 427 824 826 827 DataSheet DS40002311BDocument574 pagesATtiny424 426 427 824 826 827 DataSheet DS40002311BCho Cho TunNo ratings yet

- bq24780S 1-To 4-Cell Hybrid Power Boost Mode Battery Charge Controller With Power and Processor Hot MonitoringDocument56 pagesbq24780S 1-To 4-Cell Hybrid Power Boost Mode Battery Charge Controller With Power and Processor Hot MonitoringsasNo ratings yet

- InterruptDocument25 pagesInterruptPallvi BhardwajNo ratings yet

- 8085 Microprocessor QuestionsDocument15 pages8085 Microprocessor QuestionsVirendra GuptaNo ratings yet

- Computing Scheme of Work and Planning: All Saints Upton Primary School Computing CurriculumDocument29 pagesComputing Scheme of Work and Planning: All Saints Upton Primary School Computing CurriculumWalid SassiNo ratings yet

- Notebook Disassembly GuideDocument18 pagesNotebook Disassembly GuidechapanezNo ratings yet

- Laptop Spec. As Per UIDAIDocument2 pagesLaptop Spec. As Per UIDAIMoonNo ratings yet

- GI MicroElectronics Data Catalog 1978 Index PDFDocument22 pagesGI MicroElectronics Data Catalog 1978 Index PDFAnonymous KuTQvYTuNo ratings yet

- CMUcam4 Programming GuideDocument3 pagesCMUcam4 Programming GuideMaureen LaFayetteNo ratings yet

- Fundamentals of IT: Data vs. InformationDocument21 pagesFundamentals of IT: Data vs. InformationVineetSharmaNo ratings yet

- The 8051 Microcontroller and Embedded Systems: 8051 Addressing ModesDocument28 pagesThe 8051 Microcontroller and Embedded Systems: 8051 Addressing Modesanand787No ratings yet